Vacuum device and vacuum pump

a vacuum pump and vacuum technology, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of large power consumption and increase in and achieve the effect of reducing the manufacturing cost of semiconductor devices and suppressing the power consumption of vacuum pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

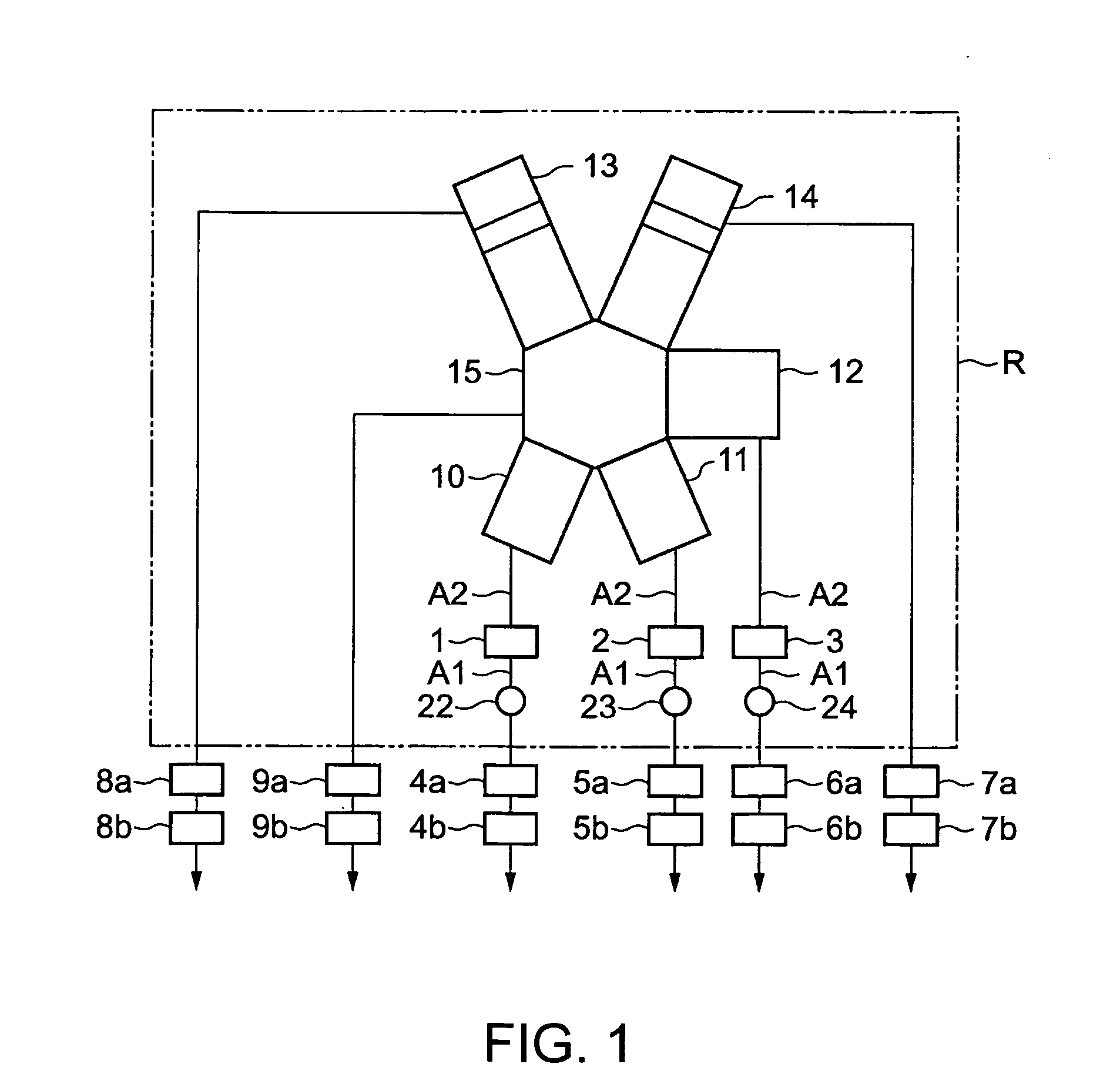

[0042] In the embodiment 1 of this invention, screw pumps A are used as the back pumps 4b, 5b, and 6b in FIG. 1, respectively.

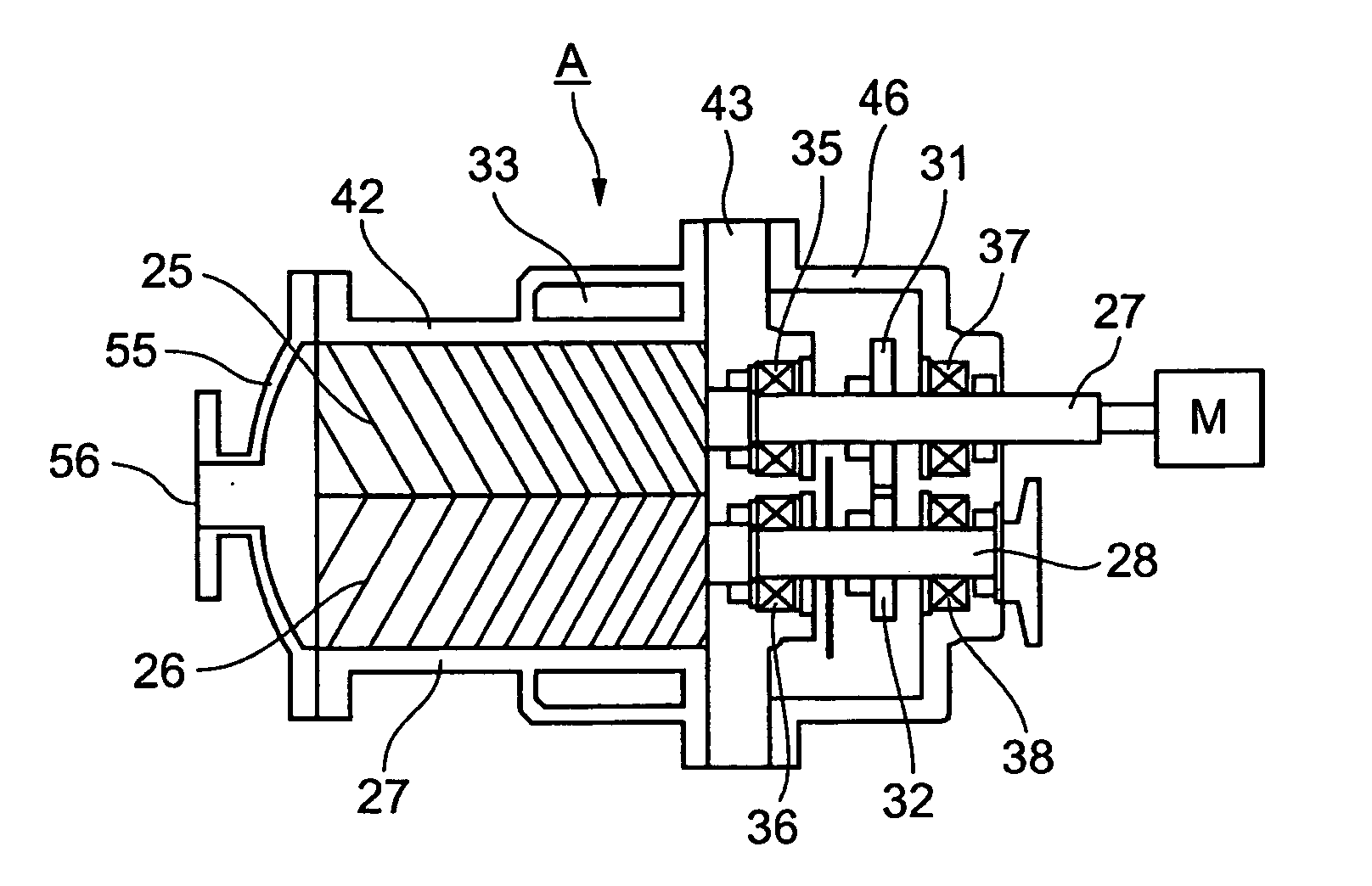

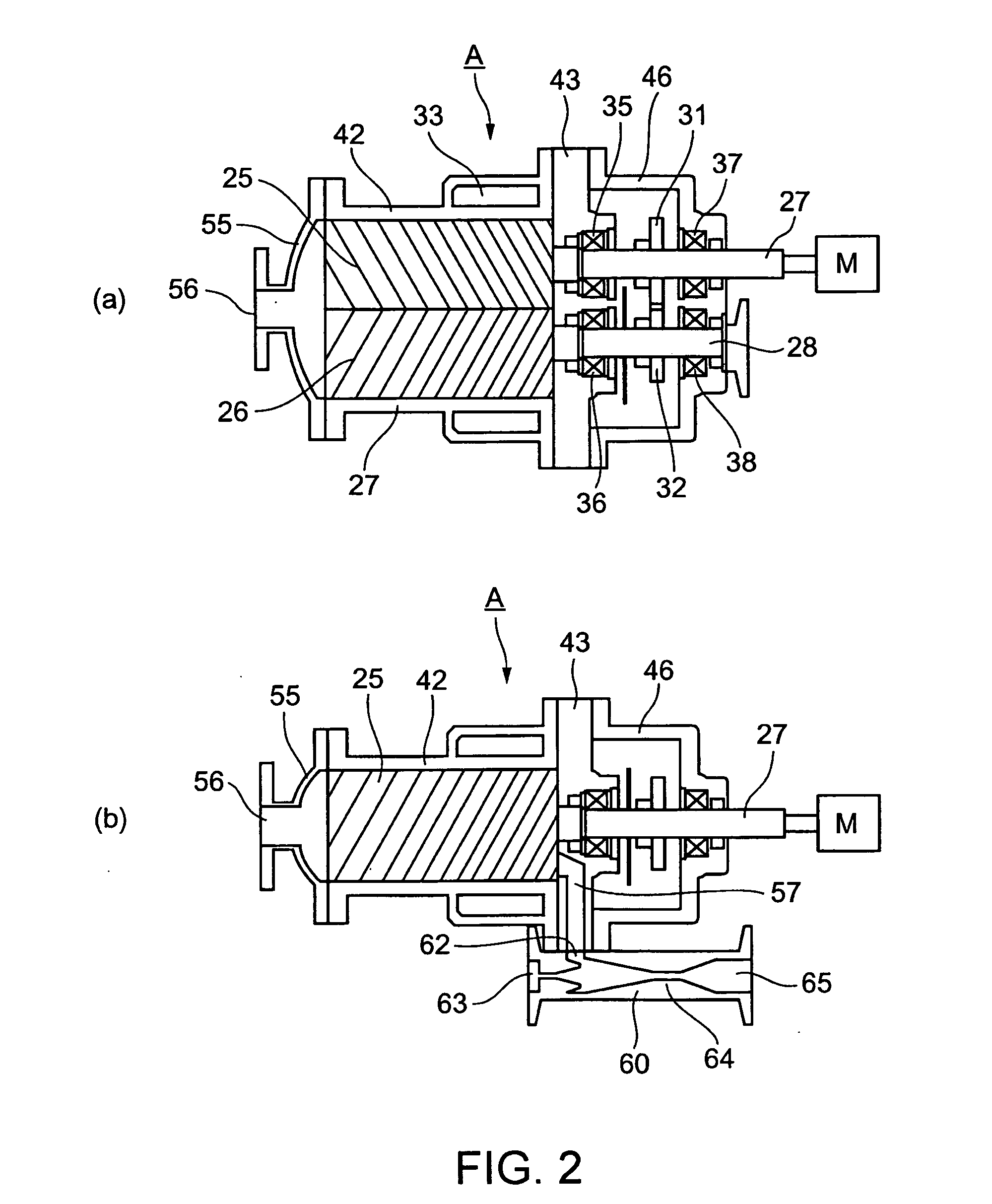

[0043] Referring to FIG. 2,(a) and (b), a male rotor 25 and a female rotor 26 of the screw pump A are received in a main casing 42 and rotatably supported by bearings 35 and 36 attached to an end plate 43 sealing the main casing 42 on its one end side and bearings 37 and 38 attached to an auxiliary casing 46, respectively.

[0044] Timing gears 31 and 32 accommodated in the auxiliary casing 46 are mounted on rotation shafts 27 and 28 of the male and female rotors 25 and 26, respectively, and a gap between the male rotor 25 and the female rotor 26 is adjusted so that both rotors do not contact each other. Further, a motor M is attached to the rotation shaft of the male rotor 25 through a coupling or timing gear. It is configured that the rotation of the motor M is transmitted to the male rotor 25 and rotates the female rotor 26 through the timing gears 31 and 3...

embodiment 2

[0056] In the embodiment 2 of this invention, screw pumps B are used as the back pumps 4b, 5b, and 6b in FIG. 1, respectively.

[0057] Referring to FIG. 4,(a) and (b), in the screw pump B, like in the screw pump A shown in FIG. 2,(a) and (b), a male rotor 25 and a female rotor 26 are received in a main casing 42 and rotatably supported by bearings 35 and 36 attached to an end plate 43 sealing the main casing 42 on its one end side and bearings 37 and 38 attached to an auxiliary casing 46, respectively.

[0058] Timing gears 31 and 32 accommodated in the auxiliary casing 46 are mounted on rotation shafts 27 and 28 of the male and female rotors 25 and 26, respectively, and a gap between the male rotor 25 and the female rotor 26 is adjusted so that both rotors do not contact each other. Further, a motor M is attached to the rotation shaft of the male rotor 25 through a coupling or timing gear. It is configured that the rotation of the motor M is transmitted to the male rotor 25 and rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com