Method for designing and manufacturing ultra-plastic forming and diffusion bonding mould suitable for complex titanium alloy parts

A technology of superplastic forming and diffusion joining, used in manufacturing tools, welding equipment, welding equipment, etc., to achieve the effect of improving manufacturing cycle, improving quality, and fine-grained structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with specific embodiments and drawings.

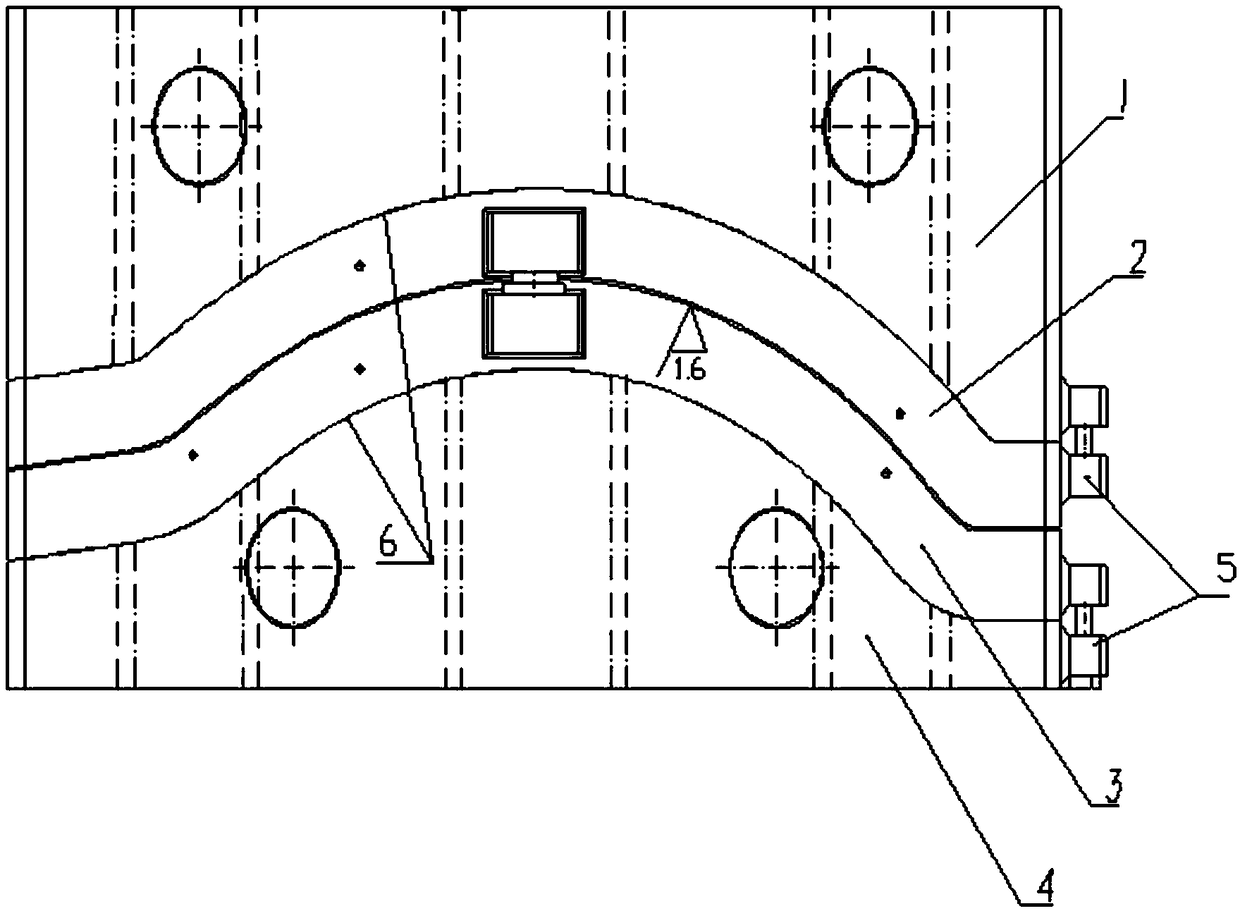

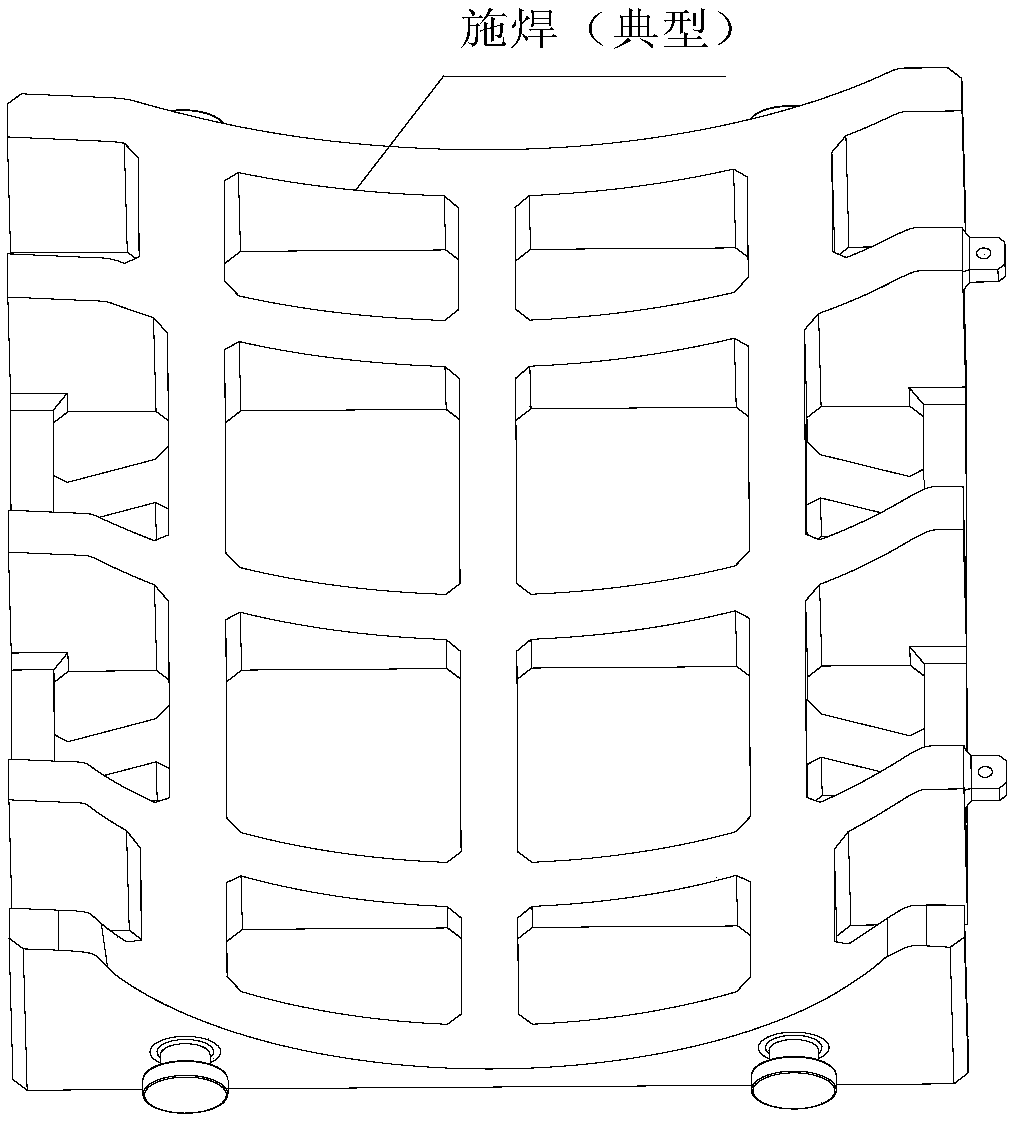

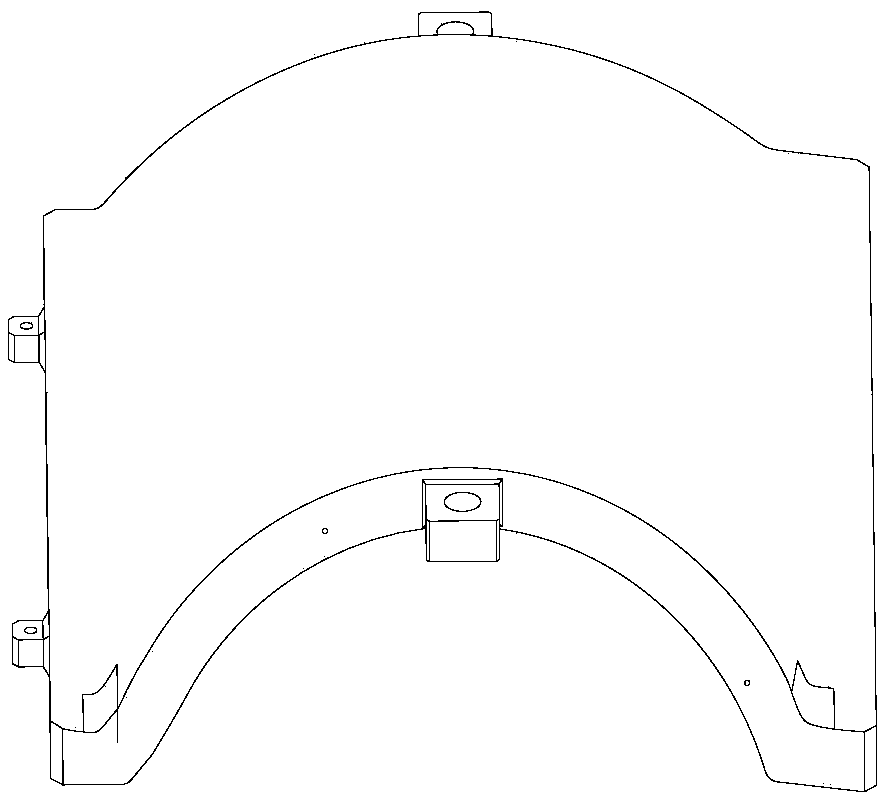

[0030] A superplastic forming / diffusion bonding mold suitable for complex titanium alloy parts, including an upper mold assembly and a lower mold assembly; the upper mold assembly consists of an upper mold base reinforcement rib 1, an upper mold surface web 2 and a welding positioning lug device 5 Composition; the lower mold assembly is composed of the lower mold surface web 3, the lower mold base reinforcement 4 and the welding positioning lug device 5; the upper mold base reinforcement 1 and the upper mold surface web 2 are cast separately, between the two Positioning by welding positioning lug device 5, the bonding surfaces of the two are connected by welding; the lower mold base reinforcement 3 and the lower mold surface web 4 are cast separately, and the two are positioned by welding positioning lug device 5 , The joint is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com