High-altitude drill positioning method of building

A positioning method and building technology, applied in drilling equipment, directional drilling, earth-moving drilling, etc., can solve the problems of unguaranteed work quality, increased safety hazards for construction workers, and lack of reliable focus points, and shorten the preparation time. Time, eliminate potential safety hazards, and improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

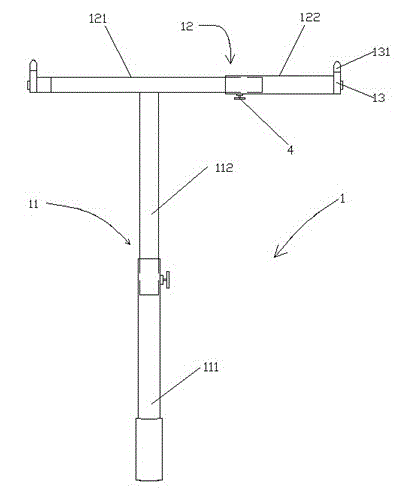

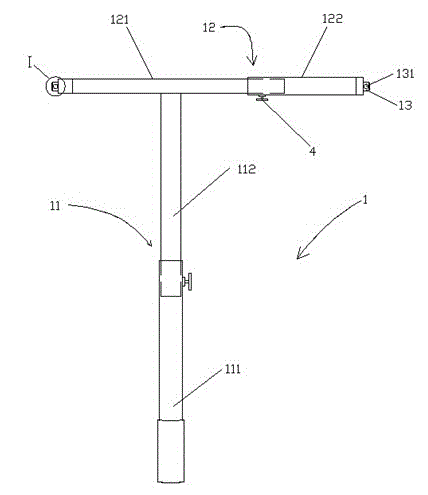

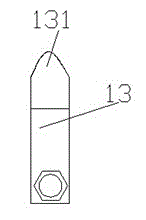

[0035] Such as figure 1 , 3 , 5, and 7, the method for positioning holes at high places in buildings includes a high-altitude marking device 1, a high-altitude drilling device 2 and a high-altitude fastening device 3, and also includes expansion bolts for fixing, including the following steps: When making a plurality of fixed holes on the facade, adjust the length of the adjusting rod 12 with reference to the scale line of the adjusting rod 12 on the high-altitude marking device 1, so that the scale read out is equal to the hole distance of any two fixed holes; adjust the high-altitude marking The support bar 11 of device 1, makes the marking bar 13 that is fixed on described high-altitude marking device 1 adjusting rod 12 two ends heights from the ground equal to the height of described fixing hole distance ground; End 131, draw the marking points of two fixing holes; place the high-altitude punching device 2 under the fixed hole at the marked position, and press down the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com