A pipeline monitoring system based on neural network

A technology of neural network and monitoring system, applied in the field of pipeline monitoring system based on neural network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

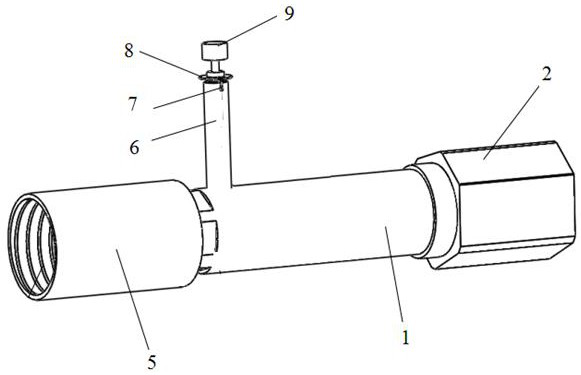

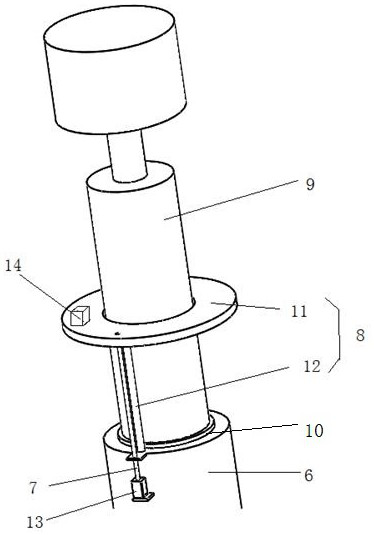

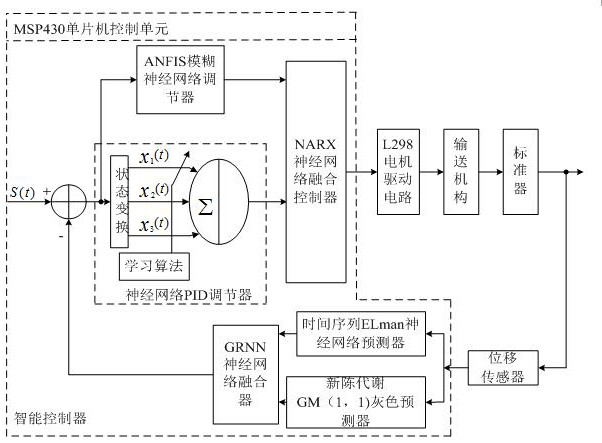

[0029] A kind of pipeline monitoring system based on neural network in the present embodiment, such as Figures 1 to 3 As shown, it mainly consists of a main body tube 1, a standard device placement tube 6, a standard device bracket 8 installed at the mouth of the standard device placement tube 6, a delivery mechanism for controlling the standard device bracket 8, and a standard for controlling the displacement of the standard device. The two ends of the main pipe 1 are respectively connected with the movable joint 2 and the fixed joint 5 which can be threadedly connected with both sides of the detection part of the pipeline to be tested; the bottom end of the standard place pipe 6 is connected with the main pipe 1 The middle part of the standard is connected, and the probe of the standard is installed in the standard placement tube 6 through the standard bracket 8 downward. During measurement, the standard is placed in the installation collar 11 , and the probe of the standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com