Ultralow-temperature deep drawing forming method for aluminum alloy thin-wall curved surface part

A technology of ultra-low temperature and curved surface parts, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven thermal drawing deformation, loss of tissue performance, uneven deformation, etc., to improve deformation resistance and strain hardening index, Effects of recovery/recrystallization inhibition and promotion of tissue performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

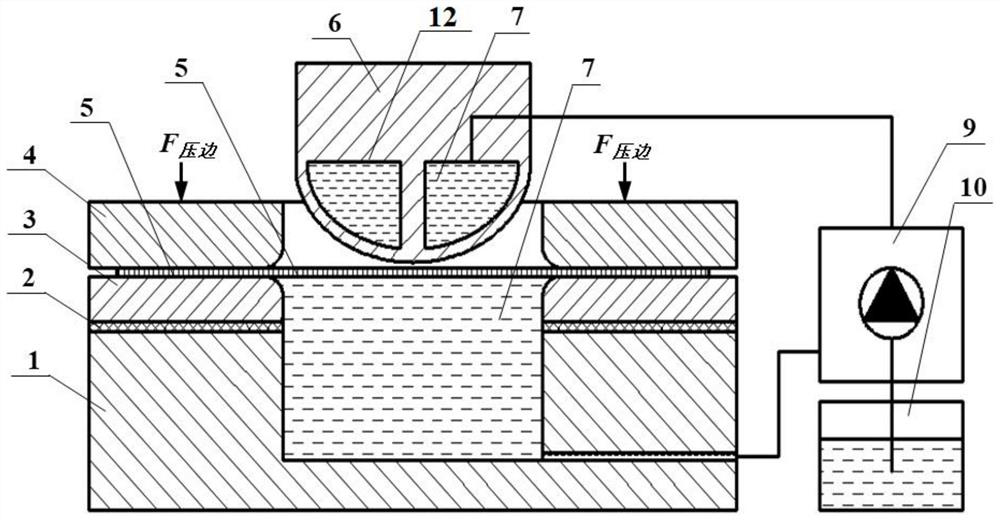

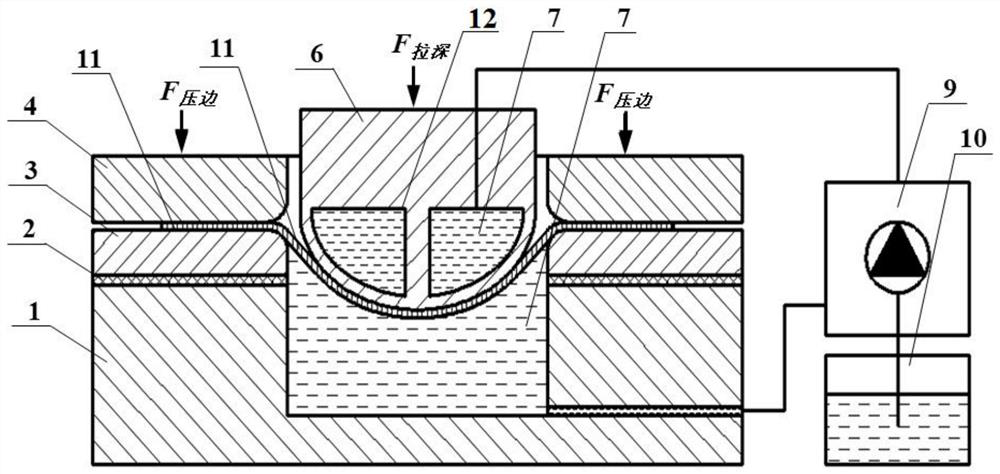

[0038] Such as Figure 1 to Figure 7 As shown: this embodiment provides a method for ultra-low temperature deep drawing of aluminum alloy thin-walled curved surface parts. Based on the ultra-low temperature gradient distribution of the aluminum alloy plate 5, the formability and flow stress are controlled to form a deep cavity thin-walled curved surface part, which specifically includes the following step:

[0039] Step 1, put the aluminum alloy plate 5 on the die 3, close the blank holder 4 to compress the flange area of the aluminum alloy plate 5; before implementing step 1, pre-cool the profile area of the punch 6 to the set constant temperature, the punch 6 can also be provided with a cavity 12 for containing the ultra-low temperature medium 7, and the cavity 12 forms a circulation loop with the low-temperature container 10 of the ultra-low temperature medium 7 through the low-temperature filler 9; The ring 4 and the die 3 are cooled to a cooling temperature of -180°C...

Embodiment 2

[0045] Such as Figure 1 to Figure 4 As shown: the plate 5 in this embodiment is a solid solution state 2219 aluminum alloy plate, and its thickness is 4mm; the diameter of the deep cavity thin-walled curved surface part 11 is 400mm, the drawing depth is 400mm, the bottom is an ellipsoid, and the axial length ratio is 1.6; The plate in the die area is directly cooled by liquid nitrogen, and the plate in the flange area is indirectly cooled by heat transfer through the plate in the die area; the punch is cooled by liquid nitrogen, and the plate in the die area can also be indirectly cooled. Specific steps are as follows:

[0046] Step 1: Inject liquid nitrogen into the inner cavity of the punch 6 to cool the temperature of the surface area to below -180°C.

[0047] Step 2: Put the decontamination-treated room-temperature plate 5 on the die 3 , close the blank holder 4 , and press the aluminum alloy plate 5 .

[0048] Step 3: Fill the lower side of the aluminum alloy plate 5 w...

Embodiment 3

[0053] Such as Figure 5 As shown: the plate 5 in this embodiment is an annealed 5A06 aluminum alloy plate with a thickness of 6 mm; the deep cavity thin-walled curved surface part 11 has a diameter of 600 mm, a drawing depth of 800 mm, an ellipsoidal bottom, and an axial length ratio of 1.4 ;The plate in the die area is directly cooled by liquid nitrogen, and the plate in the flange area is indirectly cooled by a liquid argon precooling mold. Specific steps are as follows:

[0054] The first step: using liquid argon as the ultra-low temperature medium 7 to simultaneously cool the die 3 and the blank holder 4 to a temperature below -120°C; the die 3 and the binder ring 4 are provided with a circulation passage 8 for circulating the ultra-low temperature medium 7, The mold is cooled and lowered through the circulation channel 8 . The liquid argon fills the die 3 and the blank holder 4 with ultra-low temperature medium through the low temperature filler.

[0055] Step 2: Put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com