Stress-relieving device for seamless rails by using vibration method

A seamless steel rail and stress relief technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of the overall weight of the impact equipment, large impact force, inaccurate measurement results, etc., to achieve real-time monitoring, improve impact efficiency, Measuring Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

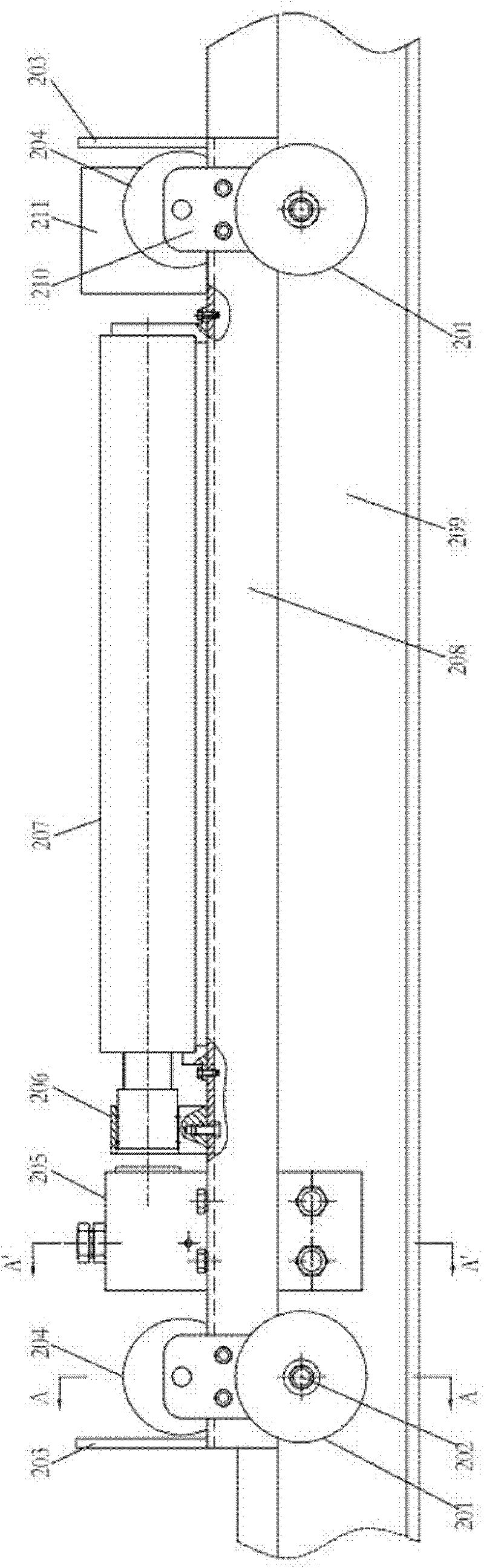

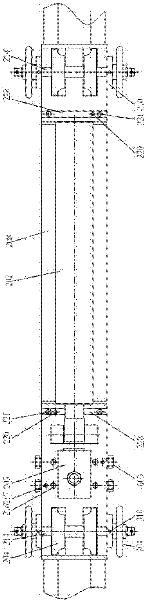

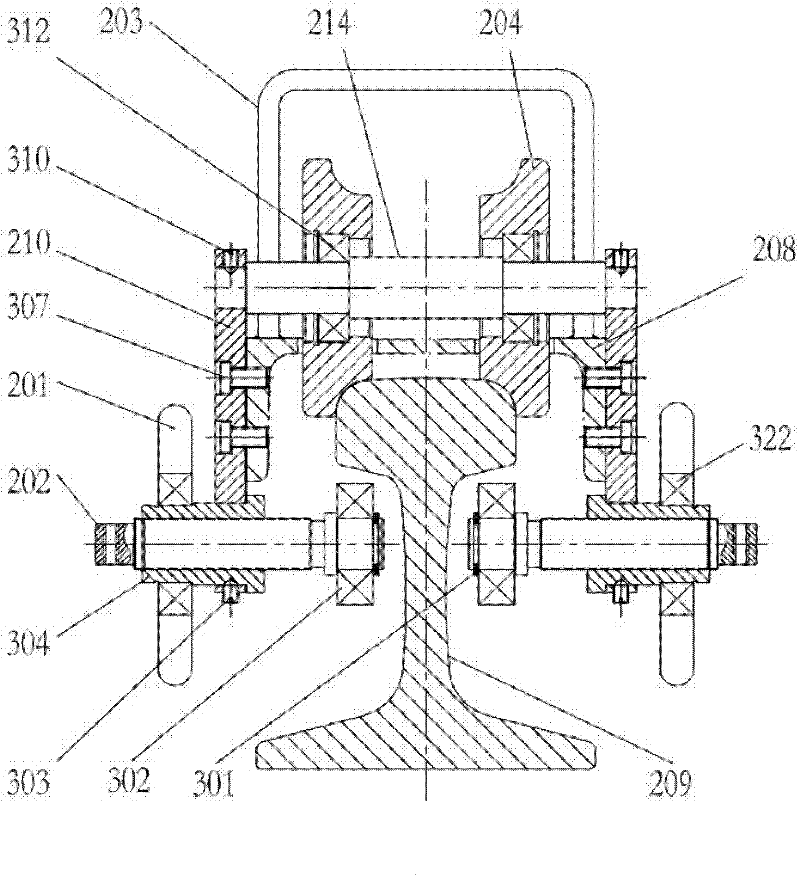

[0023] Markings in the attached drawings:

[0024] attached figure 1 , 201—hauling wheel, 202—anti-covering wheel shaft, 203—handle, 204—traveling wheel, 205—clamp body, 206—guiding support block, 207—impact gas-hydraulic booster cylinder, 208—channel steel, 209— Rail, 210—rely on cladding plate, 211—side plate.

[0025] attached figure 2Among them, 214—walking axle, 216—bolt, 217—pin, 220—pin, 221—bolt, 228—fixed plate, 310—positioning hole, 603—bolt.

[0026] attached image 3 , attached Figure 4 Among them, 301—circlip, 302—anti-covering wheel, 303—locating pin, 304—anti-covering wheel axle sleeve, 307—bolt, 312—traveling wheel bearing, 322—hauling wheel bearing.

[0027] attached Figure 5 In, 401—impact rod, 402—flange, 406—oil chamber, 408—oil chamber, 409—piston, 410—air pressure chamber, 411—flange with holes, 412—air pressure chamber, 413—piston rod, 414—air pressure chamber, 415—flange with holes, 416—air pressure chamber, 417—base flange, 418—air hole, 420—...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com