Patents

Literature

30results about How to "Solve fair use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

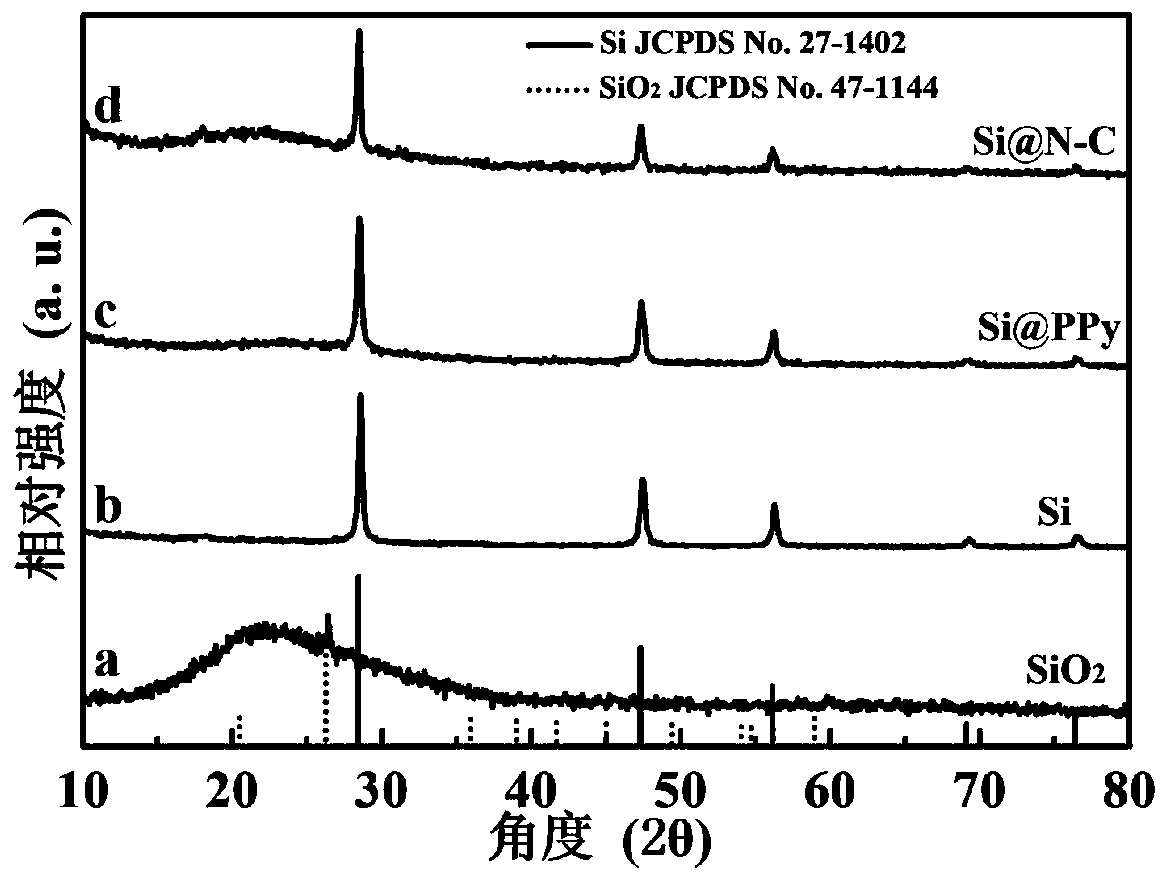

High-performance lithium ion battery negative electrode Si@N-C composite material and preparation method therefor

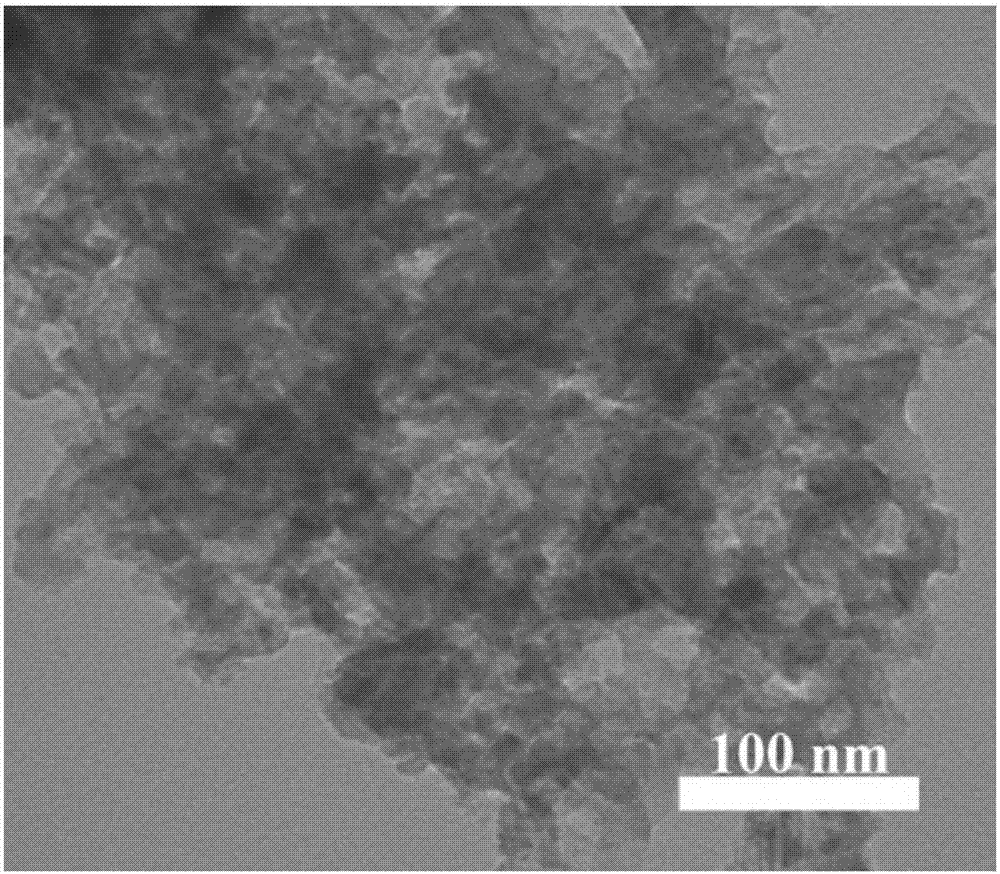

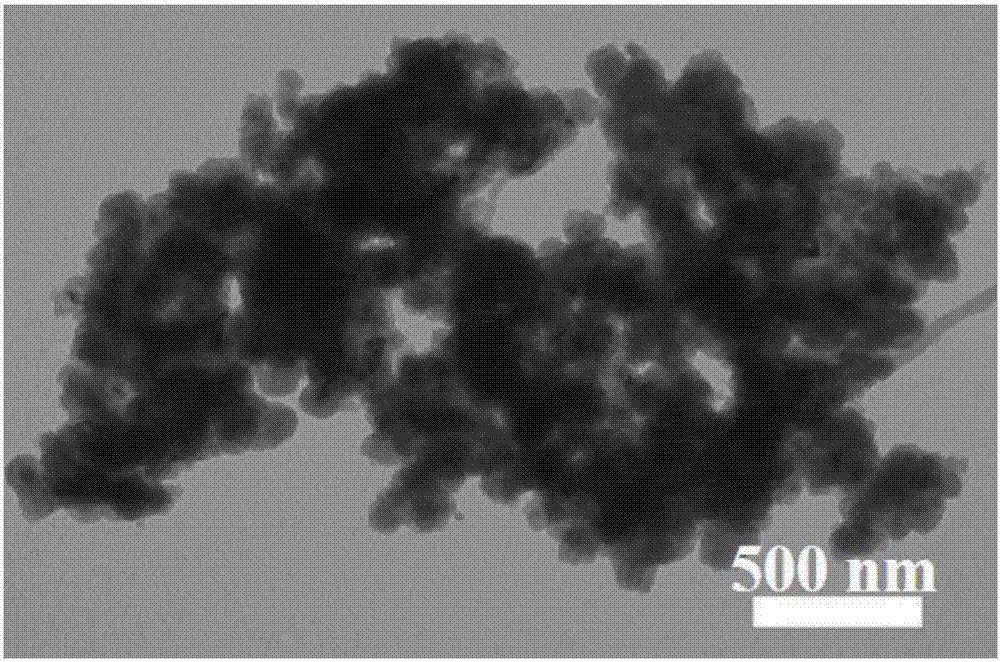

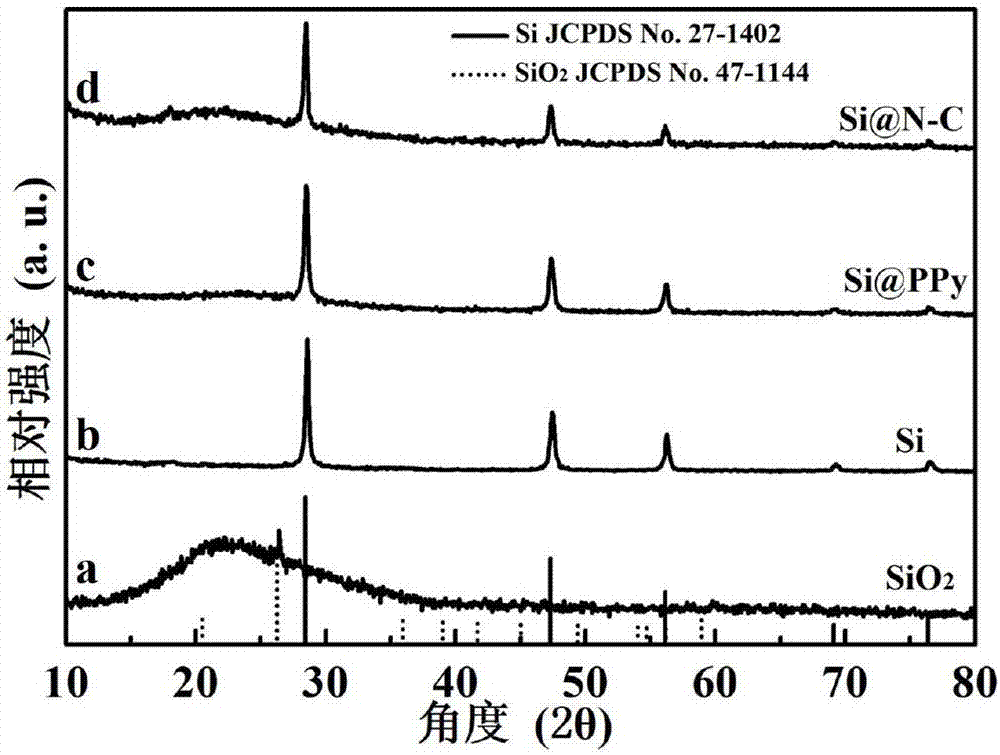

ActiveCN107195890AGood dispersionHigh nitrogen contentCell electrodesSecondary cellsHazardous substancePolypyrrole

The invention relates to a high-performance lithium ion battery negative electrode Si@N-C composite material and a preparation method therefor. According to the method, gulfweed is used as the raw material to prepare SiO<2> and then reduction is preformed to obtain a Si material; and next, pyrrole is used as the main raw material to coat polypyrrole on the surface of the Si material, and calcining is preformed to obtain the Si@N-C composite material. The raw materials adopted in the method are simple and easily available, low in cost and environment friendly, and toxic and harmful material generation in the preparation process is avoided; in addition, the problem existing in reasonable utilization of gulfweed is solved effectively, and economic efficiency and environment protection are realized; in addition, the silicon material extraction method disclosed in the invention has certain universality for extracting the silicon material form other silicate-containing plants; furthermore, heteroatom N-doped C coating is realized through high-molecular polymer polypyrrole pyrolysis is realized, so that the conductivity and the stability of the Si material are greatly improved, thereby improving the lithium ion battery performance of the Si@N-C composite material.

Owner:SHANDONG UNIV

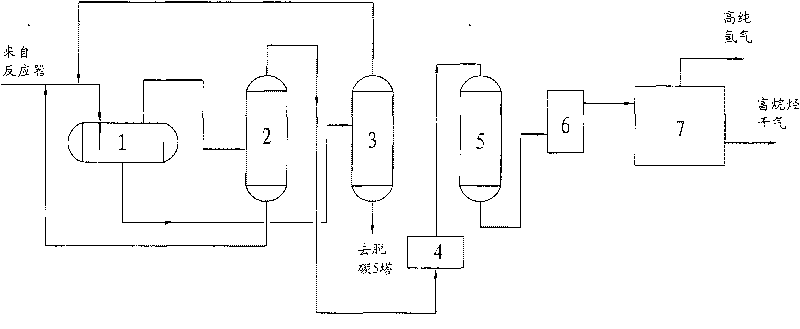

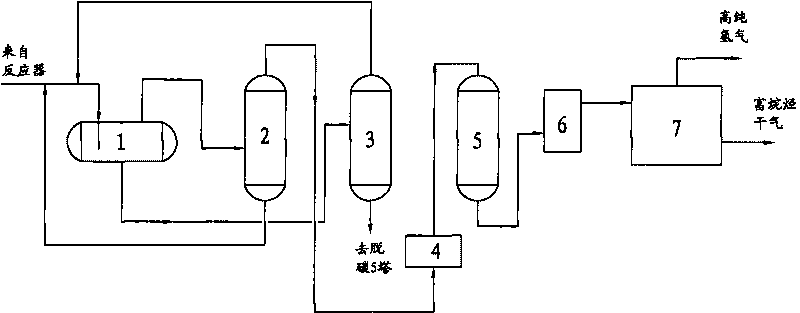

Method for separating light dydrocarbon aromatization dry gas

ActiveCN101759517AEliminate damageGood dry gas qualityHydrogen separation using liquid contactHydrocarbonsHydrogenAbsorption column

The invention relates to a method for separating light dydrocarbon aromatization dry gas, which belongs to the technical field of light dydrocarbon aromatization. The method is characterized by comprising a reaction liquid separation tank, an absorption column and an analytical column; reaction gas of the reaction liquid separation tank enters the bottom of the absorption column to absorb and separate condensable hydrocarbons further; the material flow at the bottom of the absorption column returns to the reaction liquid separation tank; gas on the top of the column passes through a primary gas-liquid separation tank, a hydrogenation reactor and a secondary gas-liquid separation tank and then enters a hydrogen manufacturing device; high-purity hydrogen is separated out from the top of thehydrogen manufacturing device, and alkane-rich dry gas is separated out from the bottom to enter a pyrolysis device; and a liquid phase of the reaction liquid separation tank enters the analytical column, and the gas of the top of the analytical column returns to the reaction liquid separation tank. Aiming at the defects in the prior art that the dry gas is only subjected to simple gas-liquid separation, the quality of the dry gas is poor, and the uncompleted and unreasonable factors exist in the aspect of reasonable utilization of the aromatization, the invention provides the method for separating the dry gas thoroughly and completely, so that the quality of the dry gas is high, and the components of the dry gas are divided into components containing high-purity hydrogen and CH4, C2+,C3,C4 and over C4 which do not contain alkene, and the dry gas is utilized reasonably and effectively and meets the requirement of peripheral resource environment of enterprises.

Owner:淄博宜达新材料科技有限公司

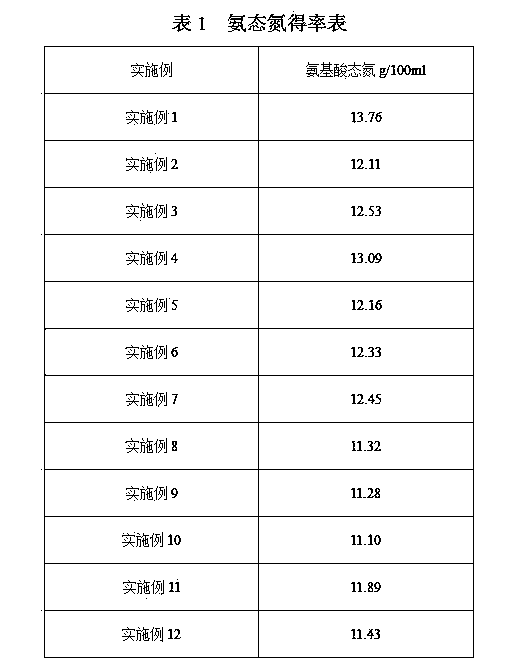

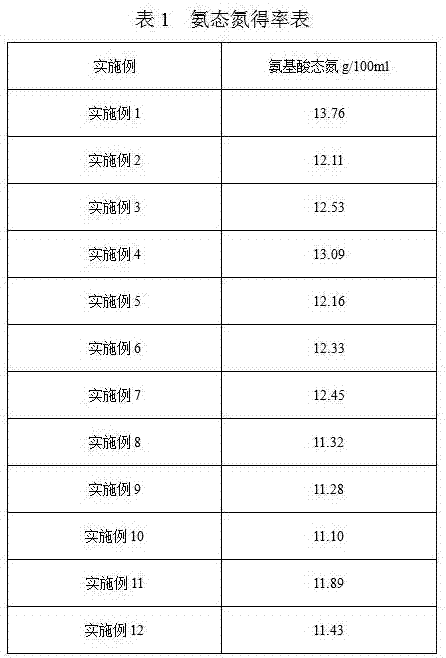

Method for preparing yeast extract from vinasse solution

ActiveCN104351800AImprove overall economic efficiencyReduce pollutionFungiFood preparationChemistryWinery

The invention relates to the field of seasoning manufacture, in particular to a method for preparing yeast extract from a vinasse solution. The method comprises the following steps: S1, putting yeasts in water, activating and preparing a yeast emulsion; S2, after sterilizing the vinasse solution, adding sterilized YPD liquid culture medium and yeast emulsion, and culturing at the constant temperature of 25-40 DEG C in a shading way for 16-24 hours until the culture solution is turbid; S3, sieving the culture solution, and separating culture solution solids from liquid to obtain a yeast mud; S4, adding water into the yeast mud to make a yeast suspension, and adding compound enzymes to carry out enzymolysis; S5, heating the yeast suspension, inactivating enzymes in the yeast suspension and separating in a centrifuge way to obtain a supernatant; S6, concentrating the supernatant prepared in S5 to a paste form to obtain the yeast extract. Wastes in the brewing process are fully utilized, the wastes in the production process of a winery are comprehensively utilized, the pollution to environments can be reduced, and benefits can be maximized for the factory.

Owner:广东顺德酒厂有限公司 +1

Preparation method of ecological organic compound (fertilizer) snow-melting powder

PendingCN110128201ASolve fair useReduce wasteSuperphosphatesOther chemical processesWater contentFertilizer

According to the method, various plant mixtures are used as carriers, a sufficient amount of various wastewater containing urea is sprayed on (soaked in) the carriers, the mixtures are dried until themoisture content is 30%-50%, and the mixtures are smashed into powder with the thickness of 0-1-1.5 cm; drying the powder until the water content is 18-30%, and uniformly stirring the plant powder, pickling wastewater, kitchen waste wastewater, a plant soaking mixed solution, grain and oil food wastewater and urea according to a mass ratio of 1:3:3:3:3:0.02 by using a stirrer; drying the mixtureto a moisture content of 18%-30%; and inspecting the product, packaging the product in bulk, packing the product in 50 kg by bags, and storing and delivering the product. The product is semi-decomposed ecological organic compound (fertilizer) snow melting powder, is dark green in color, and can be pre-sowed, sowed after snow and re-sowed before and after snow by a manual machine. The product has anti-skid performance, and does not corrode the ground, facilities, greening vegetation, rubber tires, underground pipe networks and bridge construction workers. The product reduces the number of garbage, reduces sewage discharge, saves resources, protects the environment, and creates economic and social benefits.

Owner:云 翔

Process method of white clam peanut paste

Disclosed is a Mastra peanut butter processing method, including the following steps: grinding Mastra meat, removing silt in the Mastra meat and dehydrating; preparing peanut seeds into fine grains; adding appropriate amount of edible oil in a boiler; after the oil is cooked, sequentially adding Mastra meat, various of auxiliary materials, prepared seasonings and additives; adding appropriate amount of water while stirring; drying through fire until most of the water is evaporated; adding appropriate amount of monosodium glutamate and mixing to be even; cooling naturally and hot filling according to required specifications. The processing method solves the technical difficulty that due to large content of silt, Mastra meat is unsuitable to be processed and eaten. Through special preparing and processing techniques, the processed product is delicious in taste and flavor and rich in nutrition, and can better satisfy the food demand of the consumers.

Owner:SHANDONG WEIFANG LONGWEI IND

Mactra quadrangularis meat balls processing method

A processing method for rolled Mactra veneriformis meat comprises the following steps: crushing fresh Mactra veneriformis meat, cleaning out sand with water and then dehydrating; cutting and mixing the clam meat and animal meat into meat mash, then adding auxiliary materials, seasoning matters and additives, blending the mixing materials evenly to prepare the stuffing of the rolled meat; and making the rolled meat seasoned and tasty through curing, and finally obtaining the rolled meat and obtaining a finished product after processing and packaging according to different demands. The method solves the technical difficult problem that the Mactra veneriformis meat is inconveniently processed, utilized and edible because of great sand content. With the unique seasoning and processing technology, the product which is tasty and nutritive can better meet the catering demand of a plurality of consumers.

Owner:SHANDONG WEIFANG LONGWEI IND

Process method of white clam chilli garlic sauce

Disclosed is a Mastra mashed garlic catsup processing method, including the following steps: grinding Mastra meat and dehydrating after silt removal; peeling garlic and preparing the garlic into mashed garlic; adding appropriate amount of edible oil into a pan, heating and then sequentially adding Mastra meat, mashed garlic, various auxiliary materials, prepared seasoning matters and additives, adding appropriate amount of water, boiling until most of the water is evaporated, adding appropriate amount of monosodium glutamate and mixing to be even; naturally cooling and filling when the catsup is hot. The invention solves the technical difficulty that due to large content of silt, Mastra meat is unsuitable to be processed, utilized and eaten. The invention adopts special preparing and processing techniques and the prepared product is delicious in flavor and rich in nutrition and can better satisfy the food demand of the consumers.

Owner:SHANDONG WEIFANG LONGWEI IND

Processing method for white clam meat thick chilli sauce

The invention provides a method for processing a mactra meat chili sauce. The method comprises the following processing steps: fresh mactra meat is crushed, de-sanded and dewatered; proper amount of edible oil is added in a pot, after the edible oil is heated, mactra meat, auxiliary materials and prepared condiments and additives are sequentially added in the pot under the condition of endless stirring, proper amount of water is added in the pot while stirring, heating is stopped until the water is dried up, proper amount of sodium glutamate is added in the pot, and the mixture is evenly stirred; the mixture is naturally cooled, and while the mixture is still hot, the mixture is filled up according to needed specification. The method resolves the technical problem of inconvenient processing and eating of the mactra meat due to big sand content, and by utilizing special preparing and processing techniques, processed products have good and fresh taste and abundant nutrition and can better meet needs of general consumers on diet.

Owner:SHANDONG WEIFANG LONGWEI IND

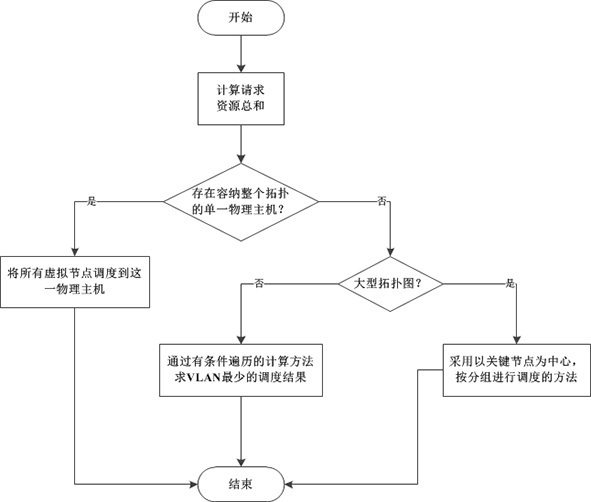

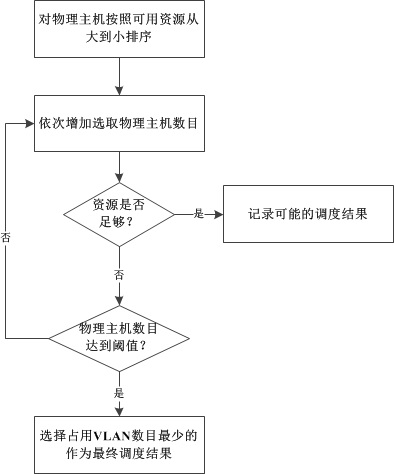

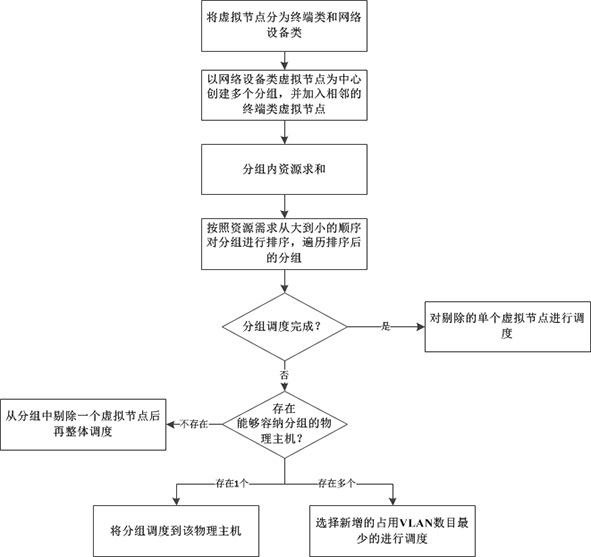

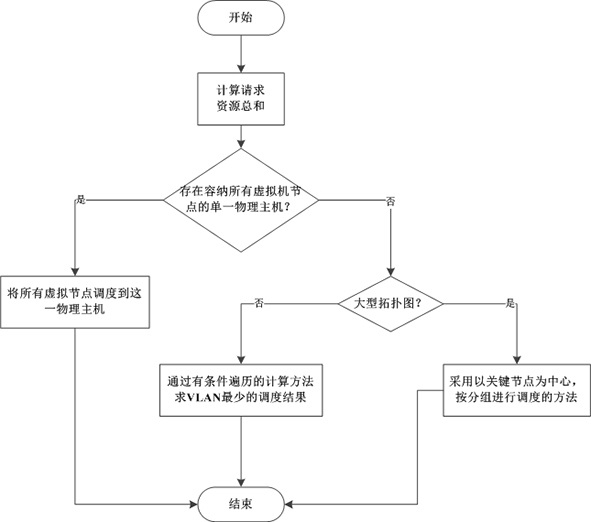

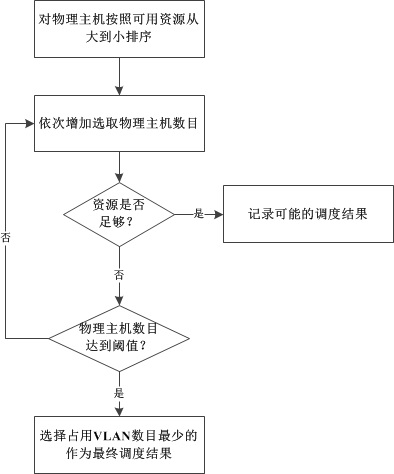

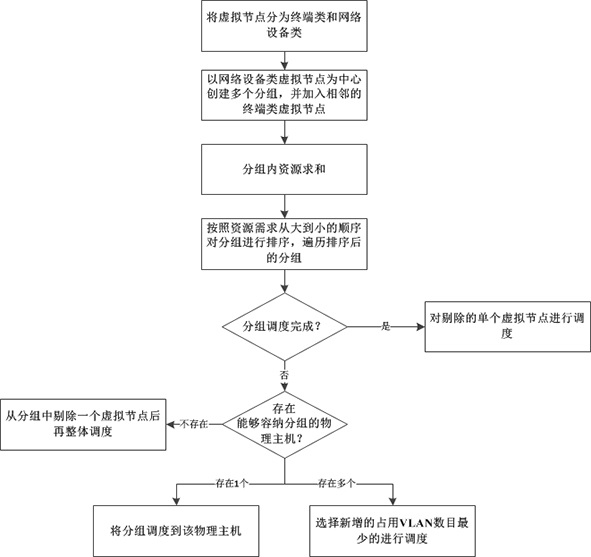

Virtual node scheduling method and system for VLAN (Virtual Local region Network) interconnection of network simulation platform

ActiveCN113395183ASolve fair useCompact distributionResource allocationNetworks interconnectionEngineeringReal-time computing

The invention discloses a virtual node scheduling method and system for VLAN (Virtual Local region Network) interconnection of a network simulation platform. The method comprises the following steps: firstly, counting the sum of resources applied by a virtual node requested to be started, and if a single physical host capable of accommodating all virtual nodes exists, scheduling to the physical host; otherwise, selecting a small topological graph scheduling method or a large topological graph scheduling method for the total number of the virtual nodes; in the small topological graph scheduling method, a scheduling result with minimum VLANs is obtained through a conditional traversal calculation method, and in the large topological graph scheduling method, a packet scheduling method with a key node as a center is adopted, so that the newly added VLANs are minimum as much as possible during packet scheduling. A plurality of topological graphs which are started at the same time can be combined and processed, so that the occupied VLAN is minimum. According to the method, the problem of reasonable utilization of VLAN resources of a multi-host network simulation platform is solved, the distribution of the whole topological graph on the physical hosts is more compact, and the calculation process is simple and visual.

Owner:南京赛宁信息技术有限公司

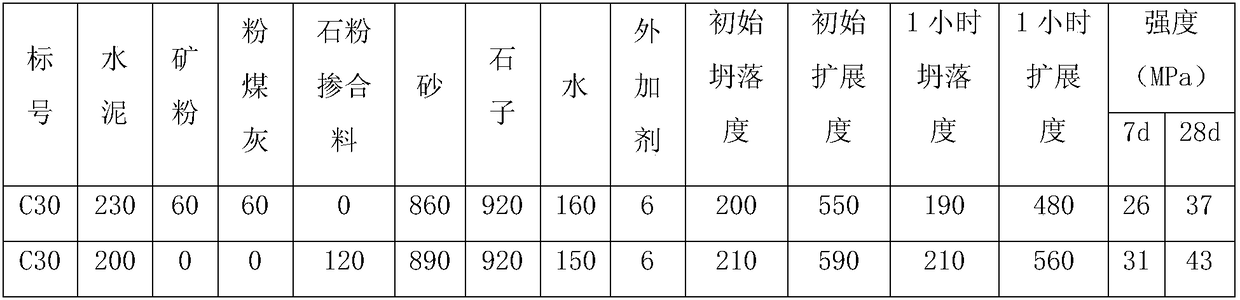

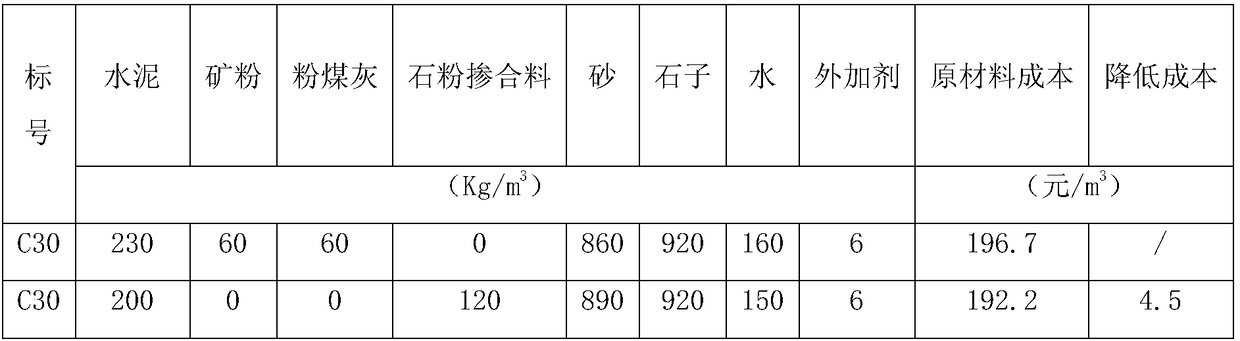

A kind of stone powder concrete admixture and preparation method thereof

The invention provides a stone flour concrete composite admixture and a preparation method thereof. The admixture comprises, by weight, 20-70% of stone flour, 10-40% of smelting waste slag, 0-25% of calcined clay, 0-25% of a pozzolanic material, 10-40% of cement clinker, 0-10% of dolomite and 0-15% of gypsum. Cooperation of various substances makes the flour become one of raw materials for preparing the composite admixture, so wastes are changed into valuables; and the stone flour unsuitable for preparing the concrete composite admixture become one of the raw materials for preparing the concrete composite admixture, and can substitute increasingly scarce ore powder and parts of cement, so the raw material shortage problem of building engineering is solved, the engineering cost is reduced, the reasonable utilization problem of stone flour generated in machine production of sand is solved, resource wastes are reduced, environment is protected, and the composite admixture and the preparation method have very good economic and social benefits.

Owner:山东众森新材料有限公司

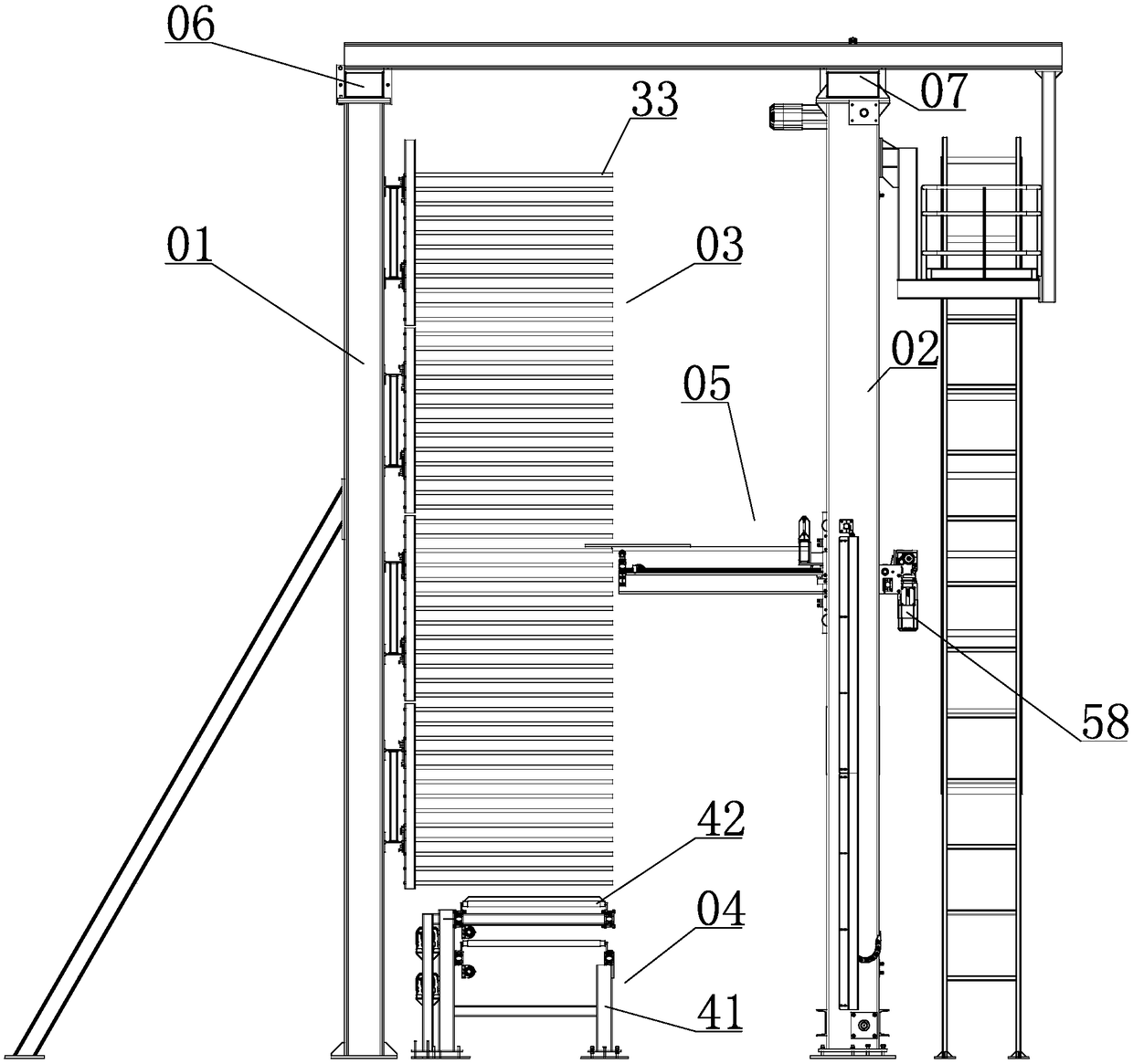

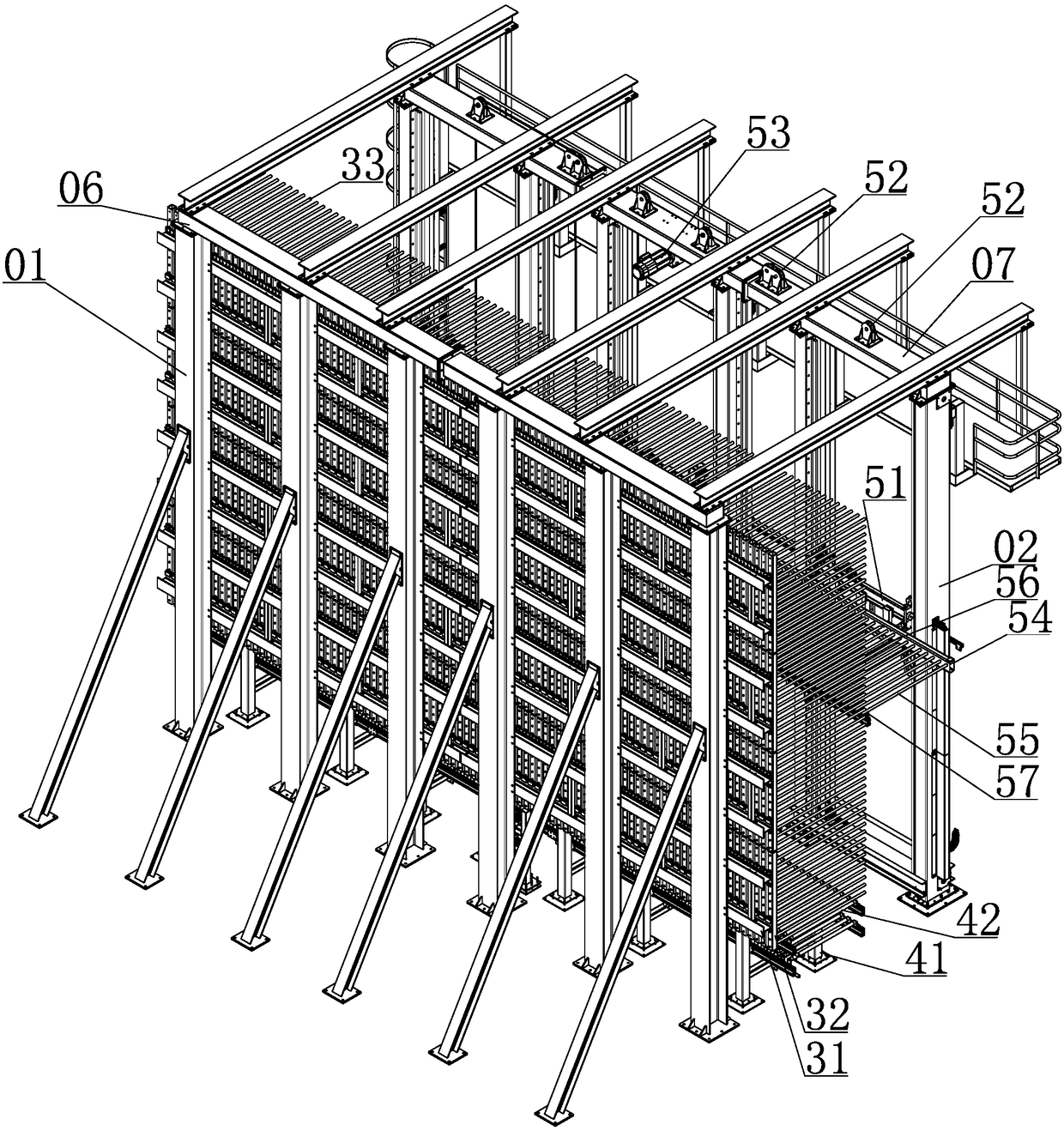

Plate caching cabin

PendingCN109422077ASolve storage timeSolve fair useStacking articlesDe-stacking articlesEngineeringPulley

The invention discloses a plate caching cabin. The plate caching cabin comprises first stand columns, second stand columns, a first shuttle-shaped frame structure, a roller conveying line and a secondshuttle-shaped frame structure, wherein a first fixed rod is arranged at the tops of the first stand columns; a second fixed rod is arranged at the tops of the second stand columns; the first shuttle-shaped frame structure comprises cross beams and vertical connection rods; the second shuttle-shaped frame structure comprises a bracket, multiple rolling wheels arranged on the second fixed rod anda lifting motor arranged on the second fixed rod; the lifting motor is connected with a rope which is connected with the bracket through the rolling wheels; a cross rod is arranged on the bracket; multiple second metal rods distributed in a comb structure manner are arranged on the cross rod; a guide rail for horizontally stretching and contracting the cross rod is arranged between the bracket andthe cross rod; a pulley for assisting horizontal movement of the second metal rods is arranged on the bracket; pushing motors in transmission connection with the cross rod are arranged on the secondstand columns. The plate caching cabin has the effects that the space utilization rate is high, the labor cost is reduced, and the production efficiency is improved.

Owner:SUOFEIYA HOME COLLECTION

A high-performance lithium-ion battery negative electrode si@n-c composite material and its preparation method

ActiveCN107195890BGood dispersionHigh nitrogen contentCell electrodesSecondary cellsHazardous substancePolypyrrole

The invention relates to a high-performance lithium ion battery negative electrode Si@N-C composite material and a preparation method therefor. According to the method, gulfweed is used as the raw material to prepare SiO<2> and then reduction is preformed to obtain a Si material; and next, pyrrole is used as the main raw material to coat polypyrrole on the surface of the Si material, and calcining is preformed to obtain the Si@N-C composite material. The raw materials adopted in the method are simple and easily available, low in cost and environment friendly, and toxic and harmful material generation in the preparation process is avoided; in addition, the problem existing in reasonable utilization of gulfweed is solved effectively, and economic efficiency and environment protection are realized; in addition, the silicon material extraction method disclosed in the invention has certain universality for extracting the silicon material form other silicate-containing plants; furthermore, heteroatom N-doped C coating is realized through high-molecular polymer polypyrrole pyrolysis is realized, so that the conductivity and the stability of the Si material are greatly improved, thereby improving the lithium ion battery performance of the Si@N-C composite material.

Owner:SHANDONG UNIV

Process method of white clam fish ball

Disclosed is a Mastra meat-fish ball processing method, including the following steps: grinding fresh Mastra meat, washing to get rid of the silt and dehydrating to prepare main material; mixing above main material and prepared minced fillet according certain proportion, adding auxiliary materials, seasonings and additives in necessary amounts, shredding and mixing to be even, then adding appropriate amount of water and mixing to be even to make fillings with moderate hardness and stickiness; processing according to different requirements, packing and making into finished products. The processing method solves the technical difficulty that due to large content of silt, Mastra meat is unsuitable to be processed and eaten. Through special preparing and processing techniques, the processed product is delicious in taste and flavor and rich in nutrition, and can better satisfy the food demand of the consumers.

Owner:SHANDONG WEIFANG LONGWEI IND

Virtual node scheduling method and system for network simulation platform vlan interconnection

ActiveCN113395183BSolve fair useCompact distributionResource allocationNetworks interconnectionComputation processEngineering

The invention discloses a virtual node scheduling method and system for VLAN interconnection of a network simulation platform. The present invention first counts the sum of the resources requested to start the virtual nodes, and if there is a single physical host that can accommodate all virtual nodes, then it is scheduled to this physical host; otherwise, the total number of virtual nodes is selected to use the small topology map scheduling method or the large topology map scheduling method ; In the small-scale topology map scheduling method, the scheduling result with the fewest VLANs is obtained through the calculation method of conditional traversal. In the large-scale topology map scheduling method, the group scheduling method centered on key nodes is used to minimize the newly added VLANs during each group scheduling. . Multiple topology diagrams started at the same time can be combined and processed to achieve the least occupied VLAN. The invention solves the problem of reasonable utilization of VLAN resources on a multi-host network simulation platform, makes the distribution of the entire topology map on the physical host more compact, and the calculation process is simplified and intuitive.

Owner:南京赛宁信息技术有限公司

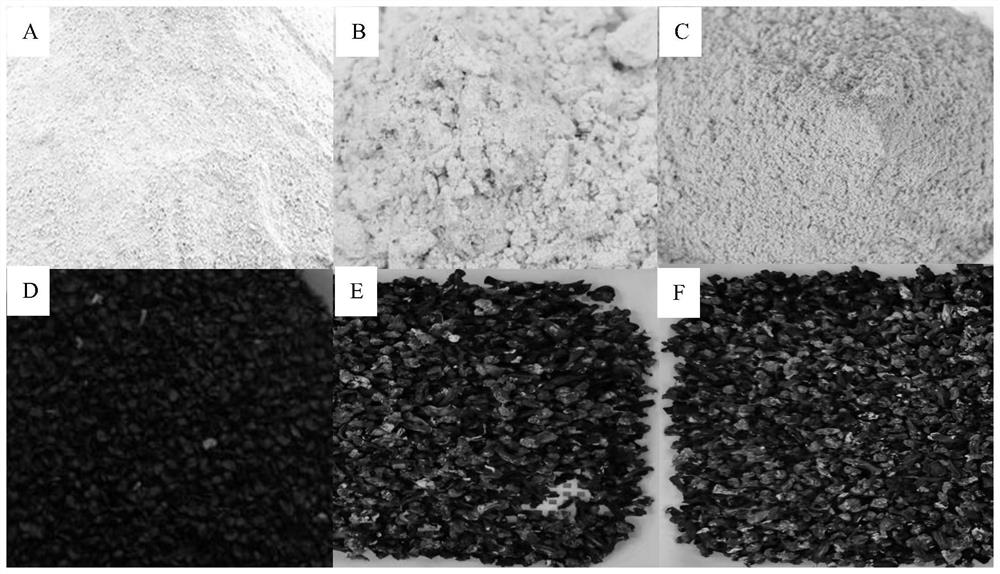

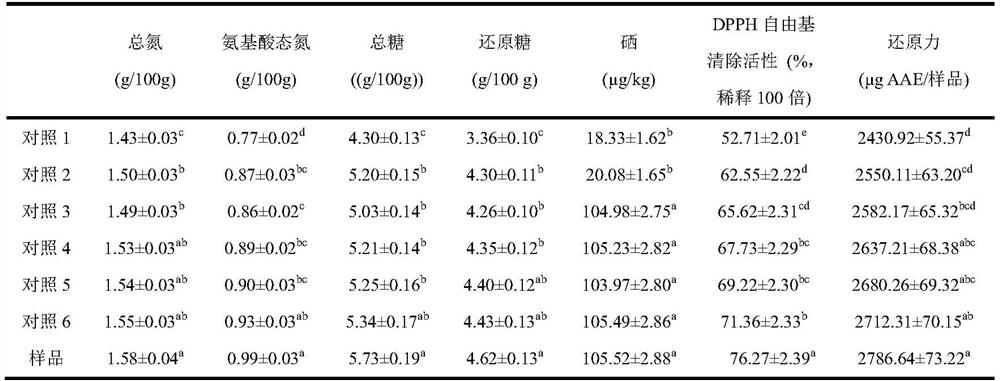

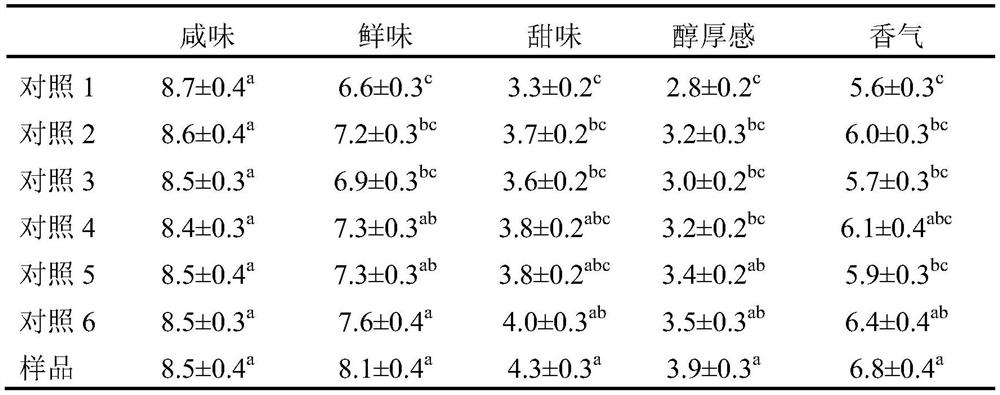

Method for improving quality of soy sauce and soybean paste by using selenium-enriched mushrooms

ActiveCN114128870AOutstanding umamiStrong sense of mellowFood ingredient functionsFood ultrasonic treatmentBiotechnologyAspergillus oryzae

The invention belongs to the technical field of seasoning processing, and relates to a method for improving the quality of soy sauce and soybean paste by using selenium-enriched mushrooms. The method comprises the following steps: selecting selenium-rich fresh mushrooms, cleaning, soaking in a color protection solution, carrying out ultrasonic treatment, draining, carrying out vacuum drying, and crushing to obtain selenium-rich mushroom powder; soaking, cooking and cooling soybeans or soybean meal; mixing flour or bran or crushed fried wheat with selenium-enriched mushroom powder, inoculating aspergillus oryzae after mixing, mixing with cooled soybeans or soybean meal after inoculating to prepare koji, obtaining mature yeast, mixing with salt water, putting into a tank for fermentation, spraying oil or squeezing oil according to a conventional method after fermentation is finished, filtering, sterilizing and packaging to obtain the high-quality soy sauce. And sterilizing and packaging the fermented soybean paste to obtain the high-quality soybean paste. The taste substances, the selenium content and the antioxidant activity of the product are remarkably improved, and the soy sauce and the soybean paste are prominent in delicate flavor and mellow feeling and rich in fragrance. In addition, defective mushrooms left after processing can be utilized, and waste is turned into wealth.

Owner:JIANGSU UNIV

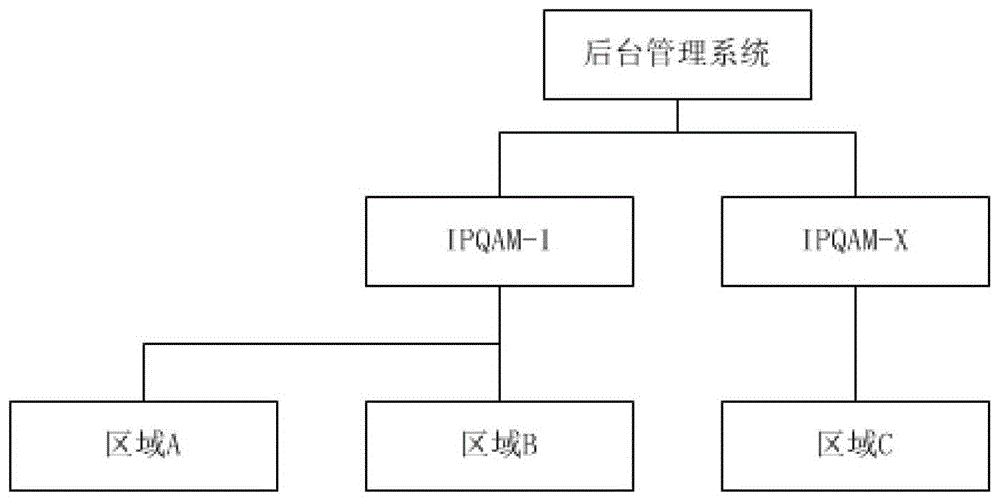

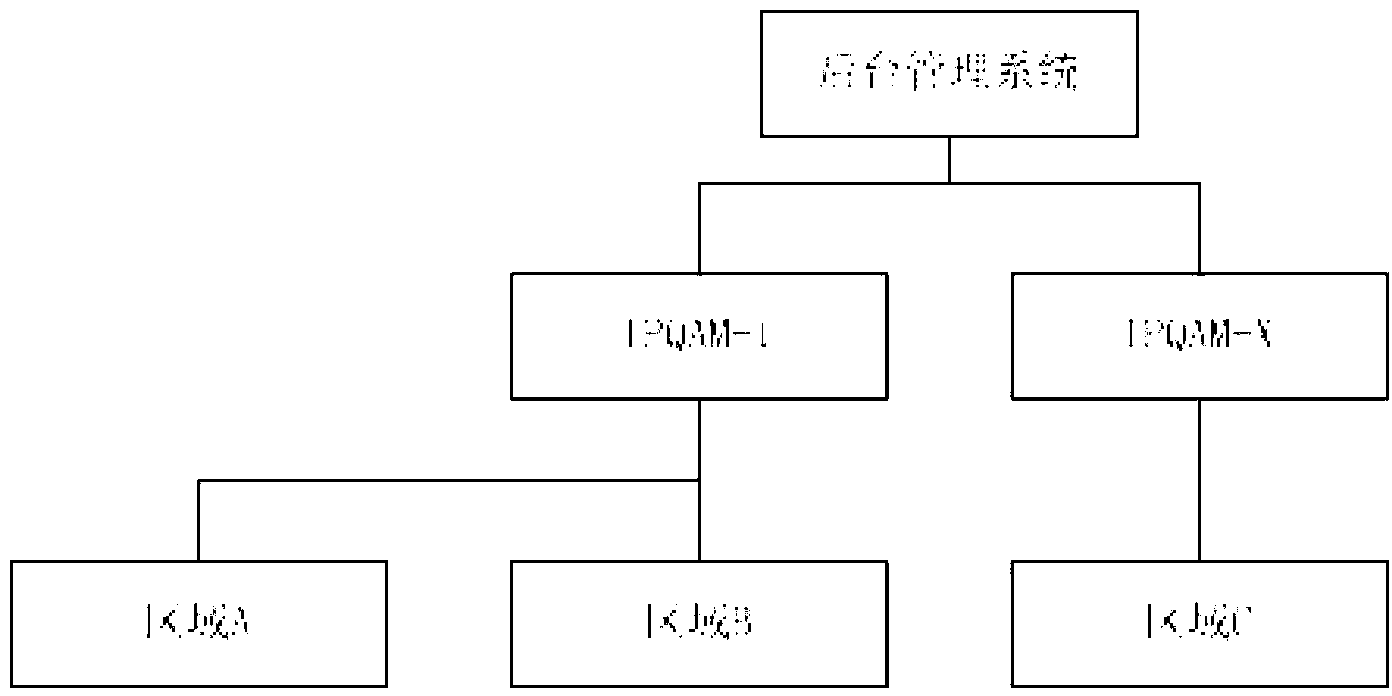

A Subregional Multi-qam Modulation System

InactiveCN103269325BSolve fair useIncrease profitMultiple carrier systemsCoaxial cableQam modulation

The invention discloses a regional multi-QAM (quadrature amplitude modulation) modulation system. Different QAD modulation modes are adopted as to different areas covered by IPQAMs (internet protocol quadrature amplitude modulation) according to the difference of network quality. A 256QAM modulation mode is adopted in the area with good network quality; and a 64QAM mode is adopted in the area with poor network quality. Thus, the utilization rate of frequency points and the utilization rate of IPQAM hardware resources are improved. Different IPQAM modulation modes are set in a background management system at the front end according to the coaxial cable network quality investigation of IPQAM coverage areas. Meanwhile, the QAM modulation mode is also set by IPQAM equipment according to the network quality. A user terminal obtains the QAM modulation mode adopted by the network after communicating with the background management system, and demodulates the signal by adopting the QAM modulation mode.

Owner:常熟市广播电视总台

Process method of white clam chilli garlic sauce

Owner:SHANDONG WEIFANG LONGWEI IND

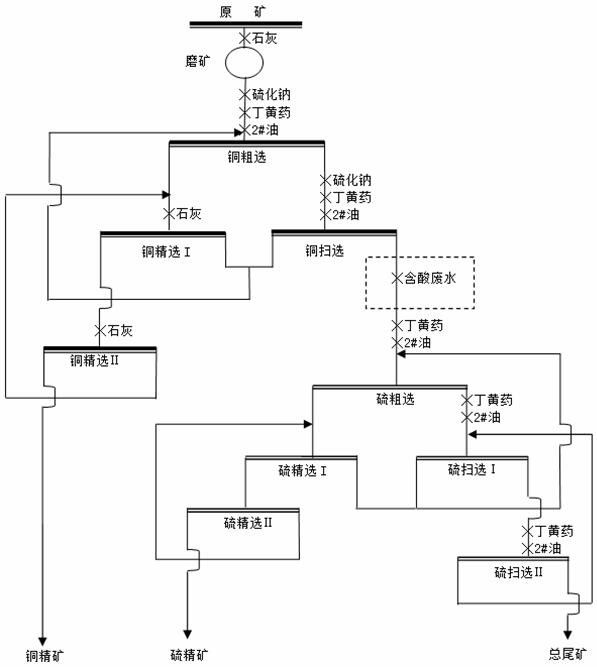

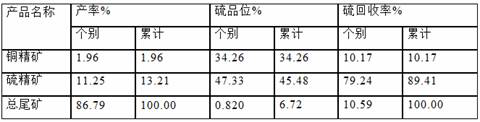

A method for activated flotation of sulfur in copper tailings of copper sulfide sulfur ore dressing

ActiveCN108672101BSolve fair useReduce production cost of sulfur selectionFlotationWastewaterSulfide

Owner:YUXI MINING

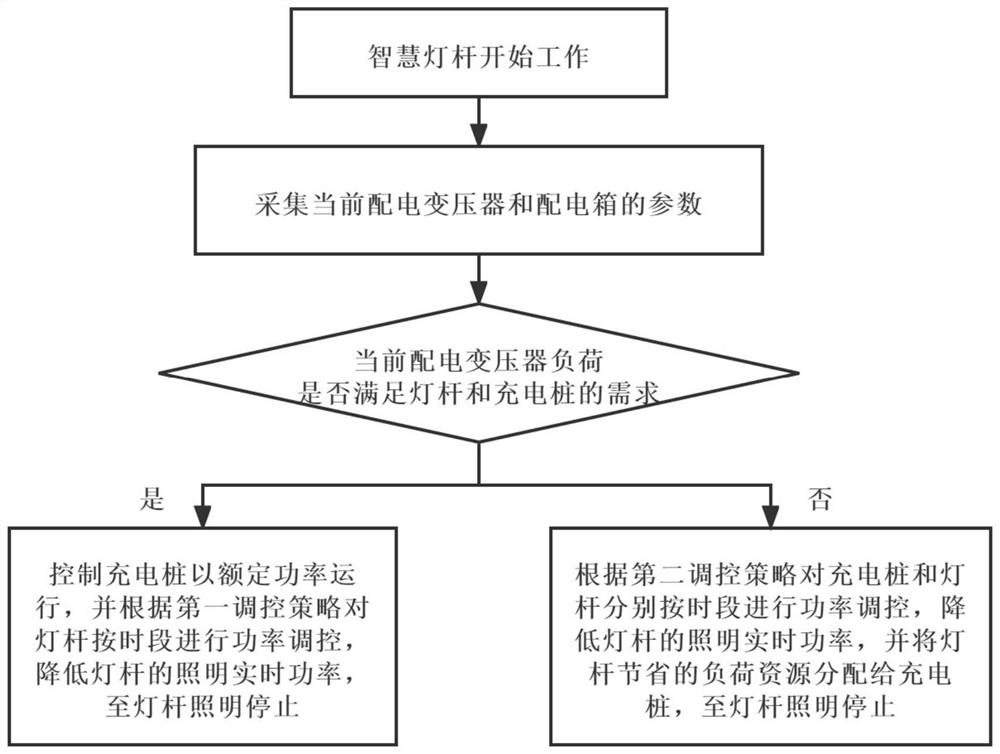

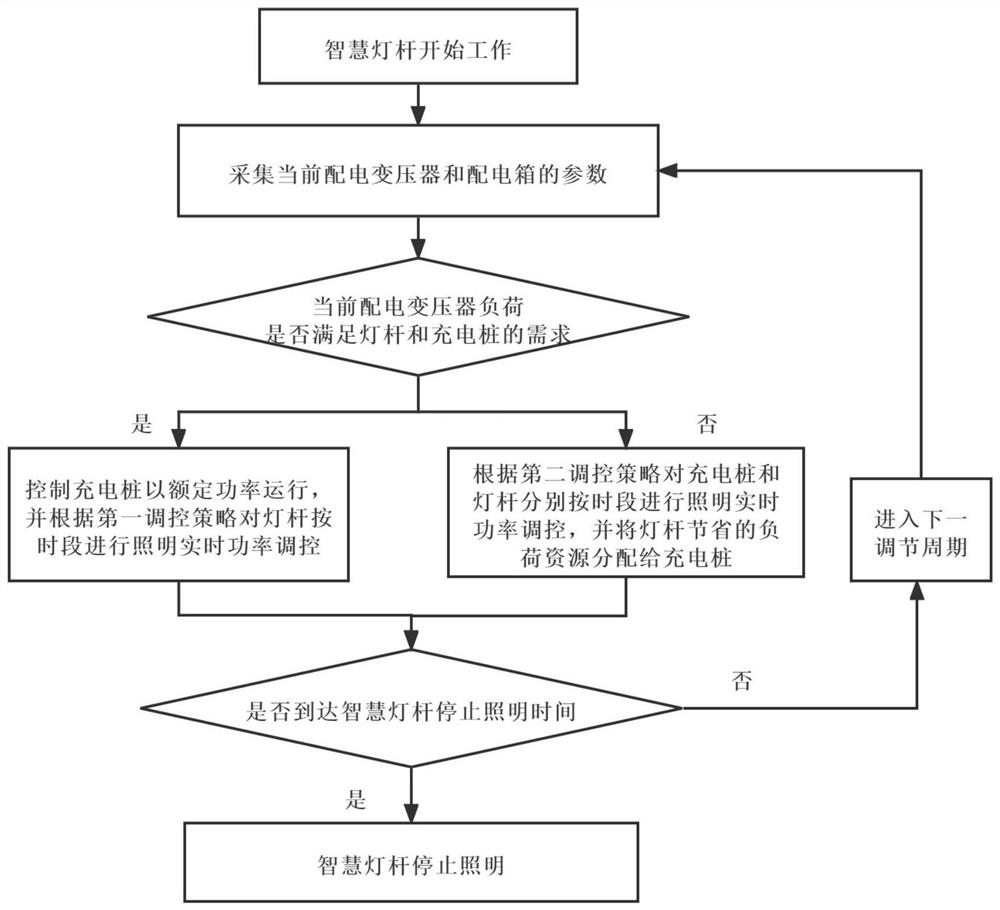

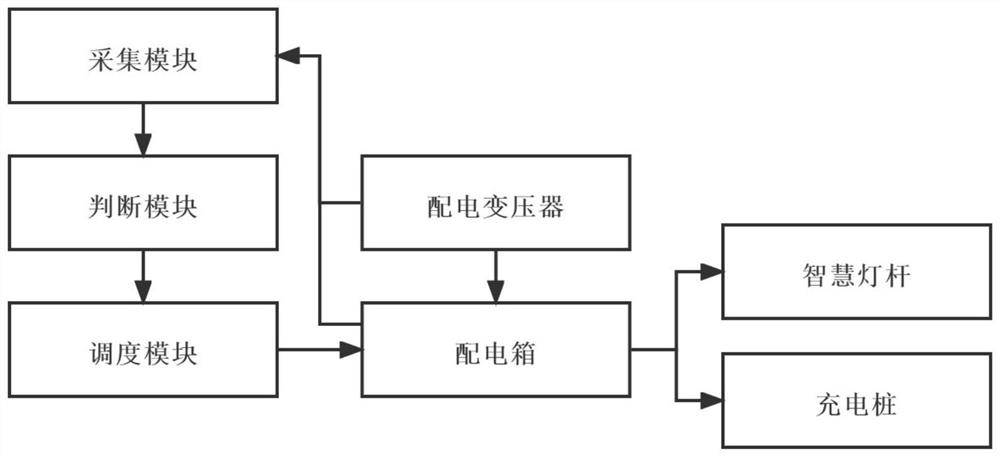

Intelligent lamp pole power dynamic distribution method and system

PendingCN114552592AReduce resource consumptionReasonable use Reasonable solutionElectric vehicle charging technologyAc network voltage adjustmentCurrent loadDistribution transformer

The invention relates to the technical field of power dispatching, and provides an intelligent lamp post power dynamic distribution method and system, and the method comprises the following steps: collecting the parameters of a current distribution transformer and a current distribution box when a lamp post starts to work; according to the real-time power of the distribution transformer and the distribution box, judging whether the current load of the distribution transformer meets the requirements of lamp pole illumination and a charging pile or not: if yes, controlling the charging pile to operate at rated power, and performing power regulation and control on the lamp pole according to time periods according to a first regulation and control strategy to reduce the illumination real-time power of the lamp pole, lighting of the lamp pole is stopped; and otherwise, performing power regulation and control on the charging pile and the lamp post according to time periods according to a second regulation and control strategy, reducing the real-time illumination power of the lamp post, and allocating the load resources saved by the lamp post to the charging pile until the illumination of the lamp post is stopped. According to the invention, lighting and charging pile charging power distribution in the intelligent lamp pole is reasonably realized, and load resources are reasonably utilized during urban lamp pole transformation, so that waste is avoided.

Owner:ZHONGRUI COMM PLANNING & DESIGN

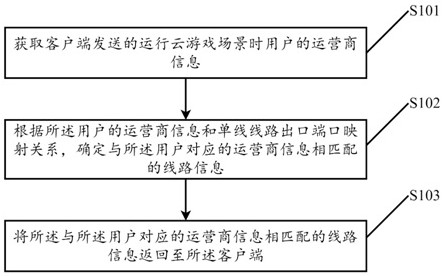

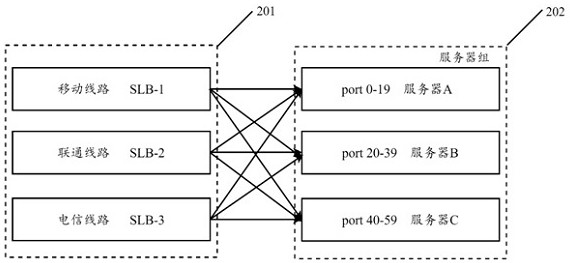

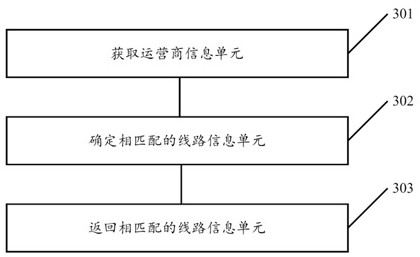

A line scheduling method and device suitable for cloud game scenarios

ActiveCN113877199BSolve fair useIncrease usageVideo gamesData switching networksDistributed computingIndustrial engineering

This application provides a line scheduling method suitable for cloud game scenarios, including: obtaining the user's operator information sent by the client when running the cloud game scenario; according to the user's operator information and the single-line line exit port mapping relationship, determine The line information matching the operator information corresponding to the user, the export port mapping relationship of the single line line is the relationship between the single line line IP information corresponding to the operator and the server port information corresponding to the single line line; The line information matching the operator information corresponding to the user is returned to the client. This application solves the problems of reasonable utilization of single-line lines and bandwidth costs of cloud game services through single-line scheduling, and at the same time improves the utilization rate of small and medium-sized computer rooms across the country, so that small computer rooms with only one line can also be applied to cloud game services. The present application also provides a line scheduling device suitable for cloud game scenarios.

Owner:WELLINK TECH

Process method of white clam tomato sauce

Disclosed is a Mastra tomato catsup processing method, including the following steps: grinding Mastra meat, then washing and dehydrating to prepare the main material; peeling the tomatoes, bloating with brine, and grinding to prepare tomato catsup; adding appropriate amount of edible oil in a pan, heating, sequentially adding the main material, auxiliary materials and prepared seasoning matters and additives, adding appropriate amount of water, boiling until most of the water is evaporated, adding appropriate amount of monosodium glutamate, and mixing to be even; cooling naturally and fillingwhen the catsup is hot. The invention solves the technical difficulty that due to large content of sand, Mastra meat is unsuitable to be processed, utilized and eaten. The invention adopts special preparing and processing techniques and the prepared product is delicious in flavor and rich in nutrition and can better satisfy the food demand of the consumers.

Owner:SHANDONG WEIFANG LONGWEI IND

A method for preparing yeast extract from distiller's grains

ActiveCN104351800BReduce pollutionMaximize the benefit of the factoryFungiFermentationEmulsionVinasse

The invention relates to the field of seasoning manufacture, in particular to a method for preparing yeast extract from a vinasse solution. The method comprises the following steps: S1, putting yeasts in water, activating and preparing a yeast emulsion; S2, after sterilizing the vinasse solution, adding sterilized YPD liquid culture medium and yeast emulsion, and culturing at the constant temperature of 25-40 DEG C in a shading way for 16-24 hours until the culture solution is turbid; S3, sieving the culture solution, and separating culture solution solids from liquid to obtain a yeast mud; S4, adding water into the yeast mud to make a yeast suspension, and adding compound enzymes to carry out enzymolysis; S5, heating the yeast suspension, inactivating enzymes in the yeast suspension and separating in a centrifuge way to obtain a supernatant; S6, concentrating the supernatant prepared in S5 to a paste form to obtain the yeast extract. Wastes in the brewing process are fully utilized, the wastes in the production process of a winery are comprehensively utilized, the pollution to environments can be reduced, and benefits can be maximized for the factory.

Owner:广东顺德酒厂有限公司 +1

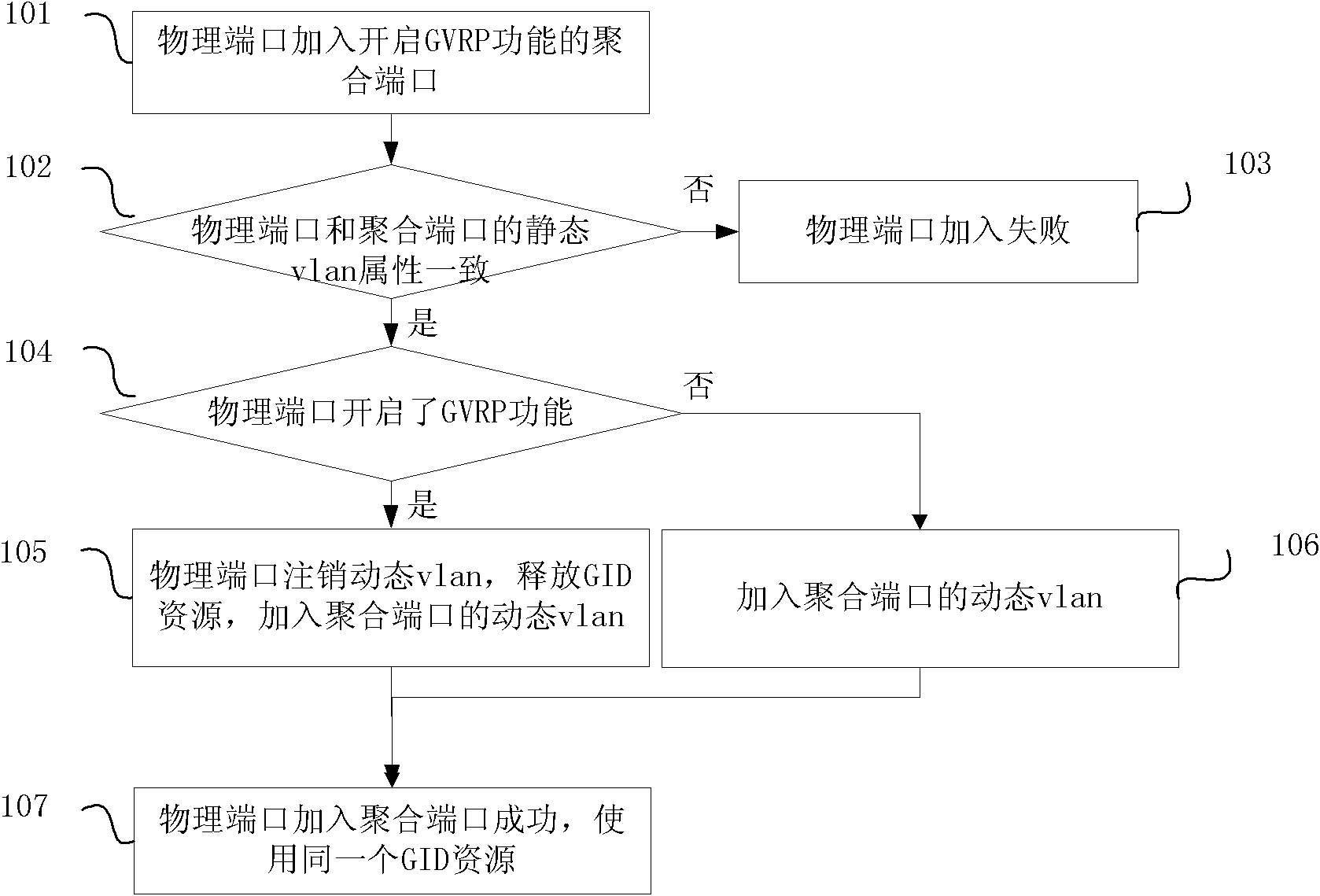

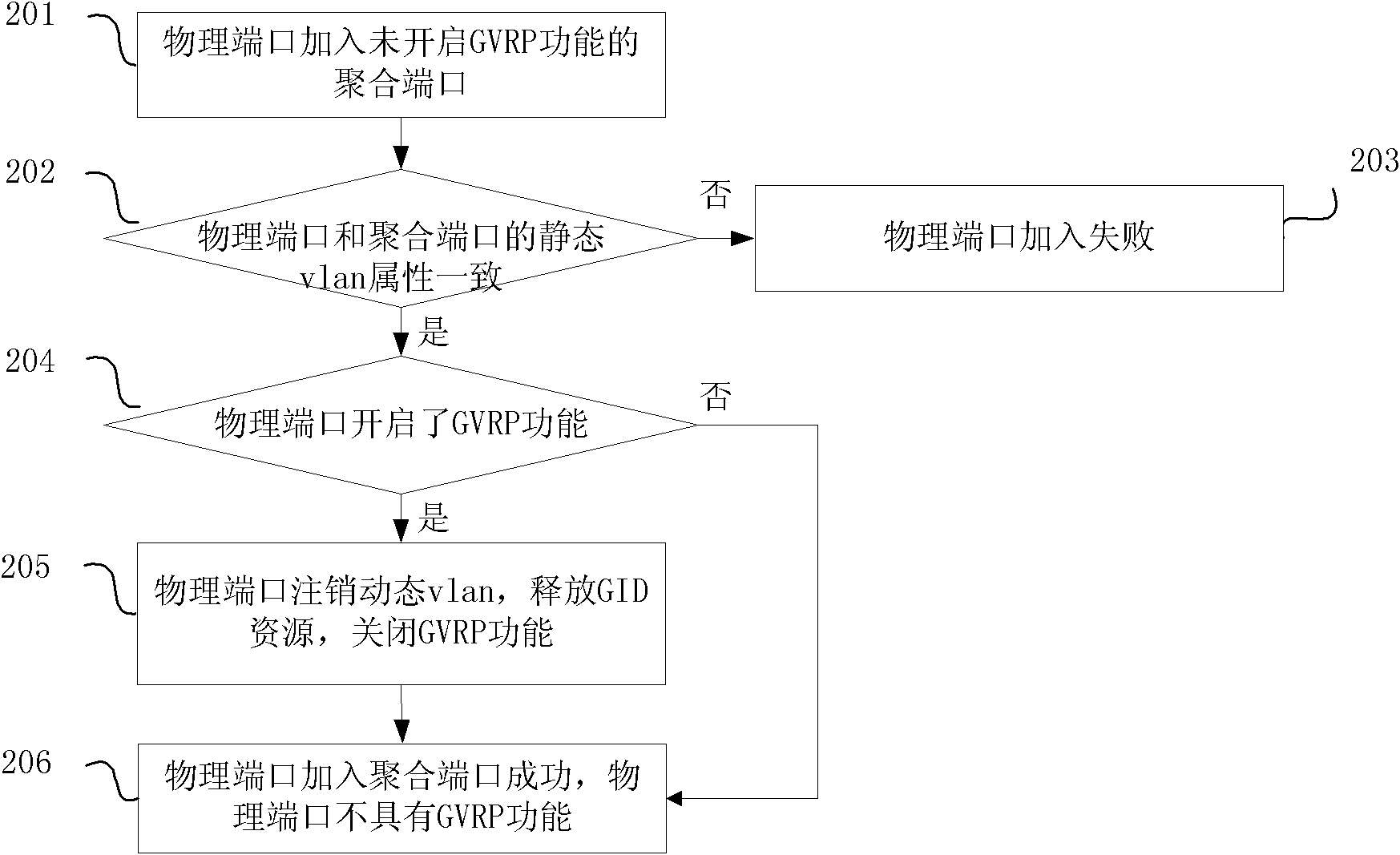

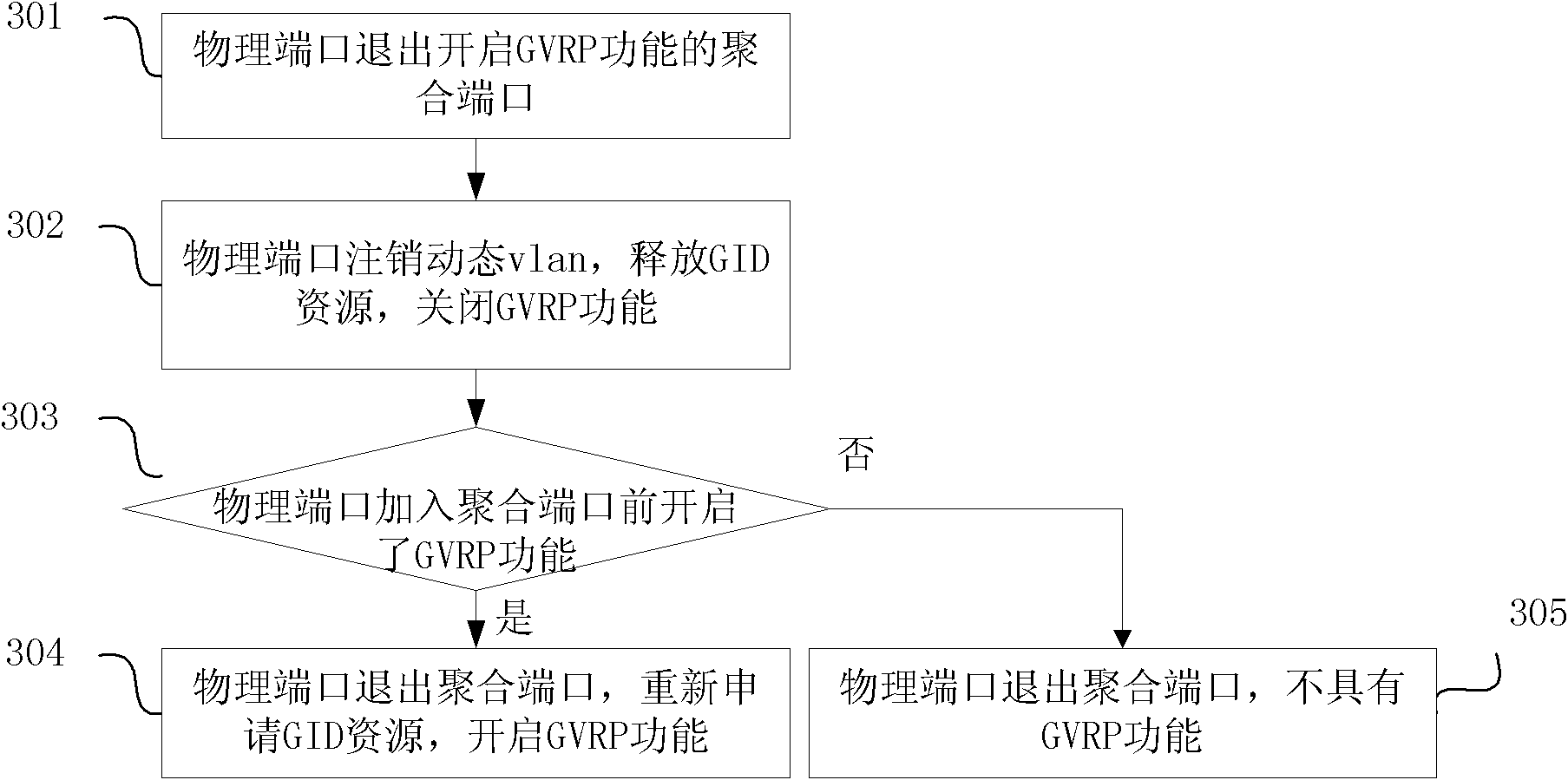

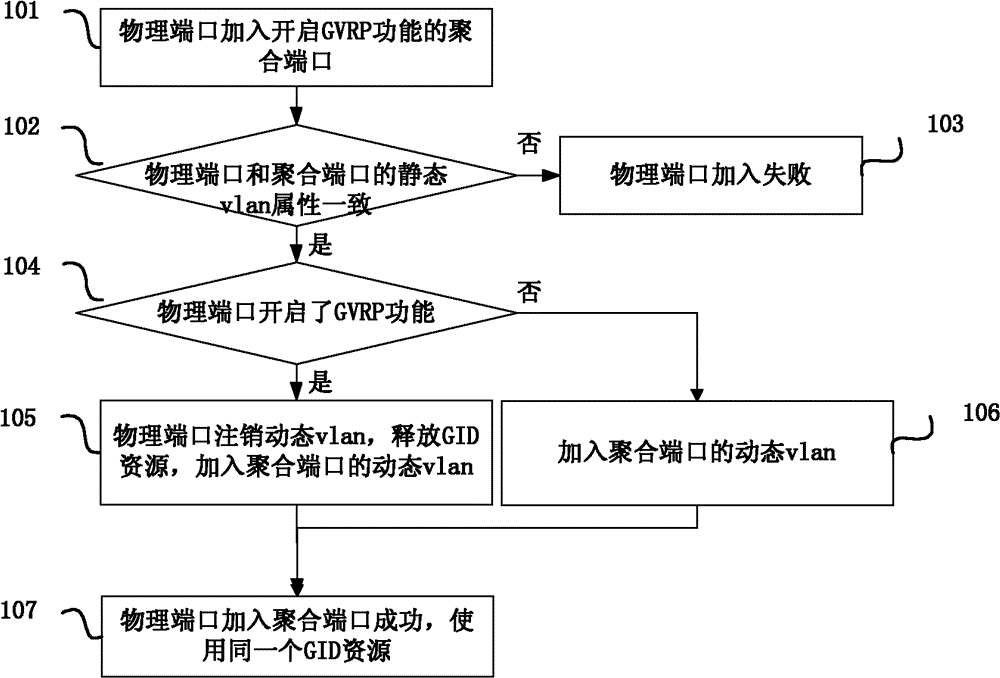

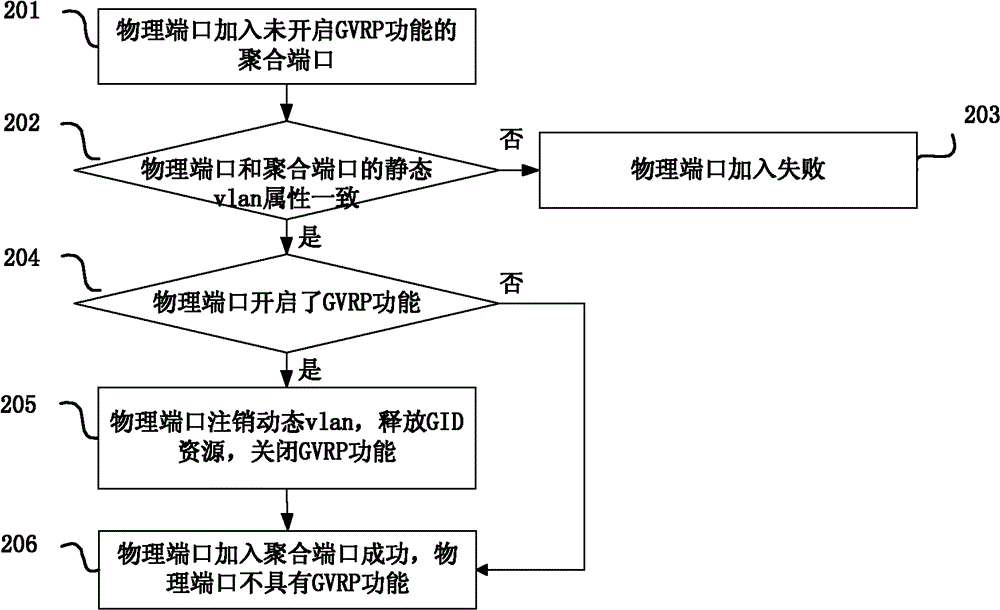

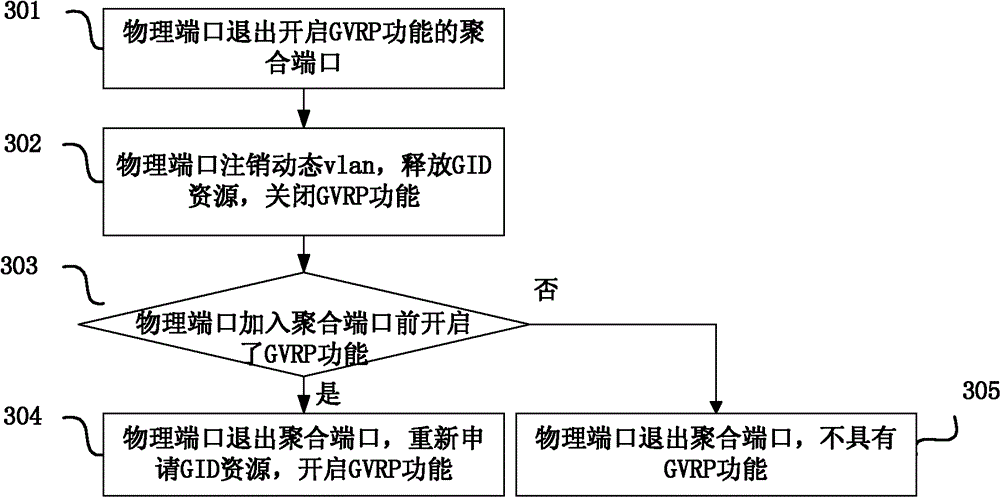

Method and device for adding/exiting physical port to/from aggregation port

InactiveCN102098213ASolve fair useSave storage spaceNetworks interconnectionVirtual LANEmbedded system

The invention provides a method and a device for adding / exiting a physical port to / from an aggregation port, wherein the method for adding the physical port to the aggregation port comprises the following steps of: executing a command for adding the physical port to the aggregation port; judging whether the generic attribute registration protocol (GVRP) of the physical port is started; and if so, releasing the GID resource (GVRP information declaration) of the physical port and adding the physical port to the aggregation port. By adopting the method and the device, when the physical port is added to the aggregation port, the GID resource of the aggregation port is released, so the problem that the GID resource in the GVRP cannot be utilized reasonably is solved. Therefore, the effects of saving CUP (central processing unit) and the storage space are achieved.

Owner:ZTE CORP

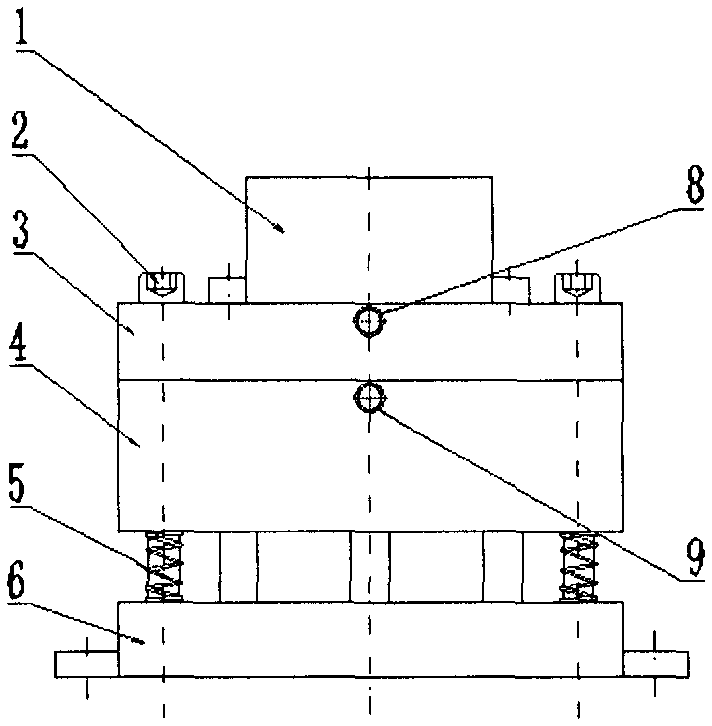

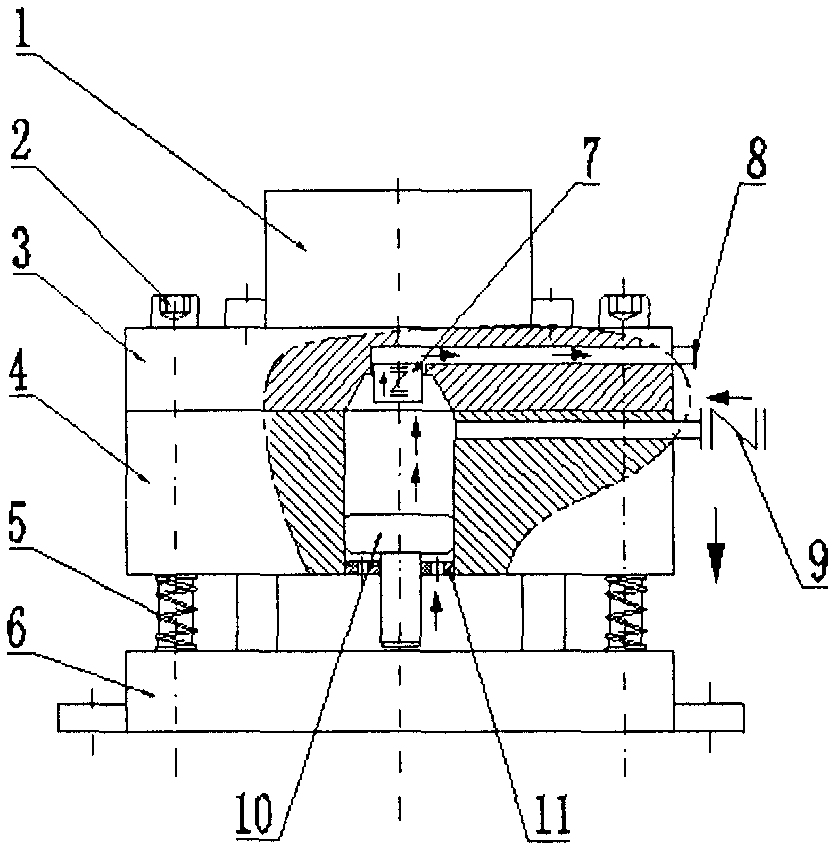

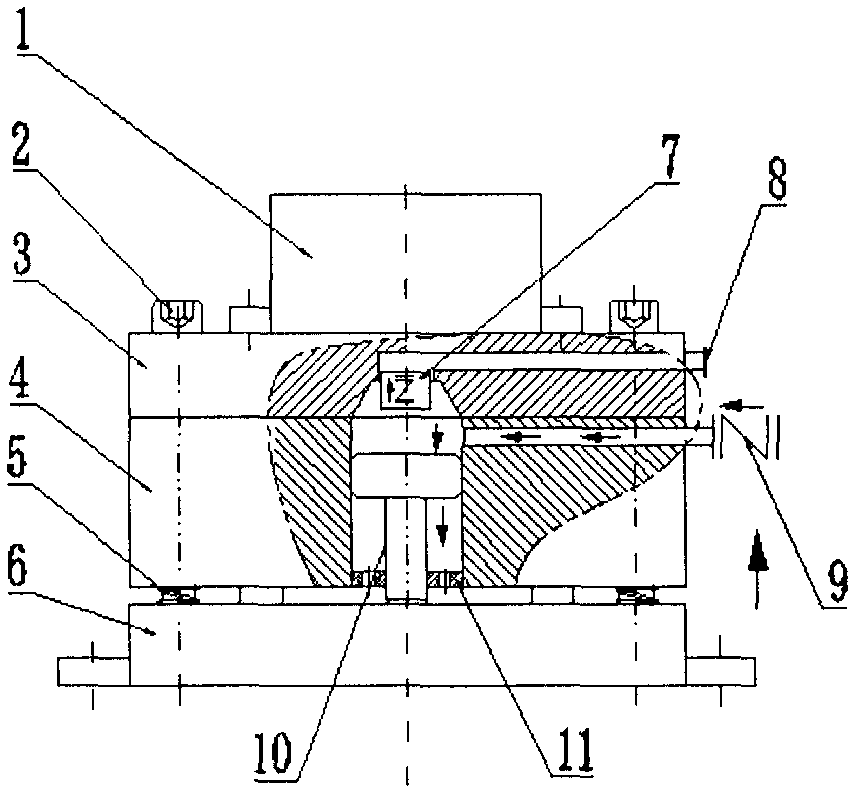

Buffer machine base for absorbing mechanical vibration energy and outputting fluid energy

InactiveCN105276074ARealize deliveryRealize the use effectSpringsNon-rotating vibration suppressionPiston cylinderEngineering

The invention discloses a buffer machine base for absorbing mechanical vibration energy and outputting fluid energy, and belongs to buffer machine bases for absorbing mechanical vibration energy. The buffer machine base comprises guide column bolts, an exhaust integrated plate, a gas producing module, compression springs, a supporting and fixing seat, an exhaust one-way valve, a main exhaust opening, a gas inlet one-way valve, a piston and a diaphragm plate. The exhaust integrated plate and the gas producing module are connected with the supporting and fixing seat through the guide column bolts. A clearance is arranged between the gas producing module and the supporting and fixing seat, the guide column bolts in the clearance are connected with the compression springs, a piston cylinder and a piston are arranged on the gas producing module, and the piston cylinder is connected with the gas inlet one-way valve through a pipeline. A piston rod of the piston protrudes out of the gas producing module, and is located between the gas producing module and the supporting and fixing seat. The diaphragm plate is arranged at the position, on the piston rod, of the gas producing module. An air cylinder hole corresponding to the piston cylinder is formed in the exhaust integrated plate and communicated with the main exhaust opening, and the exhaust one-way valve (7) is arranged between the air cylinder hole and the main exhaust opening. The buffer machine base has the advantages of achieving transferring, conveying, storage and use of energy.

Owner:甘仲光

Mactra quadrangularis meat balls processing method

A processing method for rolled Mactra veneriformis meat comprises the following steps: crushing fresh Mactra veneriformis meat, cleaning out sand with water and then dehydrating; cutting and mixing the clam meat and animal meat into meat mash, then adding auxiliary materials, seasoning matters and additives, blending the mixing materials evenly to prepare the stuffing of the rolled meat; and making the rolled meat seasoned and tasty through curing, and finally obtaining the rolled meat and obtaining a finished product after processing and packaging according to different demands. The method solves the technical difficult problem that the Mactra veneriformis meat is inconveniently processed, utilized and edible because of great sand content. With the unique seasoning and processing technology, the product which is tasty and nutritive can better meet the catering demand of a plurality of consumers.

Owner:SHANDONG WEIFANG LONGWEI IND

A kind of method of producing phenol by salicylic acid sublimation residue

ActiveCN103073394BAvoid the impact of puritySolve fair useOrganic chemistryOrganic compound preparationSALICYLIC ACID/UREADistillation

The invention discloses a method for producing phenol from salicylic acid sublimation residue. The method comprises the following steps: a, carrying out high-temperature pyrolysis, to be specific, stirring and heating the salicylic acid sublimation residue in a reaction chamber with a temperature of 450-550 DEG C and a vacuum degree of -0.01-0.06MPa to generate crude phenol; and b, distilling and purifying, to be specific, introducing the generated crude phenol into a distillation kettle with a vacuum degree of -0.05--0.07MPa, heating and purifying by using steam of 0.3-0.5MPa, and cooling and recovering. According to the invention, the salicylic acid sublimation residue is subjected to proper processing of heating pyrolysis and distillation and purification to be prepared into high-purity phenol which can be used as an important chemical raw material, thus the problem that a large quantity of salicylic acid sublimation residue waste cannot be reasonably utilized is successfully solved, the waste is changed into valuables, the environment pollution is reduced, and higher economic value is created.

Owner:HEBEI JINGYE CHEM CO LTD

Method and device for adding physical port to or exiting aggregation port

InactiveCN102098213BSolve fair useSave storage spaceNetworks interconnectionComputer hardwareVirtual LAN

A method and device for enabling a physical port to join or exit from a trunk port are provided in the present invention, wherein, the method for enabling a physical port to join a trunk port includes the following steps: executing a instruction for enabling a physical port to join a trunk port, and judging whether the physical port has started general virtual local area network registration protocol (GVRP) function; if yes, enabling the physical port to release generic attribute registration protocol information declaration (GID) resources and join the trunk port. With the invention, when joining the trunk port, the physical port releases its own GID resources, and therefore the problem of rational utilization of the GID resources in the GVRP protocol is solved, and the effect of saving CPU and storage space is achieved.

Owner:ZTE CORP

Regional multi-QAM (quadrature amplitude modulation) modulation system

InactiveCN103269325ASolve fair useIncrease profitMultiple carrier systemsQuadrature modulationCoaxial cable

The invention discloses a regional multi-QAM (quadrature amplitude modulation) modulation system. Different QAD modulation modes are adopted as to different areas covered by IPQAMs (internet protocol quadrature amplitude modulation) according to the difference of network quality. A 256QAM modulation mode is adopted in the area with good network quality; and a 64QAM mode is adopted in the area with poor network quality. Thus, the utilization rate of frequency points and the utilization rate of IPQAM hardware resources are improved. Different IPQAM modulation modes are set in a background management system at the front end according to the coaxial cable network quality investigation of IPQAM coverage areas. Meanwhile, the QAM modulation mode is also set by IPQAM equipment according to the network quality. A user terminal obtains the QAM modulation mode adopted by the network after communicating with the background management system, and demodulates the signal by adopting the QAM modulation mode.

Owner:常熟市广播电视总台

Processing method for white clam meat thick chilli sauce

The invention provides a method for processing a mactra meat chili sauce. The method comprises the following processing steps: fresh mactra meat is crushed, de-sanded and dewatered; proper amount of edible oil is added in a pot, after the edible oil is heated, mactra meat, auxiliary materials and prepared condiments and additives are sequentially added in the pot under the condition of endless stirring, proper amount of water is added in the pot while stirring, heating is stopped until the water is dried up, proper amount of sodium glutamate is added in the pot, and the mixture is evenly stirred; the mixture is naturally cooled, and while the mixture is still hot, the mixture is filled up according to needed specification. The method resolves the technical problem of inconvenient processing and eating of the mactra meat due to big sand content, and by utilizing special preparing and processing techniques, processed products have good and fresh taste and abundant nutrition and can better meet needs of general consumers on diet.

Owner:SHANDONG WEIFANG LONGWEI IND

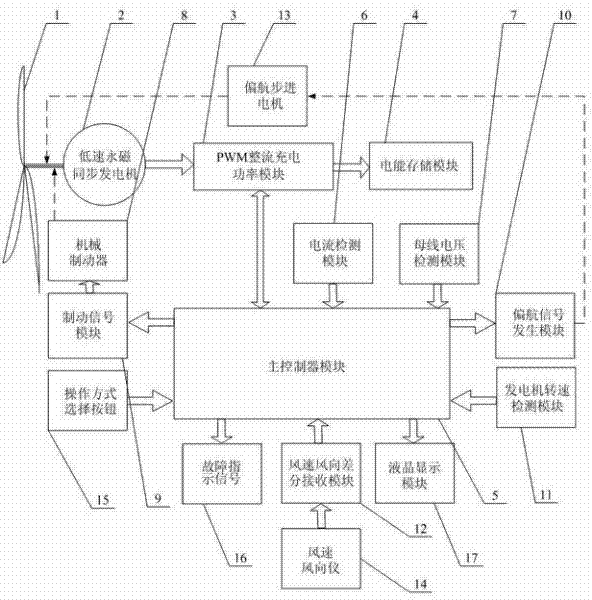

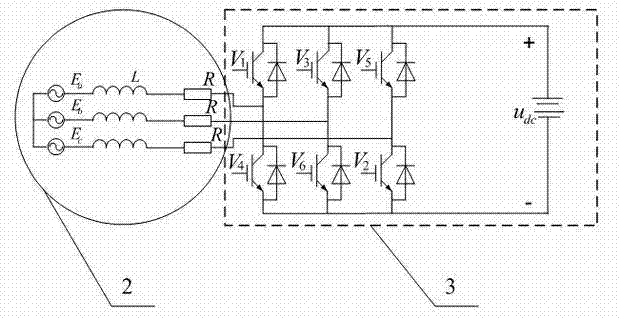

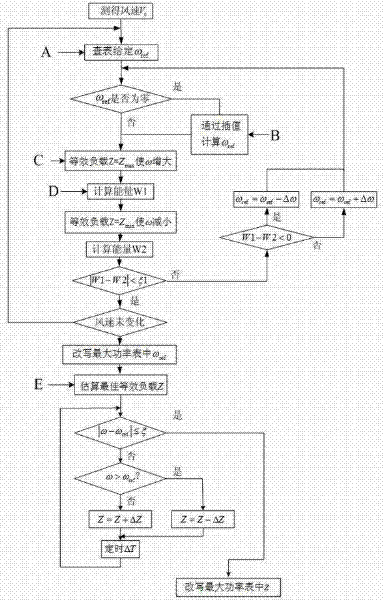

Maximum power tracking type wind power generation device with energy predicting function and method thereof

InactiveCN101793235BAchieve quasi-unity power factor outputRealize rational utilizationWind motor controlWind motor combinationsLow speedCharge current

The invention discloses a maximum power tracking type wind power generation device with an energy predicting function and a method thereof, which belong to the field of wind power generation energy conversion, and solve the problems that a low-power wind power generation device and a power generation method delay system control and cannot predict and control the charging current of a storage battery. The device comprises a blade, a low-speed permanent magnet synchronous generator, a PWM rectification charging power module, an electric energy storage module, a main controller module, a currentdetection module, a busbar voltage detection module, a mechanism brake, a brake signal module, an off-course signal generating module, a generator rotating speed detection module, a wind speed and wind direction difference receiving module, an off-course step motor and an anemoclinograph. The power generation method of the device comprises the following steps of: adjusting the blade according to wind speed signals; controlling the low-speed permanent magnet synchronous generator to realize the tracking of the maximum power; and controlling the PWM rectification charging power module to realize the output of unit power factors of the low-speed permanent magnet synchronous generator. The device and the method are used for wind power generation.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com