Resistance switch memory based on organic ferroelectric film and preparation method thereof

A technology of resistive switch and organic iron, which is applied in the direction of electrical components and the like, can solve the problems such as the lack of effective breakthrough of organic resistive memory, restricting the diversified development of memory devices, etc., and achieves the preparation method is simple and easy to operate, low in cost, and simple in raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

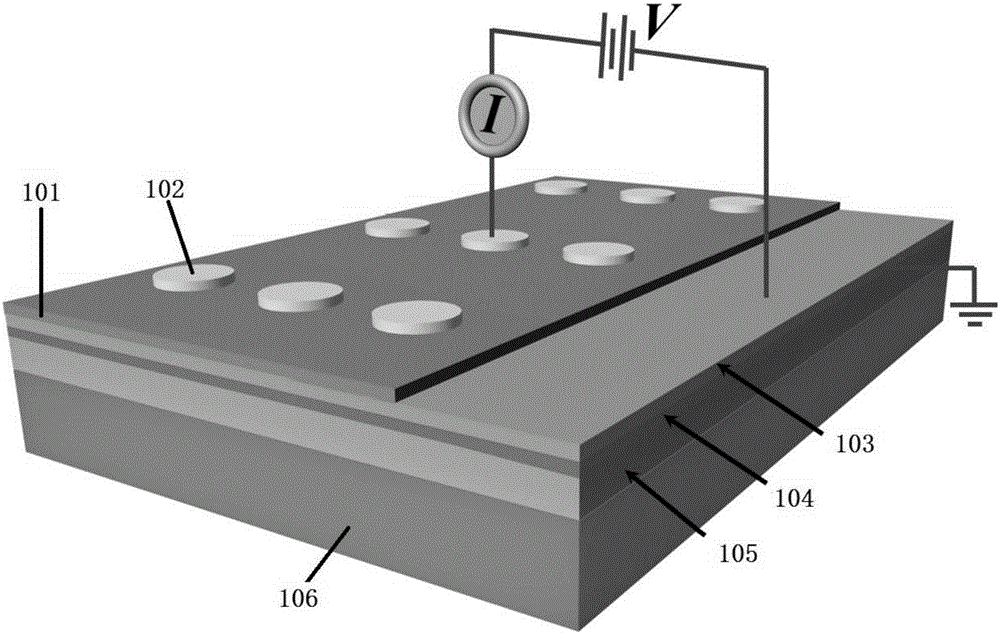

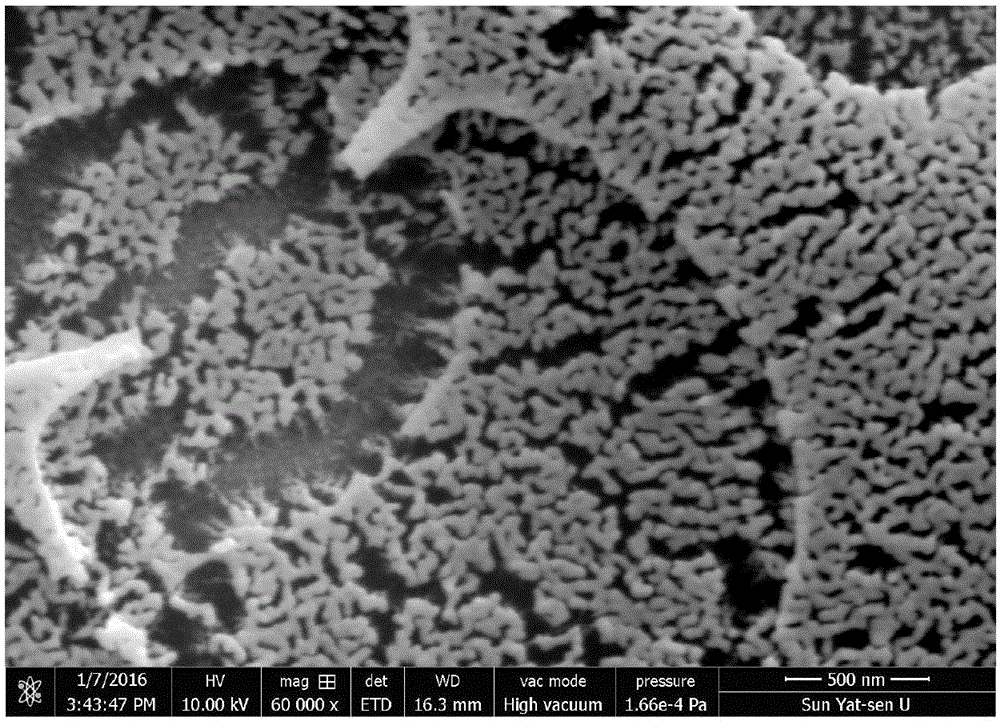

[0022] Dissolve the P(VDF-TrFE) particles with a substance molar ratio of 70:30 in a butanone solution, prepare a solution with a concentration of 20%, and stir at a constant temperature of 70°C on a magnetic stirrer for 7 hours to make the P(VDF-TrFE ) particles are fully dissolved in the methyl ethyl ketone solvent, and finally the solution is placed in a light-shielding environment and allowed to stand for 24 hours. The used substrate of the spin-coated film is grown on a silicon wafer with a layer of 50nm conductive Pt. The spin-coating rate when spinning the glue is 2500r / min, and the spin-coating time is 40s. The obtained film was pre-fired at 90°C for 10 minutes, and the solvent was evaporated. In order to make the film better crystallized, it was placed in a temperature control box, vacuumed to 10Pa, and heat-treated at 120°C for 10 hours. Naturally cool to room temperature. A 30nm gold film was vapor-deposited on the surface of the well-crystallized film as the top ...

Embodiment 2

[0024] Dissolve the P(VDF-TrFE) particles with a substance molar ratio of 70:30 in a butanone solution, prepare a solution with a concentration of 20%, and stir at a constant temperature of 70°C on a magnetic stirrer for 7 hours to make the P(VDF-TrFE ) particles are fully dissolved in the methyl ethyl ketone solvent, and finally the solution is placed in a light-shielding environment and allowed to stand for 24 hours. The used substrate of the spin-coated film is grown on a silicon wafer with a layer of 50nm conductive Pt. The spin-coating rate when spinning the glue is 2500r / min, and the spin-coating time is 40s. The obtained film was pre-fired at 80°C for 10 minutes, and the solvent was evaporated. In order to make the film better crystallized, it was placed in a temperature control box, vacuumed to 10Pa, and heat-treated at 135°C for 10 hours. Naturally cool to room temperature. A 30nm gold film was vapor-deposited on the surface of the well-crystallized film as the top ...

Embodiment 3

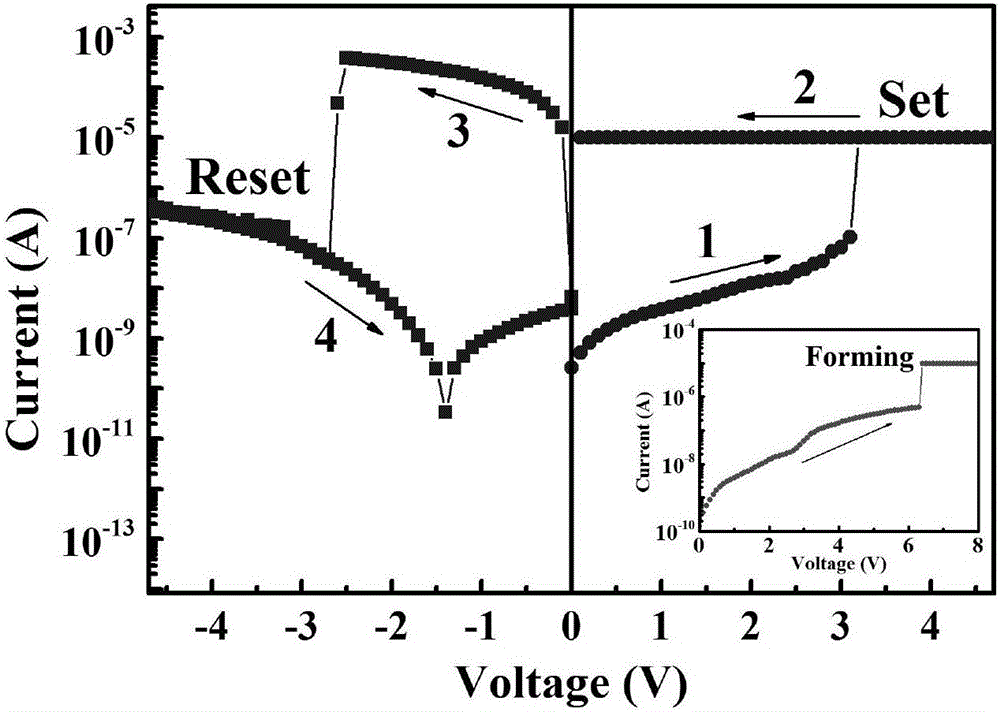

[0026] Dissolve the P(VDF-TrFE) particles with a molar ratio of 70:30 in diethyl carbonate solution to prepare a solution with a concentration of 20%, and stir at a constant temperature of 60°C on a magnetic stirrer for 7h to make P(VDF -TrFE) particles were fully dissolved in diethyl carbonate solvent, and finally the solution was placed in a light-shielding environment for 24 hours. The substrate used for the spin-on thin film is grown on a silicon wafer with a layer of 50nm Pt. The spin-coating rate when spinning the glue is 2000r / min, and the spin-coating time is 40s. The obtained film was pre-fired at 90°C for 10 minutes, and the solvent was evaporated. In order to make the film better crystallized, it was placed in a temperature control box, vacuumed to 10Pa, and heat-treated at 140°C for 10 hours. Naturally cool to room temperature. A 30nm gold film was vapor-deposited on the surface of the well-crystallized film as the top electrode. Through the electrical performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com