Plate caching cabin

A buffer warehouse and plate technology, applied in the stacking of objects, unstacking of objects, conveyors, etc., can solve the problems of slow tempo, difficult tracking, and large amount of manual operations, so as to reduce errors and omissions and improve conversion efficiency , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, invention is described in further detail.

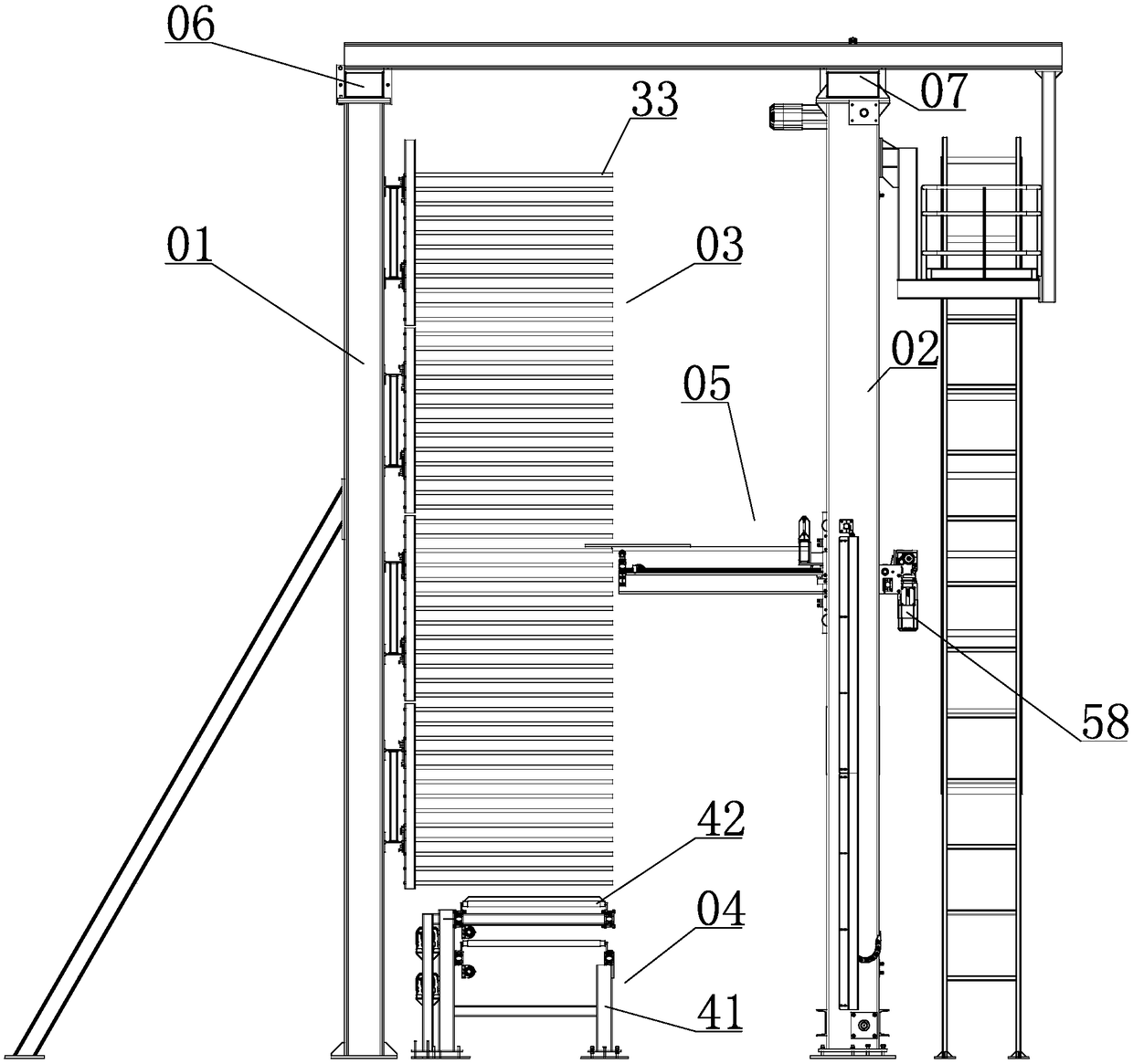

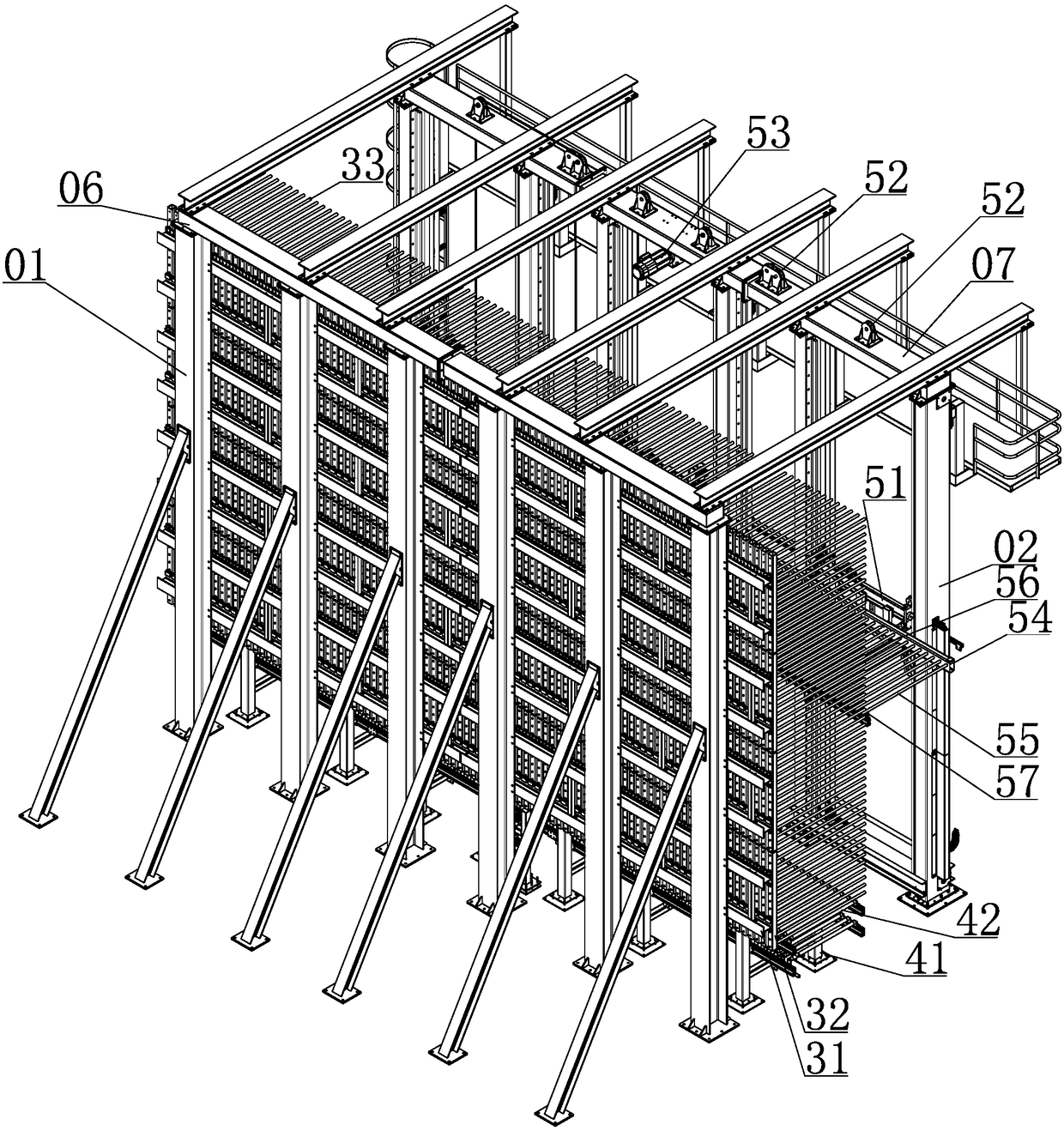

[0010] Such as Figure 1-2 As shown, a plate buffer warehouse includes a plurality of side-by-side first columns 01, a second column 02 provided at a corresponding position on one side of the plurality of side-by-side first columns 01, and a second column 02 provided on the first column 01. A shuttle frame structure 03 , a roller conveying line 04 provided under the first shuttle frame structure 03 , and a second shuttle frame structure 05 provided on the second column 02 . A first fixing rod 06 is provided on the top of the first column 01 . A second fixing rod 07 is provided on the top of the second column 02 . The first shuttle frame structure 03 includes a plurality of vertically arranged beams 31 arranged on a plurality of side-by-side first columns 01, and a plurality of horizontally arranged vertical connecting rods arranged on the plurality of vertically arranged beams ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com