A method for preparing yeast extract from distiller's grains

A technology of yeast extract and yeast, which is applied in the field of preparation of yeast extract, can solve problems such as pollution, achieve the effects of reducing pollution, shortening production time, and improving overall economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

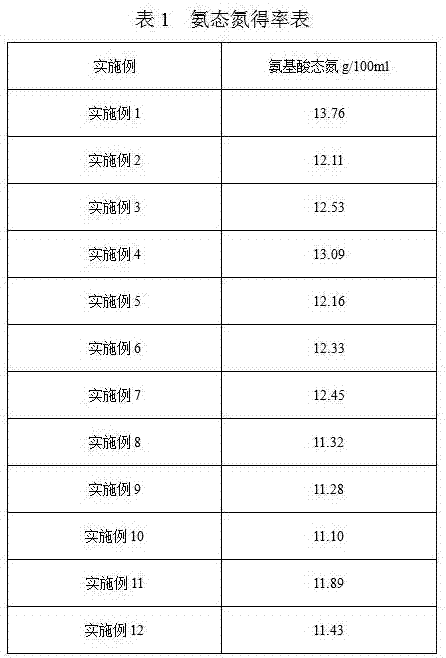

Examples

Embodiment 1

[0033] Example 1 Preparation of Yeast Extract

[0034] S0. Select rice wine waste distiller's grains (Guangdong Shunde Distillery Co., Ltd.), with a total solid content of 6.8% by weight, a pH value of 3.9, and a protein total nitrogen content of 0.44% by weight.

[0035] S1. The dry yeast should be activated before use. In the experiment, the ratio of 1:10 of Angel koji, that is, 40g of Angel koji was put into 400ml of warm water at a temperature of 36-40°C (heat after sterilization to prevent contamination) Miscellaneous bacteria) was activated for 20 minutes to make yeast emulsion.

[0036] S2. Five 1L triangular flasks were filled with 700ml distiller's grains from Shunde Distillery, sterilized at 121°C for 20 minutes and cooled. After cooling to room temperature, 70ml sterilized YPD liquid medium and 70ml activated yeast emulsion were added. Place in a constant temperature shaking incubator at 30°C and culture at 130r / min for 20h. At this time, the culture medium is turb...

Embodiment 2

[0041] Example 2 Preparation of Yeast Extract

[0042] The preparation method is the same as in Example 1, except that the content of each enzyme in S4., the content of each enzyme in this example is: 1.6% (based on the total mass of the yeast suspension) of alkaline protease, 1.5% (based on the yeast suspension) Suspension total mass) of papain and 2.0% (by yeast suspension total mass) of cellulase.

Embodiment 3

[0043] Example 3 Preparation of Yeast Extract

[0044] The preparation method is the same as in Example 1, except that the content of each enzyme in S4., the content of each enzyme in this example is: 1.6% (based on the total mass of yeast suspension) of alkaline protease, 2.0% (based on yeast suspension) Suspension total mass) of papain and 1.5% (by yeast suspension total mass) of cellulase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com