Inhibitor of polymerization reaction in hydrocarbon cracking and alkaline cleaning operation

A polymerization reaction and inhibitor technology, applied in the field of inhibitors, can solve problems such as scaling, equipment hazards, and shortened operating cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-36

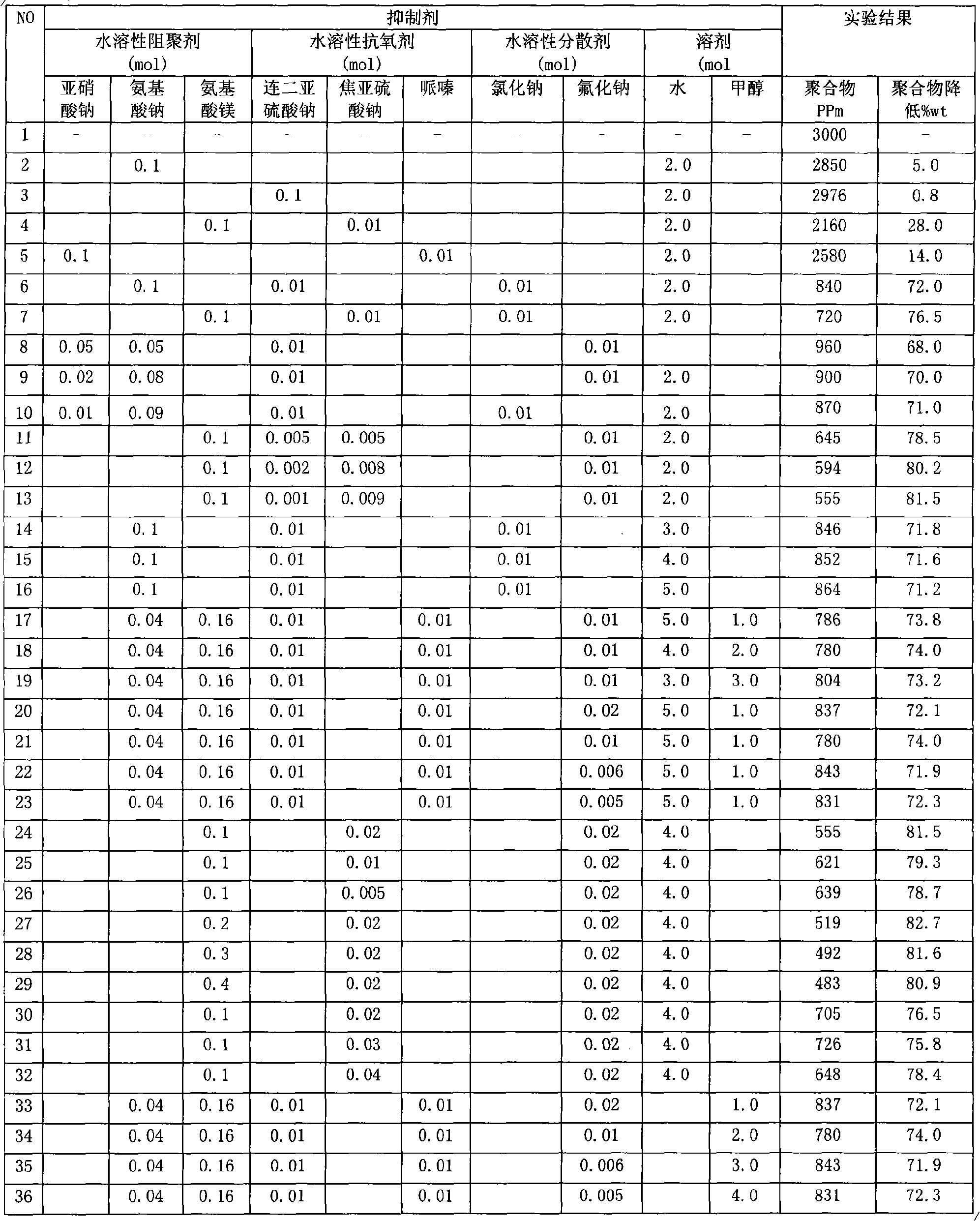

[0032] 2L of 10% NaOH solution and a certain amount of acetaldehyde were added to a 10L stainless steel reactor in advance, and inhibitors were added. The types and amounts of inhibitors added are shown in Table 1. Take the pyrolysis gas before entering the alkali cleaning operation unit and pass it into the reaction kettle. The temperature of the reaction kettle is controlled at 50°C, and the pressure is controlled at 2.0MPa. After 15 minutes, the gas is released. After the cracking gas is passed through the same method for 15 times, it is analyzed by a mass spectrometer. Method Determination of the polymer concentration in the spent caustic soda (including the polymer attached to the reactor), the results are shown in Table 1.

[0033] NO1 in Table 1 is a blank experiment, NO2-NO5 are comparative examples, and NO6-NO36 are examples of inhibitors of the present invention.

[0034] As can be seen from Table 1, the inhibitors of the present invention in Examples NO6-NO36 have o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com