Cement component crossing highway and mounting method

A cement and component technology, used in underwater structures, water conservancy projects, road bottom layers, etc., can solve problems such as high construction site requirements, cumbersome construction process, personal injury, etc., to improve integrity and bearing capacity, and avoid construction safety. Hidden danger, the effect of reducing the time of grooving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

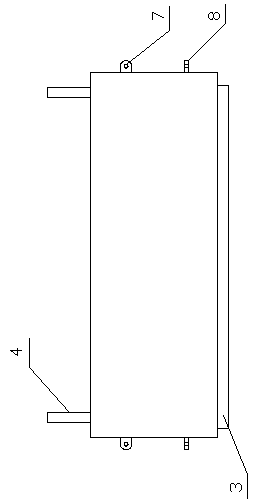

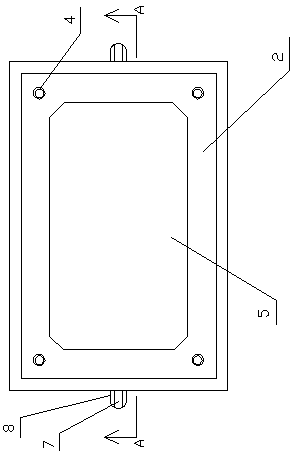

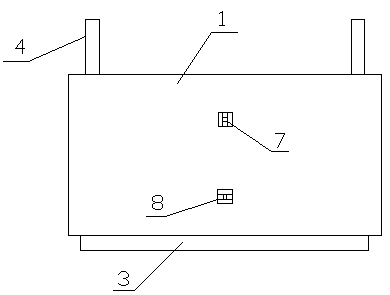

[0037] According to the cement member for crossing the highway described in Example 1, its composition includes: an assembled box culvert 1, the top mold port of the assembled box culvert is processed with a raised slot 2, the bottom of the assembled box culvert A protruding slot 3 with an annular notch is processed at the port, and the protruding slot is inserted into another protruding slot on the assembled box culvert, and the protruding The four corners of the slot are provided with PE pipes 4 for forming prestressing tendon channels, and the PE pipes are pre-buried in a straight line at the four corners above the assembled box culvert, and then placed in the joints of the PE pipes. Reserve tunnels 5 at the four corners, pass steel strands in the tunnels, and perform tensioning. After the tensioning is completed, perform joint treatment and tunnel grouting, and then perform wing wall treatment and backfill the culvert side.

Embodiment 2

[0039] According to the cement component for crossing the highway described in Example 1, the assembled box culvert is molded, and the assembled box culvert is composed of a reinforced concrete culvert body, prestressed steel strands, wing walls, foundations, and deformation joints. Composition, the culvert body of the prefabricated box culvert is an integral closed reinforced concrete frame structure composed of non-standard culverts and standard culverts, wherein the two prefabricated box culverts are connected by sockets, A grouting tunnel 6 is opened on the assembled box culvert.

Embodiment 3

[0041] According to the concrete component for crossing roads described in Embodiment 1 or 2, when the assembled box culvert is a rectangular structure, upper rings 7 and lower rings are arranged symmetrically on both sides of the short side of the assembled box culvert 8. The upper ring and the lower ring adopt a structure perpendicular to each other at 90 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com