Assembly-type reinforced concrete splay wall-type inlet and outlet of culvert and construction method

A technology of reinforced concrete and construction method, which is applied in the field of culvert and channel structure engineering, can solve the problem that the assembly data of the channel structure opening is blank, etc., achieve good economic and social benefits, shorten the construction period, and reduce the effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

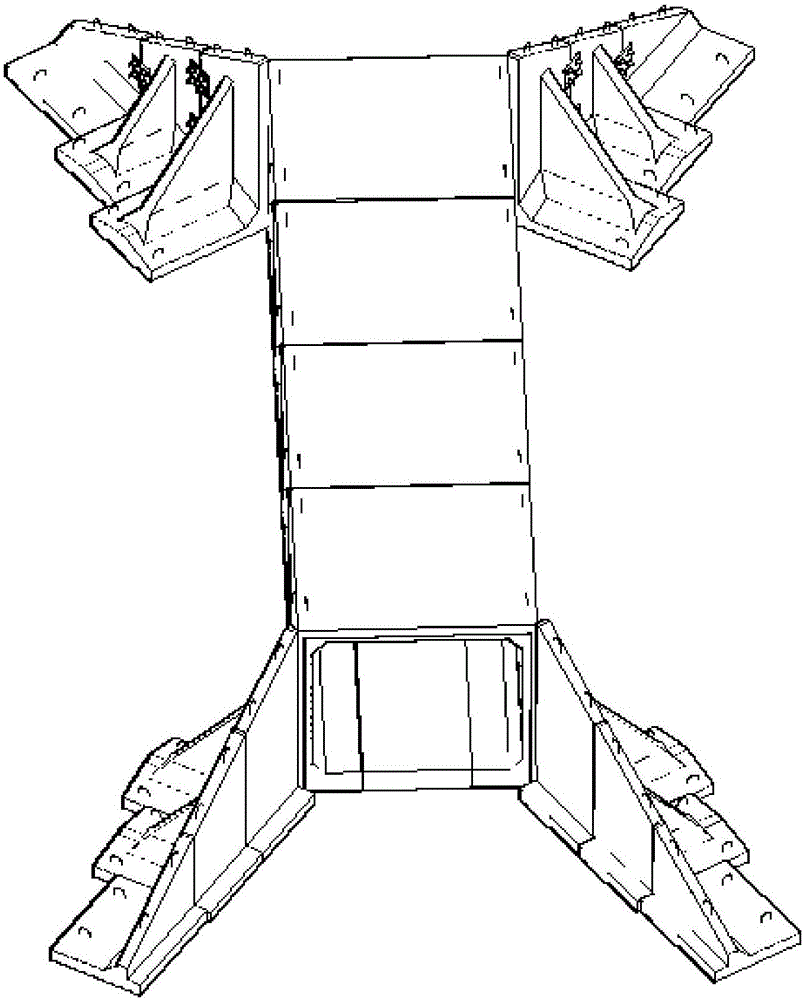

[0030] see figure 1 , The prefabricated reinforced concrete splayed wall type culvert opening of the preferred embodiment of the present invention includes wing walls (splayed walls) arranged on both sides of the culvert entrance and exit.

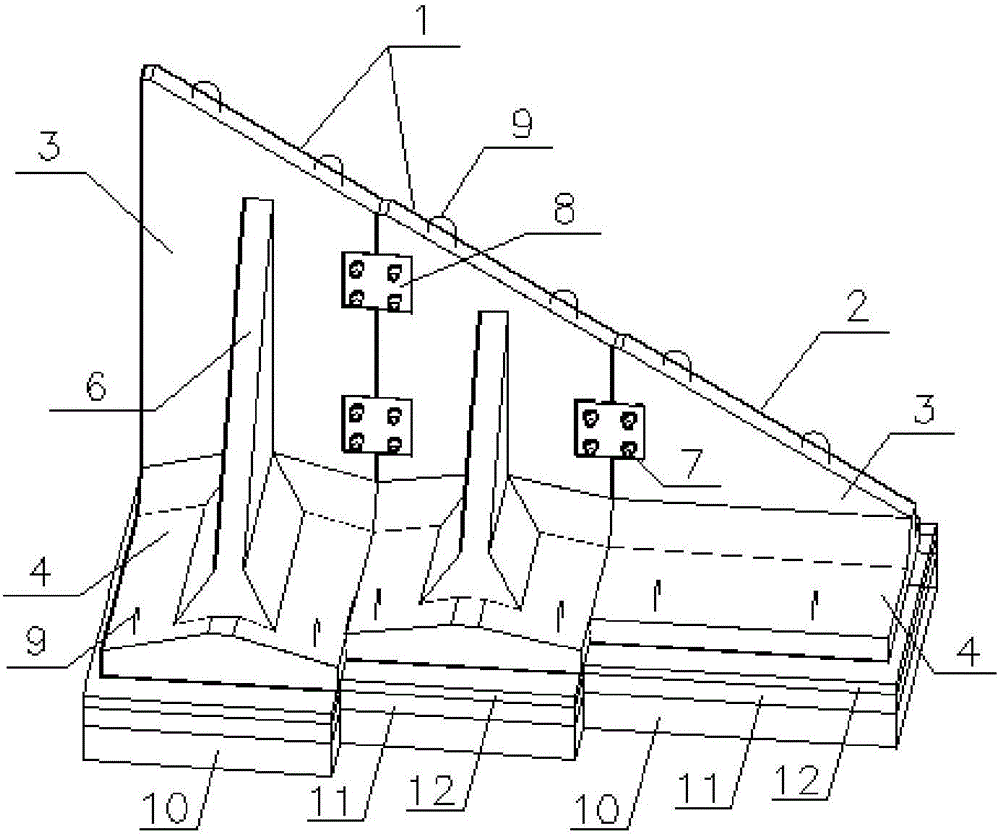

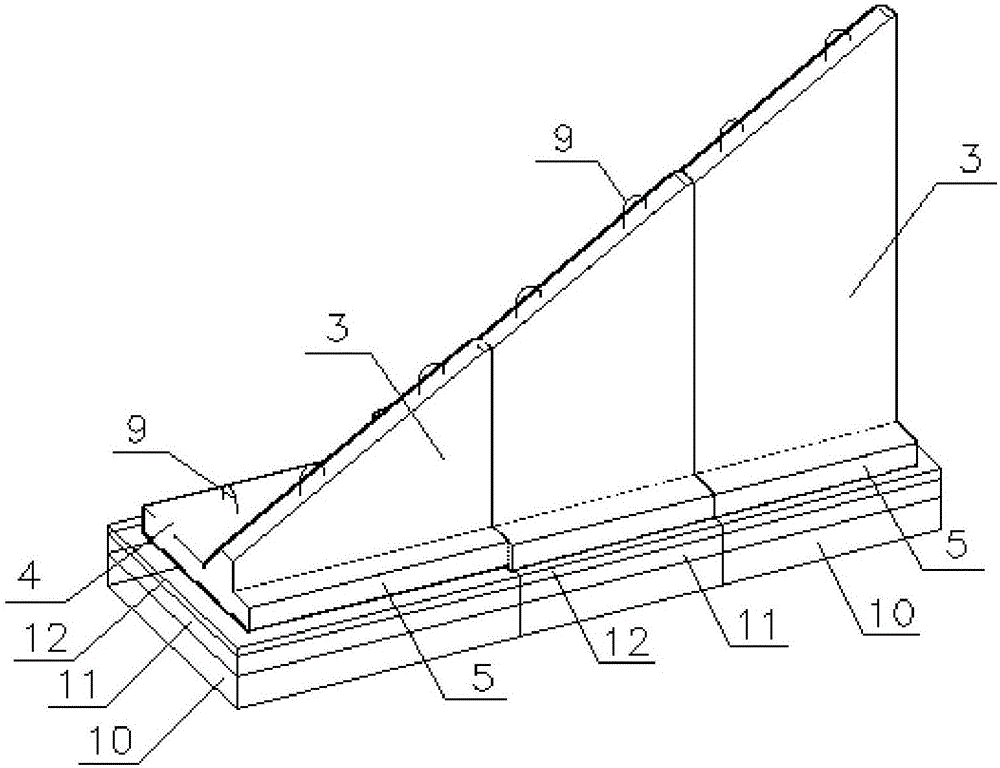

[0031] Please refer to figure 2 and image 3 , the wing walls on each side include multiple prefabricated buttress-type reinforced concrete retaining walls 1 on the inside and prefabricated cantilever-type reinforced concrete retaining walls 2 on the outside, multiple prefabricated buttress-type reinforced concrete retaining walls 1 and prefabricated cantilever walls Reinforced concrete retaining wall 2 is combined and assembled sequentially from the opening outward to both sides to form wing walls. The number of prefabricated buttress-type reinforced concrete retaining walls 1 is jointly dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com