Surface ink blotting type gold and silver cardboard and manufacturing method thereof

A production method and cardboard technology, applied in the direction of copying/marking method, wrapping paper, wrapping paper, etc., can solve the problems of high cost increase, limited use of gold and silver cardboard, high equipment investment, etc., to reduce production costs and printing Cost, good economic and social benefits, and the effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

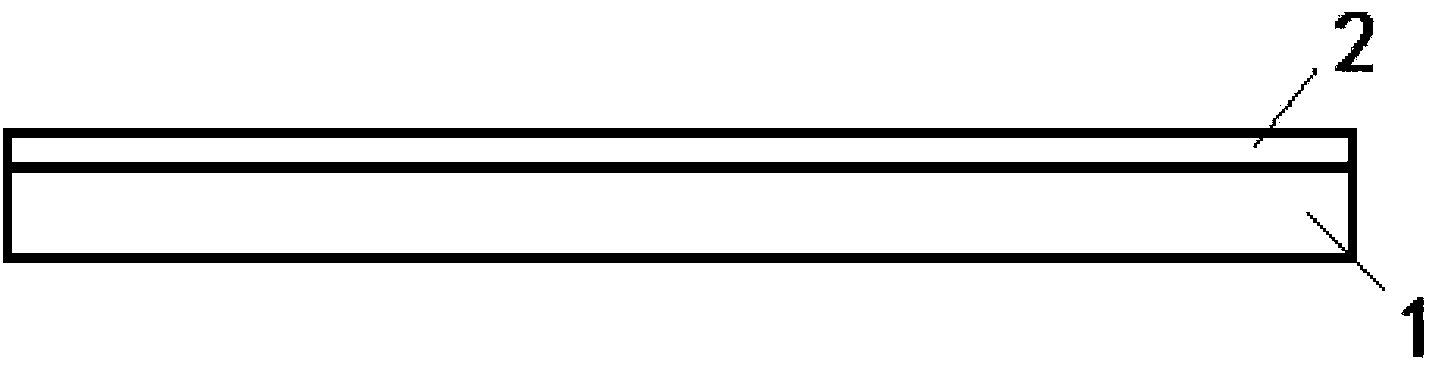

[0026] Embodiment 1: as figure 1 As shown, the surface of the ink-absorbing gold and silver cardboard or other paper base 1 is connected with a metallic ink-absorbing coating 2 on the surface.

[0027] The production method of ink-absorbing gold and silver cardboard is as follows:

[0028] The metal texture ink-absorbing coating is evenly applied to the surface of cardboard or other paper base 1 by a coating machine; after drying, the metal texture ink-absorbing coating 2 is formed, and then calendered, wound, and cut into rolls or flat sheets of blotting gold and silver cardstock.

[0029] The coating machine used in the above method is a conventional coating machine, including knife coating, air knife coating, bar coating, roll coating, comma knife coating, extrusion coating, gravure coating and the like.

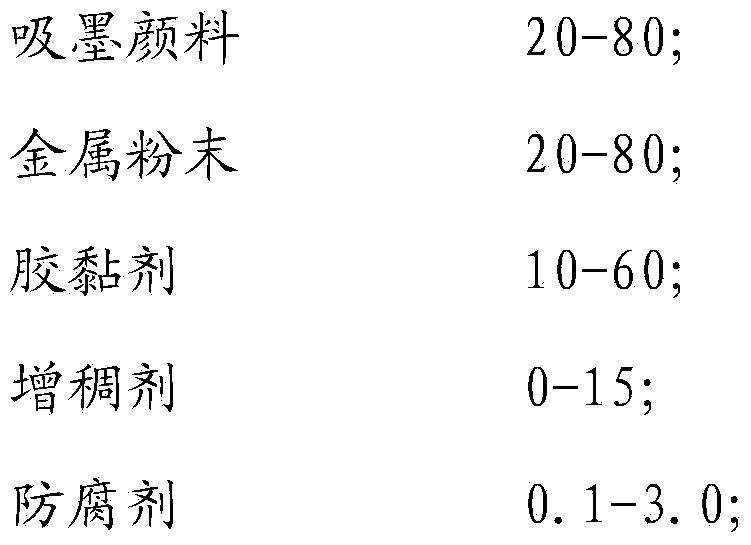

[0030] The metallic texture ink-absorbing coating used in the above method is composed of ink-absorbing pigments, metal grinding, adhesives, thickeners, preservatives a...

Embodiment 2

[0044] Embodiment 2: as figure 1 As shown, the surface of the ink-absorbing gold and silver cardboard or other paper base 1 is connected with a metallic ink-absorbing coating 2 on the surface.

[0045] The production method of ink-absorbing gold and silver cardboard is as follows:

[0046] A gold and silver cardboard with an ink-absorbing surface, which is coated with an ink-absorbing coating with a metallic texture on the surface of an ordinary cardboard or cardboard substrate;

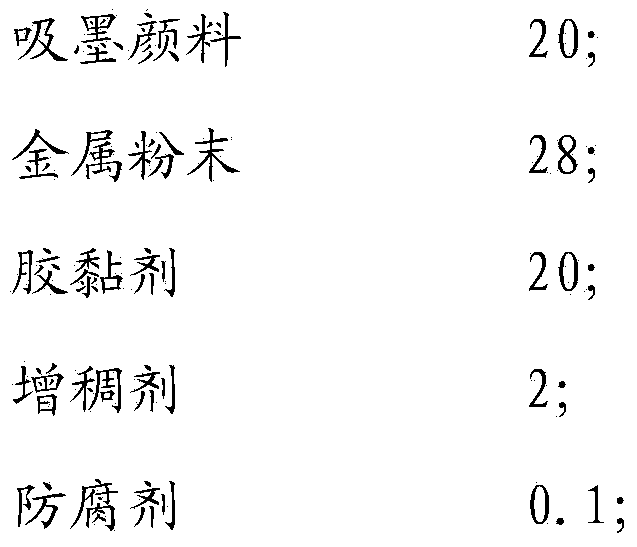

[0047] The composition of the ink-absorbing coating is as follows (weight ratio):

[0048]

[0049] Ink-absorbing pigments, including one or a combination of the following raw materials: silicon dioxide, diatomaceous earth, aluminum silicate, talc, calcium carbonate, kaolin, aluminum oxide, zinc oxide; preferably: silicon dioxide;

[0050] Metal powder, including one or a combination of several of the following raw materials: copper-gold powder, copper-gold paste or aluminum-silver powder, alumi...

Embodiment 3

[0059] Embodiment 3: as figure 1 As shown, the surface of the ink-absorbing gold and silver cardboard or other paper base 1 is connected with a metallic ink-absorbing coating 2 on the surface.

[0060] The production method of ink-absorbing gold and silver cardboard is as follows:

[0061] A gold and silver cardboard with an ink-absorbing surface, which is coated with an ink-absorbing coating with a metallic texture on the surface of an ordinary cardboard or cardboard substrate;

[0062] The composition of the ink-absorbing coating is as follows (weight ratio):

[0063]

[0064] Ink-absorbing pigments, including one or a combination of the following raw materials: silicon dioxide, diatomaceous earth, aluminum silicate, talcum powder, calcium carbonate, kaolin, aluminum oxide, zinc oxide; preferably: aluminum oxide;

[0065] Metal powder, including one or a combination of several of the following raw materials: copper-gold powder, copper-gold paste or aluminum-silver powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com