Method for integrated designing screw pump

A design method and screw pump technology, applied in the direction of calculation, computer control, program control, etc., can solve the problems that the role has not been paid attention to and brought into play, the promotion and application of CAE and CAM have been limited, and the advantages of computer-aided design have not been brought into play.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

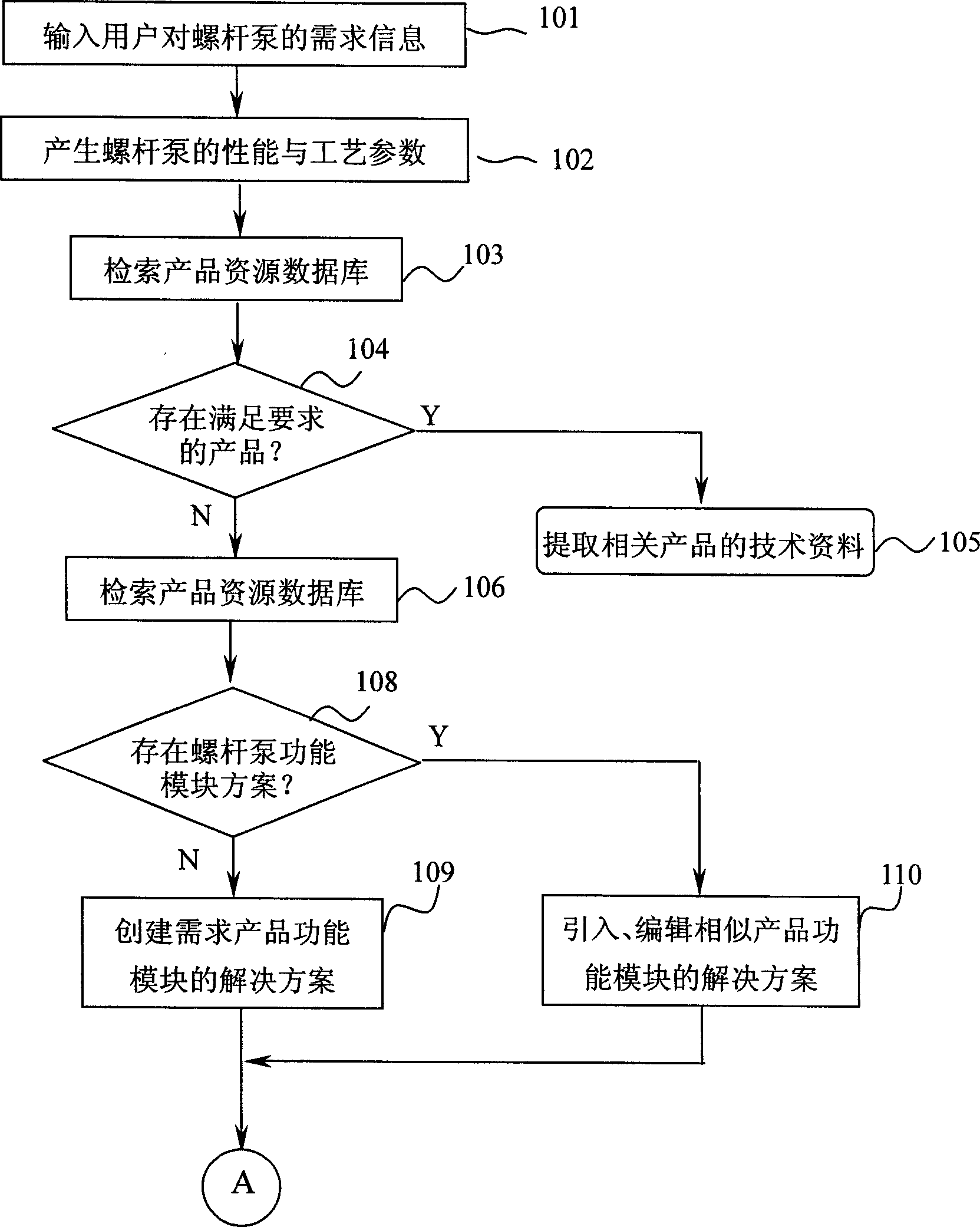

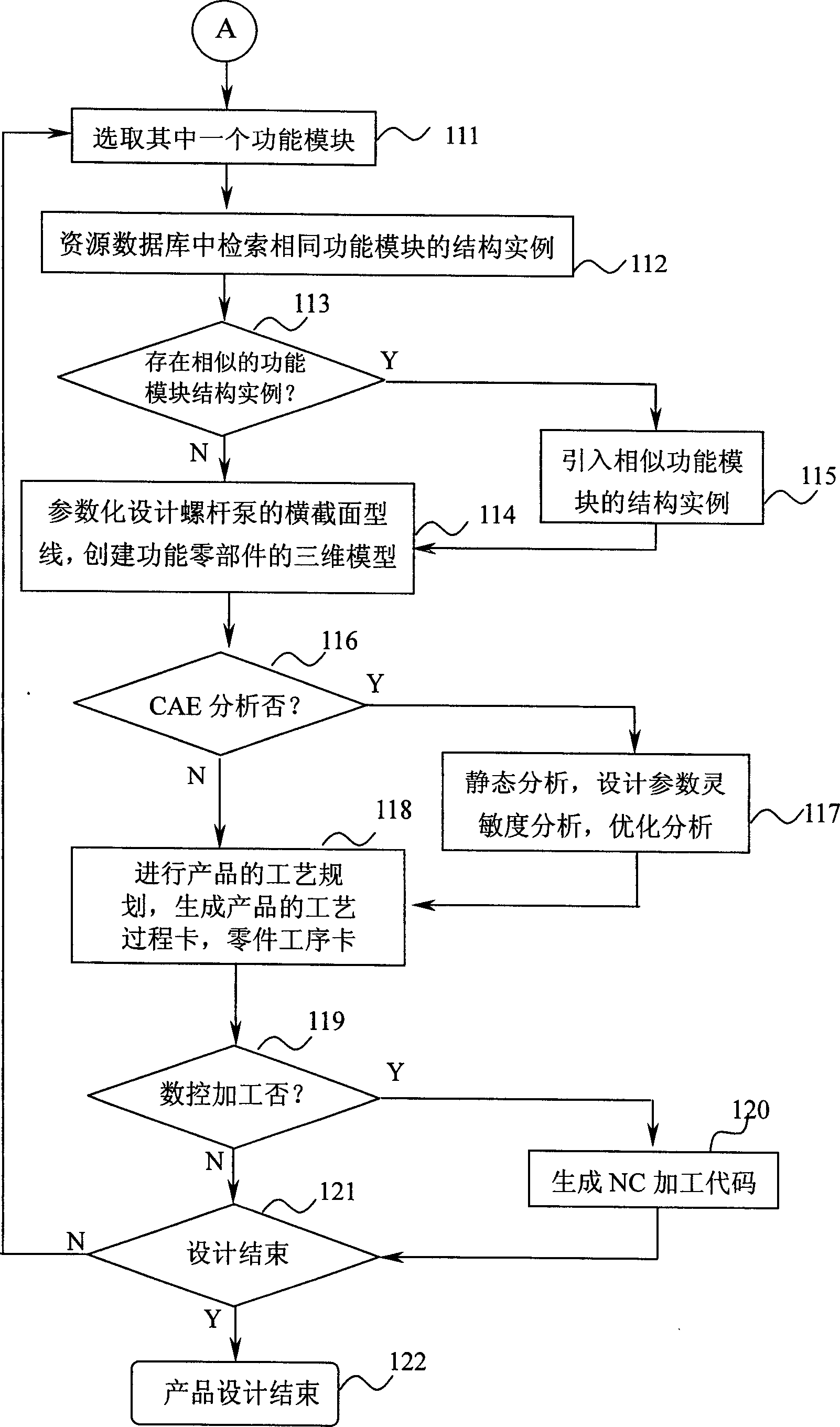

[0032] The following will be described in detail in conjunction with the embodiments and with reference to the accompanying drawings, so as to further describe the present invention.

[0033] like Picture 1-1 and Figure 1-2 As shown, first, input the user's demand information for the screw pump, including displacement, discharge pressure, suction height, maximum temperature, allowable viscosity, non-lubricating medium, fluid corrosive medium containing solid impurities, etc., step 101 .

[0034] According to the above demand information, create the initial design main parameters of the screw pump, such as the type of the screw pump, the number of heads of the screw, the diameter of the screw, the stroke, the diameter of the input shaft, the material of the screw sleeve, etc., step 102 .

[0035] According to the initial design main parameters, search from the screw pump product resource library in the system to determine whether there is a product that meets the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com