Method for preparing nano titanium dioxide by sol process at low temperature

A technology of nano-titanium dioxide and titanium dioxide, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of high production cost, large energy consumption, long process, etc., and achieve equipment investment and production costs. Simple, reduced preparation steps effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

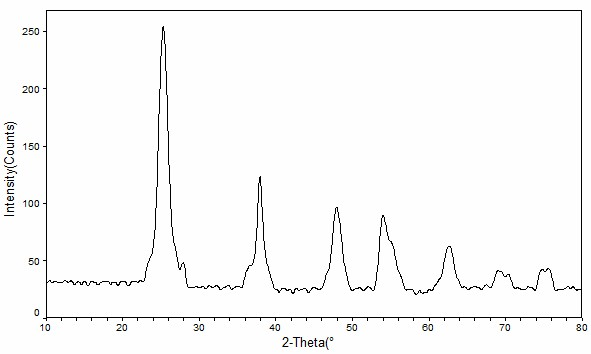

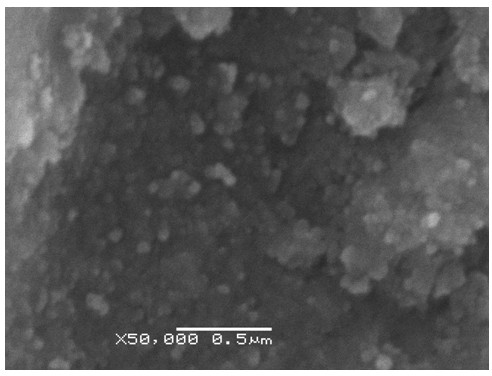

Image

Examples

Embodiment 1

[0025] Prepare 25% titanium salt solution with absolute ethanol as solvent, stir and react at room temperature to form liquid A, stir for 3 hours, add liquid B consisting of 10ml absolute ethanol, 1ml dispersant, glacial acetic acid and deionized water, continue stirring for 3h A sol solution is formed. Standing and aging for 24 hours, drying into gel powder, calcining, grinding and sieving to obtain the product.

Embodiment 2

[0027] When the light yellow sol solution was prepared in Example 1, a certain amount of absolute ethanol was added, heated in a water bath to 80°C, a mixture of deionized water, absolute ethanol and ammonia water was added dropwise, and the water bath was refluxed for 4-12 hours. Static layering to remove the supernatant, wash twice with absolute ethanol and deionized water, and dry the precipitate. Grinding and sieving to obtain a low-temperature sol to prepare nano-scale titanium dioxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com