Semiconductor micro air pressure sensor test system

A test system and micro-pressure technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve problems such as difficult to achieve vacuum dynamic balance, unstable vacuum gas components, single test circuit, etc., to achieve stable air flow, gas group The effect of stable and uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

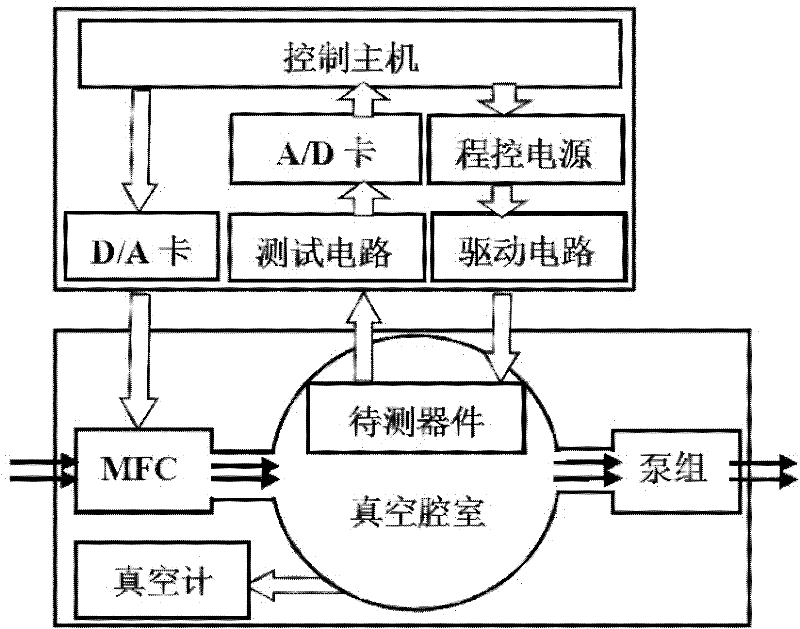

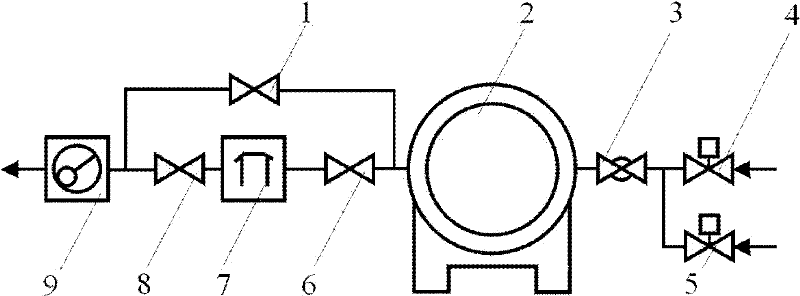

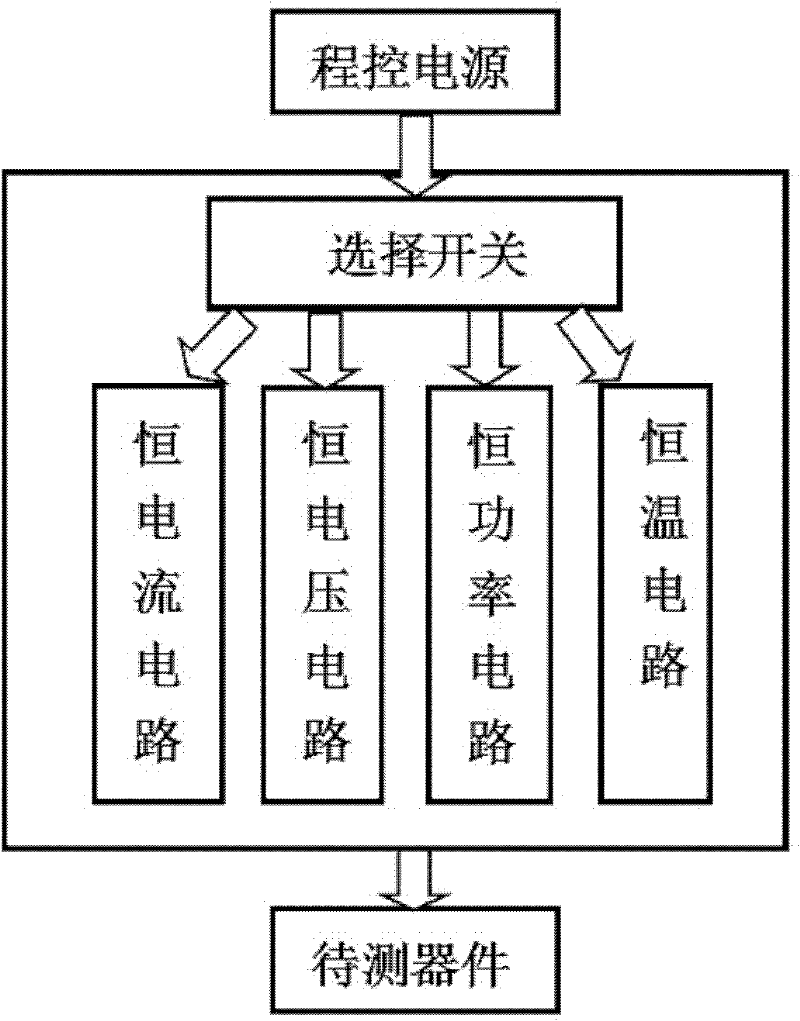

[0019] Embodiment: a kind of semiconductor micro pressure sensor testing system of the present embodiment, as figure 1 As shown, including the microcomputer control part and the vacuum acquisition part. The microcomputer control part includes control host, program-controlled power supply, drive circuit, test circuit, A / D card and D / A card. The control host controls the program-controlled power supply, loads voltage or current to the drive circuit, and provides four working modes for the device under test. , the response signal of the device under test is transmitted to the control host through the test circuit and the A / D card; the vacuum acquisition part includes a vacuum chamber, a pump unit, a mass flow controller (MFC) and a vacuum gauge, and the vacuum chamber is connected with the mass flow control The gas with stable composition flows in from the mass flow controller and flows out from the pump group. The mass flow controller is connected with the D / A card. Through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com