a water-based ink

A water-based ink and water-based polyurethane technology, applied in inks, household appliances, applications, etc., can solve the problems of affecting the appearance of packaging products, pollution of production equipment, single function, etc., to improve storage stability, reduce usage, and high printing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

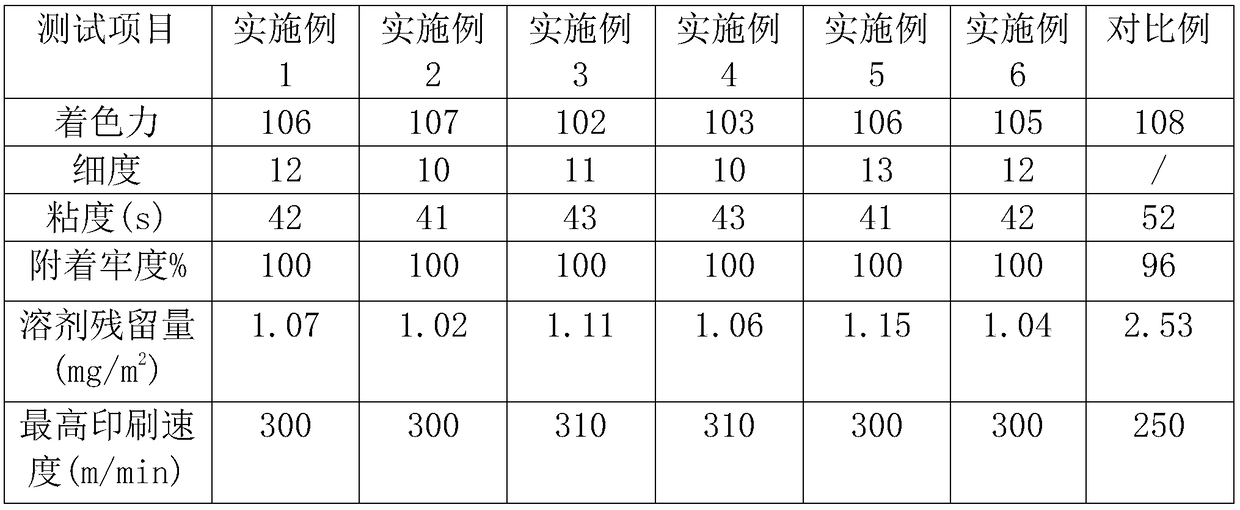

Examples

preparation example Construction

[0022] Preparation of Waterborne Polyurethane Binder

[0023] (1) Raw material pretreatment: first decompress and remove water from poly(ethylene succinate suberate)-1,4-butylene glycol ester diol at 90° C. and 0.1 MPa vacuum for 1 hour, and the polyoctylene succinate The number-average molecular weight of diacid ethylene glycol-1,4-butanediol ester diol is 3000, and xylylene diisocyanate is dehydrated and dried with activated molecular sieves;

[0024] (2) Preparation of prepolymer: 30 parts by weight of polyethylene succinate suberate glycol-1,4-butanediol ester diol is added in the flask, which is equipped with agitator, condenser, thermometer And ventilation pipe, pass into dry argon to reaction system, then start agitator, add the dimethylol propionic acid of 30 weight parts, add the xylylene diisocyanate of 8 weight parts and the diisocyanate of 0.03 weight part Dibutyltin laurate, slowly warming up to 70°C, constant temperature reaction for 2h;

[0025] (3) Cross-link...

Embodiment 1

[0031] 40 parts by weight of waterborne polyurethane;

[0032] 10 parts by weight of polypropylene emulsion;

[0033] 1 part by weight of polyamide wax;

[0034] 0.5 parts by weight of polystyrene-maleic acid triethanolamine salt;

[0035] 0.1 parts by weight of hydroxymethyl cellulose;

[0036] 0.2 parts by weight of tributyl phosphate;

[0037] 2,6-di-tert-butyl-4-methylphenol: 0.2 parts by weight;

[0038] 0.3 parts by weight of sodium alkylsulfonate;

[0039] 10 parts by weight of pigment;

[0040] 15 parts by weight of water;

[0041] 5 parts by weight of ethanol;

[0042] 0.3 parts by weight of oregano oil;

[0043] Pine red plum essential oil 0.2 parts by weight.

Embodiment 2

[0045] 45 parts by weight of waterborne polyurethane;

[0046] 15 parts by weight of polypropylene emulsion;

[0047] 2 parts by weight of polyamide wax;

[0048] 1 part by weight of polystyrene-maleic acid triethanolamine salt;

[0049] 0.8 parts by weight of hydroxymethylcellulose;

[0050] 0.6 parts by weight of tributyl phosphate;

[0051] 0.5 parts by weight of 2,6-di-tert-butyl-4-methylphenol;

[0052] 1 part by weight of sodium alkylsulfonate;

[0053] 20 parts by weight of pigment;

[0054] 30 parts by weight of water;

[0055] 15 parts by weight of ethanol;

[0056] 0.5 parts by weight of oregano oil;

[0057] Pine red plum essential oil 0.4 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com