High-temperature creep deformation prediction and creep damage analysis method for high-chrome steel component

A high-temperature creep and analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as consumption, large computing resources, and difficult determination of material parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be further described below in conjunction with specific embodiments.

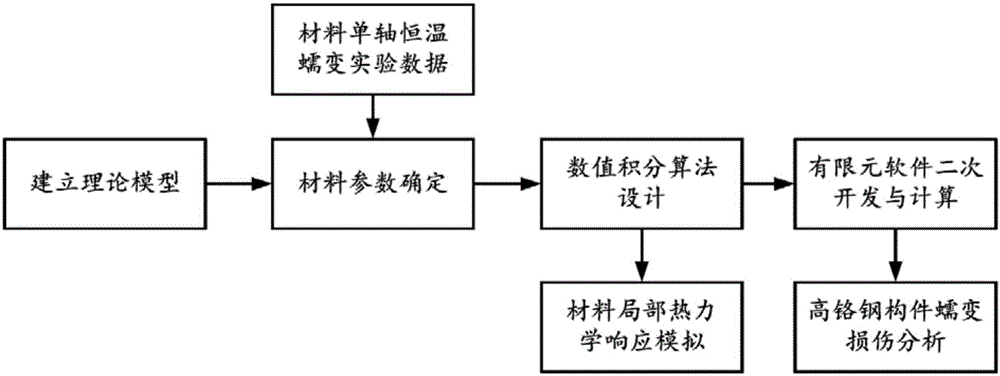

[0098] The invention aims at proposing a systematic solution for high-temperature creep deformation prediction and creep damage analysis of high-chromium steel components. The content of the scheme includes the establishment of theoretical models, the determination of material parameters, the design of numerical integration algorithms, the secondary development of finite element software, and the analysis of creep damage of components, etc. The program will pass figure 1 The implementation of the technology roadmap shown specifically includes the following steps:

[0099] 1) Establish a new material constitutive model, that is, a theoretical model, to simulate the thermodynamic response of high-chromium steel materials in the entire creep process (including three stages), and to analyze the creep damage of materials.

[0100] The theoretical model established is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com