Large-cantilever steel frame structure with pull rod and construction method thereof

A construction method and steel frame technology, applied in special structures, building components, building structures, etc., can solve the problems of high construction difficulty, high welding construction difficulty, and high risk factor, and achieve low overall construction difficulty, overall structural stability, and high risk factors. The effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

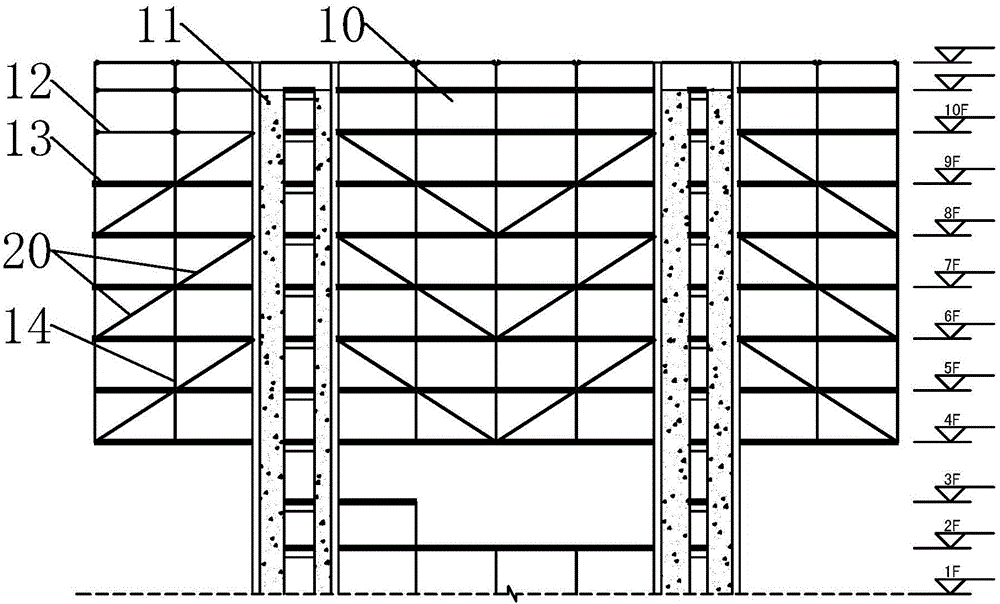

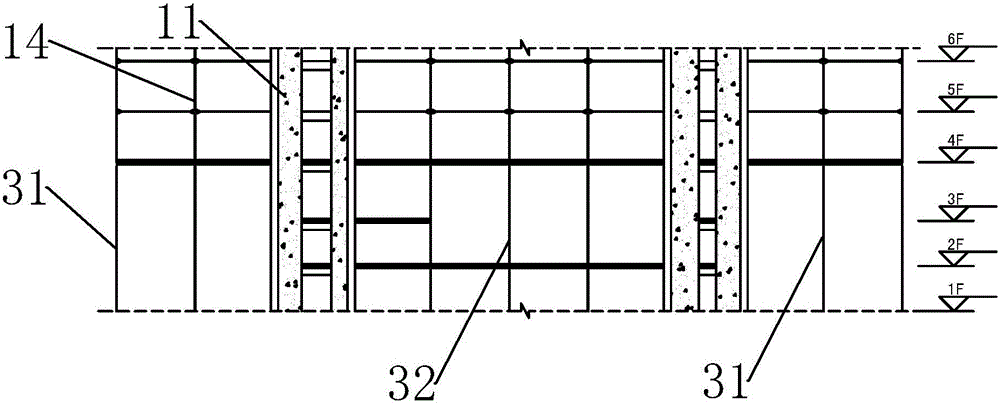

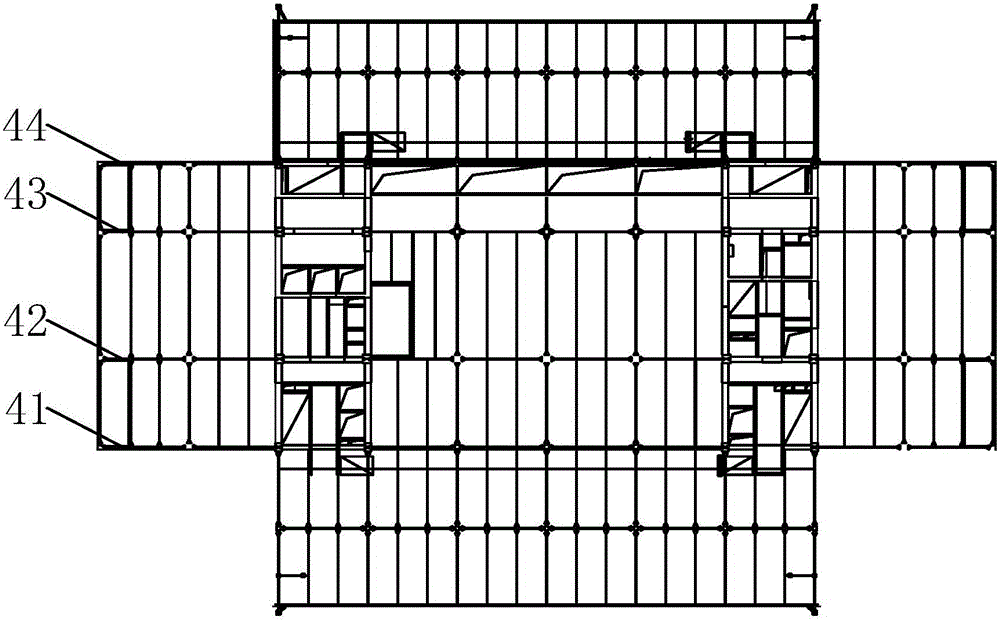

[0045] Such as Figure 1-2 As shown, the large cantilever steel frame structure with tie rods includes a steel frame body 10. The steel frame body 10 includes two vertical core tubes 11 and an N-layer steel frame erected on the core tubes 11. The steel frame includes steel beams 12. Steel columns 14 and steel truss floor decks 13. The lower end of the side of the steel frame body 11 is provided with a cantilevered floor of the M floor, and the suspended part of the cantilevered floor is provided with a detachable temporary steel column support 31, M+1 The first floor to the Nth floor is the tie rod layer. The steel frame body is longitudinally provided with several axial surfaces, and the upper and lower adjacent steel frames on the axial surface are fixed by steel tie rods 20. Up and down" slope shape.

[0046] The number of layers N of the steel frame satisfies: 7≤N≤16, in this embodiment, N=10, M=3, and a two-story tall space is built on the second floor.

[0047] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com