Method for evaluating service life of metallic structure of offshore platform crane

A metal structure and life evaluation technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems affecting mechanism movement, low detection efficiency, improper wiring, etc., to ensure normal use, improve detection efficiency, The effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

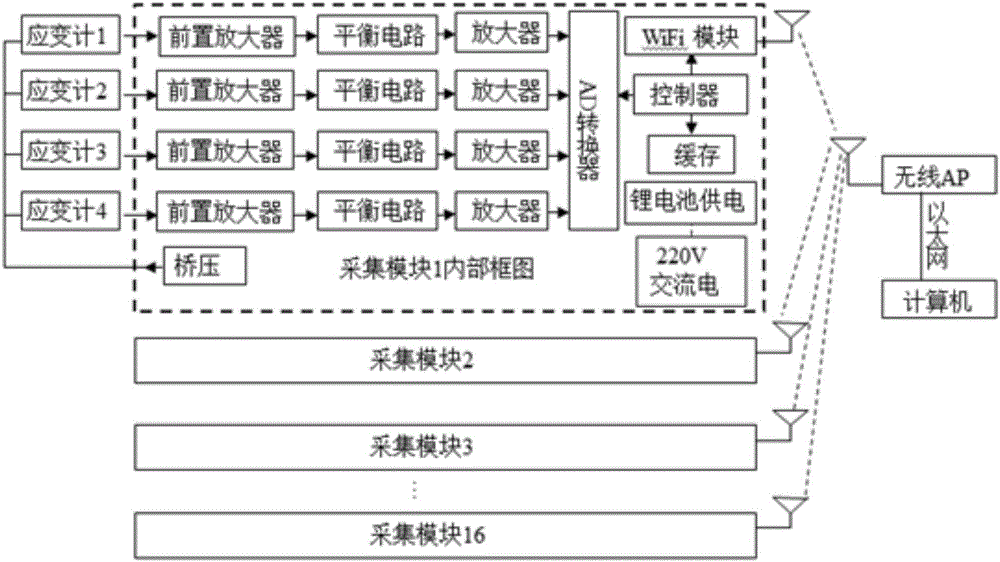

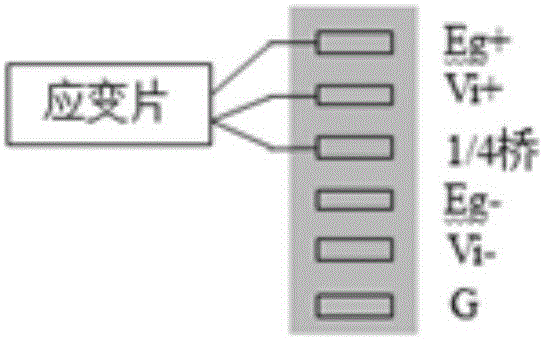

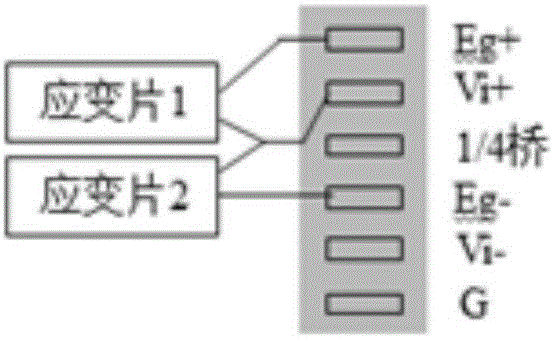

[0034] The present invention welds the corresponding strain gauges on the weak part of the metal structure of the offshore platform crane, and then connects multiple wireless dynamic strain acquisition modules (wireless dynamic strain gauges). The wireless dynamic strain gauges realize dynamic The signal transmission between the strain signal and the laptop computer, and then the computer processes the stress time history data obtained by rainflow counting within a fixed time to obtain the load spectrum of the component, and calculates the fatigue damage accumulation and remaining life of the component combined with the P-S-N curve of the component.

[0035] In the present invention, the weak point of the metal structure of the crane refers to the weak point of the metal structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com