Buffer machine base for absorbing mechanical vibration energy and outputting fluid energy

A technology of energy absorption and mechanical vibration, applied in mechanical equipment, non-rotational vibration suppression, shock absorbers, etc., can solve problems such as the inability to use mechanical kinetic energy reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

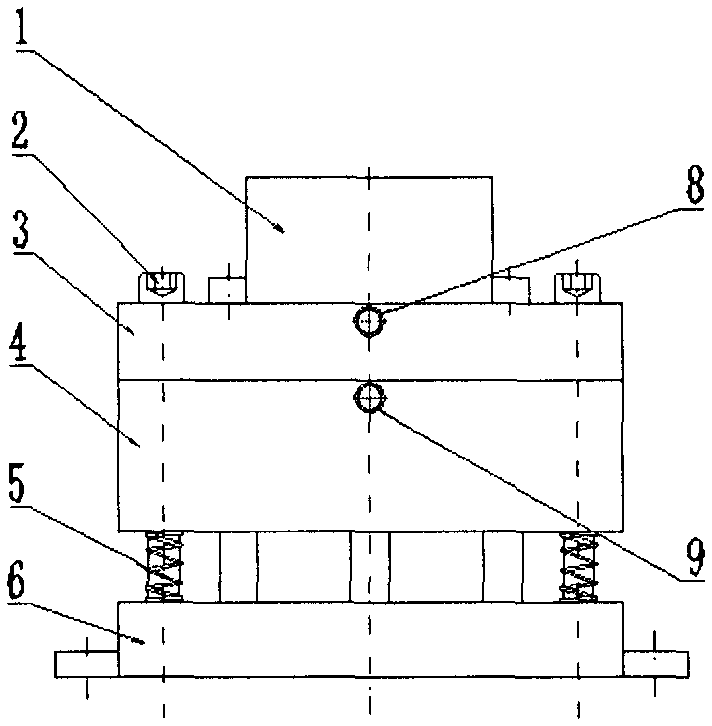

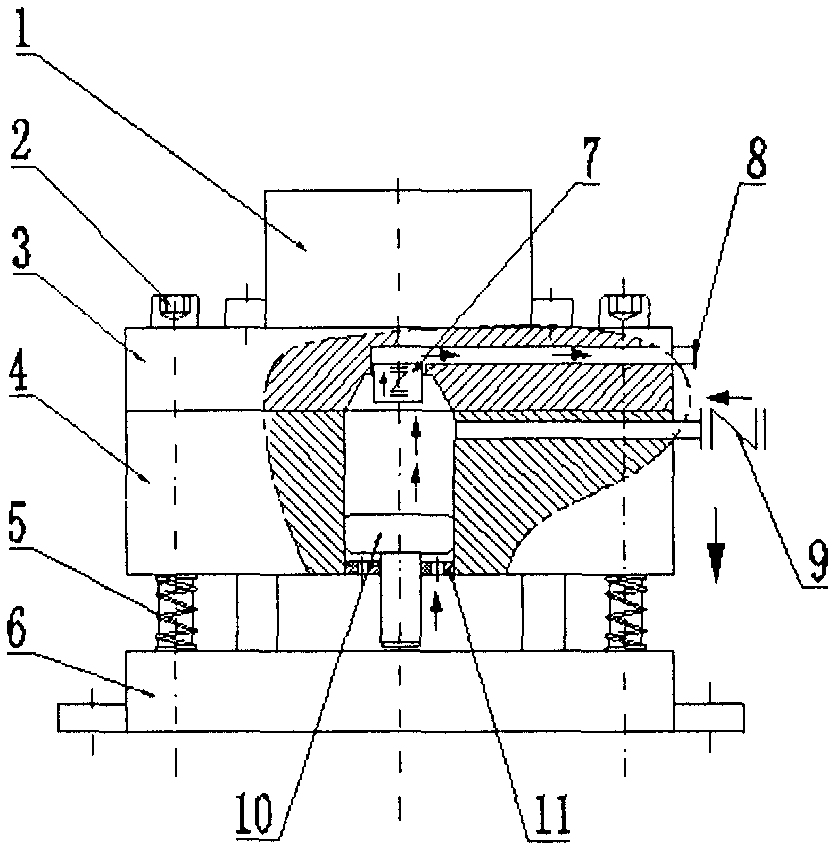

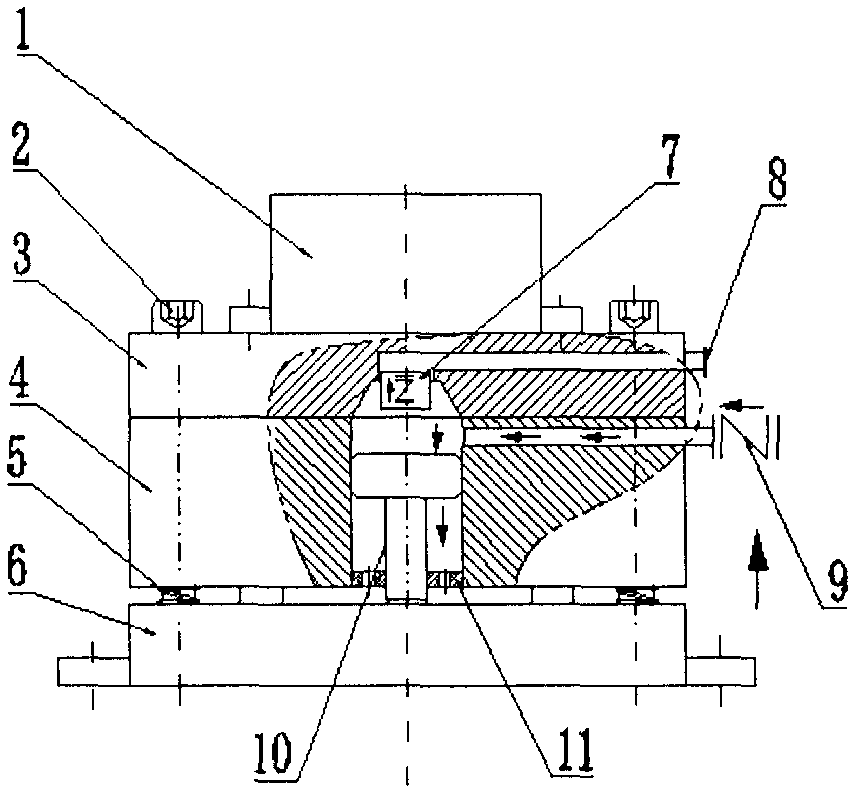

[0012] Embodiment 1: The buffer base includes guide post bolts 2, exhaust integrated board 3, gas production module 4, compression spring 5, support and fixing seat 6, exhaust check valve 7, main exhaust port 8, air intake unit Directional valve 9, piston 10 and diaphragm plate 11; exhaust integrated board 3 and gas production module 4 are connected with support and fixing seat 6 through guide bolt 2, there is a gap between gas production module 4 and support and fixing seat 6, and The guide post bolt 2 at the gap is connected with a compression spring 5, and there is a piston cylinder and a piston on the gas production module 4, and the piston cylinder is connected to the intake check valve 9 through a pipeline; the piston rod of the piston protrudes from the gas production module 4, and It is located between the gas production module 4 and the support and fixing seat 6; there is a diaphragm plate 11 on the gas production module 4 at the piston rod part; there is a cylinder ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com