Method for testing instability of a negative bias temperature

A negative bias temperature and instability technology, applied in the direction of single semiconductor device testing, semiconductor/solid-state device testing/measurement, etc., can solve the problems of inaccurate testing process, slowing down the processing speed of testing process, inaccurate measurement results, etc. , to achieve the effect of speeding up the test, avoiding recovery, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

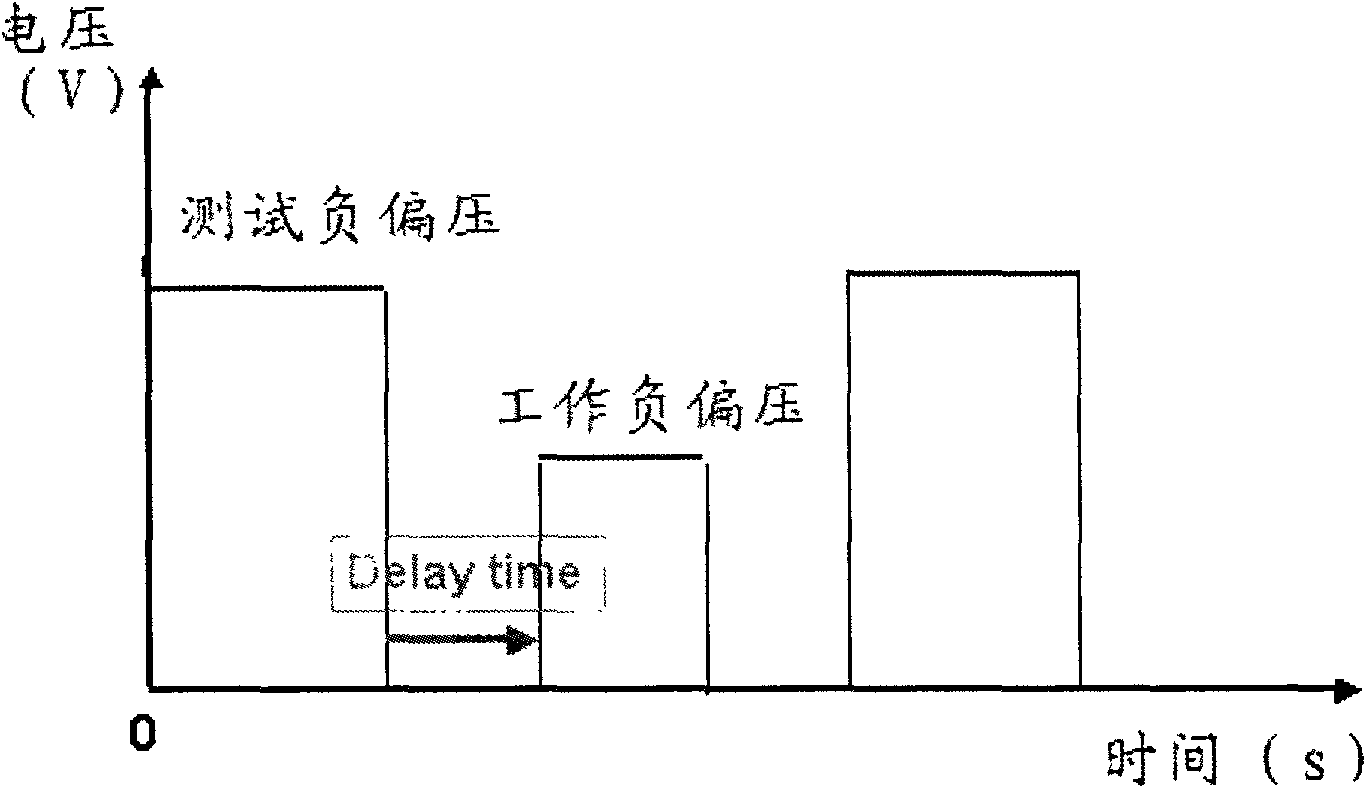

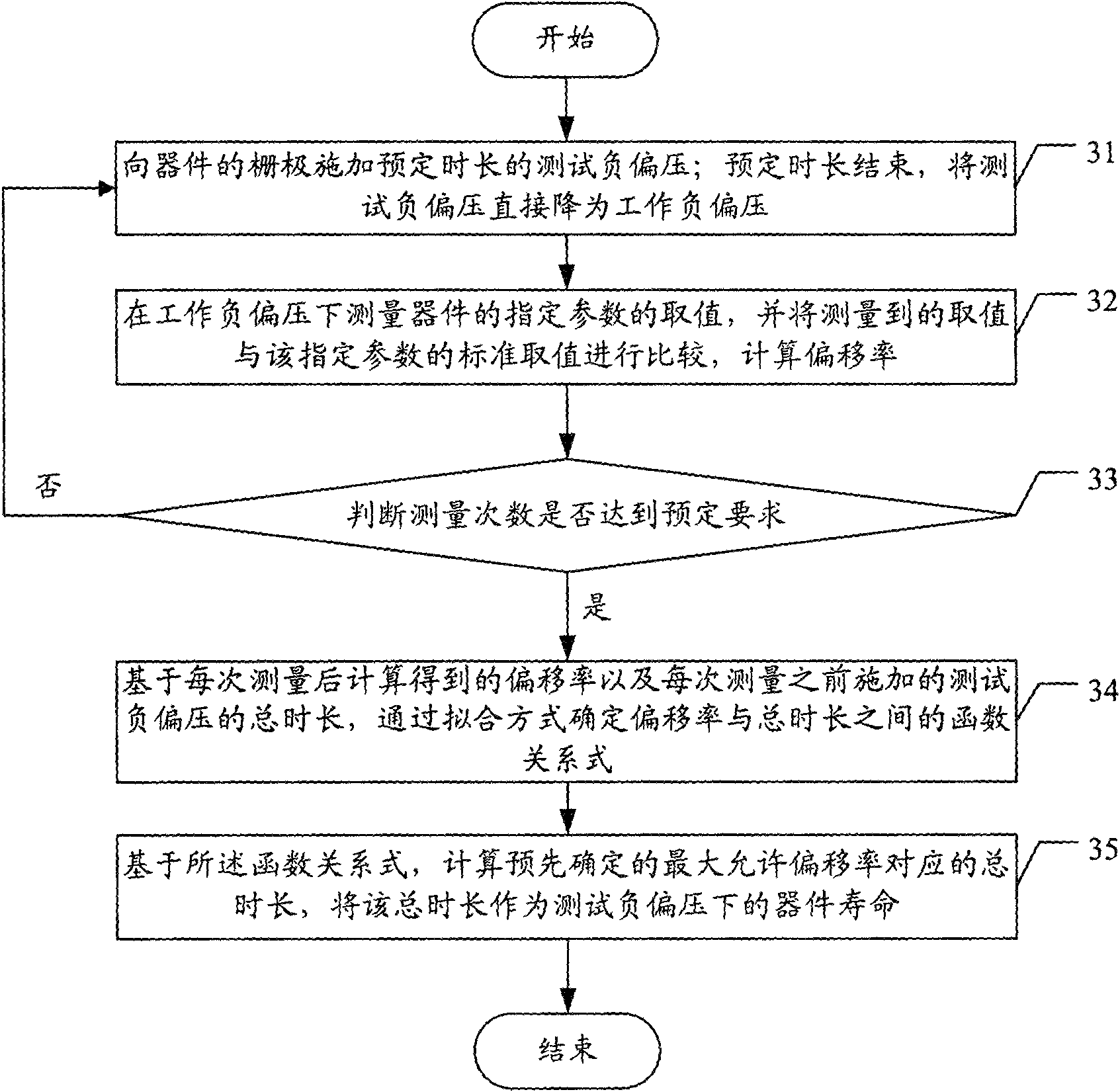

[0039] Aiming at the problems existing in the prior art, an improved negative bias temperature instability test method is proposed in the present invention, that is, in the process of testing the life of the device under different test negative bias voltages, the specified When parameterizing, without passing the Delay Time, the test negative bias voltage is directly reduced to the working negative bias voltage, thereby avoiding the recovery of device performance and ensuring the accuracy of measurement results.

[0040] In order to make the object, technical solution, and advantages of the present invention clearer, the solutions of the present invention will be further described in detail below with reference to the accompanying drawings and examples.

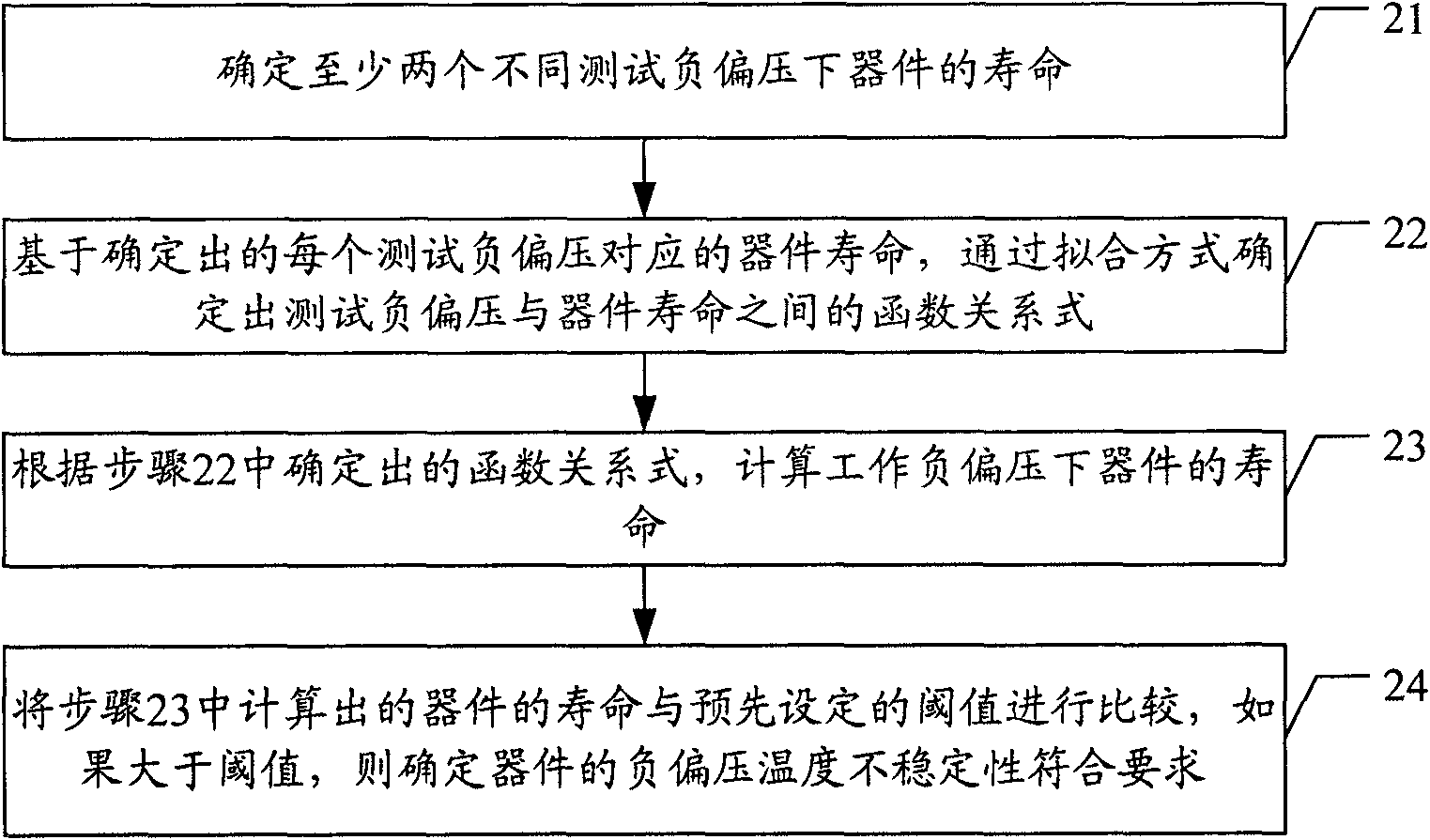

[0041] figure 2 It is a flowchart of a method embodiment of the present invention. Such as figure 2 As shown, it mainly includes the following steps:

[0042] Step 21: Determining the lifetime of the device under at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com