Method for preparing axial preferred orientated corrosion-resistant high-resistance ultra magnetostrictive material

A technology of giant magnetostriction and preferred orientation, applied in the field of Tb-Dy-Fe-Si giant magnetostrictive materials, can solve the problems of reduced magnetostrictive performance, easy corrosion, loss, etc., and achieves improved rupture potential and good durability corrosion performance, good magnetostrictive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Prepare 50g of Tb with axial preferred orientation 0.3 Dy 0.7 (Fe 0.975 Si 0.025 ) 1.95 High resistance giant magnetostrictive material

[0054] Weigh 8.9g Tb, 21.1g Dy, 19.7g Fe and 0.3g Si elements with a purity of 99.9% and put them into a vacuum electric arc furnace. The furnace is first evacuated to a degree of 2×10 -3 Pa, and then filled with high-purity argon, at this time the pressure in the furnace rose to 0.7 × 10 5 Pa, start to smelt the alloy; smelt the alloy repeatedly 4 times to make the alloy composition uniform and then cast it into Tb 0.3 Dy 0.7 (Fe 0.975 Si 0.025 ) 1.95 Rod material.

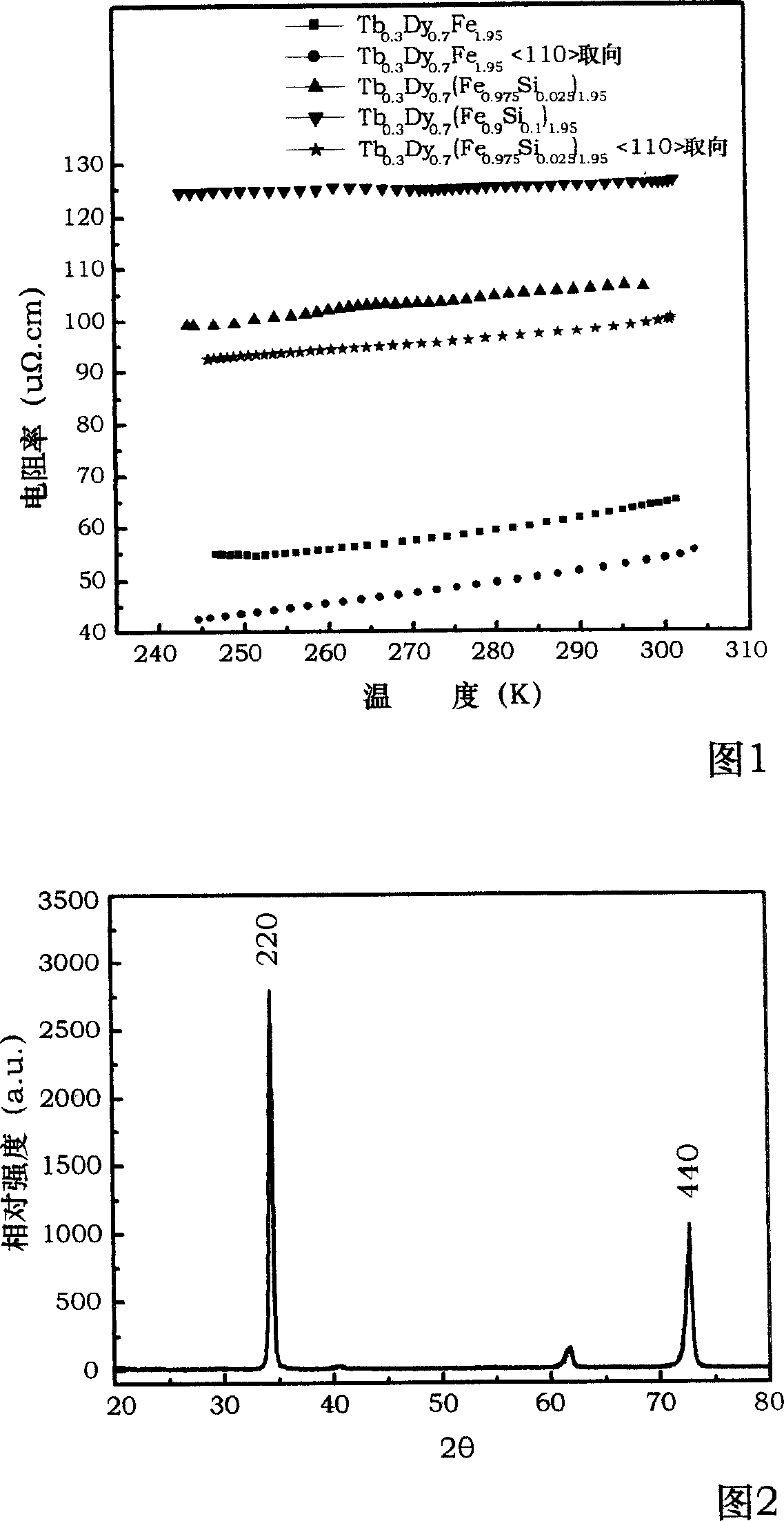

[0055] As-cast Tb 0.3 Dy 0.7 (Fe 0.975 Si 0.025 ) 1.95 For the bar material, a wire-cut 1mm×0.5mm×25mm sample is used for the resistivity test, and its 298K resistivity is 99μΩcm. (As shown in Figure 1)

[0056] The above prepared Tb 0.3 Dy 0.7 (Fe 0.975 Si 0.025 ) 1.95 The bar is placed in the high-purity corundum tube of the high-temperature grad...

Embodiment 2

[0060] Prepare 50g of Tb with axial preferred orientation 0.3 Dy 0.7 (Fe 0.9 Si 0.1 ) 1.95 High resistance giant magnetostrictive material

[0061] Weigh 9g Tb, 21.5g Dy, 18.5g Fe and 1g Si elements with a purity of 99.9% and put them into a vacuum electric arc furnace. The furnace is first evacuated to a degree of 2×10 -3 Pa, and then filled with high-purity argon, at this time the pressure in the furnace rose to 0.7 × 10 5 Pa, start to smelt the alloy; smelt the alloy repeatedly 4 times to make the alloy composition uniform and then cast it into Tb 0.3 Dy 0.7 (Fe 0.9 Si 0.1 ) 1.95 Rod material.

[0062] Measuring resistivity: for as-cast Tb 0.3 Dy 0.7 (Fe 0.9 Si 0.1 ) 1.95 For the bar material, a wire-cut 1mm×0.5mm×25mm sample was used for the resistivity test, and its resistivity at room temperature at 298K was 126μΩcm (as shown in Figure 1).

[0063] Put the prepared cast rod into the high-purity corundum tube of the high-temperature gradient induction cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com