Position and pressure master-slave control method of hydraulic servo system of valve-controlled cylinder

A hydraulic servo system and valve control technology, applied in the direction of fluid pressure actuating system components, fluid pressure actuating devices, mechanical equipment, etc. System control accuracy and the effect of improving system control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

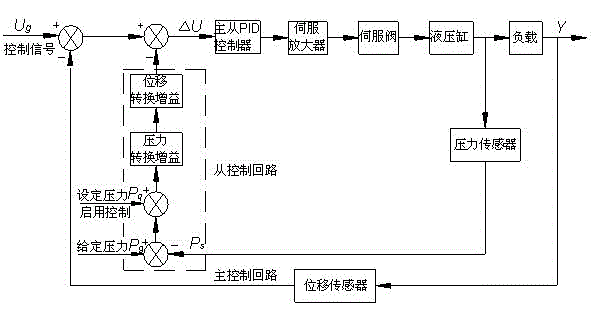

[0022] like figure 1 As shown, in the valve-controlled cylinder hydraulic servo system, the position signal and the pressure signal are two control signals, the position signal is used as the main feedback signal of the whole system, and the position control is used as the main closed-loop control of the whole system; the pressure signal is used as the slave control signal, Pressure feedback control acts as a slave closed-loop control. When the load of the actuator reaches the master-slave control pressure setting range, the position and pressure master-slave control of the valve-controlled cylinder hydraulic servo system starts, and the actual pressure feedback signal measured by the pressure sensor with given control pressure The electrical signal is compared with the pressure deviation signal obtained, the deviation signal is multiplied by the pressure conversion gain and converted into a position deviation signal, the position deviation signal is adjusted by the displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com