High-strength water-resistant plastering gypsum and producing method thereof

A plastering gypsum, high-strength technology, which is applied in the field of high-strength water-resistant gypsum-based composite plastering materials, can solve the problems of polluting the environment, groundwater resources, occupying land, etc., and achieves the effects of reducing production costs, improving water resistance and strength, and preventing erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment.

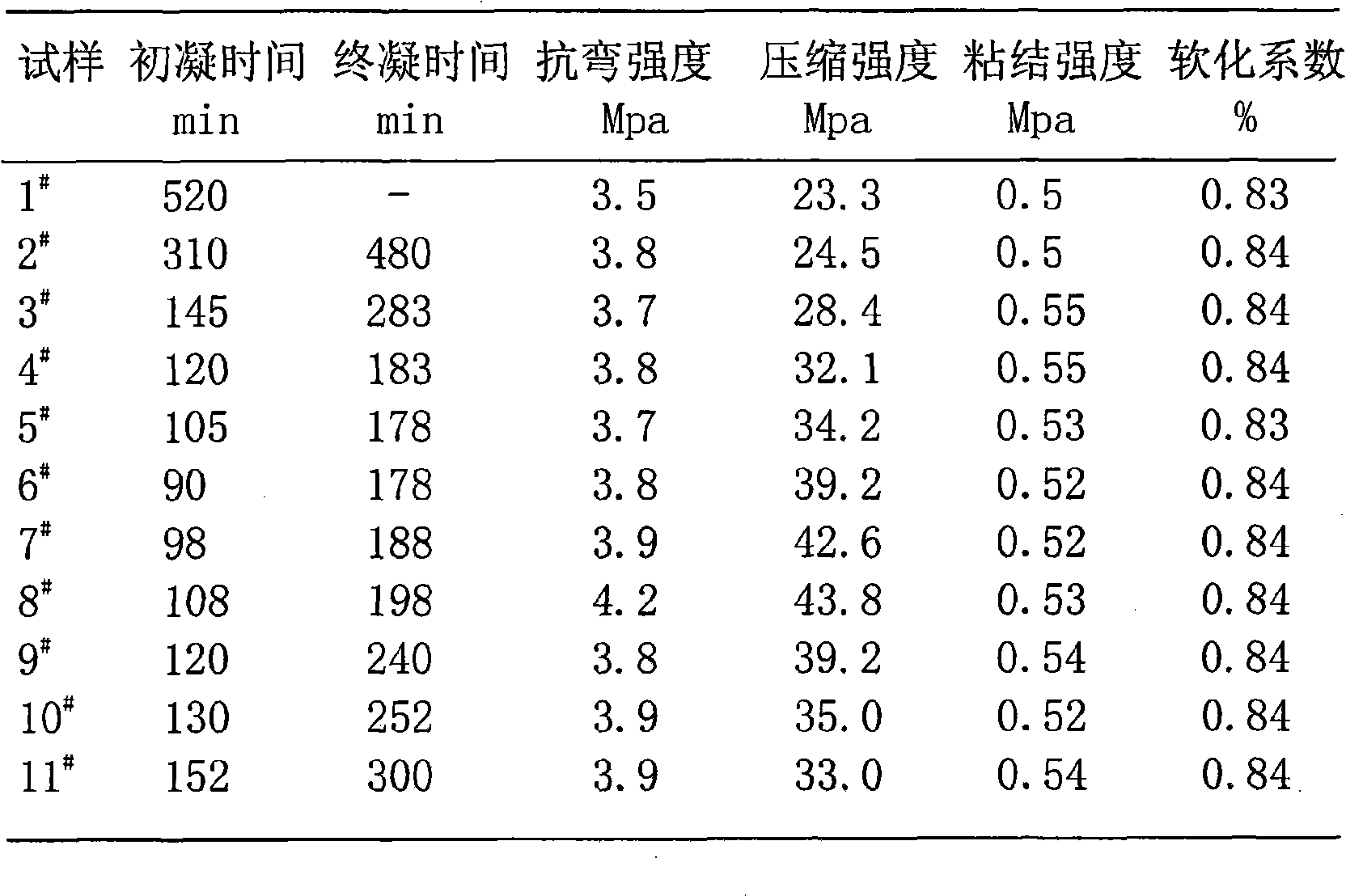

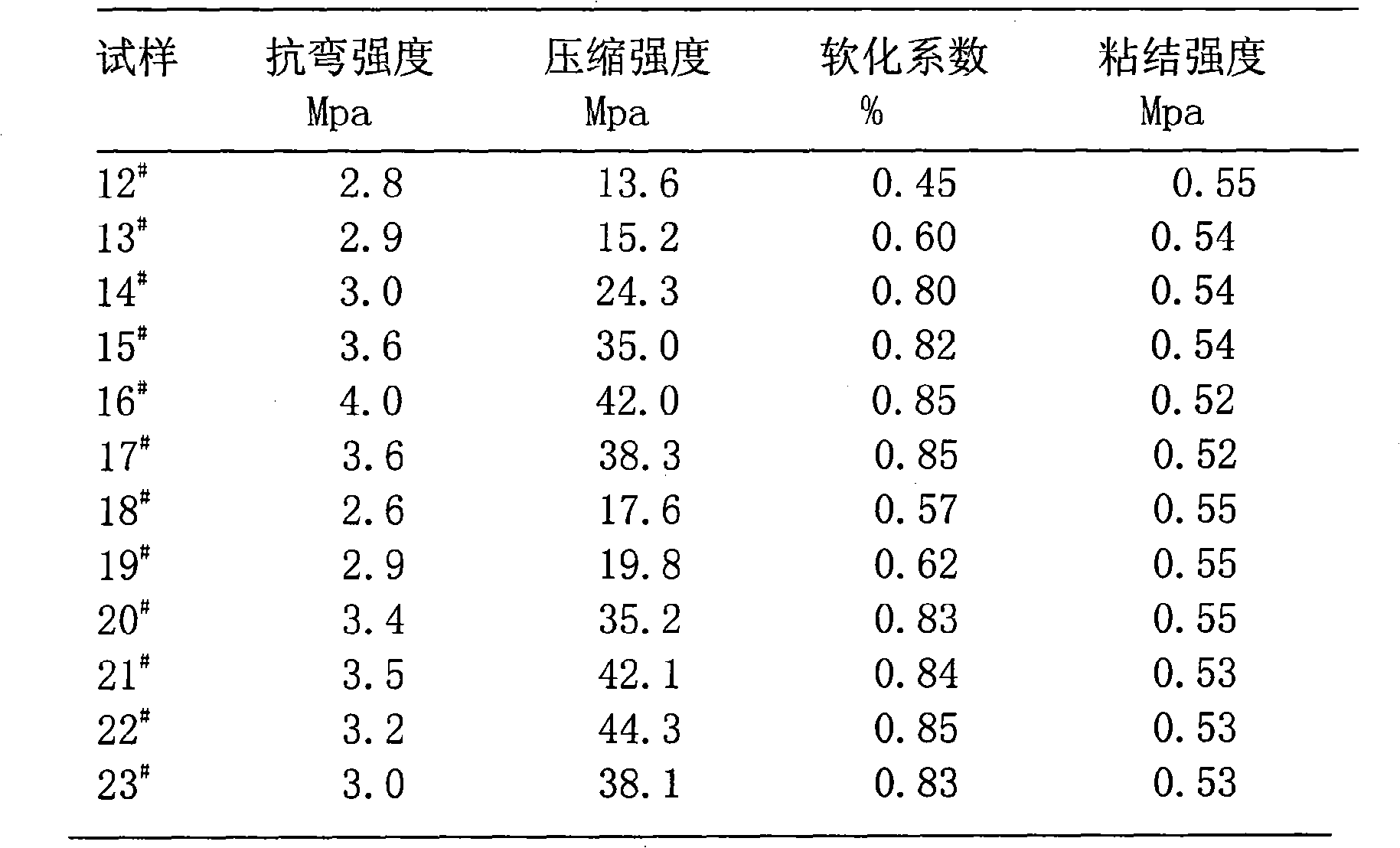

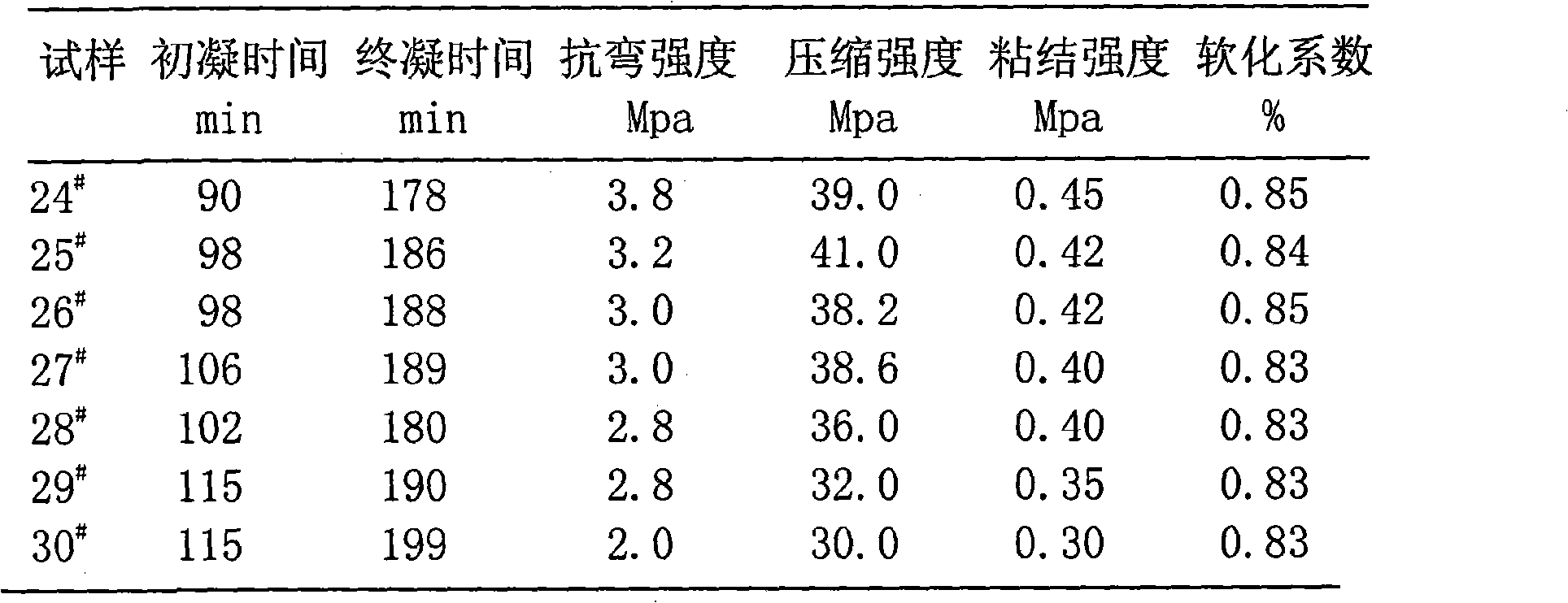

[0024] (1) Experimental Example of Optimal Proportion of Plastering Gypsum Base Materials (1)

[0025] Raw materials: gypsum base is natural dihydrate gypsum powder and natural anhydrite powder (both with a particle size of 100 mesh), the active admixture is ground water-quenched slag, and the alkaline activator is Portland cement (325 # ), the coagulant is alum [KAl(SO 4 ) 2 12H 2 [0] (100 orders of particle size), methyl cellulose MC, redispersible rubber powder, the weight ratio of each component raw material is:

[0026] Dihydrate gypsum: anhydrite: water-quenched slag: cement: alum: MC: redispersible rubber powder

[0027] 1 # =63.6 : 0 : 27.3 : 9.1 : 3.0 : 0.1 : 1.0

[0028] 2 # =58.6 : 5 : 27.3 : 9.1 : 3.0 : 0.1 : 1.0

[0029] 3 # =53.6 : 10 : 27.3 : 9.1 : 3.0 : 0.1 : 1.0

[0030] 4 # =43.6 : 20 : 27.3 : 9.1 : 3.0 : 0.1 : 1.0

[0031] 5# =38.6 : 25 : 27.3 : 9.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com