Measurement tool of edges and recesses of composite-material wing wall board

A composite material, measuring tooling technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of poor flexibility, inconvenient use, etc., to achieve the effect of simple and convenient use, high measurement efficiency, and simple tooling manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

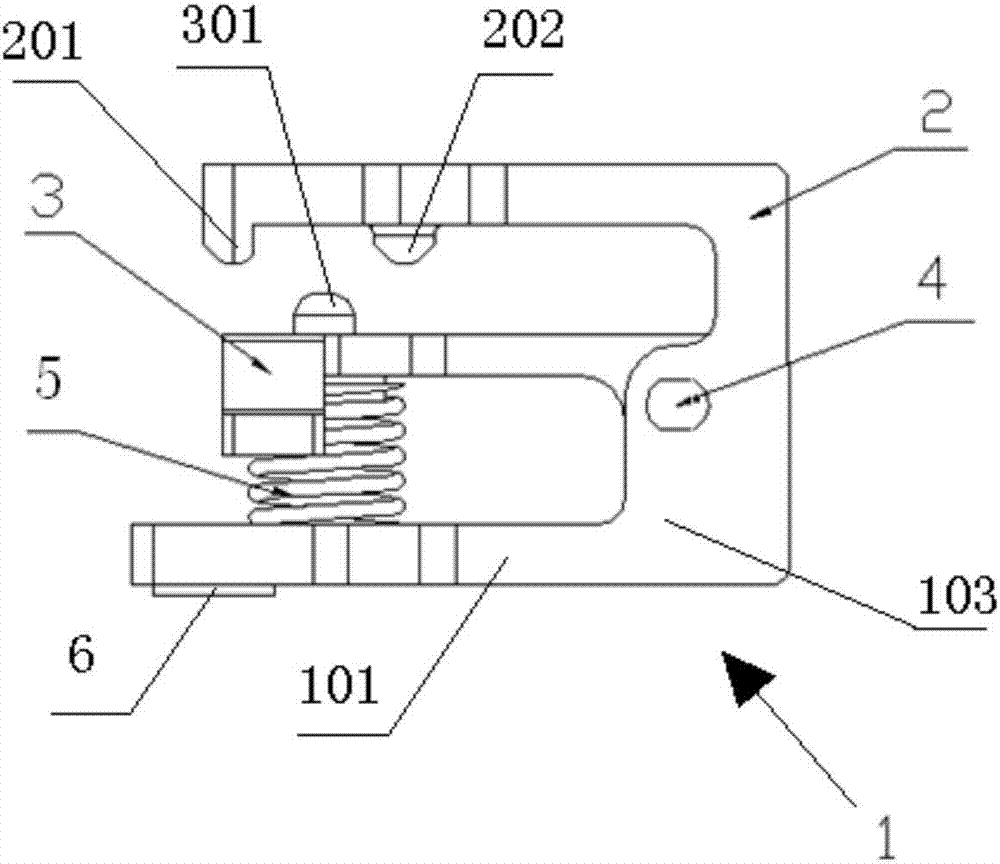

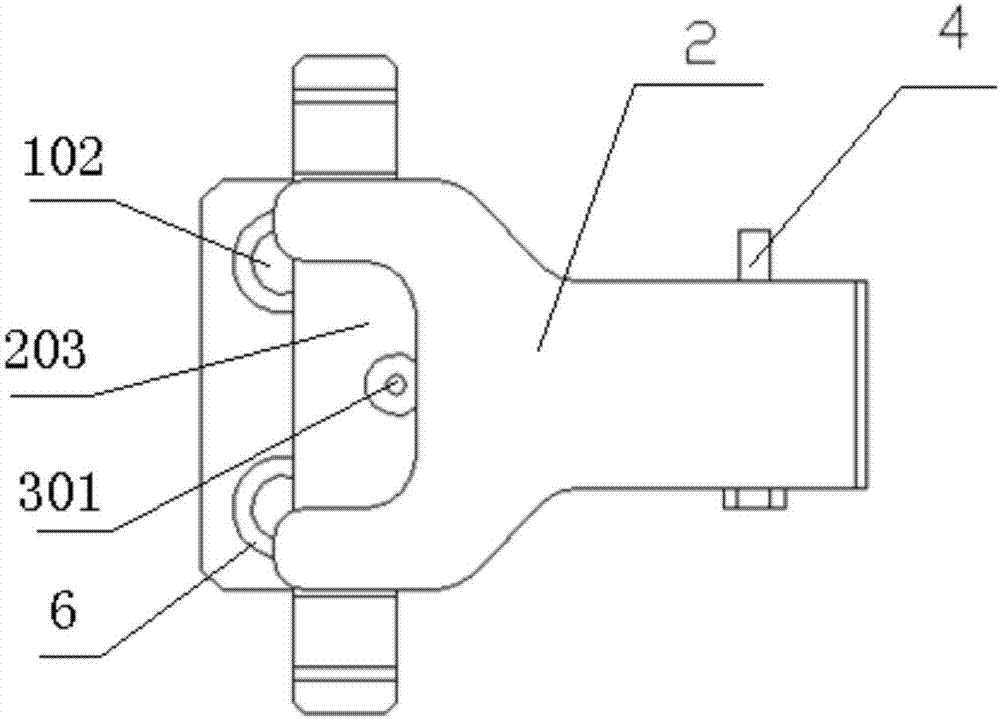

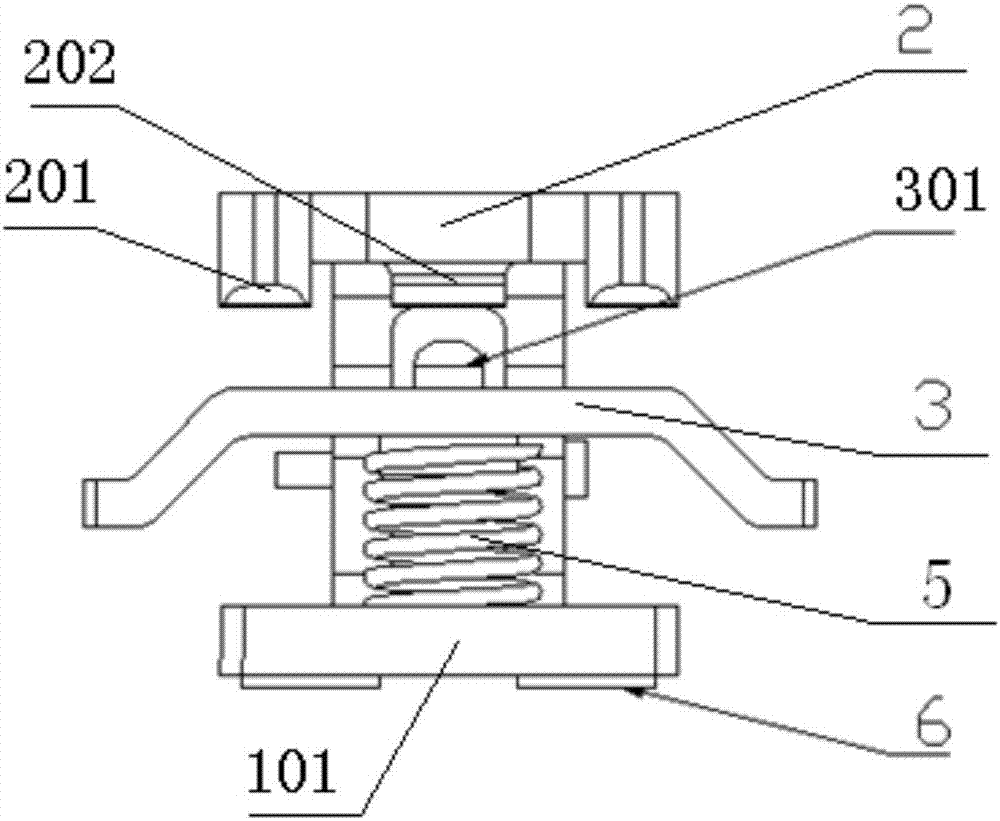

[0033] Such as Figure 1~3 As shown, the tooling for measuring the edge and depression of the composite wing panel in this embodiment includes: a mounting base 1 , a first splint 2 , a second splint 3 , a rotating shaft 4 , and a spring 5 .

[0034] Mounting seat 1 comprises: base plate 101, T-shaped plate, and the two ends of horizontal direction are respectively provided with target holder mounting hole 102; Mounting pole 103, one longitudinal end of base plate 101 bends to one side and forms; First splint 2 is fixed on the installation The clamping surface of the end of the pole 103 faces the bottom plate 101 .

[0035] The second clamping plate 3 is hinged in the middle of the installation pole 103 , the clamping surface faces the first clamping plate 2 , and the spring 5 is installed between the side of the second clamping plate 3 facing away from the clamping surface and the bottom plate 101 .

[0036] A steel sleeve 6 is inlaid on the target mount mounting hole 102, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com