Method for measuring polymer-base foam material elastic modulus by displacement sensor

A technology of displacement sensors and foam materials, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, and analyzing materials. It can solve the problems of small temperature range, large volume, and only one-time use. The effect of high accuracy and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Measuring the compressive elastic modulus of a kind of PEI foam at room temperature:

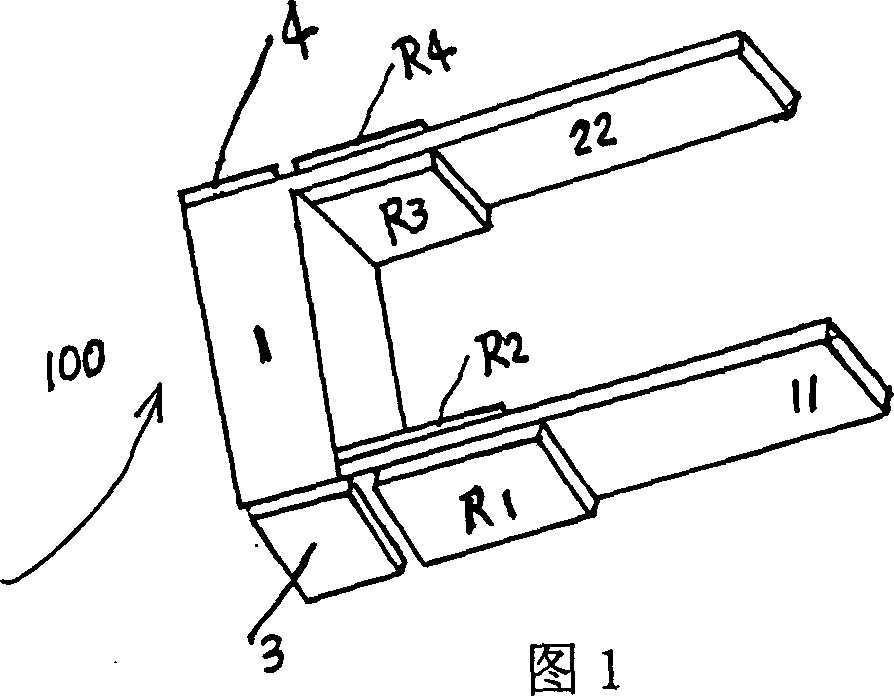

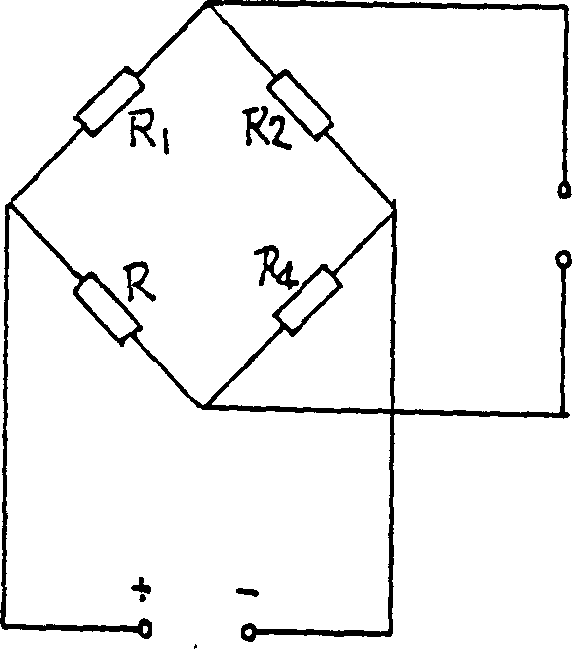

[0025] The displacement sensor (the resistance value of the strain gauges R1, R2, R3 and R4 connected to the Wheatstone bridge circuit is 120), the fixture and the sample are assembled as image 3 Shown:

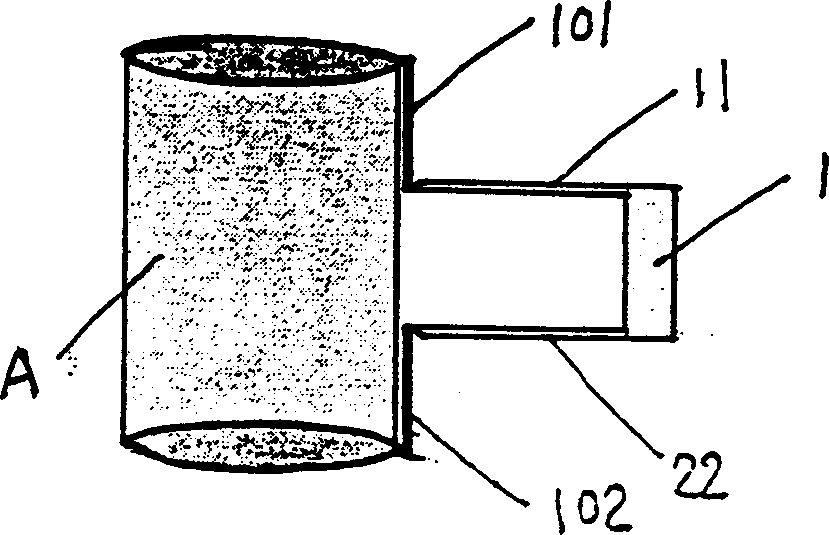

[0026] First, according to the measurement area of the sample to be tested, a connecting piece 101 and 102 (fixture) perpendicular to the clamp arm 11 and the end of the clamp arm 22 are respectively fixedly connected, and then the connecting pieces 101 and 102 are respectively connected to the end of the clamp arm 22 to be measured. The two ends of the side wall of the measuring area of the cylindrical polymer foam material are connected (such as image 3 Shown); the connecting wire of the Wheatstone bridge circuit in the displacement sensor is connected to an external strain gauge, which is connected to a computer (strain gauge and computer, not shown in the figure, and...

Embodiment 2

[0028] Example 2: Measuring the tensile elastic modulus of a kind of PEI foam plastic in liquid nitrogen temperature zone:

[0029] A connecting piece 101 and 102 perpendicular to the clamp arm 11 and the end of the clamp arm 22 of the displacement sensor are respectively fixedly connected, and then the connecting pieces 101 and 102 are connected to the side wall of the cylindrical polymer foam material A to be measured Connected in the middle (e.g. Figure 4 Shown); After assembling the displacement sensor, the displacement sensor fixture and the sample Figure 4 Shown: The connecting wire of the Wheatstone bridge circuit in the displacement sensor is connected to the external strain gauge, and the strain gauge is connected to the computer (strain gauge and computer, not shown in the figure, and the connection should be understood by those skilled in the art ). The tested foam material is dumbbell-shaped and has the same properties as the material used in Example 1. Using displacem...

Embodiment 3

[0031] Example 3, measuring the compressive elastic modulus of a kind of PEI foam plastic in liquid hydrogen temperature zone:

[0032] Displacement sensor, displacement sensor fixture and specimen are the same after assembly image 3 , Use liquid helium and temperature control equipment to achieve liquid hydrogen temperature (20K). The test materials are the same as the test materials of Examples 1 and 2. The compressive elastic modulus of the material liquid hydrogen temperature is shown in Table 3. The sample numbers in Table 3 represent four samples of the same material, and the average value of the compressive elastic modulus of the four samples is the compressive elastic modulus of the material (the standard deviation is 2.63).

[0033] Sample No

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com