IGBT module life prediction method under non-stationary working condition

A technology of life prediction and life prediction model, which is applied in the direction of single semiconductor device testing, special data processing applications, instruments, etc., and can solve problems such as poor prediction accuracy of life prediction models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following, the present invention will be further described in detail in conjunction with the accompanying drawings and the IGBT junction temperature prediction method under non-stationary working conditions.

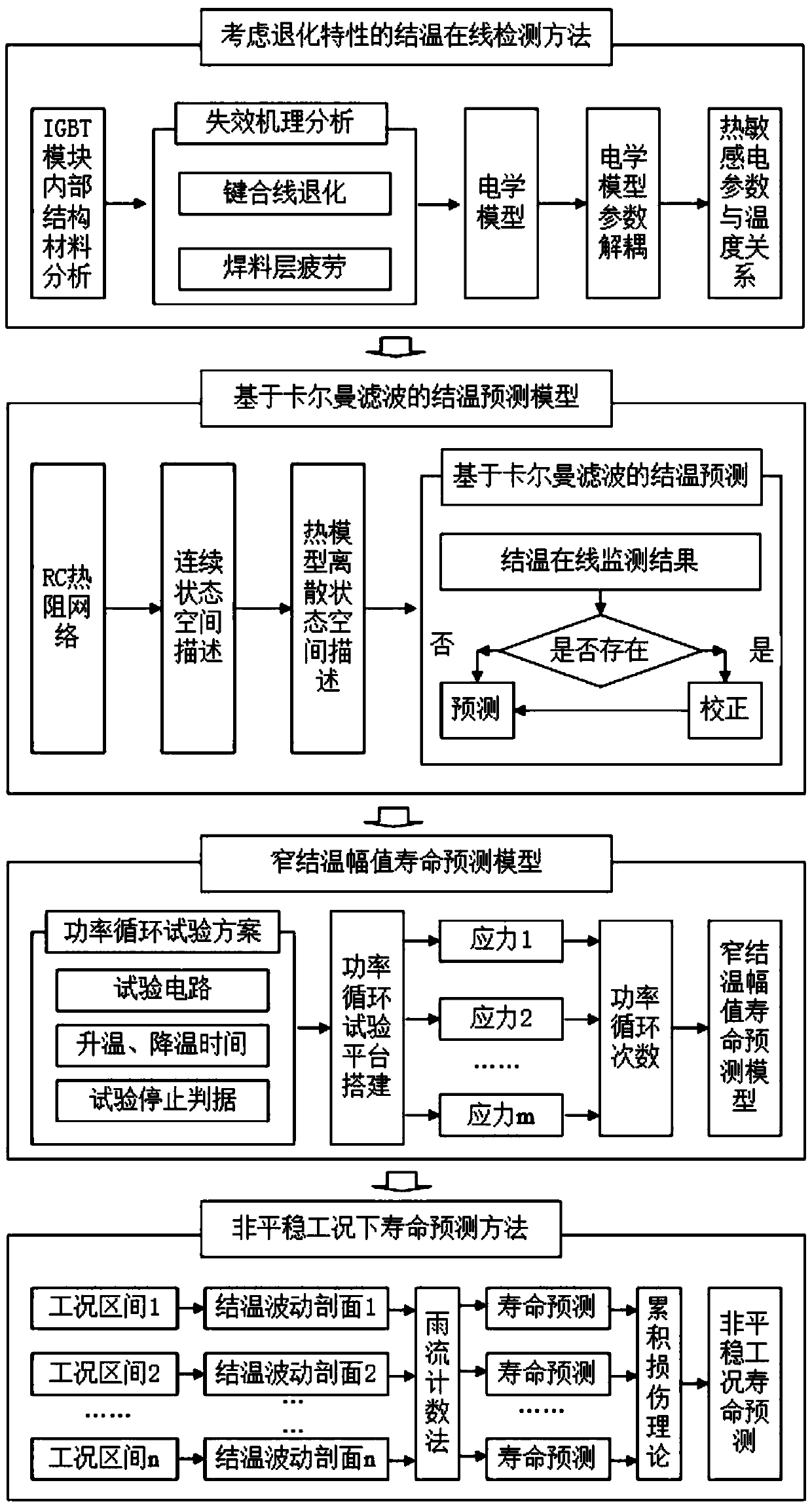

[0040] The invention discloses a method for simulating the extreme low temperature characteristics of a typical CMOS device, and the specific steps are as follows:

[0041] Step 1: Investigation of the degradation mechanism of the IGBT module

[0042]The degradation mechanism of the IGBT module can be divided into the degradation mechanism related to the chip (such as time-dependent dielectric breakdown, electromigration and aluminum metallization reconstruction, etc.) and the degradation mechanism related to the module package. Chip-related degradation is usually related to semiconductor physics, which is caused by internal defects in silicon materials and eventually leads to device degradation and failure. Although this failure is different from the degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com