Carbon fiber reinforced resin powder material for selective laser sintering

A technology of laser sintering and resin powder, which is applied in the field of materials, can solve problems such as low strength and rigidity, unsatisfactory reinforcement effect, and failure to meet the performance requirements of the mechanical performance test of molded parts, etc., to achieve good molding effect, light weight, and high strength. and the effect of high modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

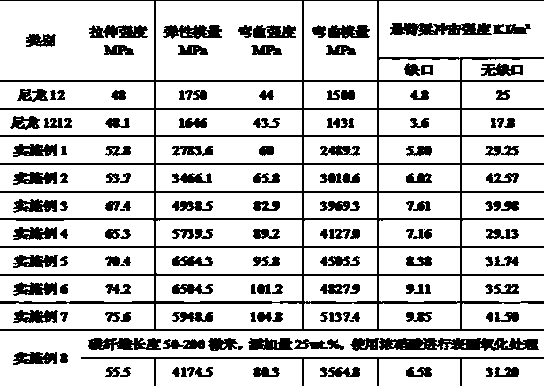

Examples

Embodiment 1

[0021] Below, the embodiment of the present invention is described, but the present invention is not limited thereto:

[0022] (1) Accurately weigh each component according to the following data: carbon fiber, 1Kg, with an average diameter of 7 microns and a length range of 201-300 microns; nylon 12 powder, 8.8Kg, with a particle size range of 20-100 microns; Silicon oxide, 100g; Dispersant graphite powder, 20g; Antioxidant 1098, 80g;

[0023] (2) Use a 2.5L high-speed stirrer to break up the agglomerated fumed silica;

[0024] (3) Stir and mix about 1Kg of nylon 12 powder with crushed fumed silica, antioxidant 1098 and graphite powder to obtain the powder, and mix in 3 times;

[0025] (4) Sieve the carbon fiber with an 80-mesh sieve to remove the agglomerated parts and impurities in the carbon fiber;

[0026] (5) Put the powder, the sieved carbon fiber and the remaining nylon 12 powder into the V-shaped stirring device and stir for 40-60 minutes;

[0027] (6) The material ...

Embodiment 2

[0029] (1) Accurately weigh each component according to the following data: carbon fiber, 2Kg, with an average diameter of 7 microns and a length range of 201-300 microns; nylon 12 powder, 7.8Kg, with a particle size range of 20-100 microns; Silicon oxide, 90g; Dispersant graphite powder, 30g; Antioxidant 1098, 80g;

[0030] (2) Use a 2.5L high-speed stirrer to break up the agglomerated fumed silica;

[0031] (3) Stir and mix about 1Kg of nylon 12 powder with crushed fumed silica, antioxidant 1098 and graphite powder to obtain the powder, and mix in 3 times;

[0032] (4) Sieve the carbon fiber with an 80-mesh sieve to remove the agglomerated parts and impurities in the carbon fiber;

[0033] (5) Put the powder, the sieved carbon fiber and the remaining nylon 12 powder into the V-shaped stirring device and stir for 40-60 minutes;

[0034] (6) The material stirred in step (5) is the target material.

Embodiment 3

[0036] (1) Accurately weigh each component according to the following data: carbon fiber, 3Kg, with an average diameter of 7 microns, and a length range of 250-350 microns; nylon 12 powder, 6.8Kg, with a particle size range of 25-120 microns; gas phase oxidation Aluminum, 80g; Dispersant EBS powder, 50g; Antioxidant 9228, 70g;

[0037] (2) Stir and mix about 1Kg of nylon 12 powder with fumed alumina, antioxidant 9228 and EBS powder to obtain primer powder, and mix in 3 times;

[0038] (3) Sieve the carbon fiber with an 80-mesh sieve to remove the agglomerated parts and impurities in the carbon fiber;

[0039] (4) Put the powder, the sieved carbon fiber and the remaining nylon 12 powder into the V-shaped stirring device and stir for 40-60 minutes;

[0040] (5) The material stirred in step (4) is the target material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com