High-molecular composite powder material for SLS and preparation method therefor

A composite powder and polymer technology, which is applied in the field of polymer composite powder materials of SLS and its preparation, can solve the problems of poor absorption of fiber lasers and limited application, and achieve the effects of improved precision of parts, easy implementation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

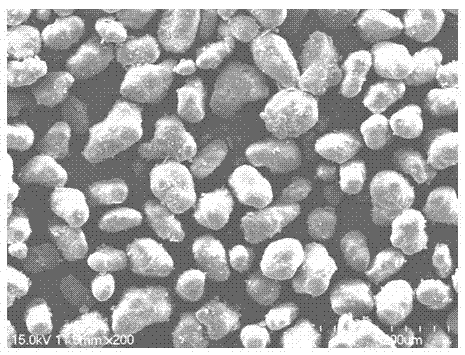

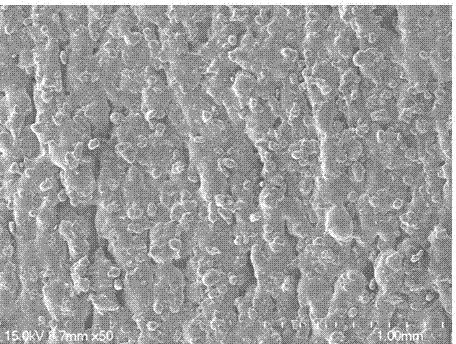

[0027] Dry nylon 12 powder in advance, add 1000 g of nylon 12 powder into a vertical mechanical stirrer, then add 30 g of laser absorber, 2 g of flow aid, and 2 g of antioxidant in sequence, and stir and mix for 1.5 h. Take out the homogeneously mixed polymer composite powder and pass through a 150-mesh sieve to obtain a nylon composite powder material that can be formed by fiber laser for SLS. The morphology of the obtained composite powder material is shown in figure 1 , it can be seen in the figure that there are fine particles attached to the polymer powder particles, which shows that this method can produce a uniformly mixed composite powder material. Using the composite powder material as the molding material, the sintering process parameters are as follows: fiber laser power 4W, scanning speed 1000 mm / s, sintering distance 0.1 mm, sintering layer thickness 0.1 mm, the surface morphology of the obtained molding is shown in figure 2 , it can be seen in the figure that t...

Embodiment 2

[0029] Dry the polystyrene powder in advance, add 1000 g of polystyrene powder into a vertical mechanical stirrer, then add 20 g of laser absorber, 2 g of flow aid, and 3 g of antioxidant in sequence, and stir and mix for 1.5 h, take out the homogeneously mixed polymer composite powder and pass through a 150-mesh sieve to obtain a polystyrene composite powder material that can be formed by SLS with a fiber laser.

[0030] The polymer composite powder material for SLS and its preparation method are simple, environmentally friendly, and easy to implement, and can obtain a polymer composite powder material with excellent molding performance, and the polymer composite powder material prepared by the present invention can use optical fiber The laser is used for SLS forming, and the precision of the parts has been effectively improved, which has effectively promoted the application and development of SLS technology in various fields. The parts formed by SLS technology have excellent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com