Constituent part of cooling system for motor vehicle

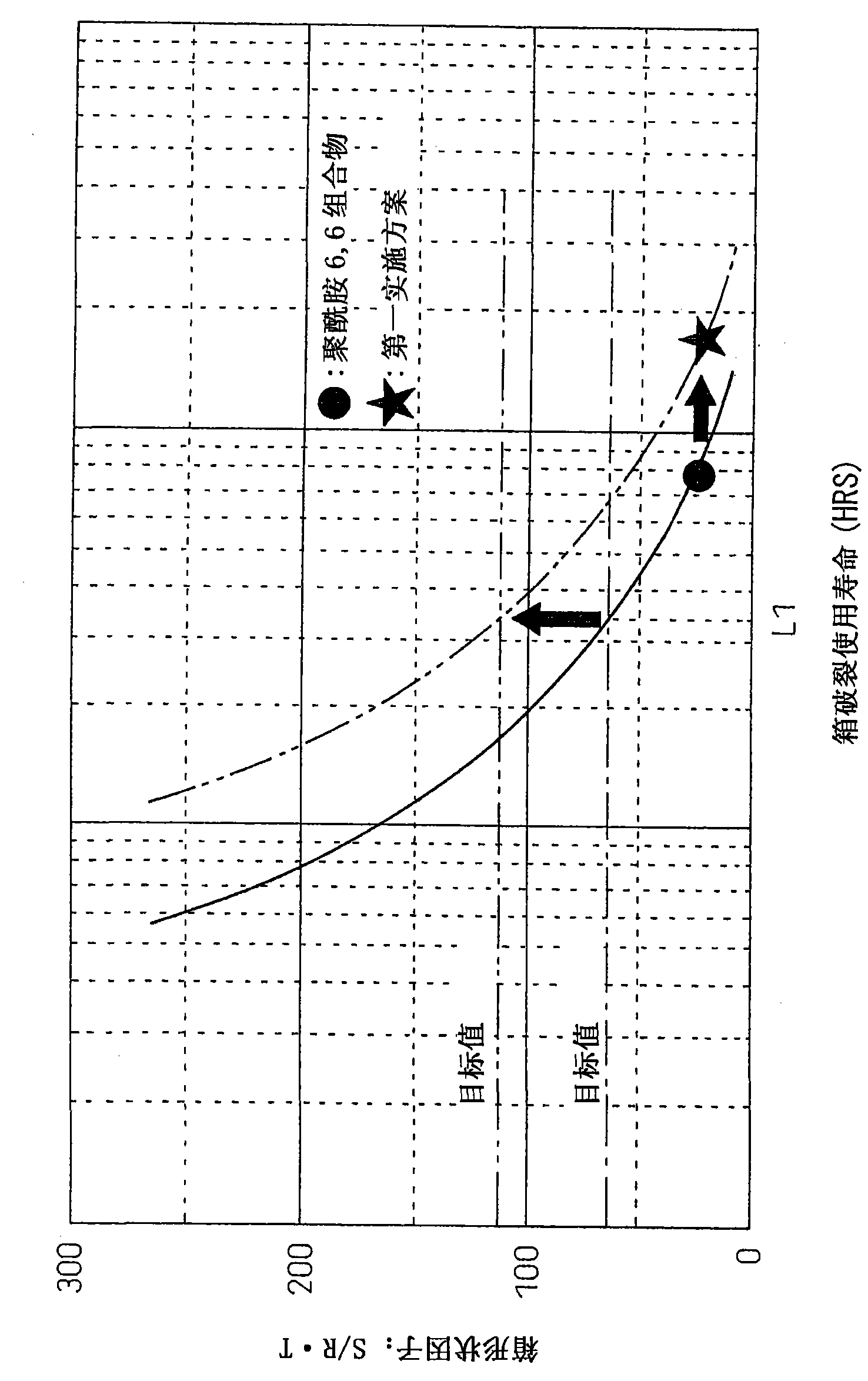

A technology for cooling systems and motor vehicles, applied in the direction of engine cooling, liquid cooling, engine components, etc., can solve problems such as undesired deformation, creep of motor vehicle cooling system components, and accelerated deterioration rate of polyamide compositions, to achieve Effects of high productivity and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] An explanation of examples of polyamide 6,10 compositions is provided below.

[0076] Table 1 shows the materials and amounts of the components used in Examples 1 to 15 and Comparative Examples 1 to 6.

[0077] The amounts of components shown in Table 1 are expressed in weight percent based on the total weight of polyamide, glass fiber, carbon black, and copper (Cu).

[0078]

[0079] Sample Preparation: Examples (in Table 1, referred to as "Examples") and Comparative Examples (in Table 1, referred to as Comparative example) composition. Copper is added in the form of CuI. The amounts shown in Table 1 correspond to the actual weight of copper present.

[0080] In Examples 1 to 15 and Comparative Examples 1 and 2, five types of polyamide 6,10 (in the column of PA 6,10 in Table 1, referred to as "A" to "E") with different relative viscosities were used. "). Their relative viscosities are as follows:

[0081] Polyamide 6, 10A: 2.9

[0082] Polyamide 6, 10B: 2.8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization time | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com