Progressive cavity pump/motor

a technology of progressive cavity and pump, which is applied in the direction of positive displacement liquid engine, piston pump, liquid fuel engine, etc., can solve the problems of large heat loss, significant deflection and stress in the elastomer, and introduction of weaknesses into the operation and life of the pump/motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

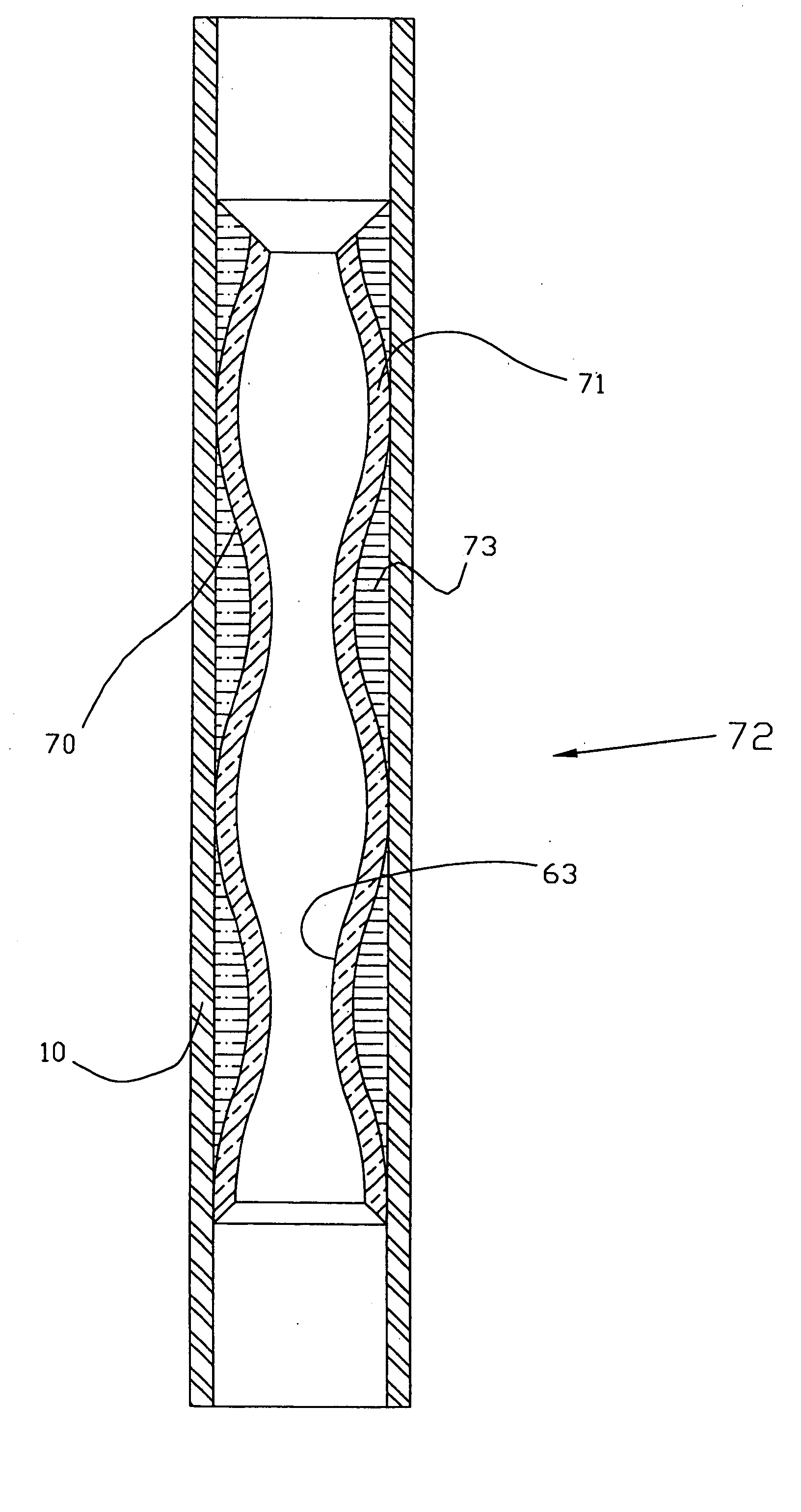

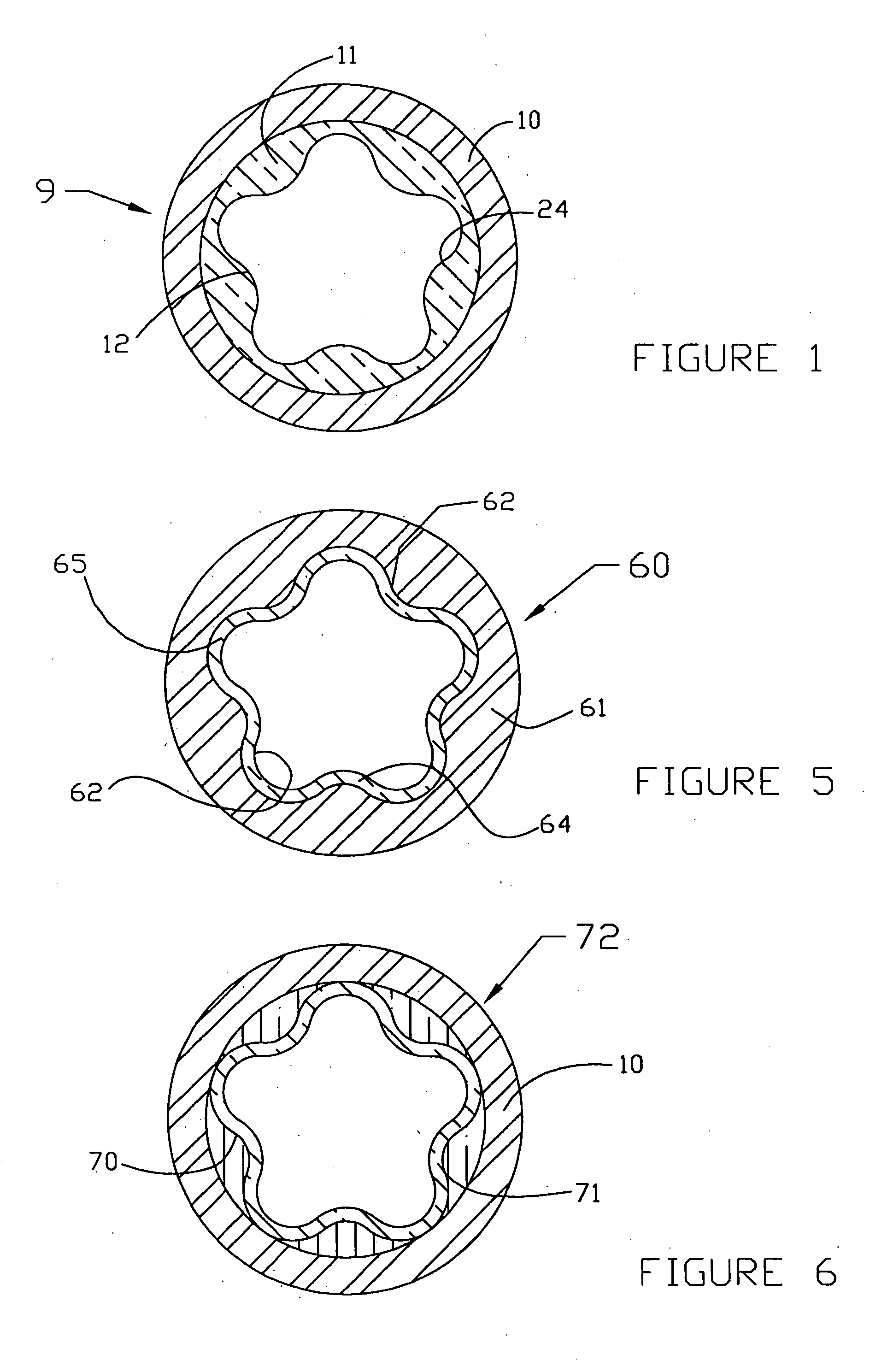

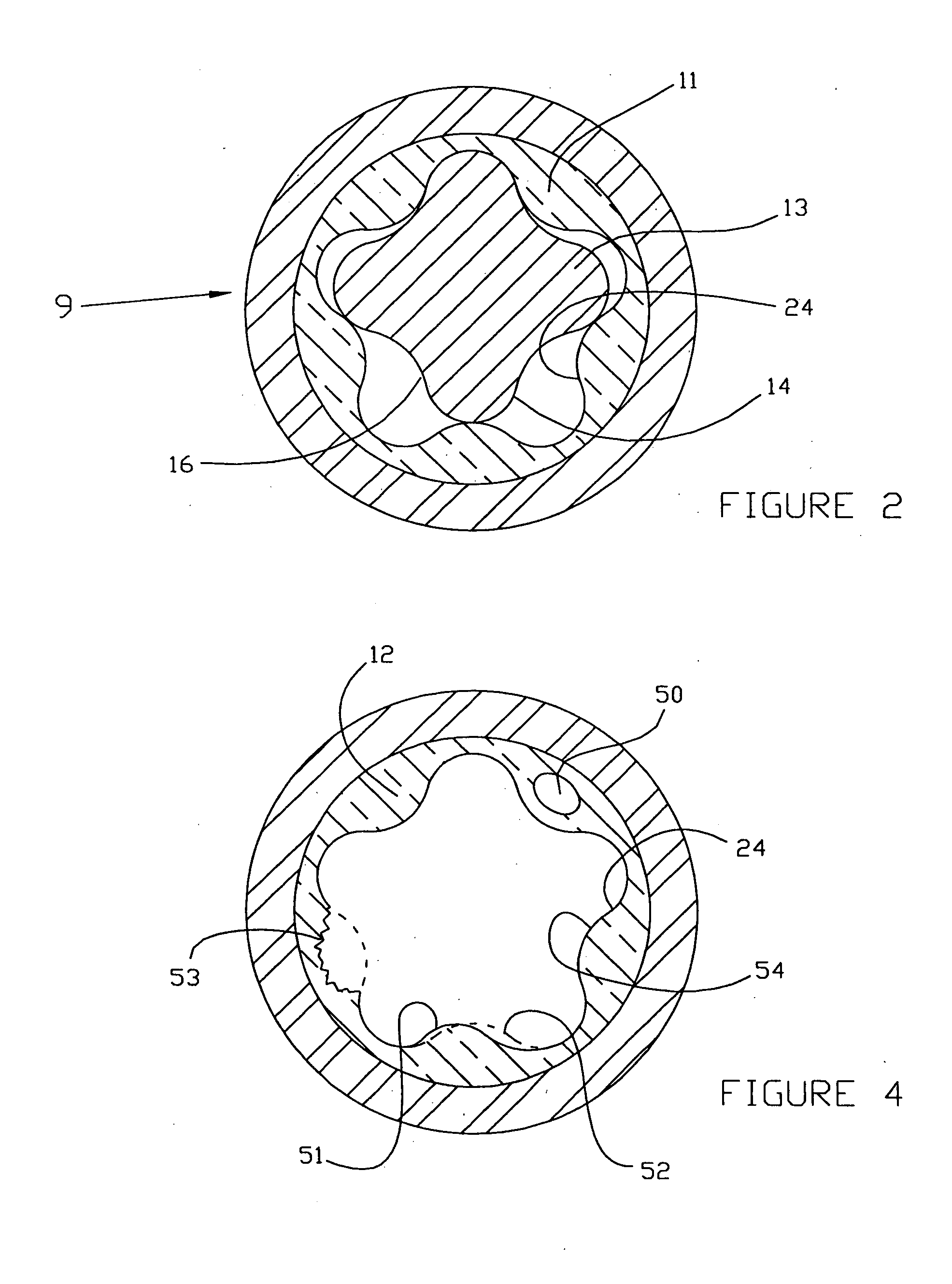

[0030]FIG. 1 depicts a conventional progressive cavity stator 9 of a pump or motor which includes a steel or similar structural material tube or housing 10. Elastomeric layer 11 is molded into the tube 10. The number of lobes 12 may be of any practical number greater than one. As can be seen in FIG. 2, the rotor 13 has one less lobe 14 than the mating stator. The number of lobes depends on the desired operating characteristics of the pump or motor. As the rotor 13 rotates inside of the stator 9, debris entrained in the fluid which supplies the energy for a motor, or is being moved by a pump, may become caught between the rotor surface 16 and the stator surface 24. The flexible nature of an elastomeric material allows this debris to be pressed into the stator surface 24, thereby allowing the rotor 13 to continue rotating unabated.

[0031]FIG. 3 illustrates a conventional technology progressive cavity motor 18, which alternatively could be a progressive cavity pump. To transmit the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com