Method for strengthening existing frame additionally provided with steel support with border

A technology of steel support and belt edge, which is applied in the direction of building maintenance, construction, building construction, etc., can solve the problems of long construction period, deviation of reinforcement design calculation model, and difficulty in guaranteeing the effect, and achieve the effect of simple operation and reliable maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

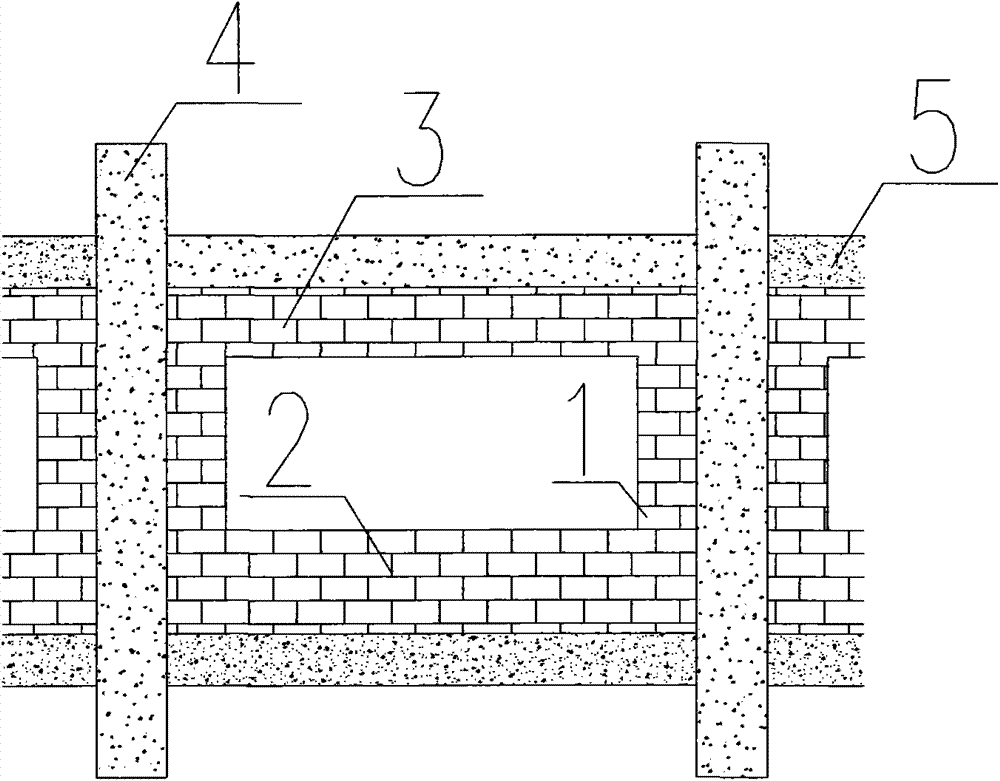

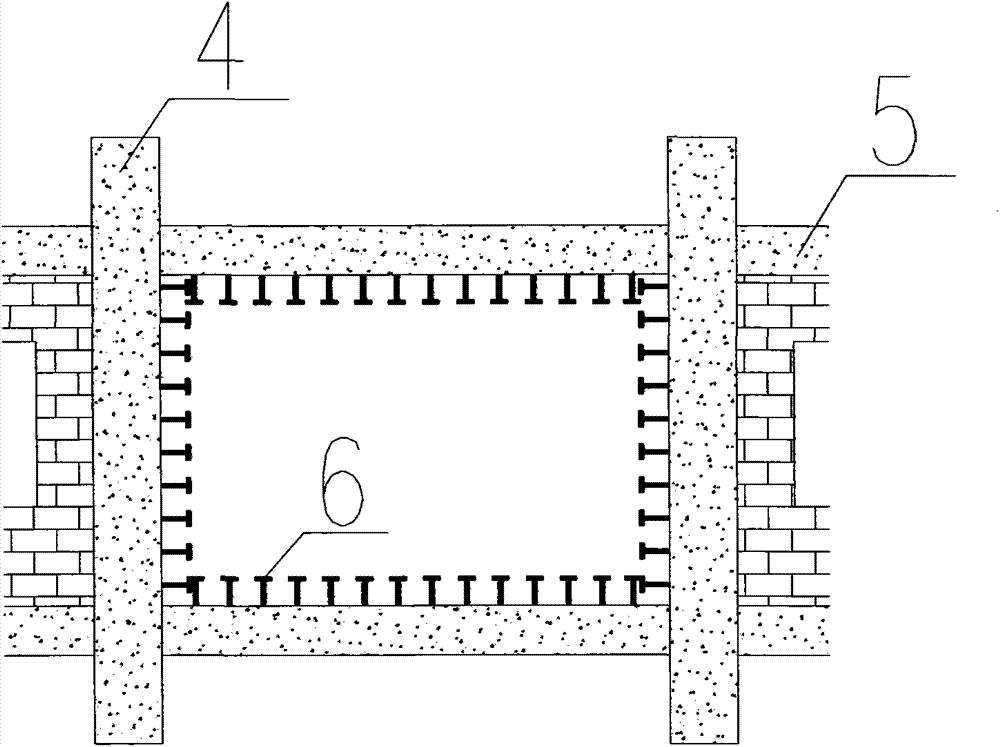

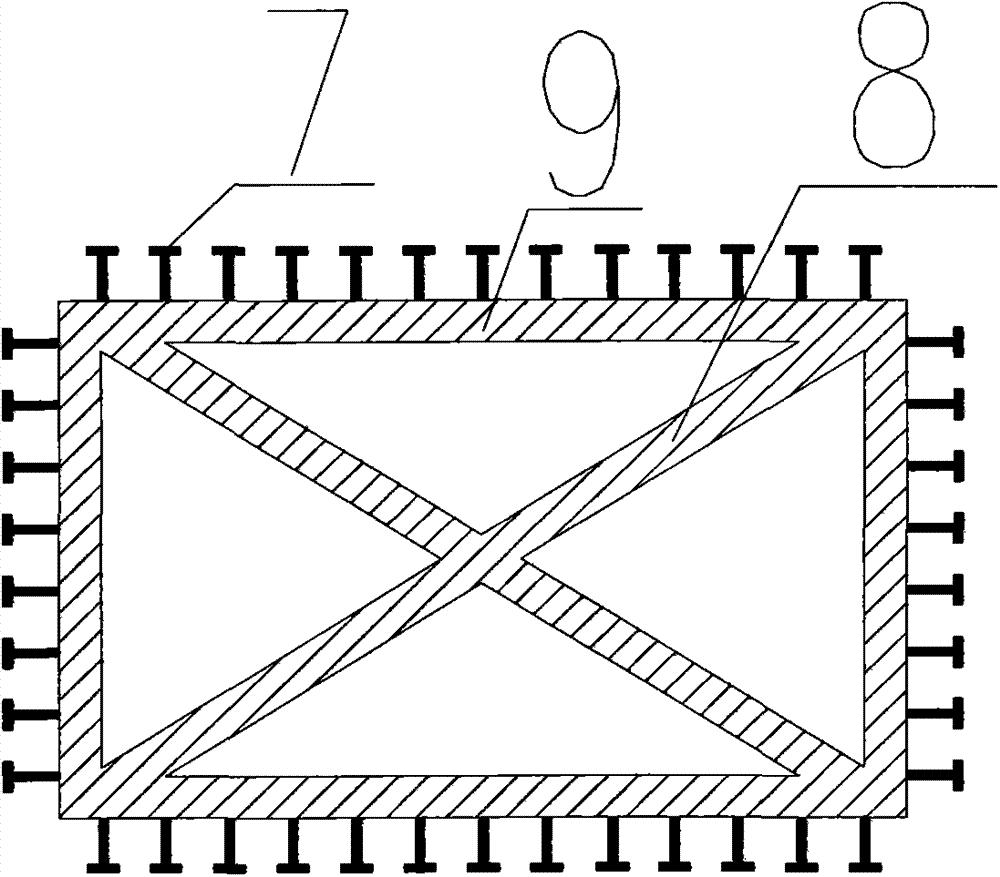

[0025] Such as Figure 1-4 As shown, the present invention is a method for strengthening an existing frame by adding a steel support with a frame. , the steel support with frame includes a steel frame 9 and a steel support 8, the X-shaped steel support 8 is set inside the steel frame 9, the stud 7 is welded on the outside of the steel frame 9, and the rear anchor bolts are embedded in the concrete frame column 4 and the concrete frame beam 5 6. The bolt 7 and the rear anchor bolt 6 are embedded in the connection, and the spiral steel bar 10 is installed, and the mortar 11 with or without shrinkage is pressed in.

[0026] The specific reinforcement method includes the following steps:

[0027] Step 1: According to the design drawings, first remove the top wall 3, waist wall 2, and wing wall 1 in the existing frame to be reinforced, and retain the concrete frame column 4 and concrete frame beam 5; and remove the concrete frame beam 5 and concrete frame column at the same time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Anchorage length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com