CFB furnace tube longevity assessment method based on gray prediction theory

A technology of gray prediction and life evaluation, which is applied in the direction of testing wear resistance, electrical digital data processing, special data processing applications, etc. It can solve problems that affect the normal operation of production and the life of furnace tubes is difficult to evaluate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

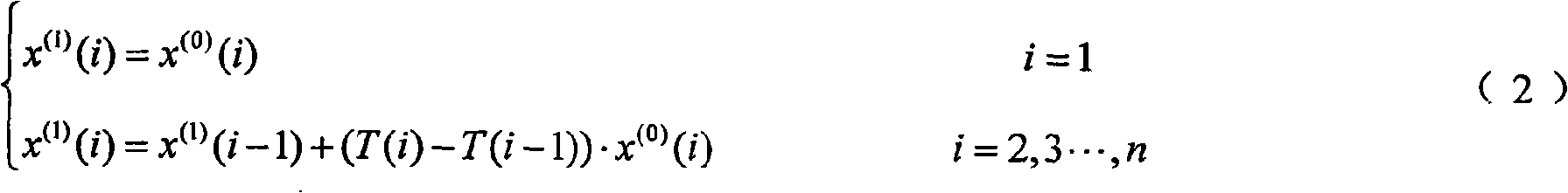

Method used

Image

Examples

Embodiment 1

[0148] 1. Wear measurement

[0149] Set up a representative measuring point on the water wall (φ63×6.5) of a 465t / h circulating fluidized bed boiler, and use NDT711 during the cumulative 11256 hours of operation, using the time of tube burst and other accident shutdowns The ultrasonic thickness gauge measures the wall thickness of each measuring point, and the initial wall thickness minus the current measured wall thickness is the current measured wear amount. The test data are shown in Table 1.

[0150] Table 1. Measured value of water wall wear of CFB boiler

[0151] times

1

2

3

4

5

6

7

8

9

10

11

cumulative run

time

t(h)

7776

8136

8496

9168

9432

9960

10296

10584

10944

11136

11256

L

(mm)

0.3

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com