Arrangement for hydrocarbon extraction in wells using progressive cavity pumps

a technology of progressive cavity and hydrocarbon extraction well, which is applied in the direction of machines/engines, liquid fuel engines, borehole/well accessories, etc., can solve the problems of tubing wearing out, poor lubrication, and inability to avoid certain contact and friction between tubing and the rod rotating inside, so as to reduce the wear and corrosion of tubing and reduce the effect of wear and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

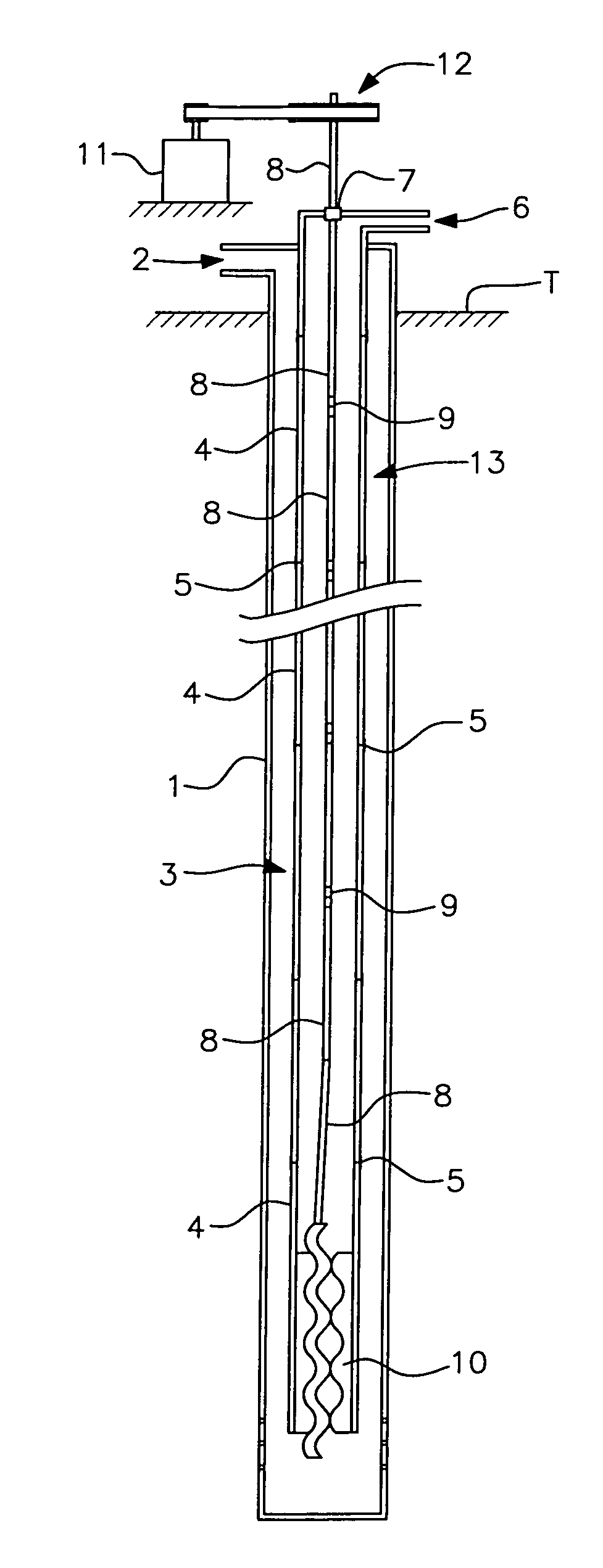

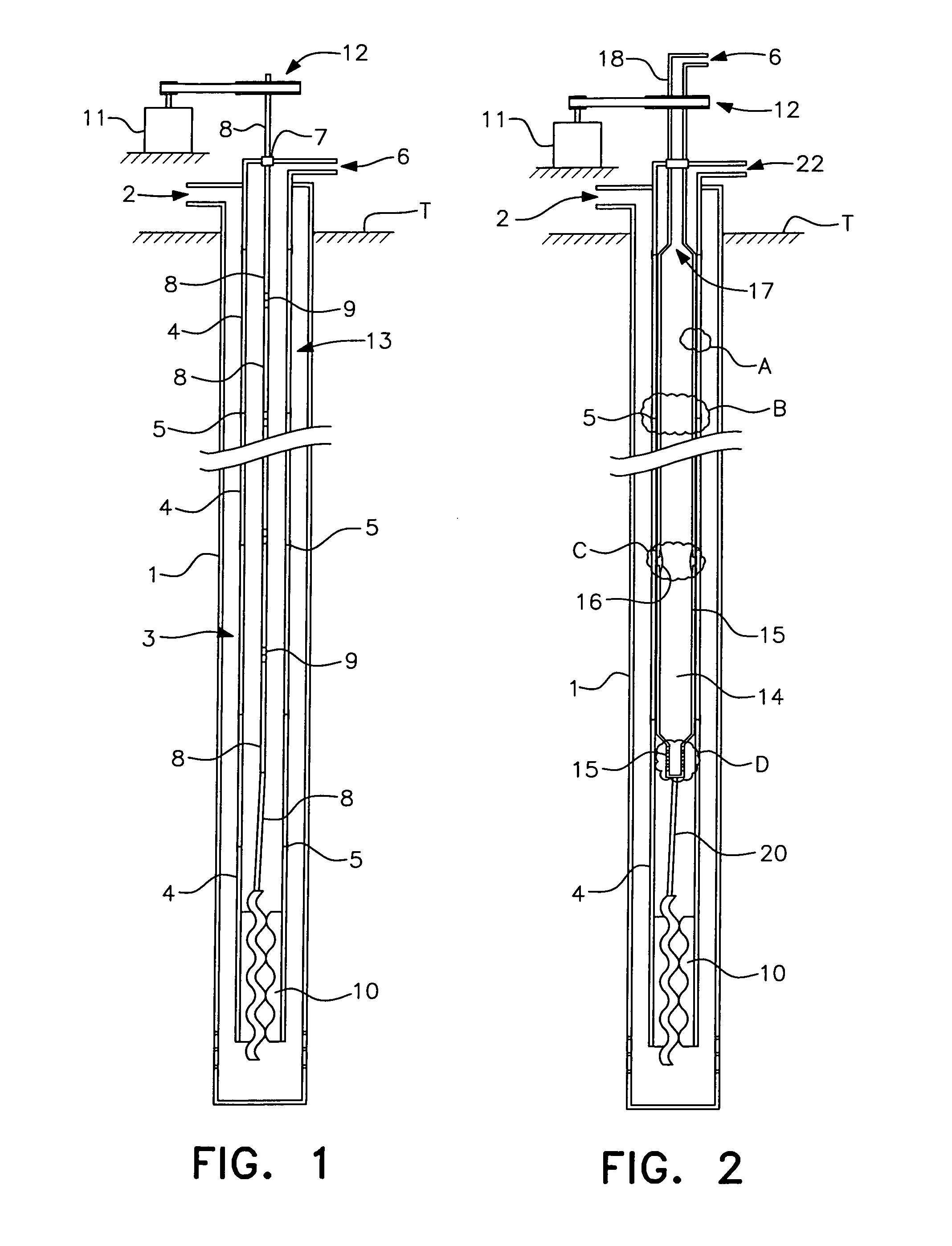

[0010]FIG. 1 shows that the illustrated example of a conventional pumping arrangement consists of a casing 1, with a wellhead outlet 2, which holds inside a tubing 3, which carries the fluid from the bottom of the well to the surface, formed by a succession of sections 4 connected among them by joints 5. Between the casing 1 and the tubing 3 there is a longitudinally defined “O” ring-type space 13. The upper section 4 of the tubing 3 which projects itself from the wellhead at the field's land T surface has a production outlet 6, through which the first of a succession of rods 8 connected among them by joints 9 passes as well as through a stuffing box 7, the last rod 8 at the tubing's lower section 4 is connected to a bottom PCP pump 10. In order to drive the rotating movement of the group of rods 8, and consequently to drive the pump 10, the upper rod 8 is connected to an electric engine 11 by means of a belt-and-pulley transmission mechanism 12.

[0011]As it has already been stated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com