Automatic cleaning deduster with butterfly-shaped crawler belt

An automatic cleaning and dust collector technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of bulky, high maintenance costs, use and installation are easily restricted by site space, etc., to achieve treatment Large air volume, long service life and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

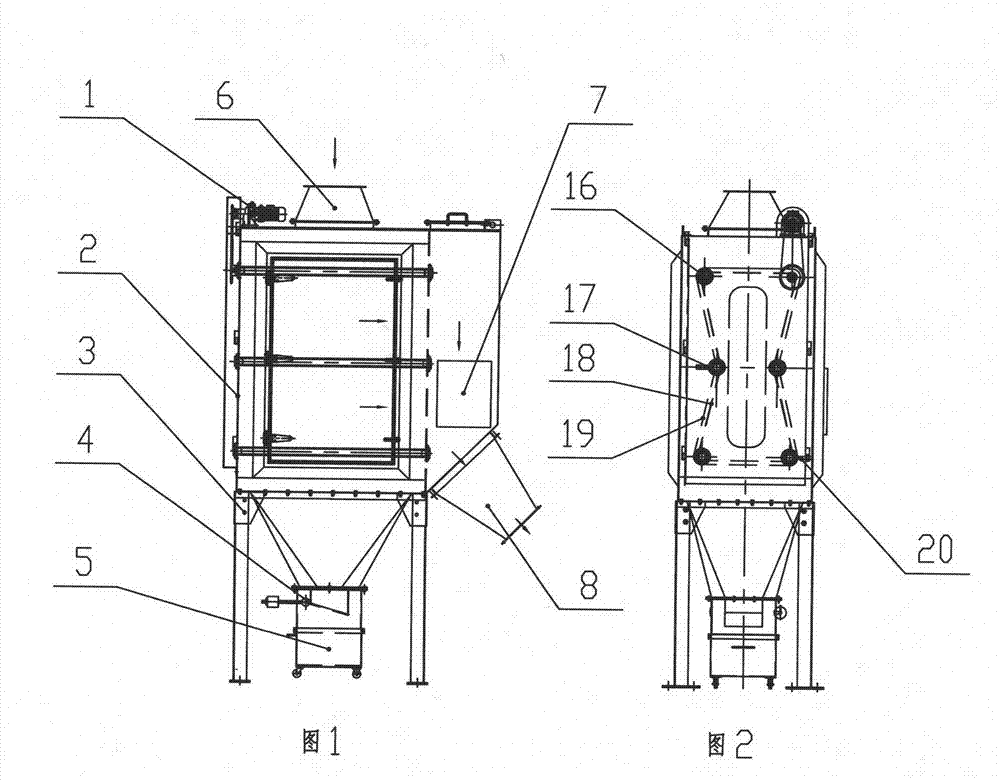

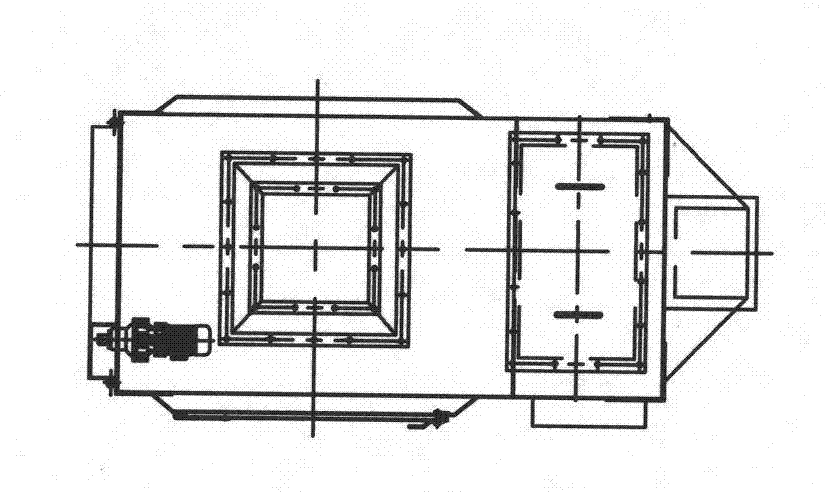

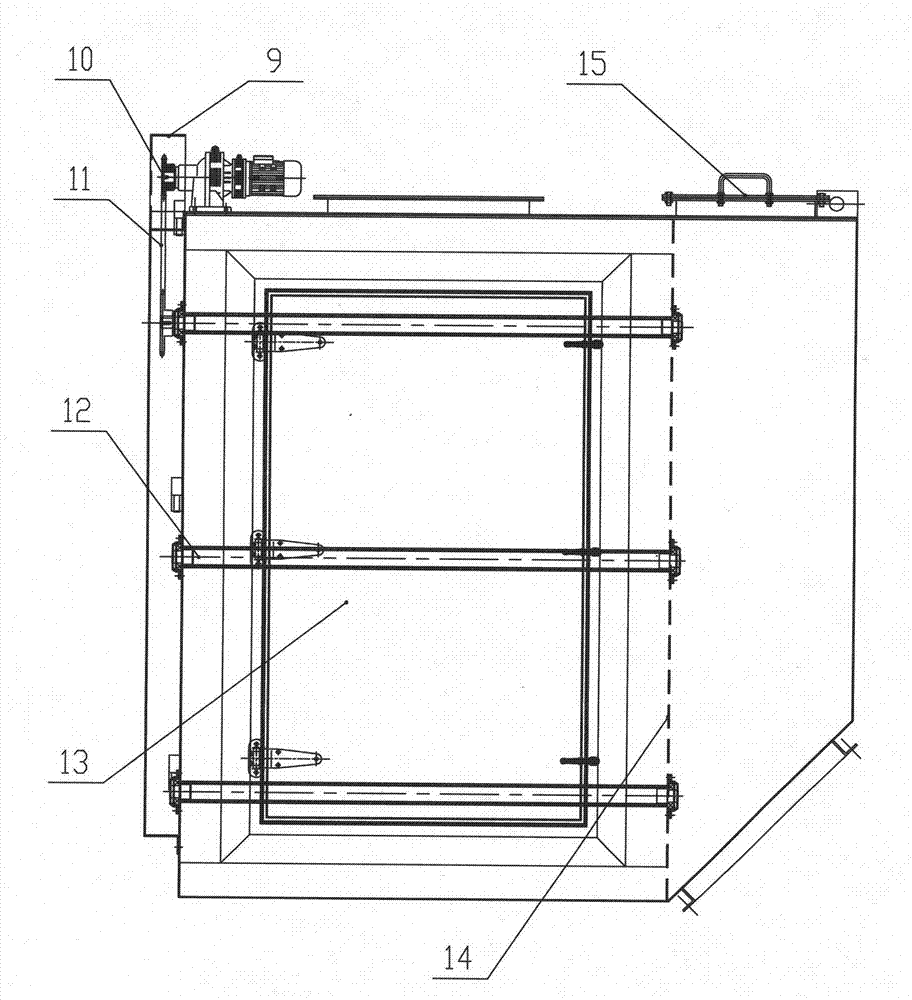

[0012] Example: such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it consists of a reducer 1, a chassis 2, a base 3, a dust discharge valve 4, a dust bucket 5, an air inlet pipe 6, an electric control box 7 and an air outlet pipe 8. The reducer 1 is installed on the top of the case 2, and is connected to the transmission shaft 12 inside the case through the sprocket 10 and the chain 11; the filter cloth 18 inside the case is set on several transmission shafts to make it a butterfly track; there are seals on both sides of the track Bar 19 is fixed on the inner wall of the case, and a fixed row brush 20 is installed in the lower part of the case; both ends of the drive shaft are fixed on the case with bearings 16 and end caps 17, and two end caps are adjustable; there is a partition 14 in the middle of the case , the cabinet is divided into the air inlet cabin and the wind outlet cabin; there is an inspection door 13 on one side of the cabinet, and a safety cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com