Method for processing shaft with small eccentricity

A processing method and technology with small eccentricity, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problem of increasing cutting amount, processing difficulty, personnel and machine tool consumption, processing cost and alloy steel raw material cost sharply increasing, and processing cycle prolongation and other problems, to achieve the effect of improving economic and social benefits, easy for operators to grasp, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

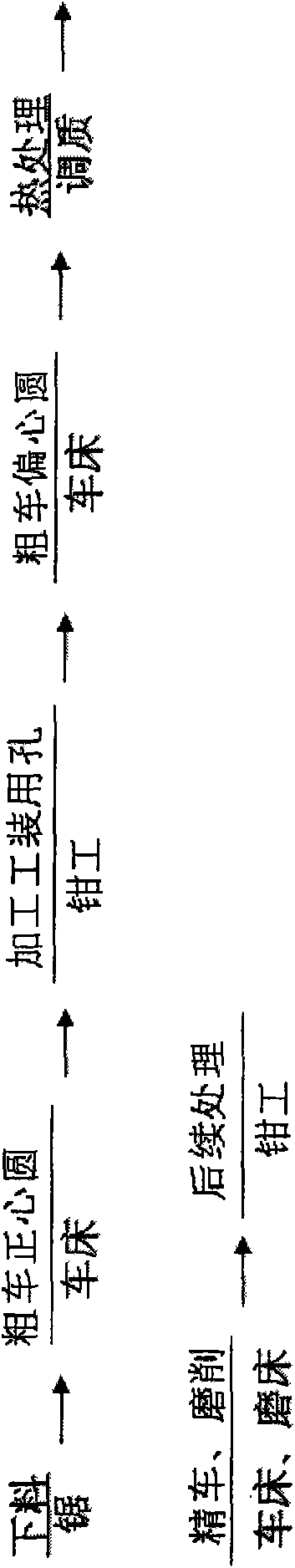

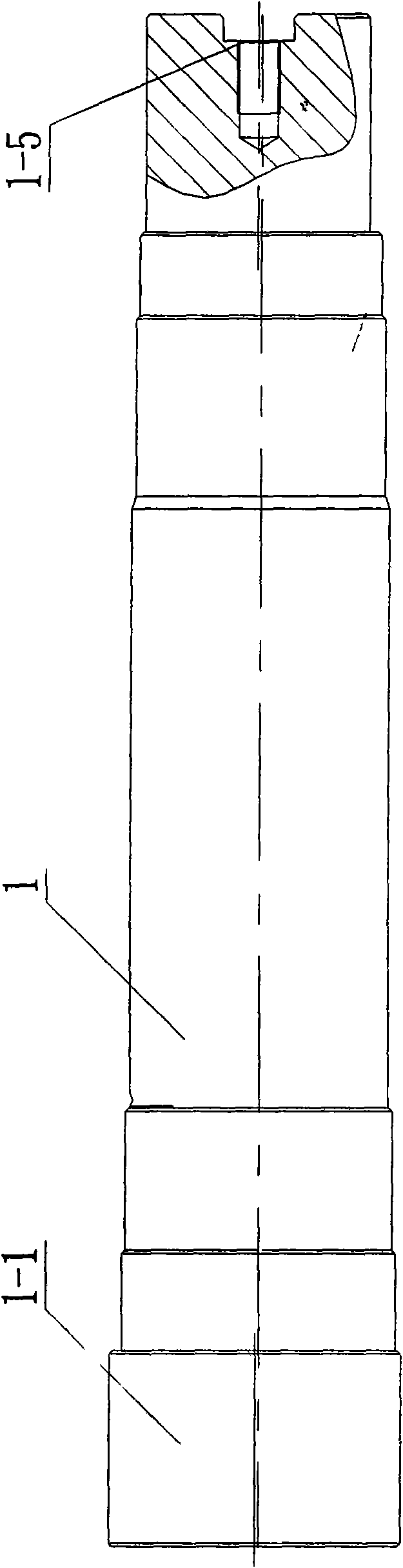

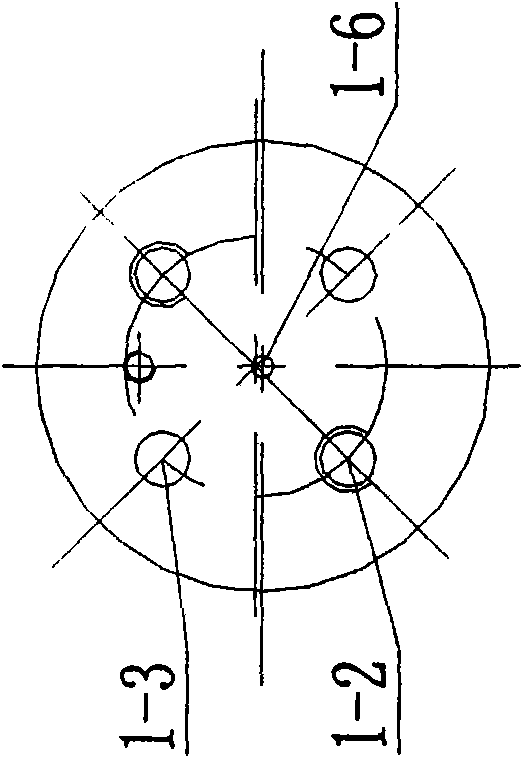

[0028] see figure 1 one Figure 11 , an implementation example of the present invention, a processing method of a small eccentricity shaft:

[0029] Taking the processing and manufacturing plan of the three-roll centering eccentric shaft 1 for rolling mill as an example,

[0030] Processing shaft blank, blanking: corrected on the bow sawing machine, the sawing size is 175×870mm round steel, the material is 42CrMo; the center circle of the rough turning blank: use a single angle gauge to find the center of the end face, the outer circle of the rough turning blank, the full length of the turning can survive, drill the center hole 1-6, and use one clip and one Top-type clamping, using the center frame U-turn method for rough turning of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com