A high-performance lithium-ion battery negative electrode si@n-c composite material and its preparation method

A technology of lithium-ion batteries and composite materials, which is applied in the field of high-performance lithium-ion battery anode Si@N-C composite materials and its preparation, can solve the problems of inability to utilize horsetail grass biomass, achieve good conductivity, realize utilization, and be cheap Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

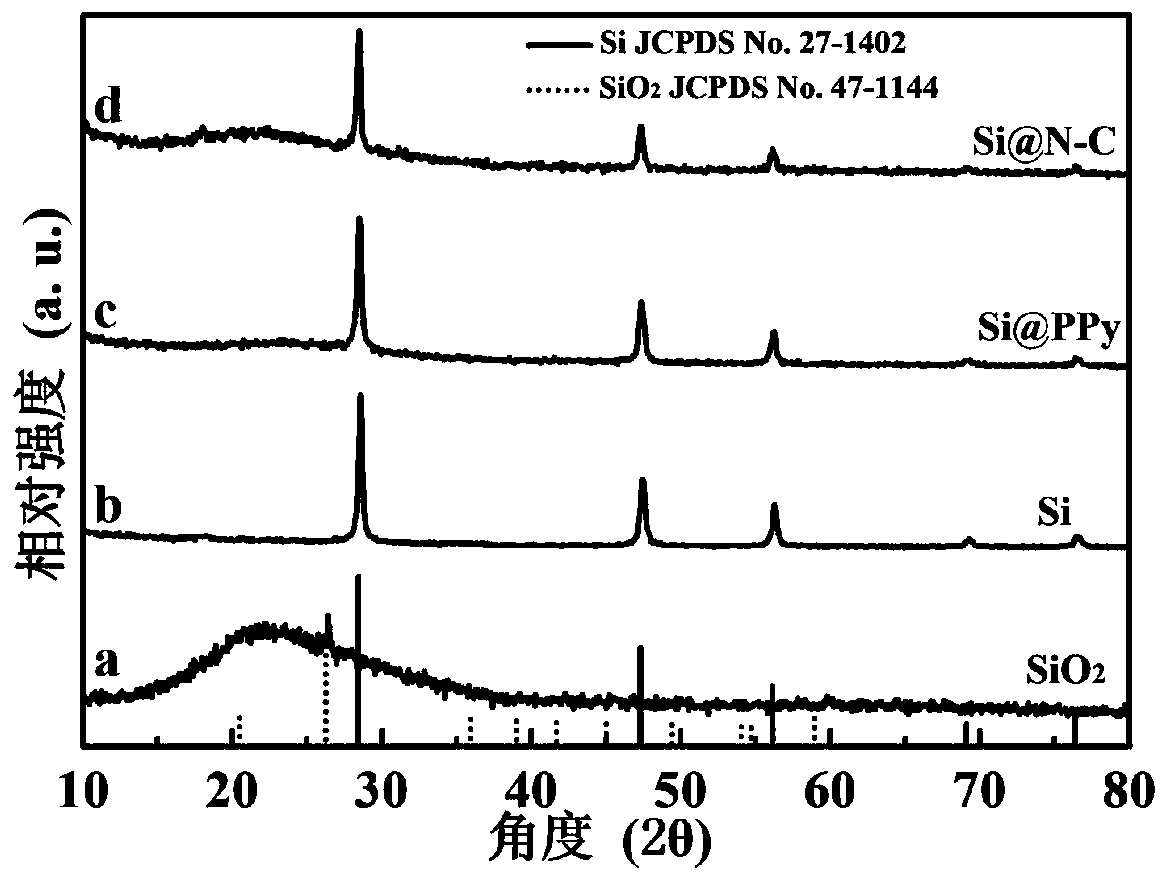

[0063] A high-performance lithium-ion battery negative electrode Si@N-C composite material, the composite material is a composite of silicon and nitrogen-doped carbon, the mass content of silicon in the composite is 45.57%, and the mass content of carbon is 49.53%, The mass content of nitrogen is 4.90%.

[0064] The preparation method of the above-mentioned Si@N-C composite material includes the following steps:

[0065] (1) Collect horsetail grass, wash, dry and crush it to obtain 1g of powder with a mesh number of 200, place it in 6mol / L 50mL hydrochloric acid aqueous solution, soak it at 120°C for 5 hours, filter it with suction, and wash it with deionized water , dried at 50°C for 12 hours to obtain pretreated horsetail grass powder. Take 1.5 grams of the above powder and put it into a tube furnace for calcination at 800 °C for 6 hours in an air atmosphere to obtain white SiO 2 powder.

[0066] (2) Take 0.15 grams of SiO 2 The powder and 1.25 g of magnesium powder were...

Embodiment 2

[0075] A method for preparing a high-performance lithium-ion battery negative electrode material Si@N-C composite material, comprising the following steps:

[0076] (1) Collect horsetail grass, wash, dry and crush it to obtain 1.5g of powder with a mesh number of 1000, place it in 10mol / L 50mL hydrochloric acid aqueous solution, soak it at 130°C for 3 hours, and filter it with deionized water Wash and dry at 50°C for 12 hours to obtain pretreated horsetail grass powder. Take 1.5 g of the above powder and put it into a tube furnace for calcination at 700 °C for 8 hours in an air atmosphere to obtain white SiO 2 powder.

[0077] (2) Take 0.15 grams of SiO 2 The powder and 0.225 g of magnesium powder were ground and mixed evenly, and then placed in a tube furnace with an argon / hydrogen (volume ratio of 95:5) atmosphere and calcined at 750° C. for 6 hours to obtain crude silicon powder. At room temperature, soak the above crude Si powder in 50 mL of 8 mol / L hydrochloric acid aq...

Embodiment 3

[0081] A method for preparing a high-performance lithium-ion battery negative electrode material Si@N-C composite material, the preparation method of the Si material is as described in Example 1, the difference is that in step (3): the prepared 50mg Si material and 0.5 grams of ten Sodium dialkyl sulfonate was added to 50 mL of deionized water, ultrasonicated until uniformly mixed, 100 microliters of pyrrole monomer was added, stirred at 0°C for 30 min, and then 20 mL of 0.1 mol / L ammonium persulfate aqueous solution was slowly added dropwise (dropping speed rate of 5ml / min), react at 0°C for 6 hours, filter with suction, wash alternately with deionized water and absolute ethanol, and dry at 50°C for 12h to obtain Si@polypyrrole composite material; place it in a tube furnace with nitrogen atmosphere Calcined at 400°C for 2 hours to obtain Si@N-C composites.

[0082] The Si@N-C composite material prepared in this example was used as the negative electrode material of the lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com