A method for activated flotation of sulfur in copper tailings of copper sulfide sulfur ore dressing

A technology for beneficiation of copper tailings and copper sulfide, applied in flotation, solid separation, etc., can solve problems such as excessive ammonia and nitrogen ion content, increased mine costs, increased beneficiation costs, etc., to eliminate pollution, reduce production costs, and save The effect of chemical cost and environmental treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

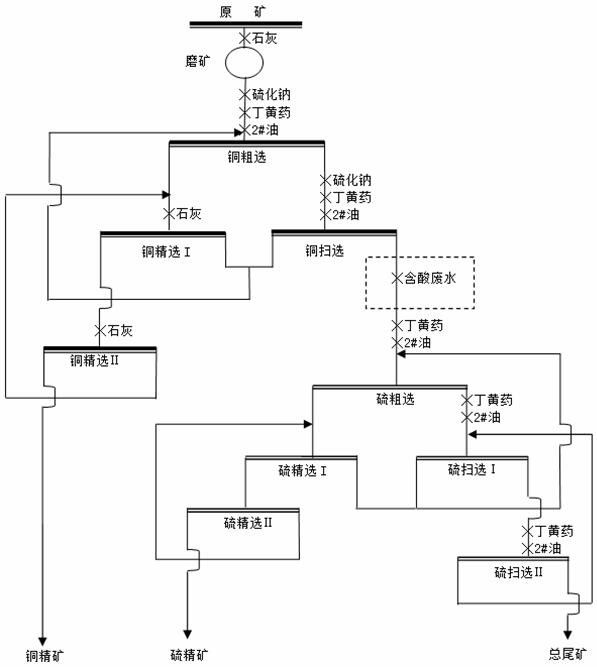

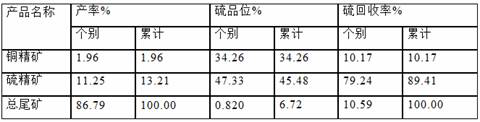

Image

Examples

Embodiment 1

[0033] A method for activated flotation of sulfur in copper sulfide ore beneficiation copper tailings, comprising the following steps:

[0034] Step (1), take copper sulfide sulfide ore for grinding, add calcium oxide at a ratio of 7000g / t before grinding to make the pH value of the flotation pulp reach 11.5, and grind until the particle size is less than 0.074mm. Take 70% of the quality of copper sulfide sulfur ore to obtain raw ore grinding products;

[0035] Step (2), adding water to the raw ore grinding product obtained in step (1), until the mass percentage concentration of the pulp [mineral amount / (mineral amount+water amount)] is 30%;

[0036] Step (3), adding sodium sulfide, butyl xanthate and 2# oil to the pulp obtained in step (2) to carry out copper sulfide flotation to obtain copper rough concentrate and copper beneficiation tailings;

[0037] Wherein, the amount of sodium sulfide added is 140g / ton, the amount of butyl xanthate is 30g / ton, and the amount of 2# oil...

Embodiment 2

[0043] A method for activated flotation of sulfur in copper sulfide ore beneficiation copper tailings, comprising the following steps:

[0044] Step (1), take copper sulfide sulfide ore for grinding, add calcium oxide at a ratio of 7000g / t before grinding to make the pH value of the flotation pulp reach 11.5, and grind until the particle size is less than 0.074mm. Take 70% of the quality of copper sulfide sulfur ore to obtain raw ore grinding products;

[0045] Step (2), adding water to the raw ore grinding product obtained in step (1), until the mass percentage concentration of the pulp [mineral amount / (mineral amount+water amount)] is 30%;

[0046] Step (3), adding sodium sulfide, butyl xanthate and 2# oil to the pulp obtained in step (2) to carry out copper sulfide flotation to obtain copper coarse concentrate and copper beneficiation tailings;

[0047] Wherein, the amount of sodium sulfide added is 140g / ton, the amount of butyl xanthate is 30g / ton, and the amount of 2# oi...

Embodiment 3

[0053] A method for activated flotation of sulfur in copper sulfide ore beneficiation copper tailings, comprising the following steps:

[0054] Step (1), take copper sulfide sulfide ore for grinding, add calcium oxide at a ratio of 7000g / t before grinding to make the pH value of the flotation pulp reach 11.5, and grind until the particle size is less than 0.074mm. Take 70% of the quality of copper sulfide sulfur ore to obtain raw ore grinding products;

[0055] Step (2), adding water to the raw ore grinding product obtained in step (1), until the mass percentage concentration of the pulp [mineral amount / (mineral amount+water amount)] is 30%;

[0056] Step (3), adding sodium sulfide, butyl xanthate and 2# oil to the pulp obtained in step (2) to carry out copper sulfide flotation to obtain copper coarse concentrate and copper beneficiation tailings;

[0057] Wherein, the amount of sodium sulfide added is 140g / ton, the amount of butyl xanthate is 30g / ton, and the amount of 2# oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com