Patents

Literature

31results about How to "Eliminate dependence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

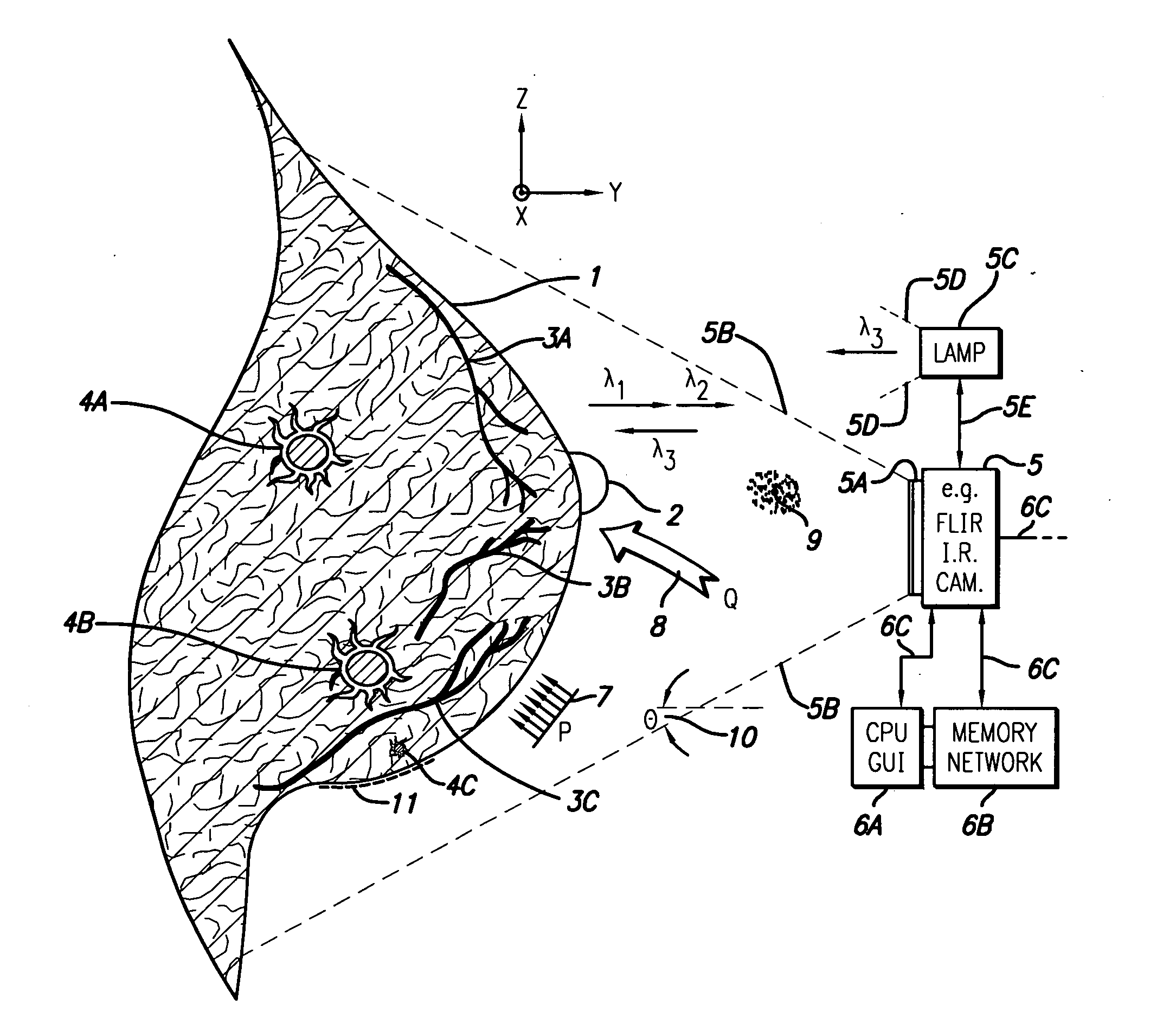

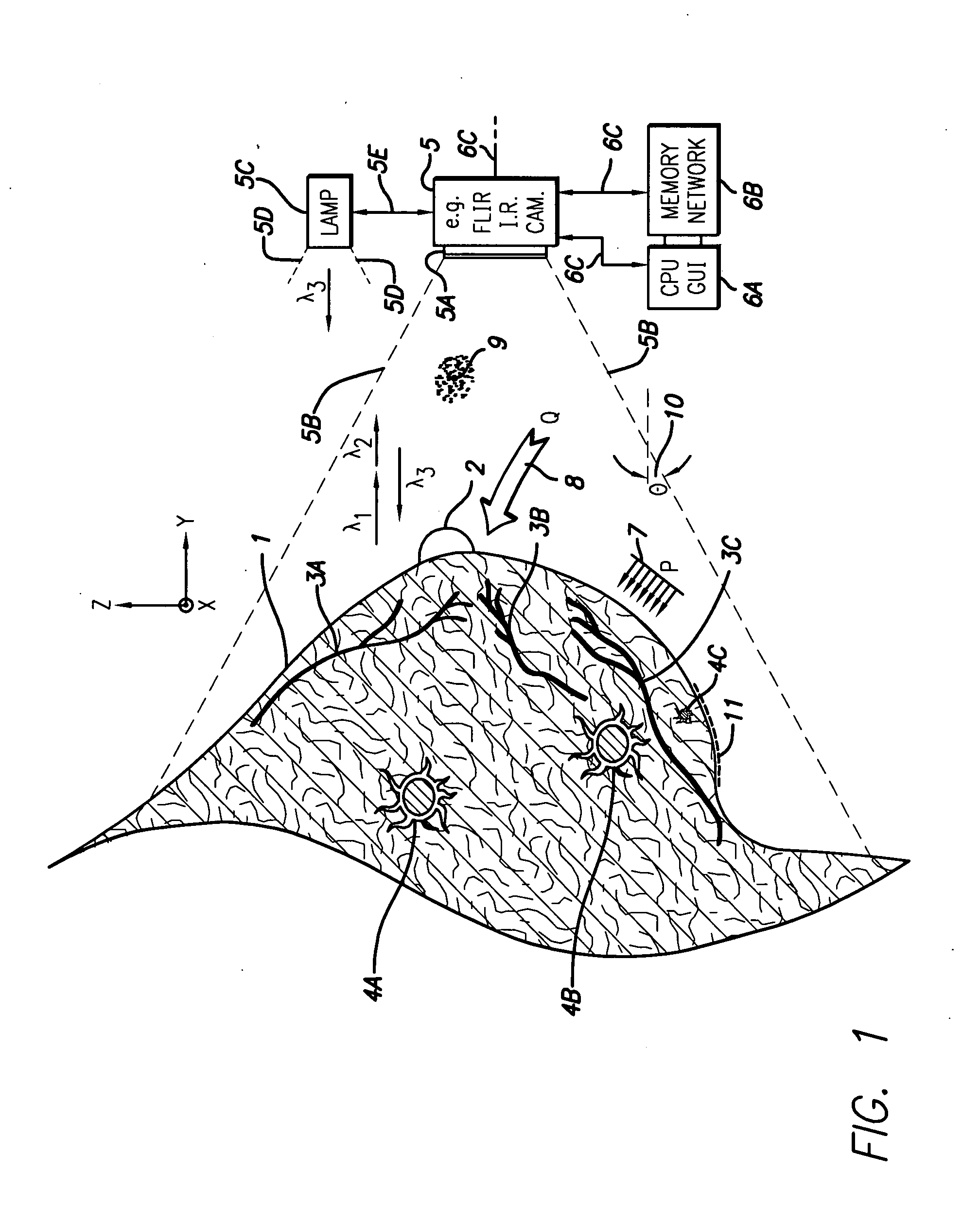

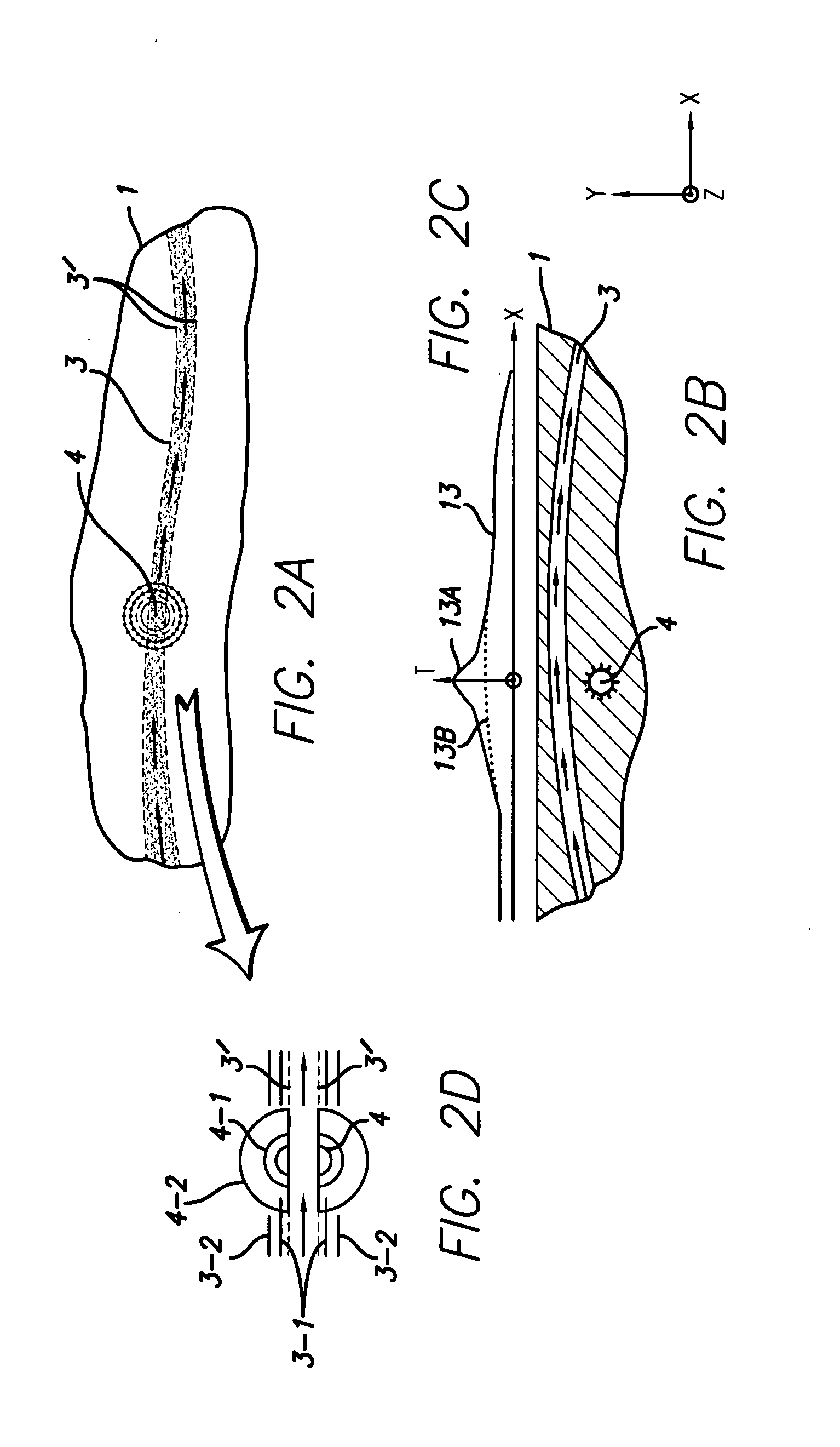

Infrared detection of cancerous tumors and other subsurface anomalies in the human breast and in other body parts

InactiveUS20070213617A1Limit it thermal contributionGood optical contactDiagnostic recording/measuringSensorsIr imageHeat flow

Apparatus and methods to further improve the performance of breast IR-imaging are provided, employing a combination of near-IR and mid-IR frequencies for detection of cancer and other types of subsurface defects. In addition, an IR transmissive or transparent window that can be IR-imaged through is disclosed that may also be utilized to one or both of distort the breast and / or manipulate an artificial heat-flow into or out of the breast.

Owner:BERMAN HERBERT L +2

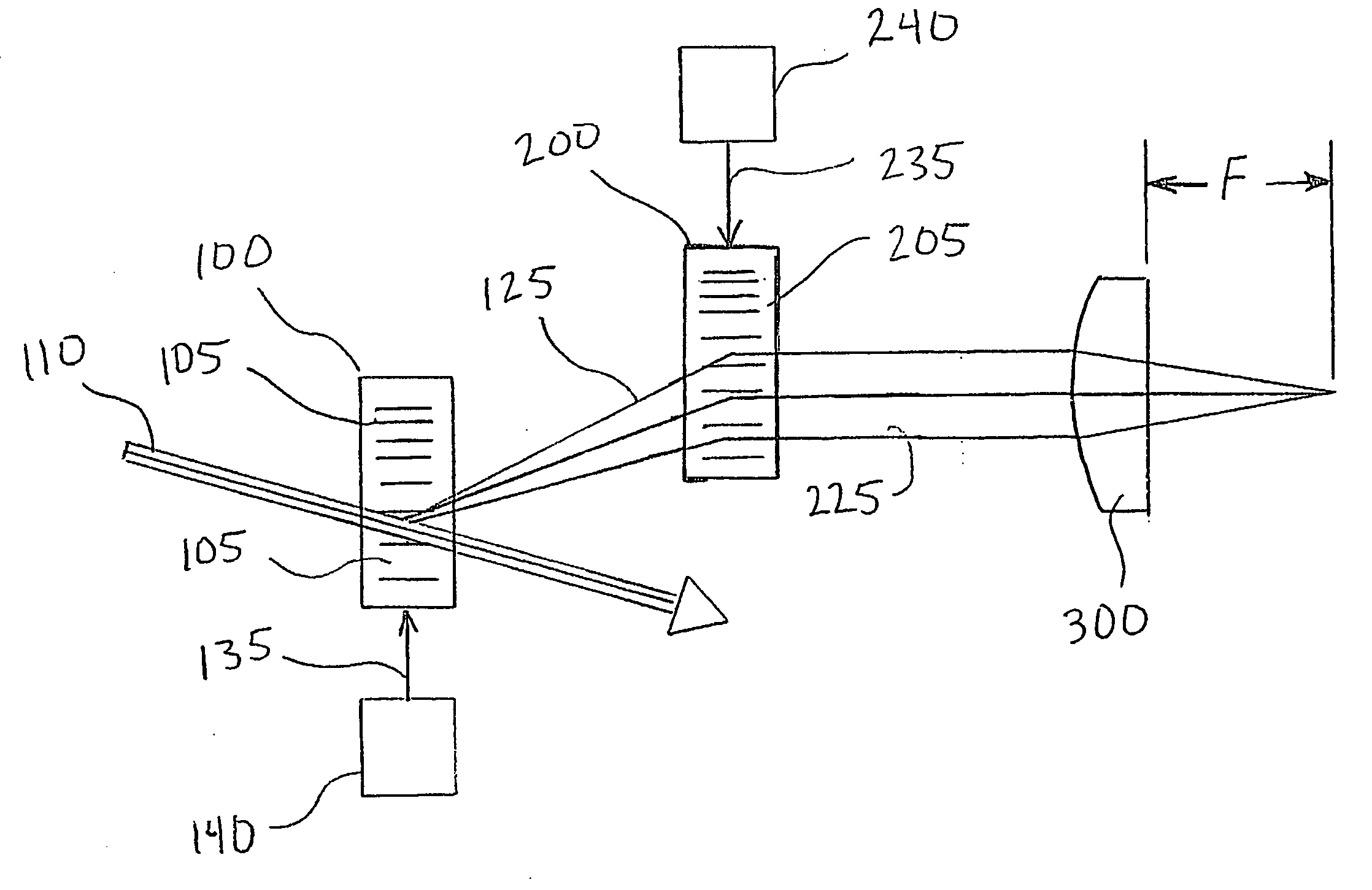

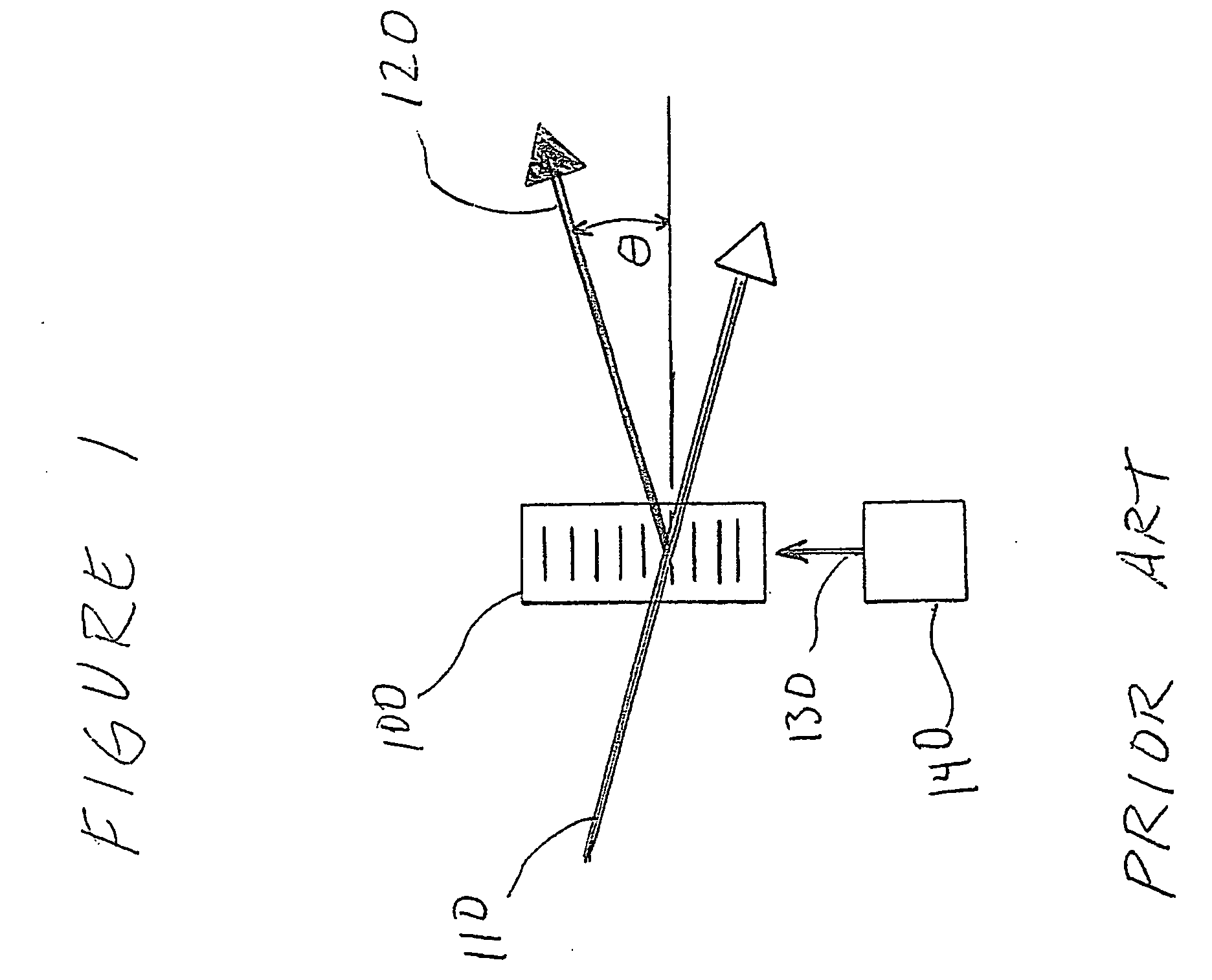

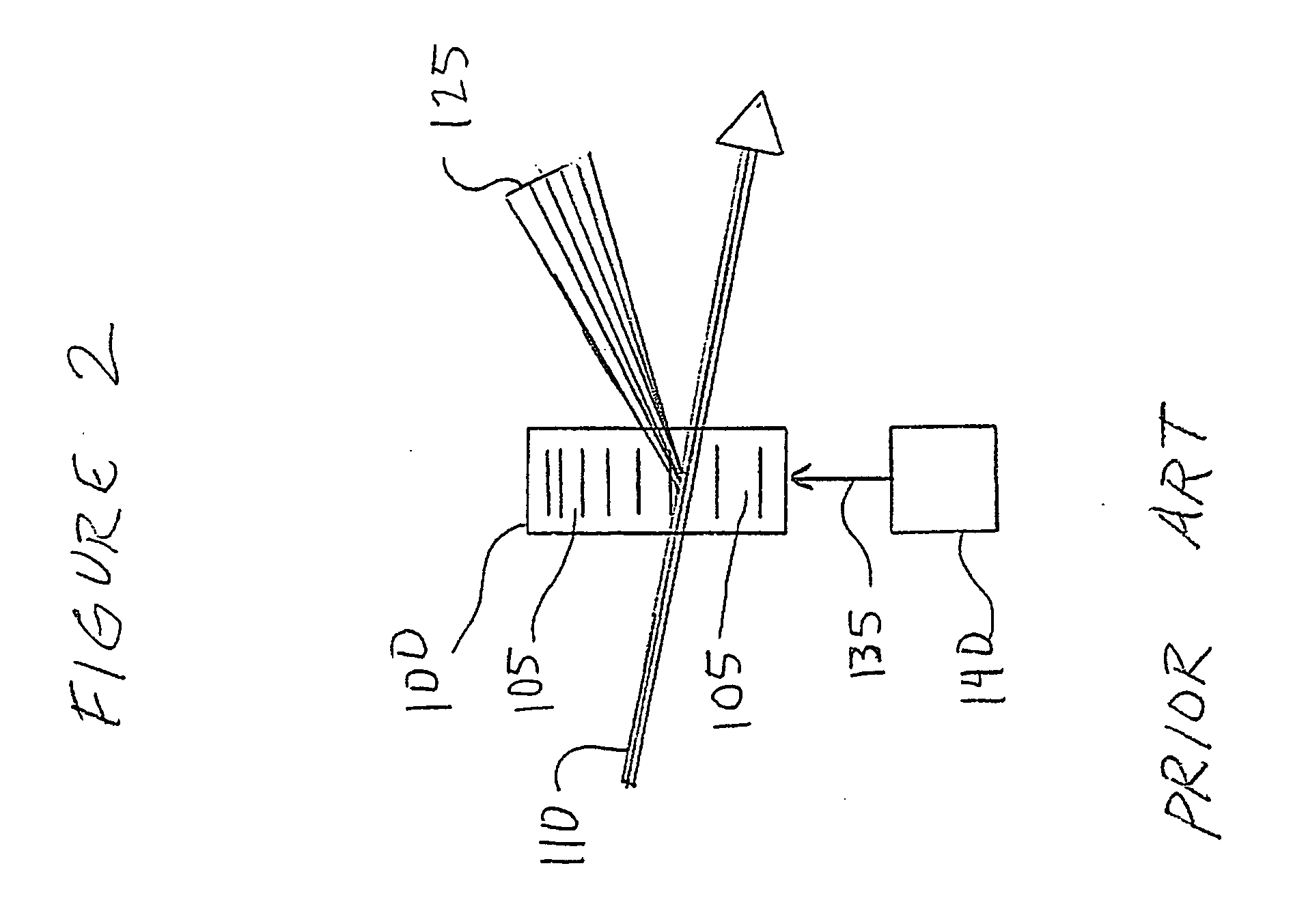

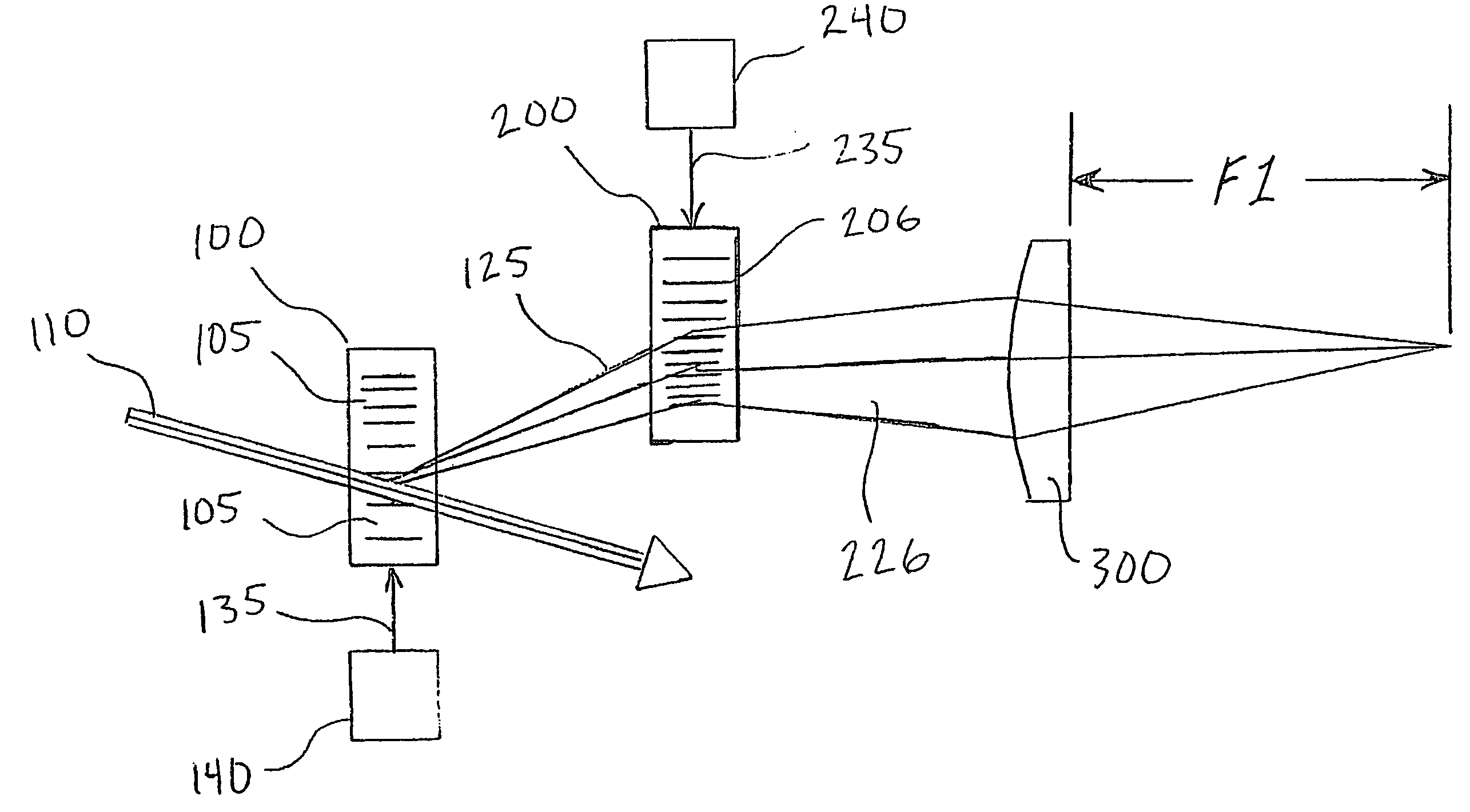

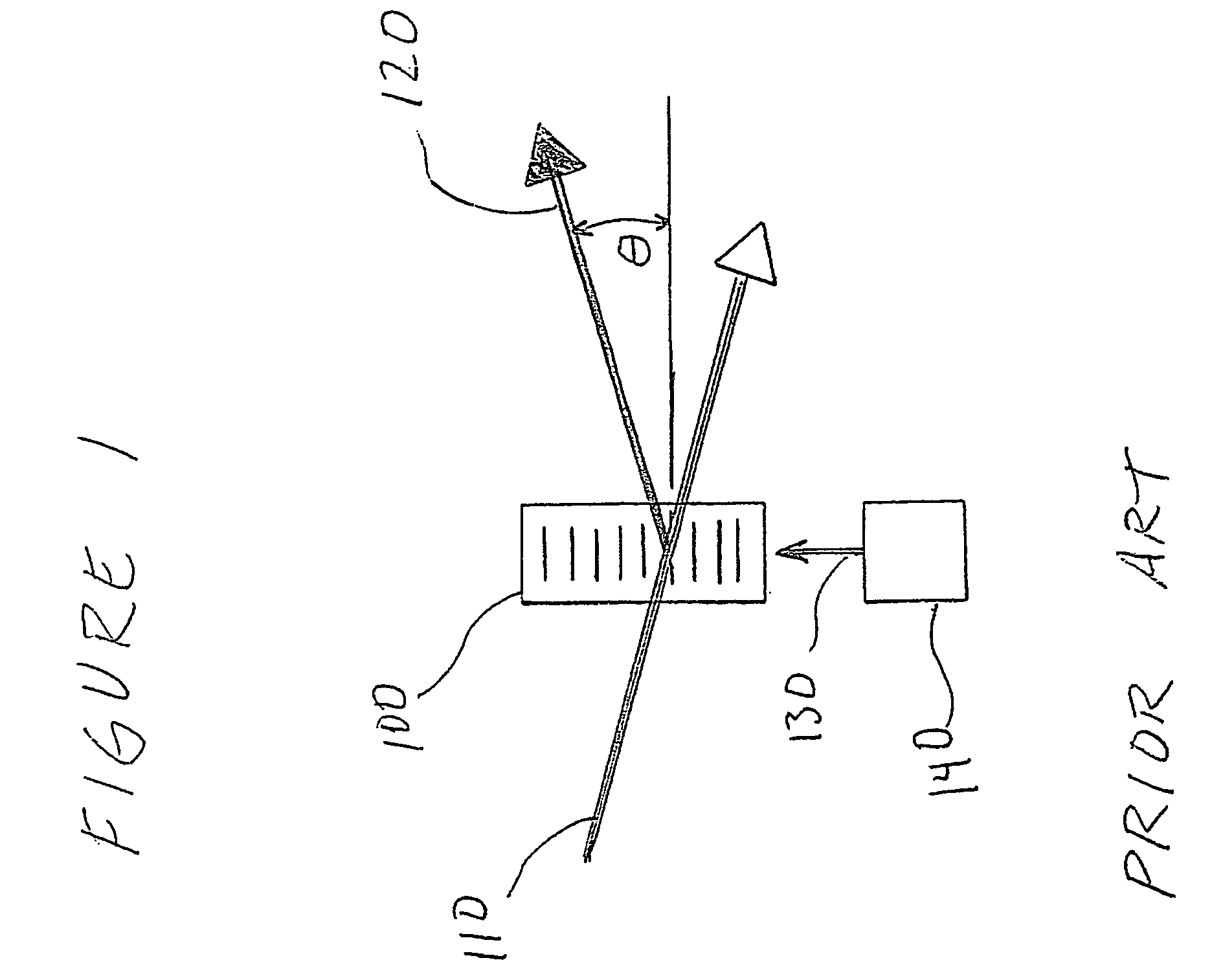

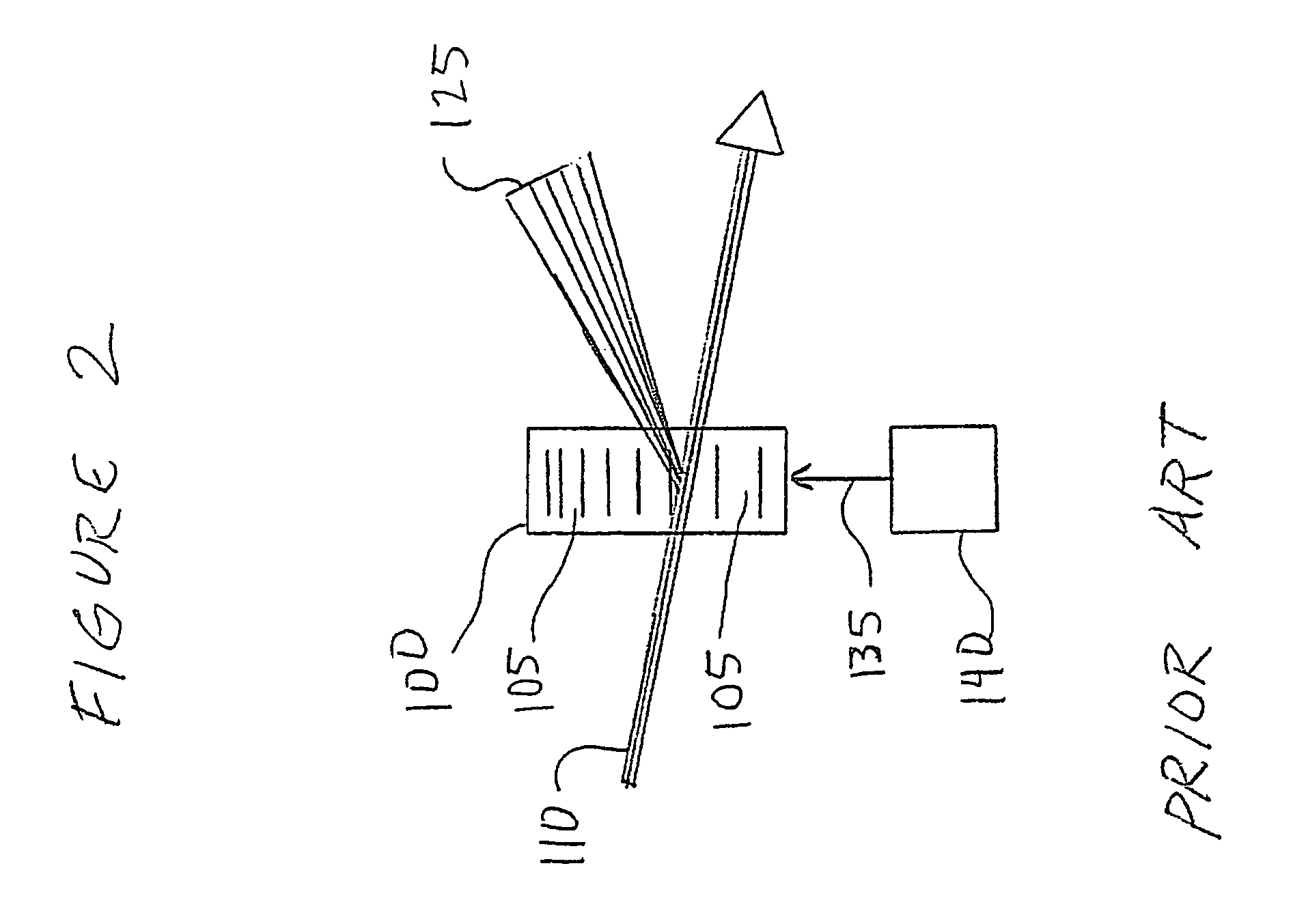

High speed microscope with three-dimensional laser beam scanning

InactiveUS20060071143A1Removes time dependenceFast scanningBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansAcousto optic deflectorLight beam

A system and method for independently controlling the collimation and lateral positioning of a light beam comprises at least one acousto-optic deflector and a pair of counter propagating acoustic waves with offset frequencies. While the frequency offset controls the lateral positioning of the light beam, a frequency gradient across the acousto-optic deflectors controls the collimation of the light beam.

Owner:BAYLOR COLLEGE OF MEDICINE

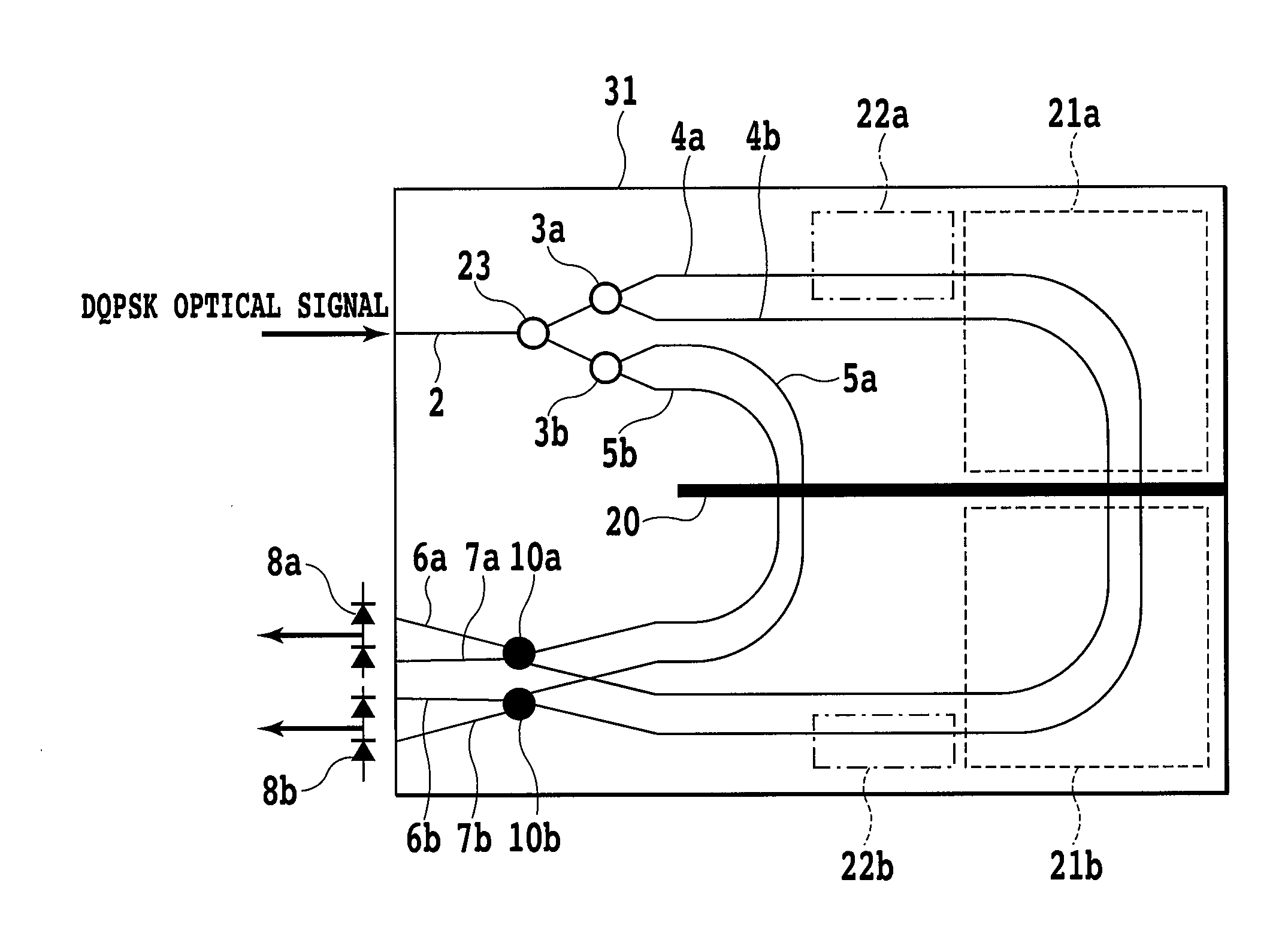

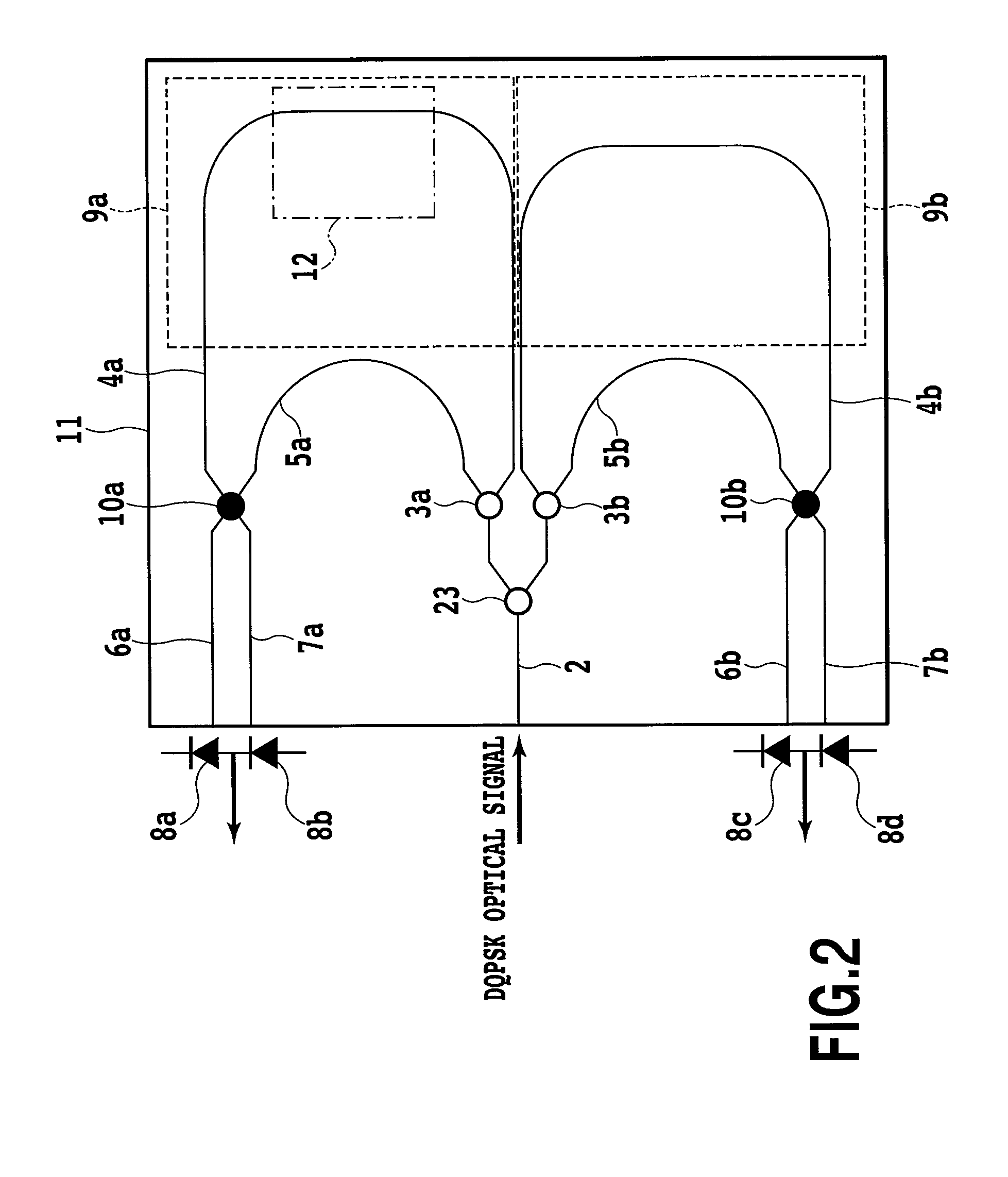

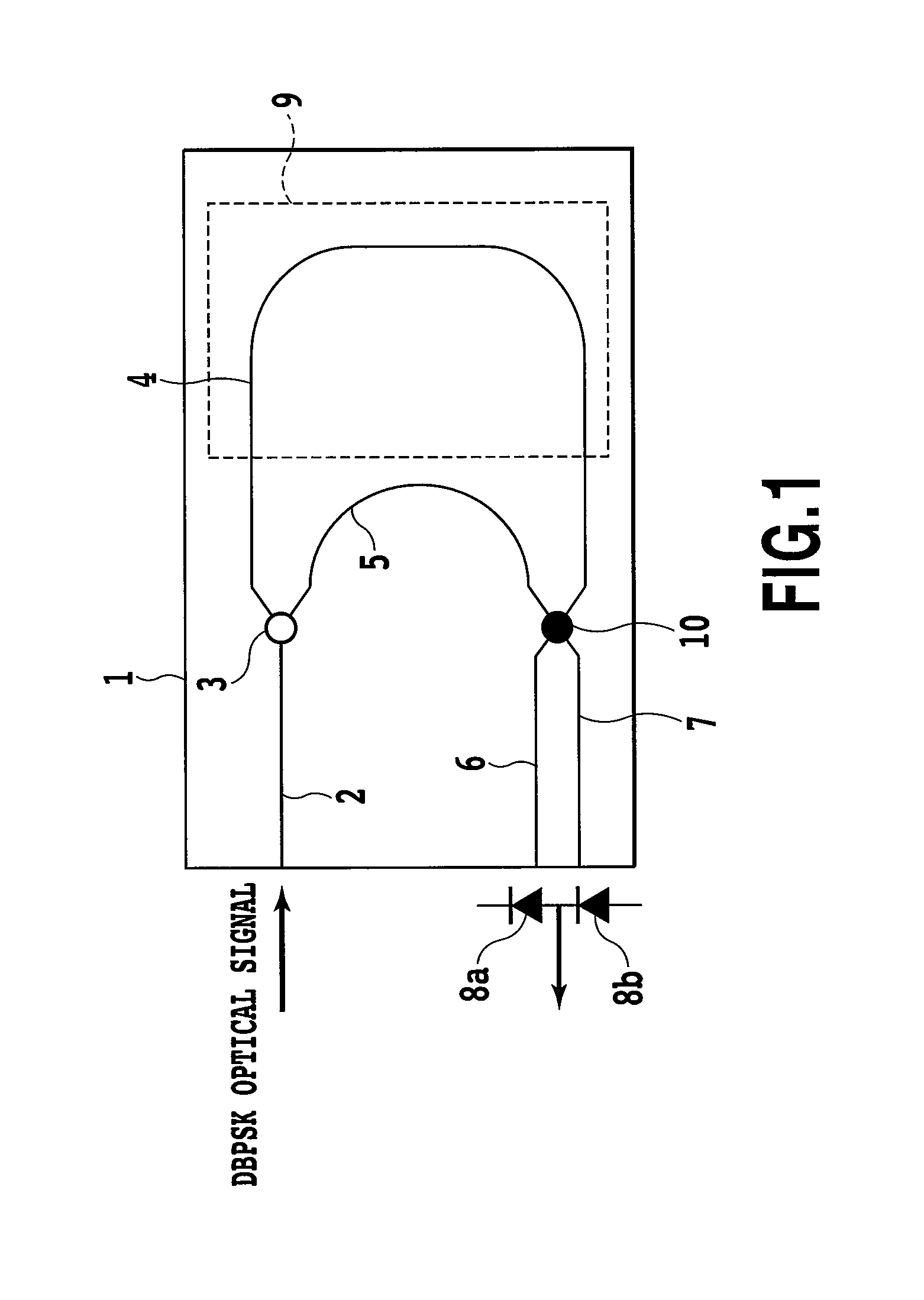

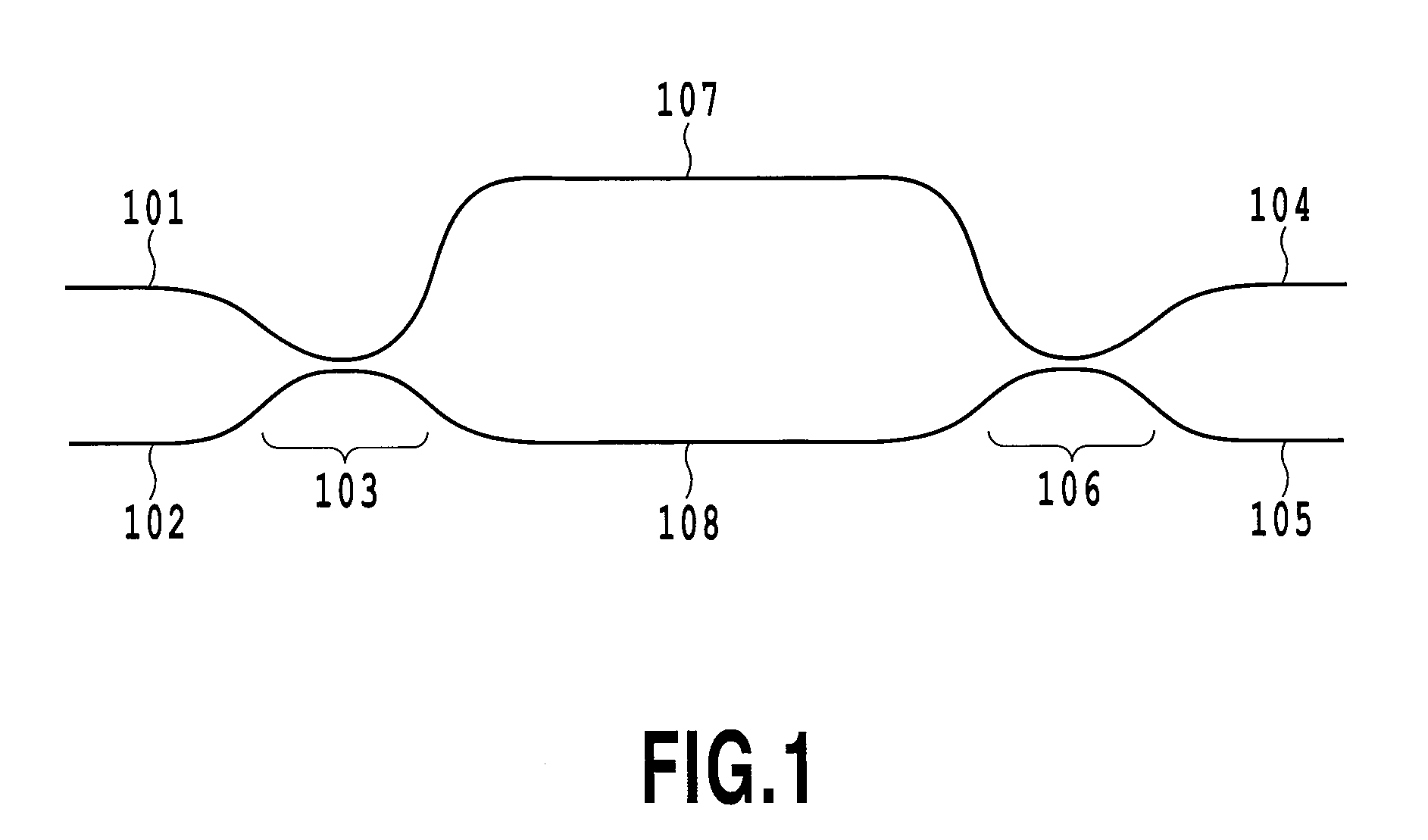

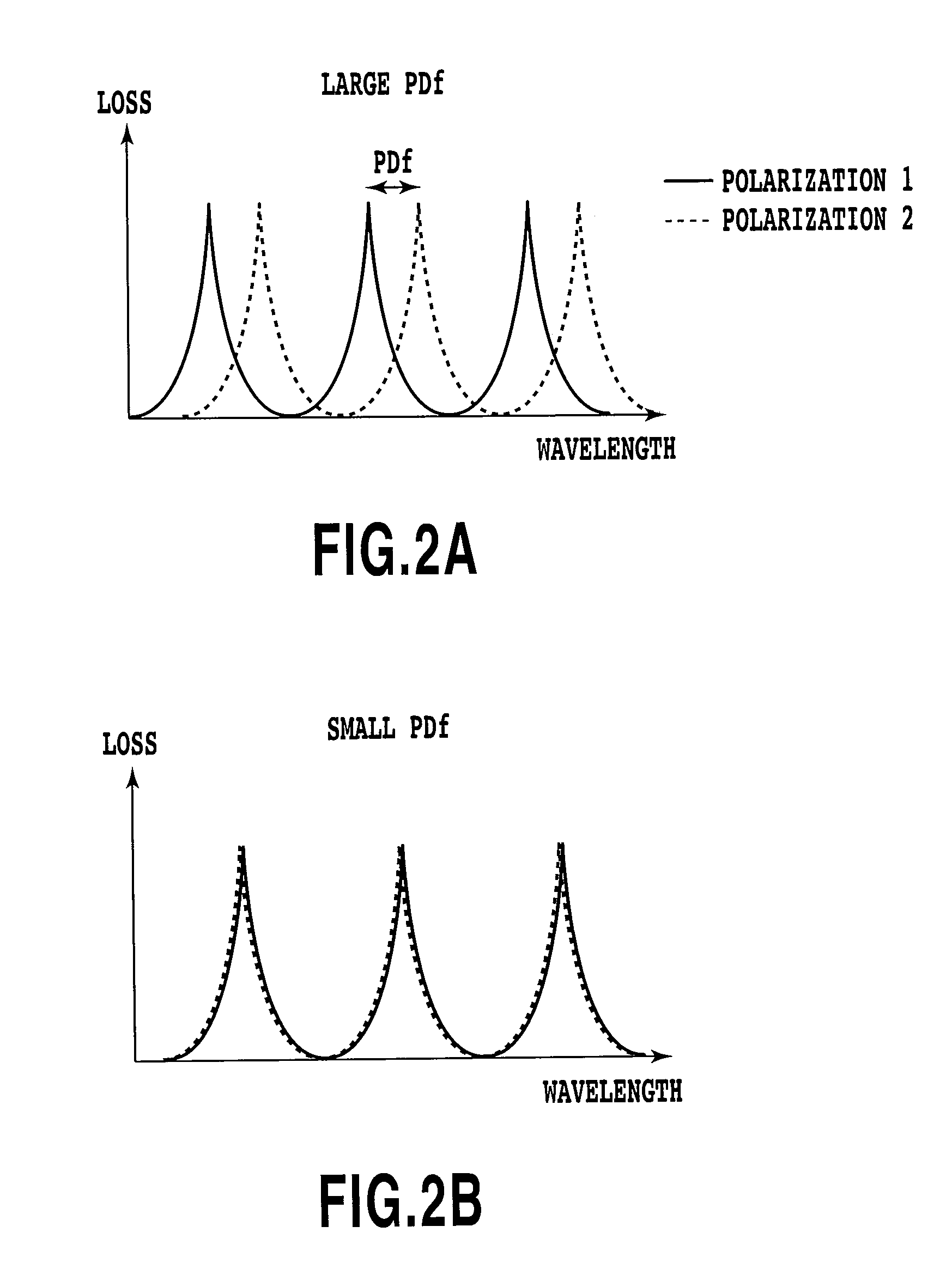

Optical delay line interferometer

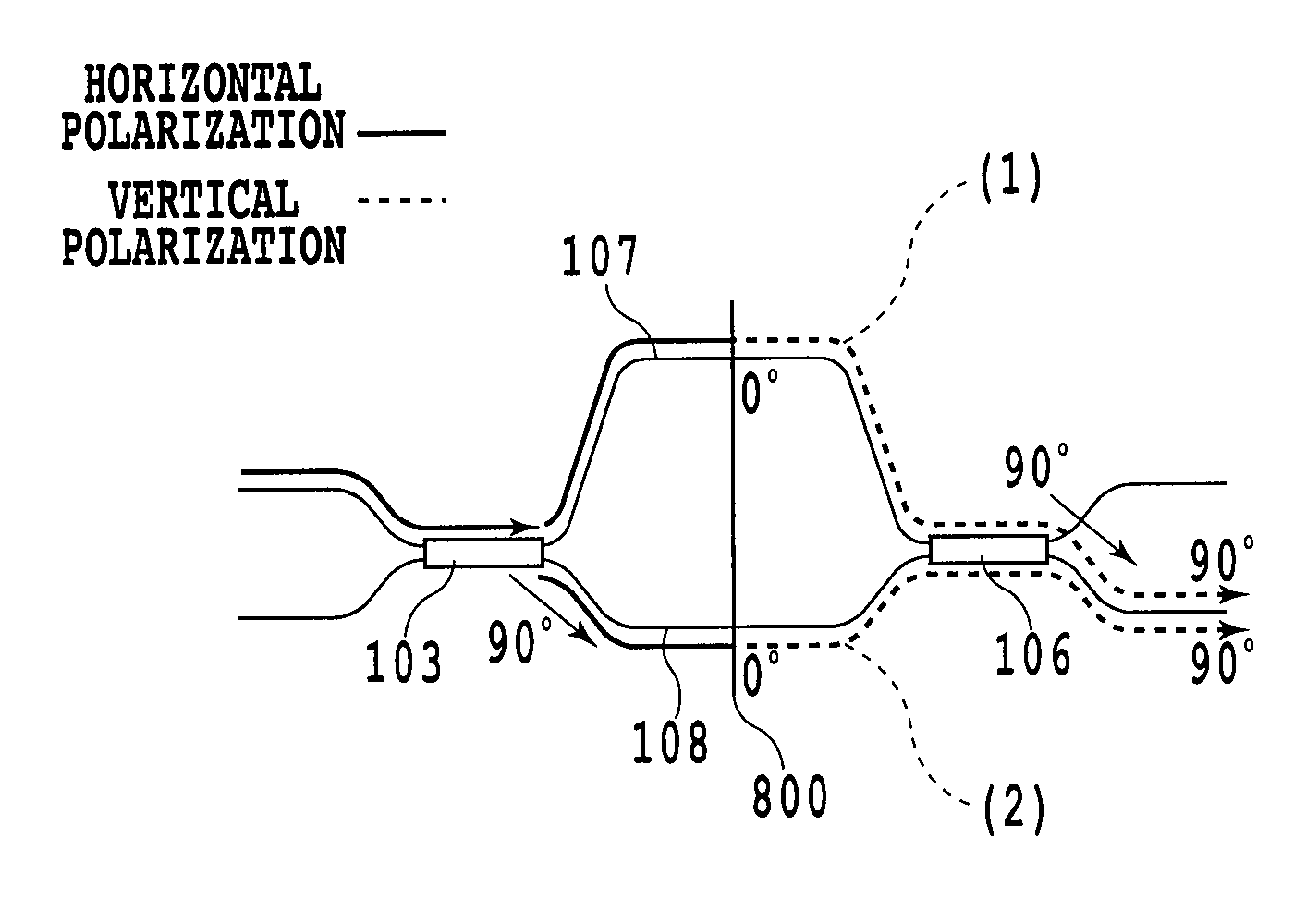

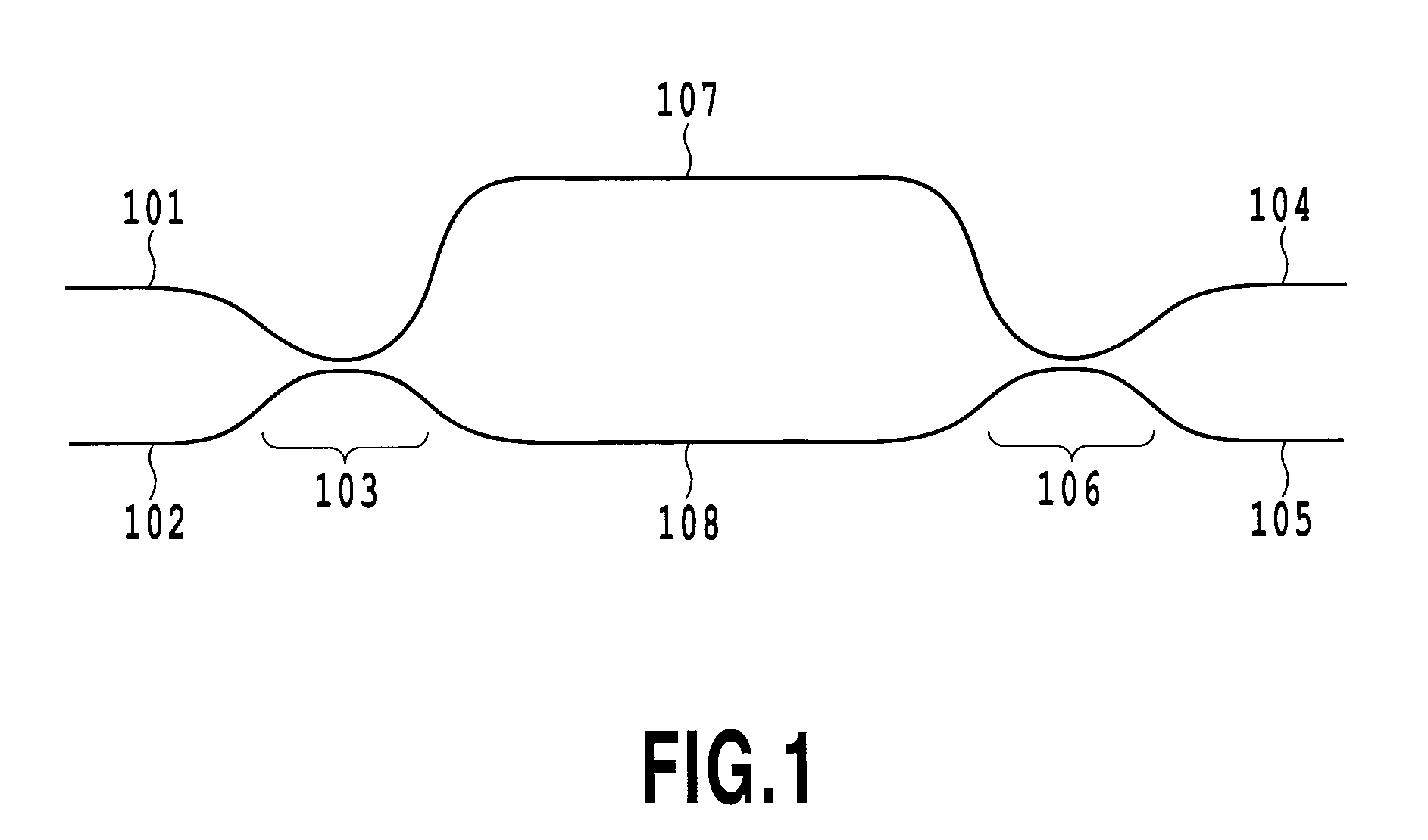

ActiveUS20100119189A1High symmetryImprove signal-to-noise ratioLight demodulationElectromagnetic receiversPhysicsPolarization coupling

A demodulator is provided for a multilevel differential phase shift keyed signal, capable of eliminating polarization dependence due to birefringence and polarization coupling-induced light resulting from a waveguide structure, and also, polarization dependence due to dynamic birefringence produced at the time of driving a variable phase adjuster. The demodulator is configured of an optical delay line interferometer of a waveguide interference type. The S / N ratio of a demodulated signal in the demodulator formed by the optical delay line interferometer can be also improved. Further, both the polarization dependence and the temperature dependence of the optical delay line interferometer can be reduced. The disposition of a polarization converter and groves filled with a temperature compensation material makes it possible to provide a circuit configuration suitable for eliminating the polarization dependence and the temperature dependence of the optical delay line interferometer.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

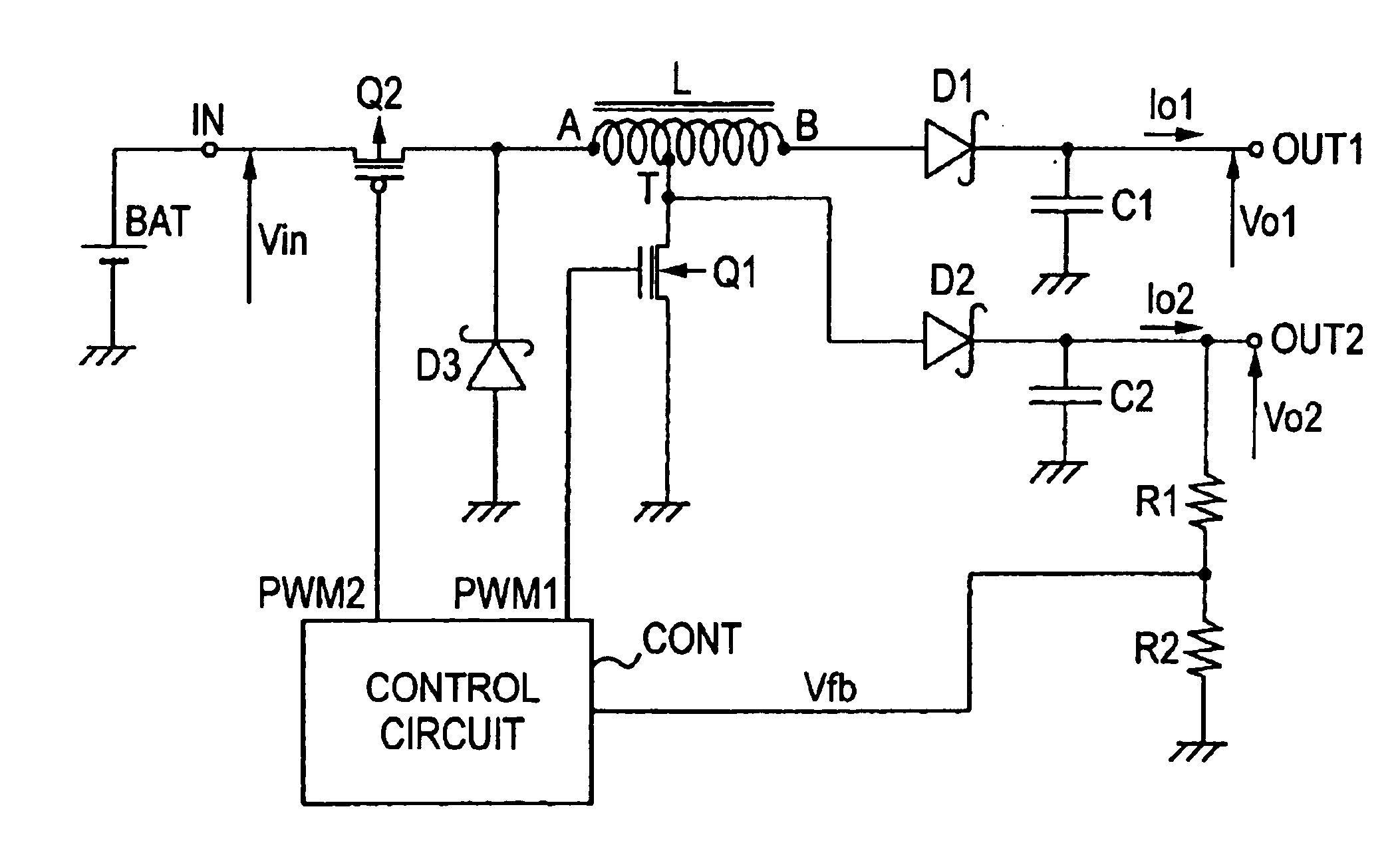

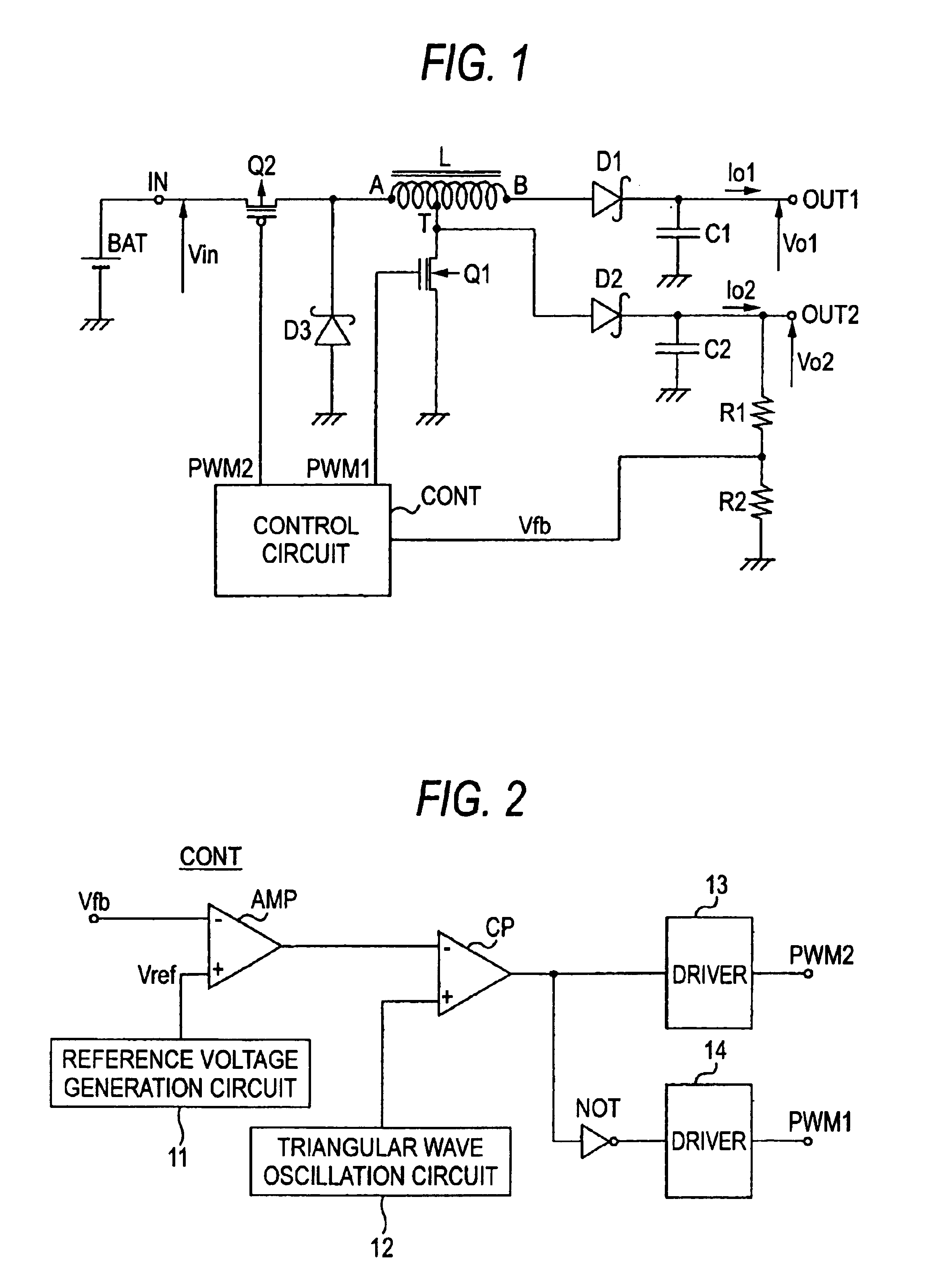

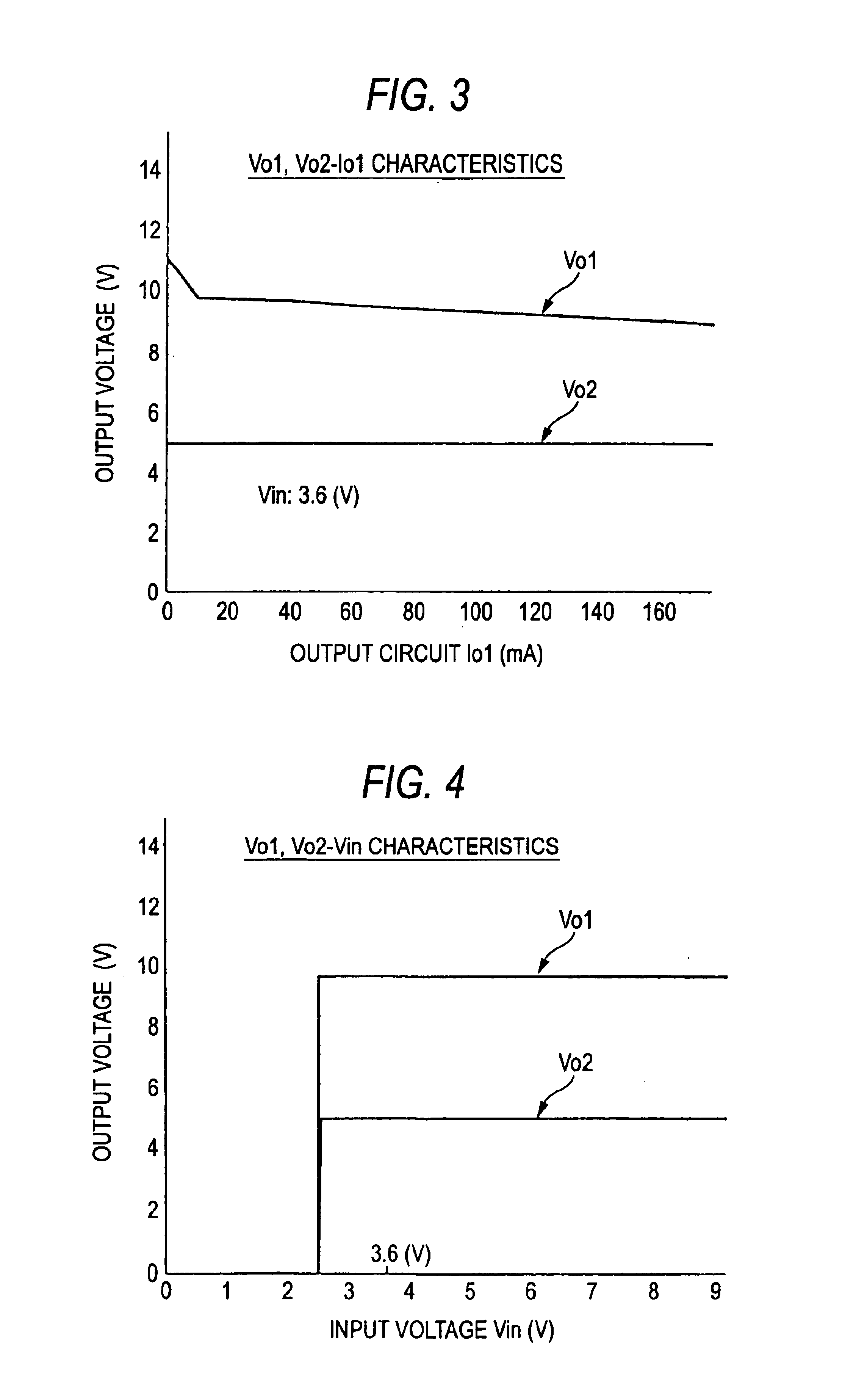

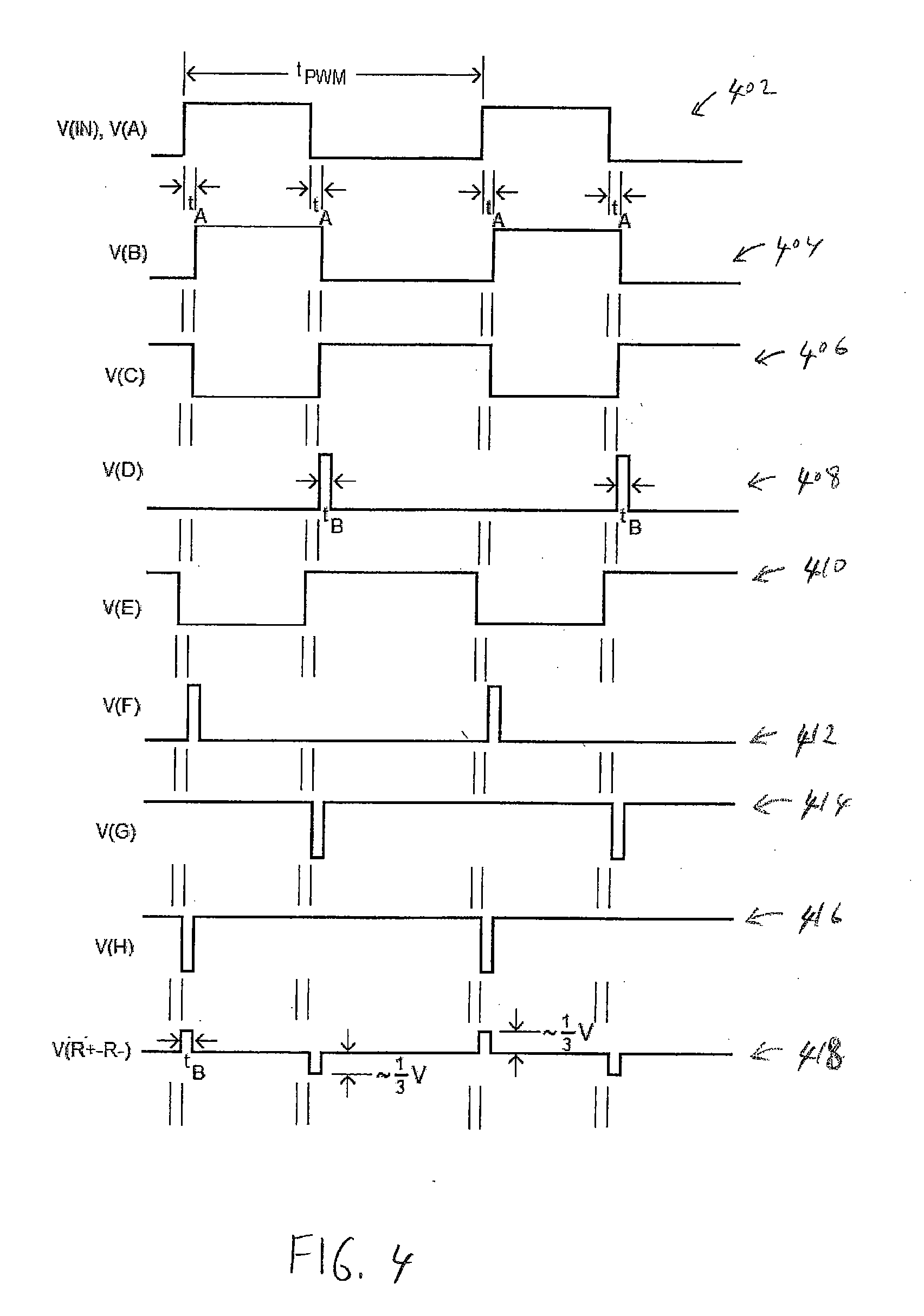

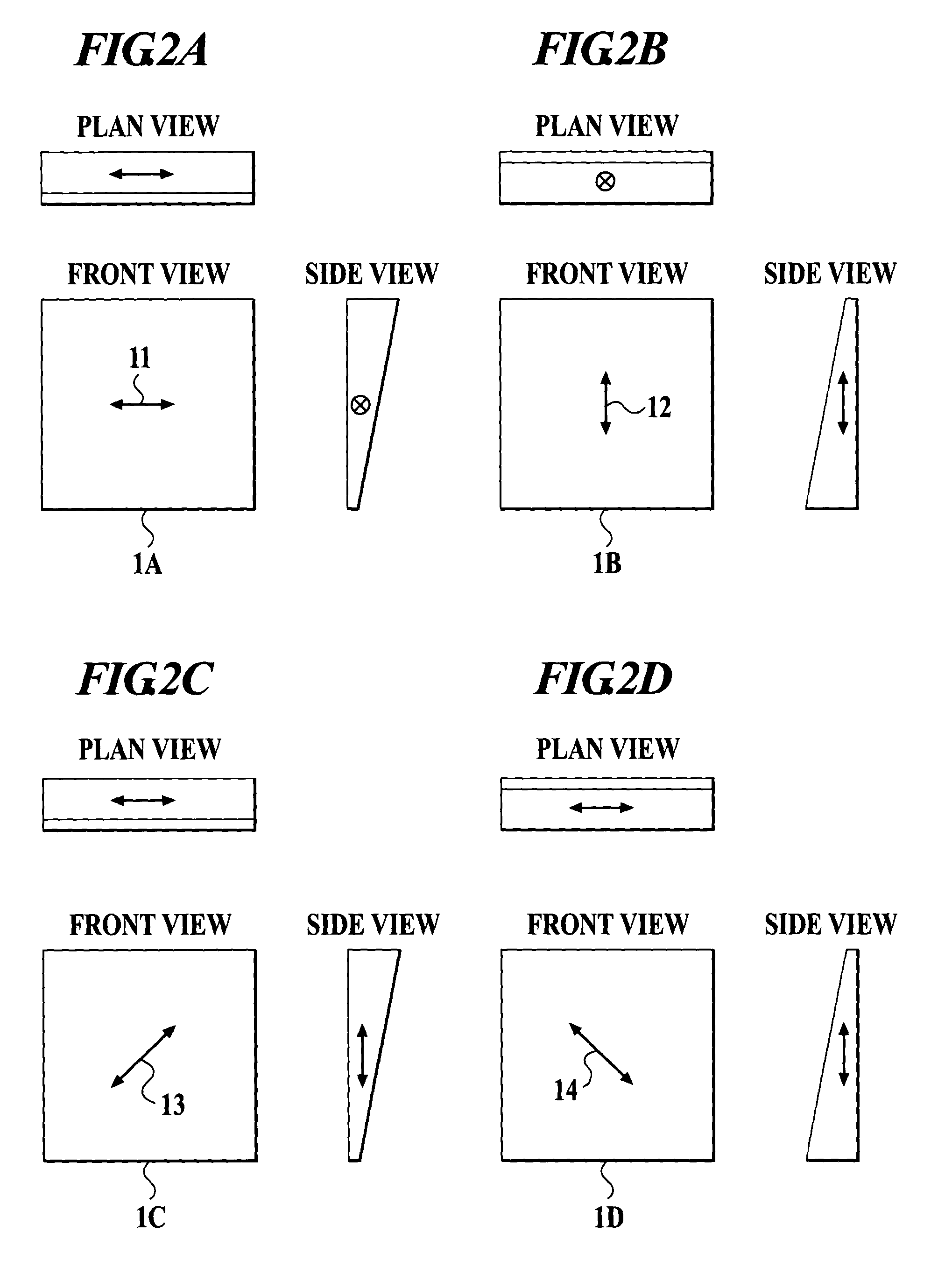

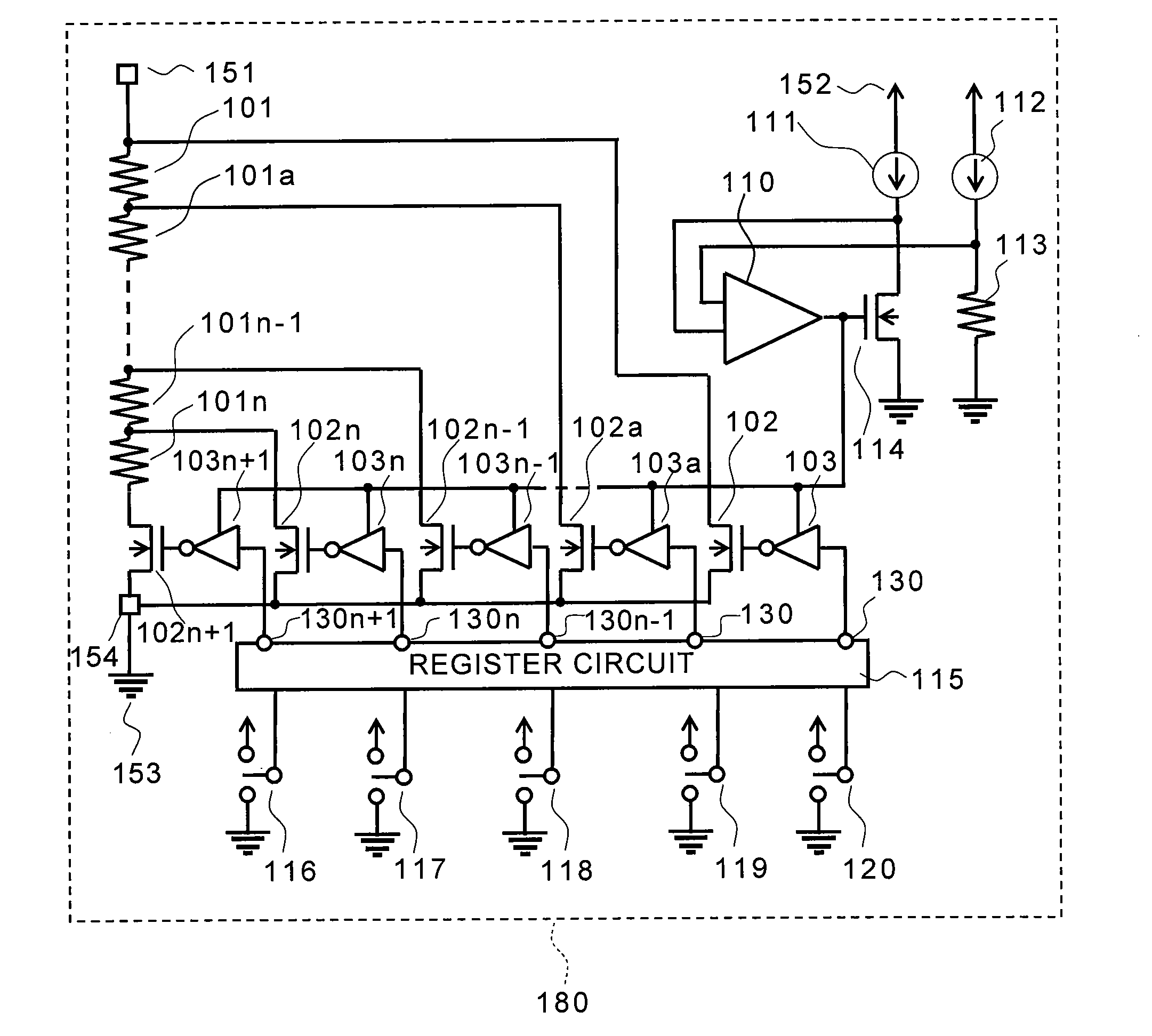

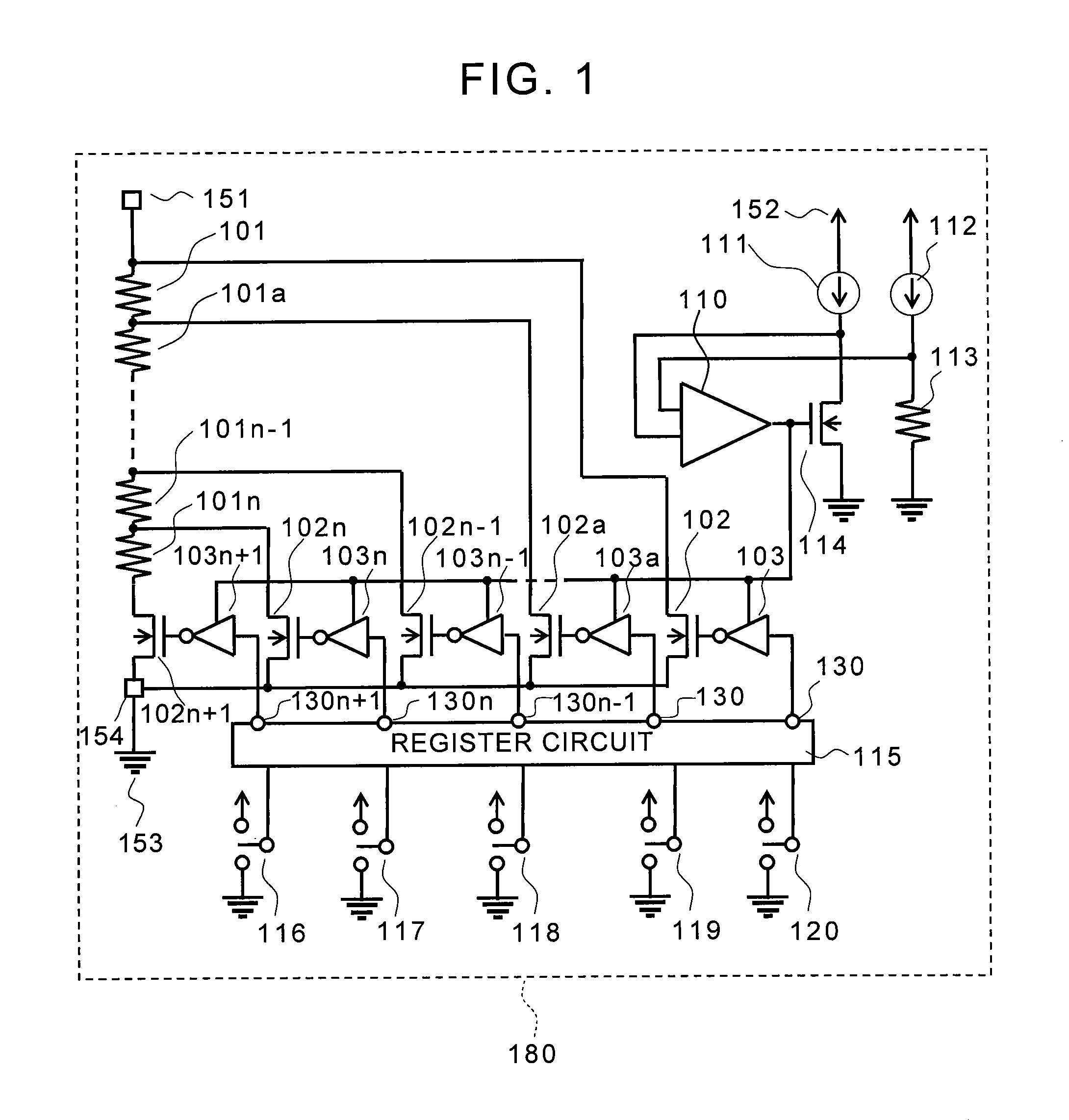

Switching power supply unit

InactiveUS6919713B2Simple configurationAchieve compactnessApparatus without intermediate ac conversionElectric variable regulationVoltage referenceEngineering

Accumulation and emission of energy in and from a coil having an intermediate tap is controlled by switching a DC input voltage from a DC power source on and off. Controlled voltages generated at a plurality of terminals are rectified and smoothed to output a plurality of DC output voltages. Connection to a reference voltage is controlled such that the voltages generated at the plurality of terminals are not dependent on the DC input voltage during the on-off switching. Therefore, a switching power supply unit is provided in which a coil having an intermediate tap is used to allow a simple configuration, to convert a DC input voltage into a plurality of DC output voltages with high efficiency, and to achieve compactness.

Owner:ROHM CO LTD

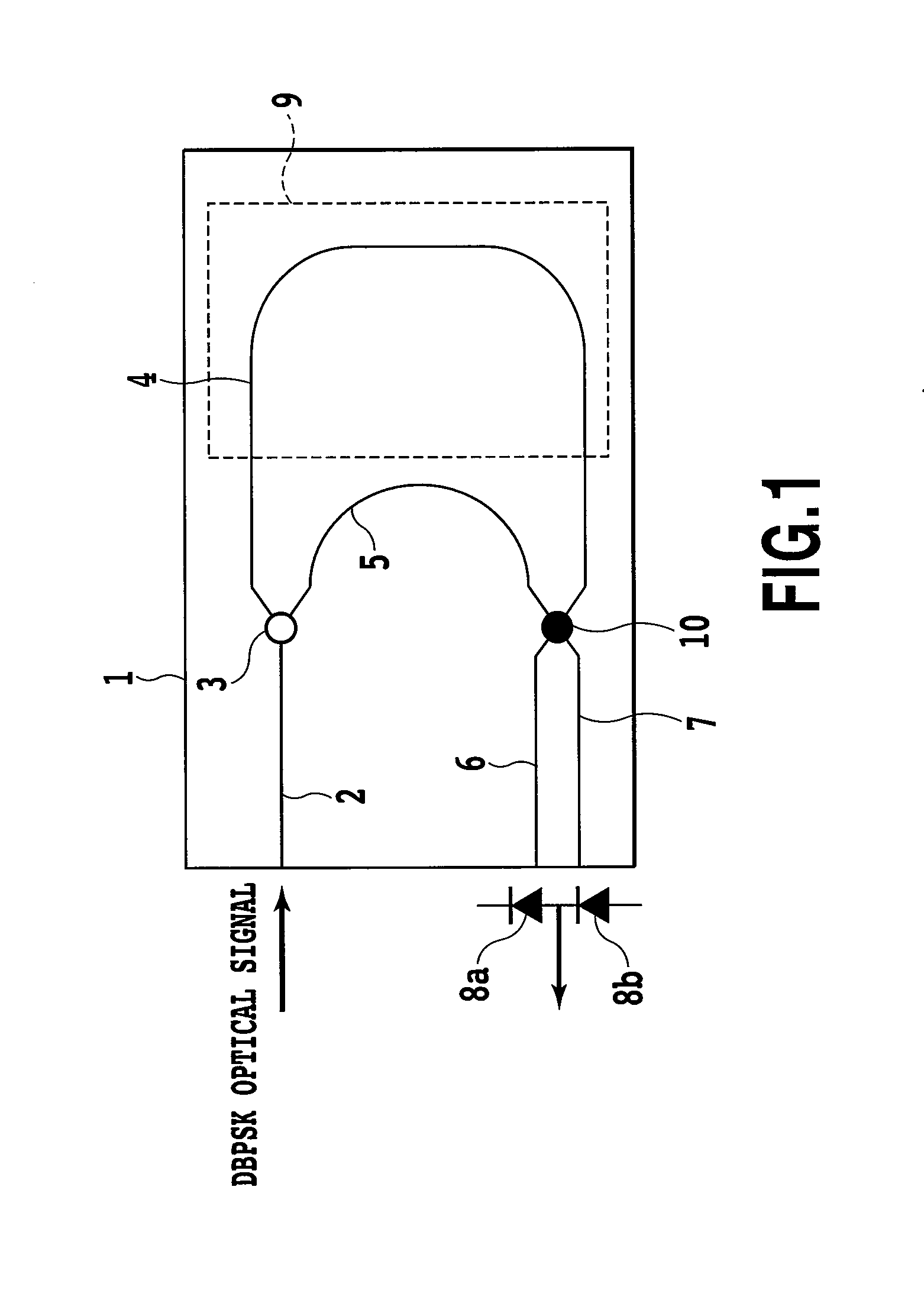

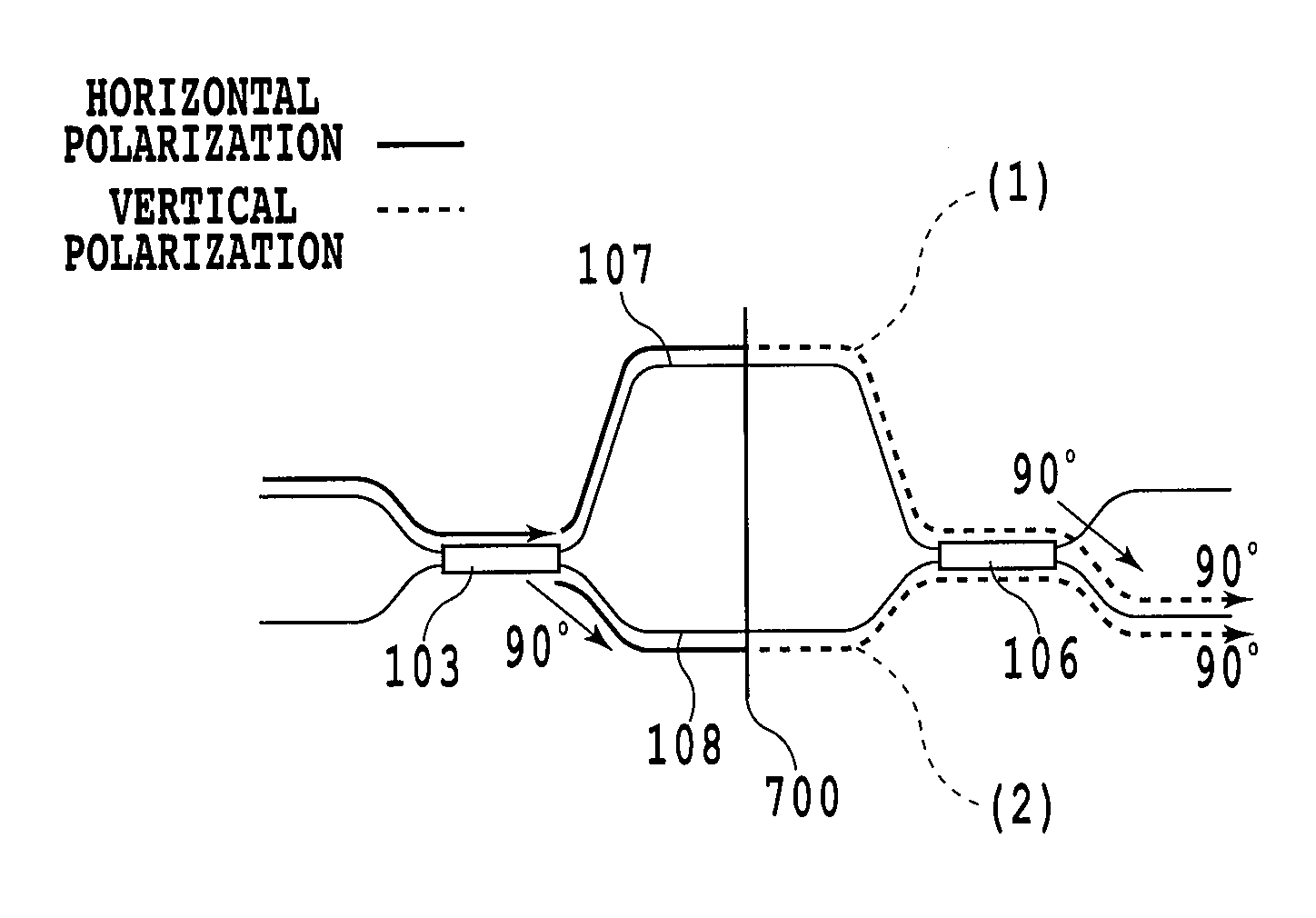

Waveguide-type optical interferometer

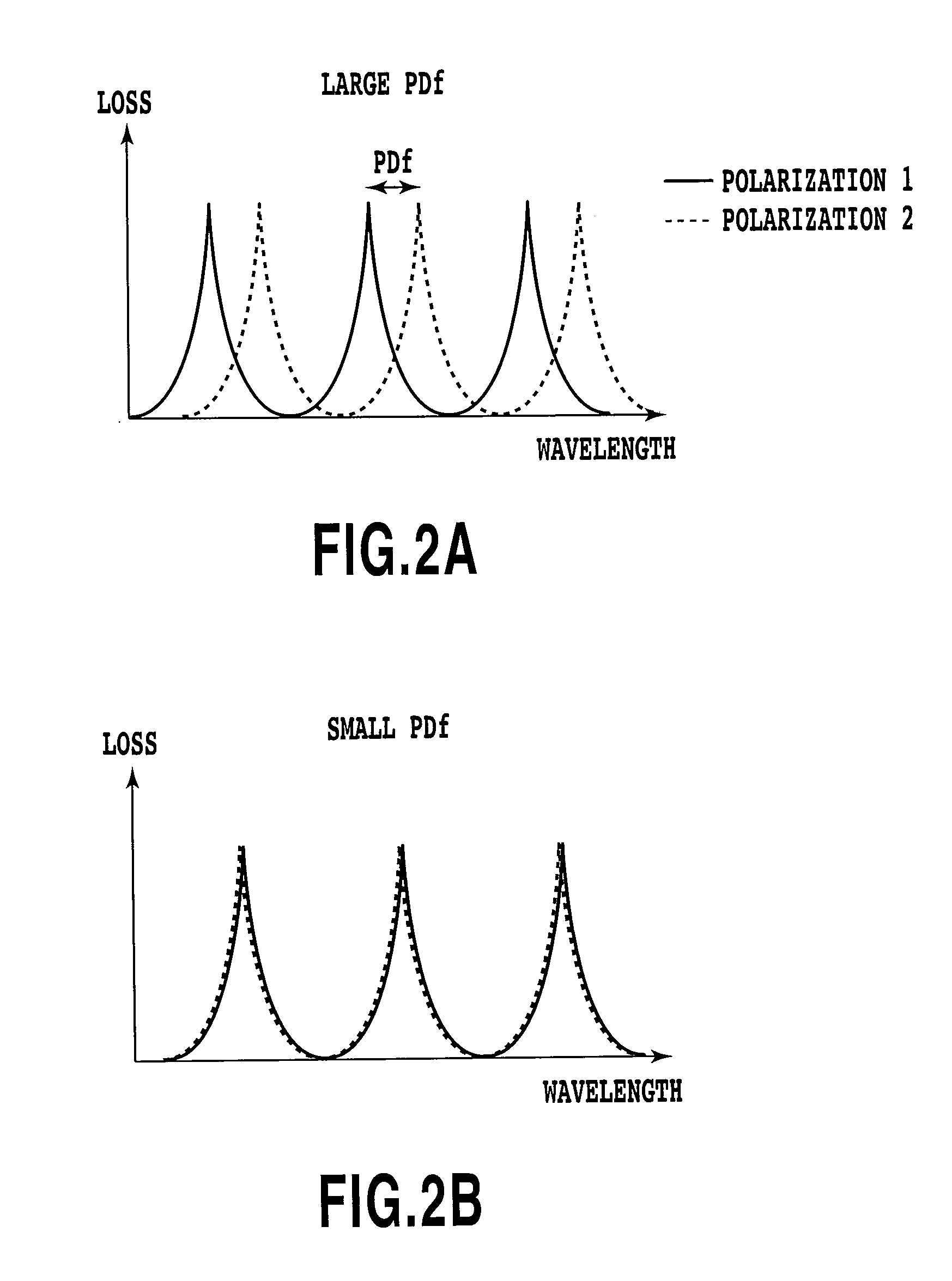

ActiveUS20100104237A1Elimination of polarization dependenceEasy to mass produceSagnac effect gyrometersSpeed measurement using gyroscopic effectsPolarization couplingOptical pathlength

In an optical interferometer, polarization dependence attributable to the optical path difference has conventionally been eliminated by inserting a half-wave plate at the center of the interferometer. However, light induced by polarization coupling produced in directional couplers used in the optical interferometer causes interference having different interference conditions from those of the normal light. Polarization rotators that effect any one of 90° rotation and −90° rotation of all states of polarization of incoming light are inserted in the optical interferometer, and thereby the interference conditions of light induced by polarization coupling are made the same as those of the normal light. Each of the polarization rotators is implemented by using two half-wave plates and by varying an angle of combination of these half-wave plates. Alternatively, each of the polarization rotators is implemented through a combination of one half-wave plate and a waveguide having birefringence properties.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

High speed microscope with three-dimensional laser beam scanning including acousto-optic deflector for controlling the lateral position and collimation of the light beam

InactiveUS7227127B2Eliminate dependenceIncrease in sizeBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansAcousto optic deflectorLight beam

A system and method for independently controlling the collimation and lateral positioning of a light beam comprises at least one acousto-optic deflector and a pair of counter propagating acoustic waves with offset frequencies. While the frequency offset controls the lateral positioning of the light beam, a frequency gradient across the acousto-optic deflectors controls the collimation of the light beam.

Owner:BAYLOR COLLEGE OF MEDICINE

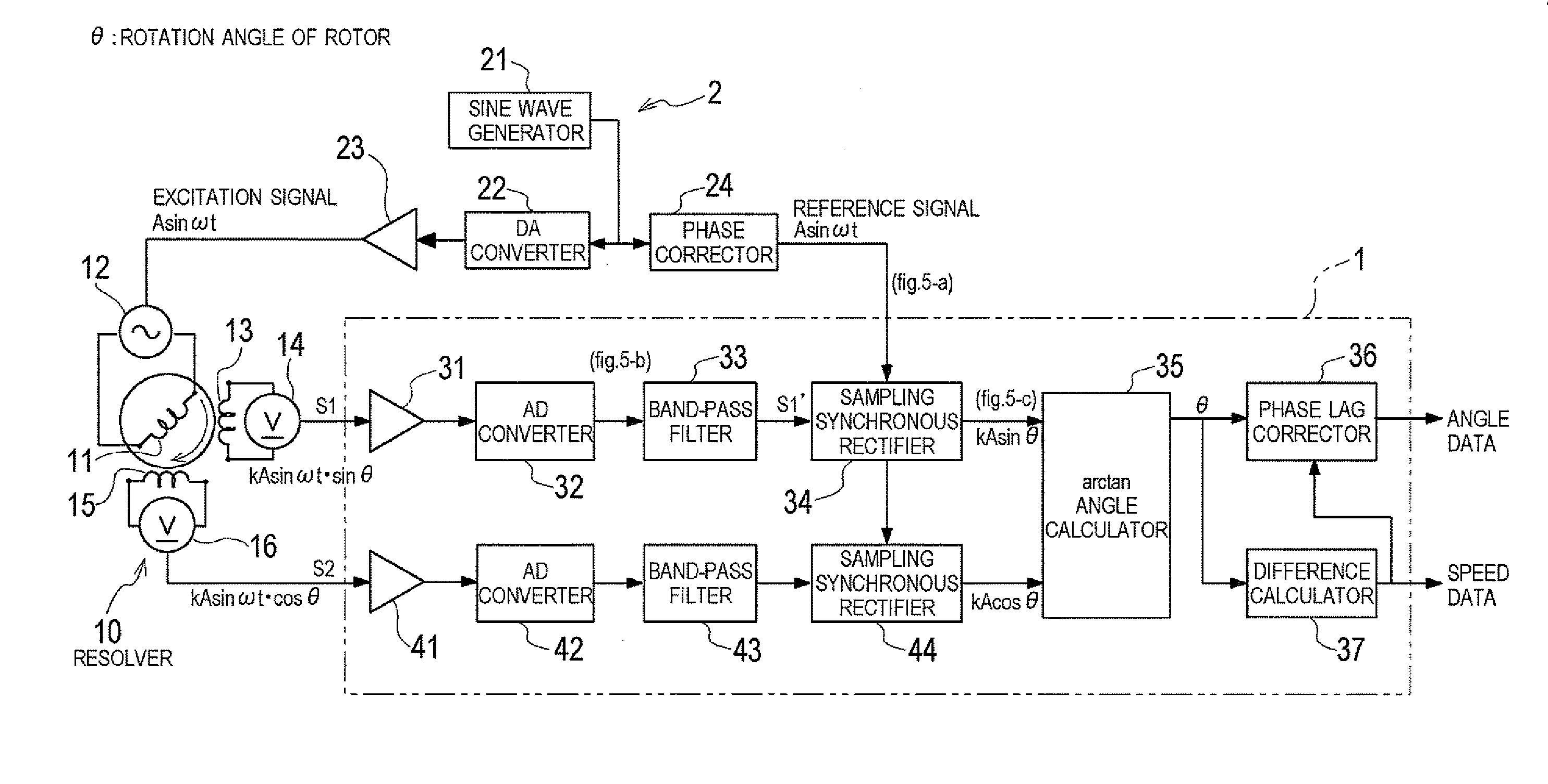

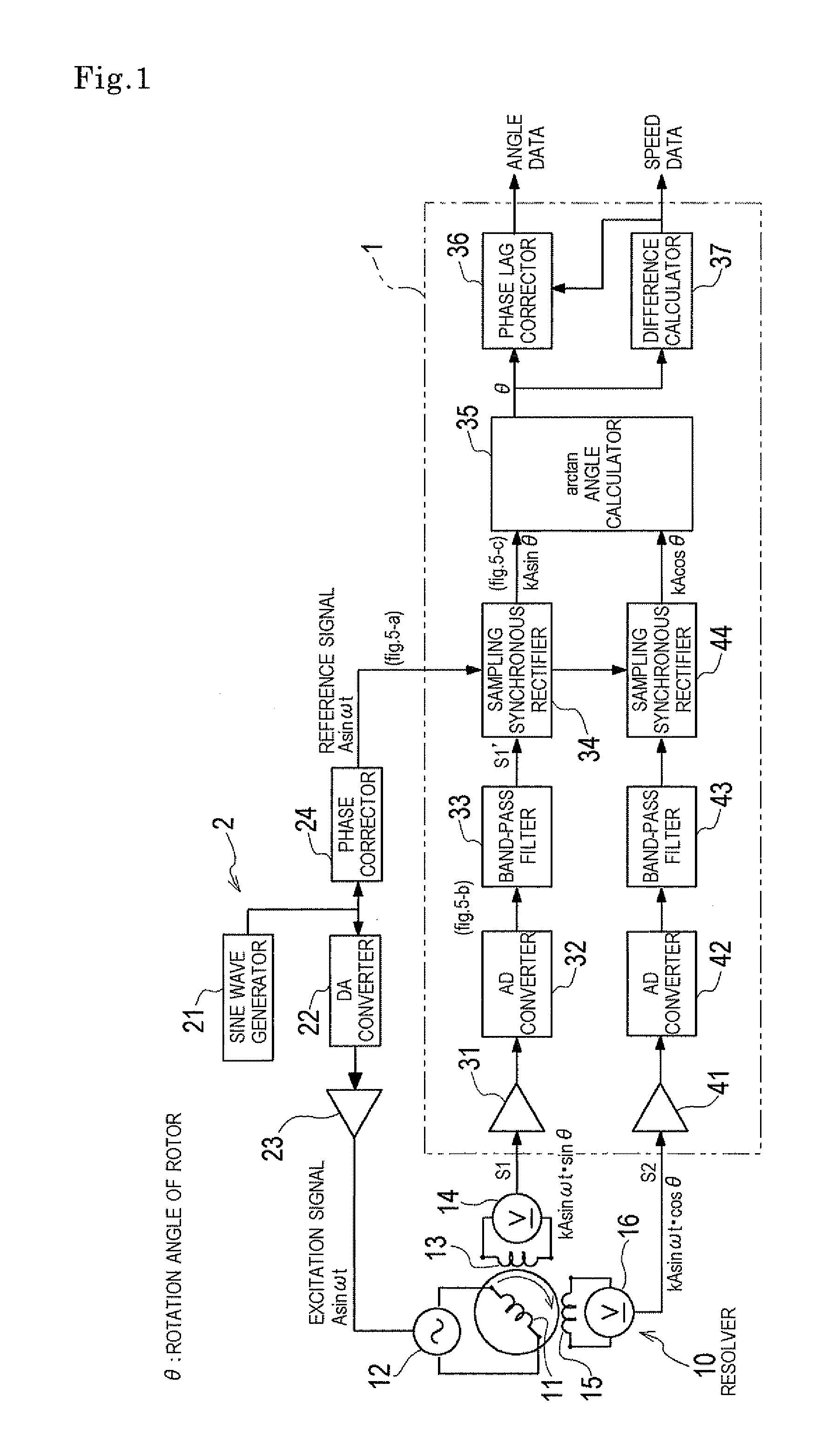

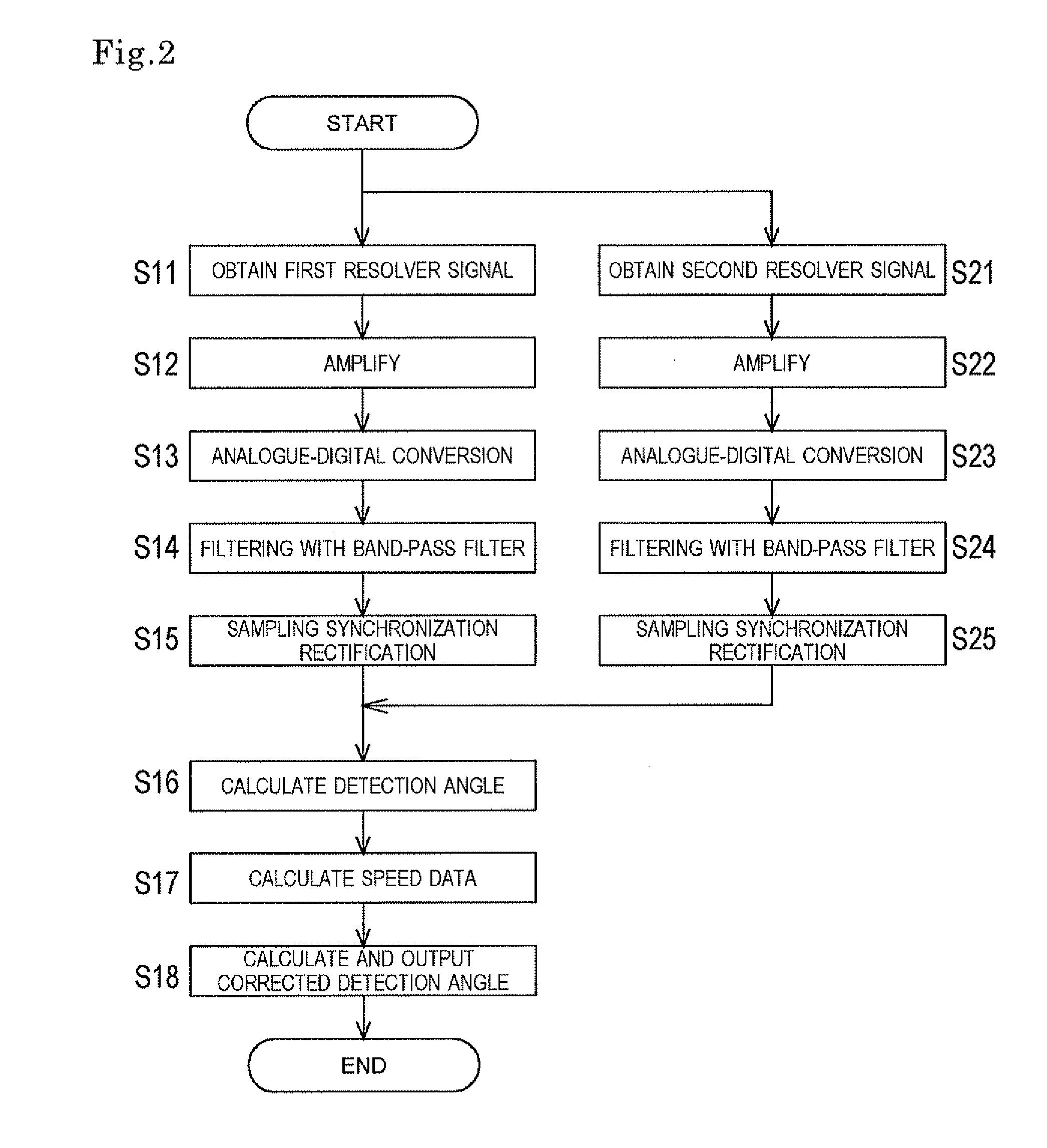

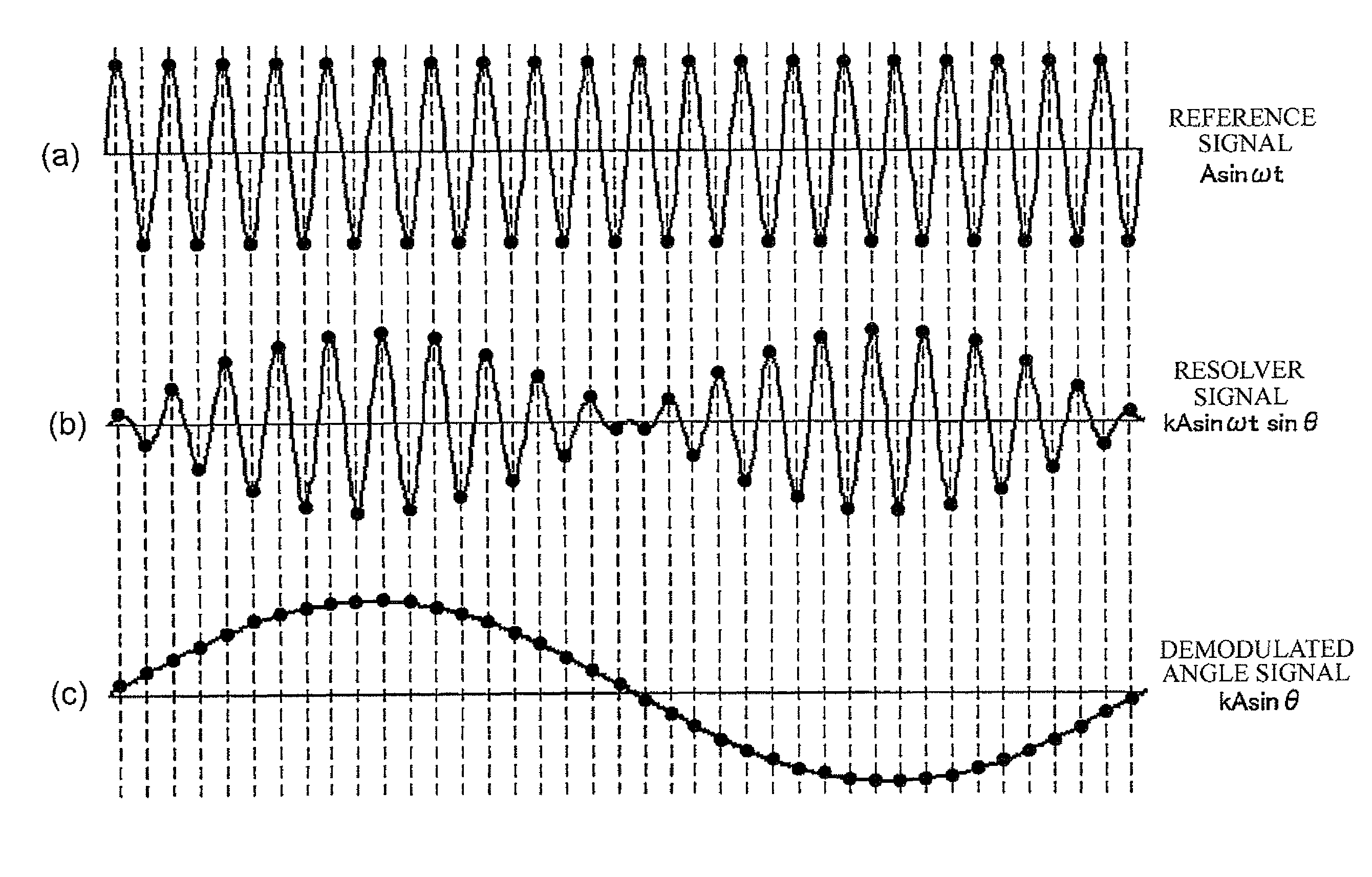

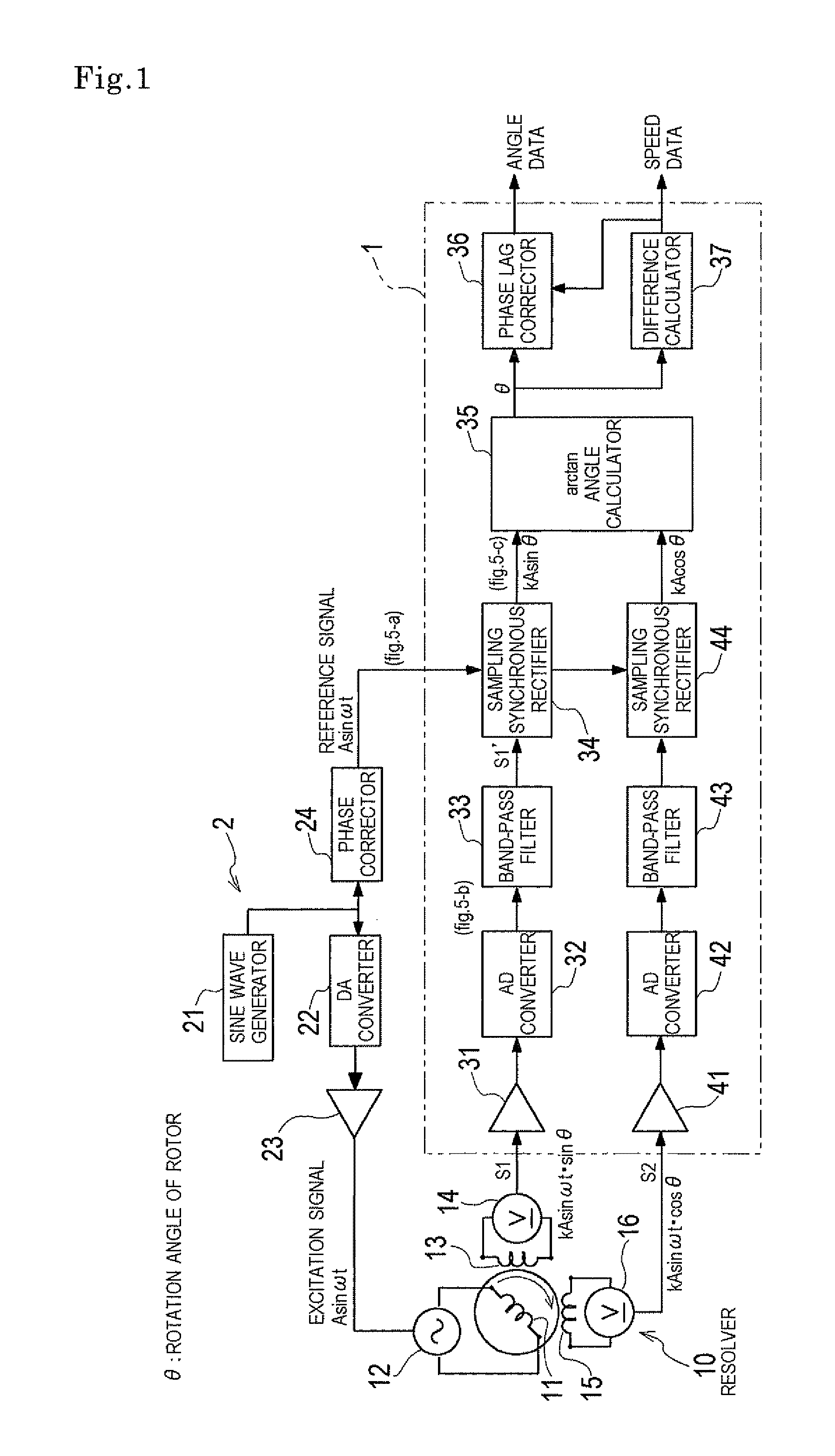

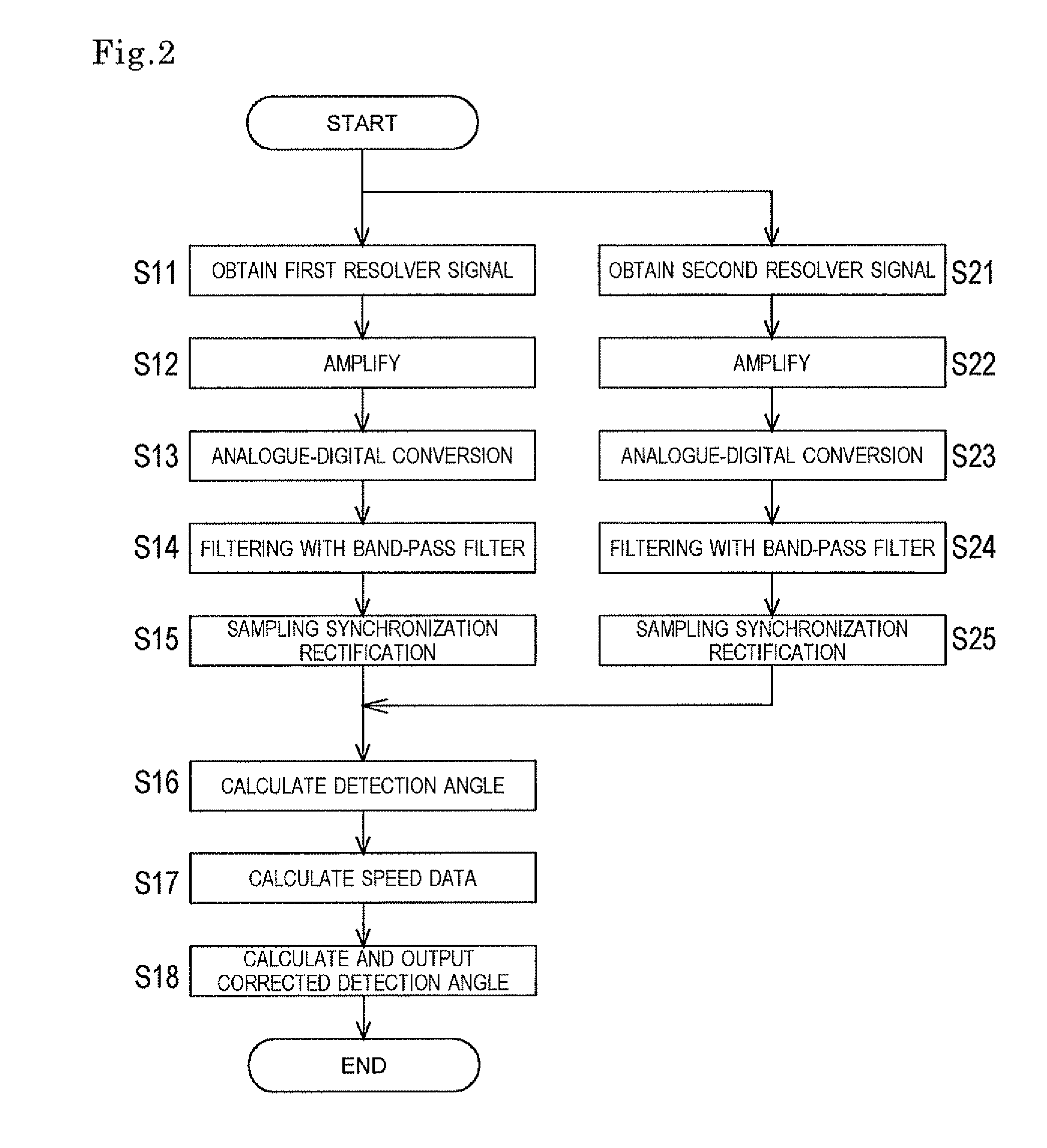

Resolver signal converter and resolver signal conversion method

ActiveUS20120010849A1Eliminate dependenceReduce impactProgramme controlAnalogue/digital conversionBand-pass filterCenter frequency

A resolver signal converter and a resolver signal conversion method amplify and perform analogue-digital conversion on a sine wave output from a resolver; thereafter, among frequency components of the sine wave output, pass and thereby extract a predetermined bandwidth of which the center frequency is the frequency of an excitation signal, by means of a band-pass filter; sample the sine wave output while synchronizing the sine wave output with a reference signal which is based on the excitation signal; and generate a detection angle signal sine value from the sampled signal. Similarly, a detection angle signal cosine value is generated from a cosine wave output from the resolver. A detection angle is calculated based on the detection angle signal sine value and the detection angle signal cosine value. Accordingly, an influence, on an input resolver signal, of disturbance noise such as noise caused due to a magnetic field generated by a motor and switching noise caused due to PWM driving, is eliminated, and frequency dependence of arithmetic processing is eliminated. As a result, detection angle errors are reduced.

Owner:KAWASAKI HEAVY IND LTD

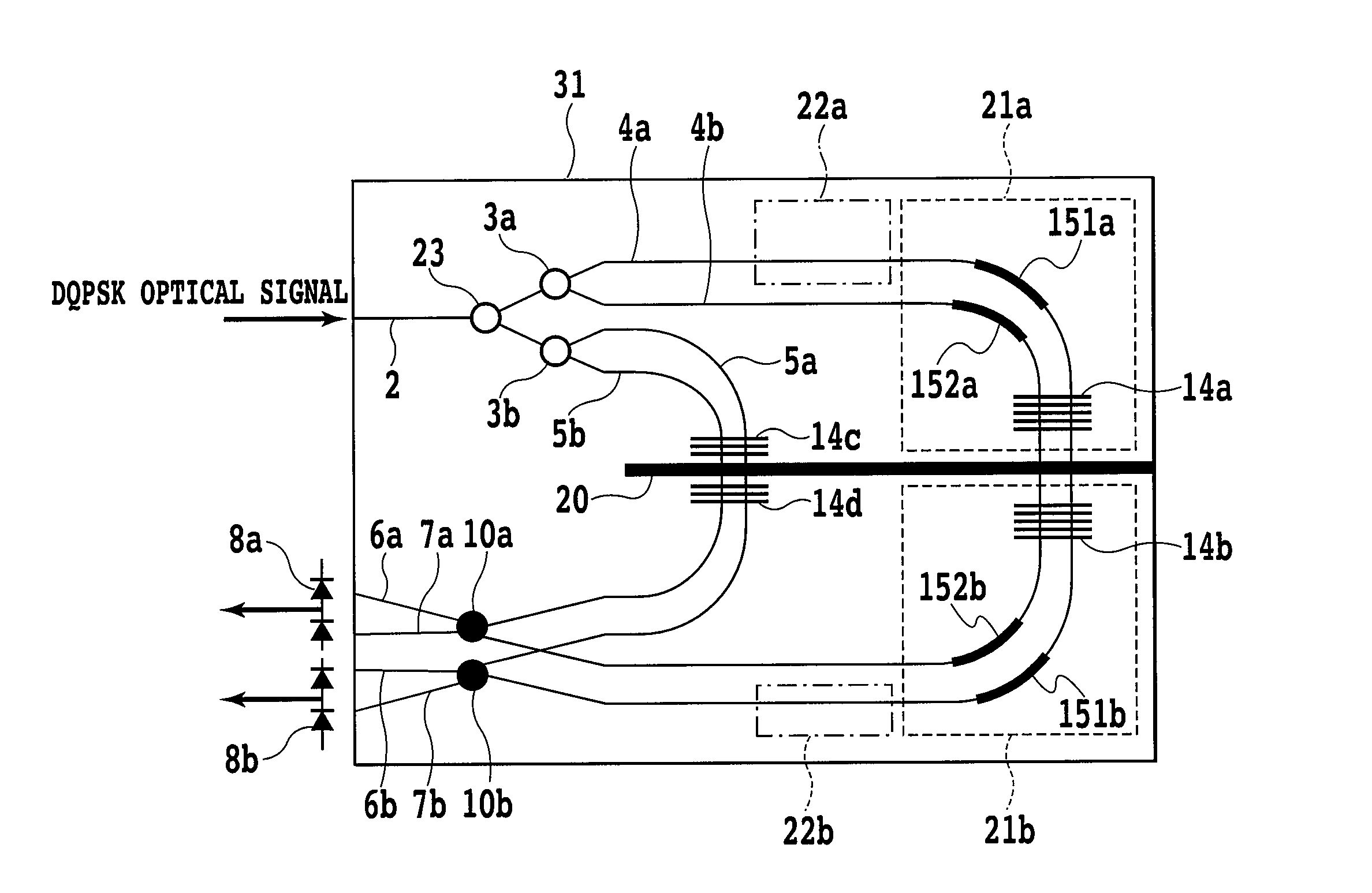

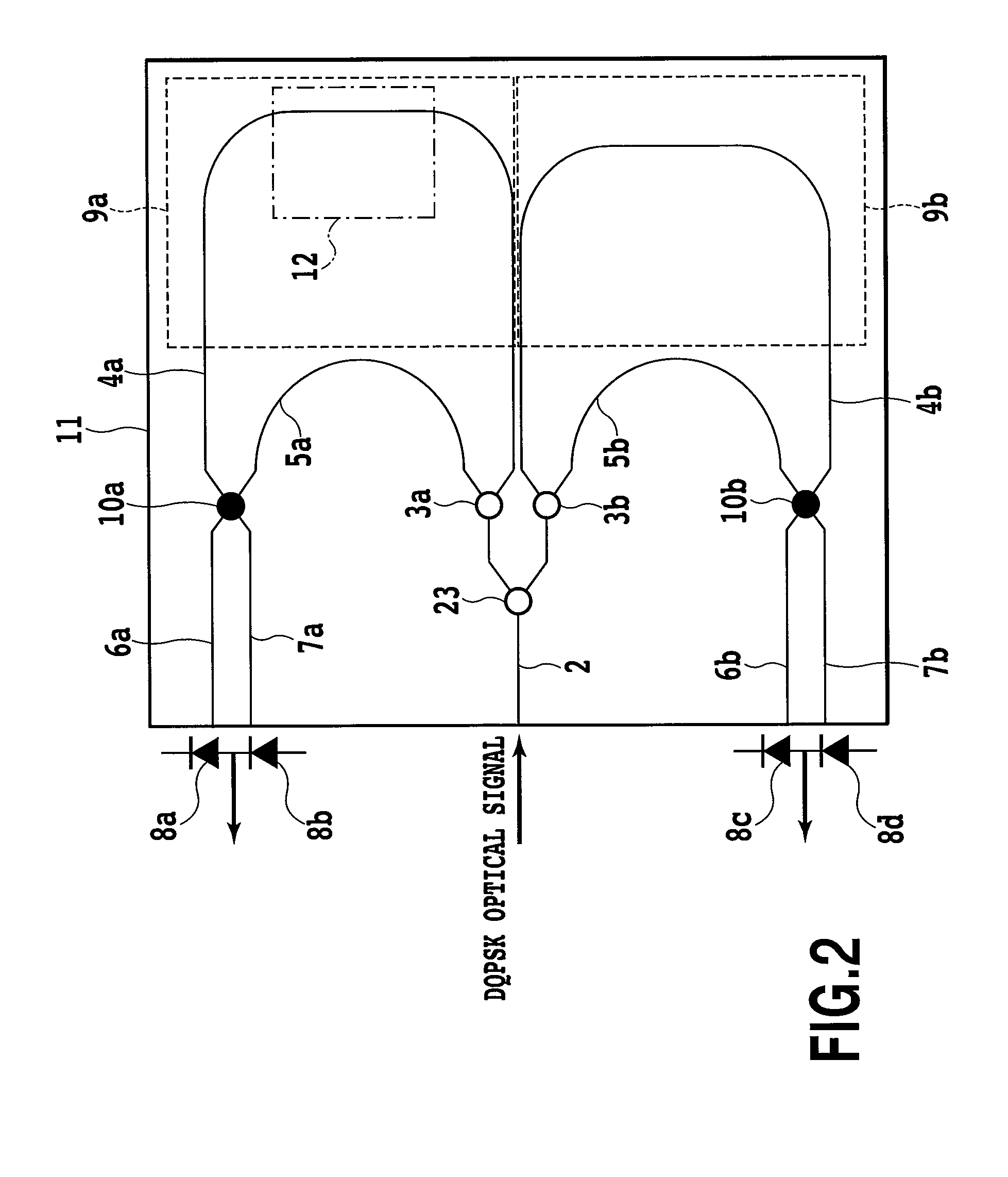

Optical delay line interferometer

ActiveUS7899279B2Eliminate dependenceSimple configurationLight demodulationElectromagnetic receiversDifferential phasePolarization coupling

A demodulator is provided for a multilevel differential phase shift keyed signal, capable of eliminating polarization dependence due to birefringence and polarization coupling-induced light resulting from a waveguide structure, and also, polarization dependence due to dynamic birefringence produced at the time of driving a variable phase adjuster. The demodulator is configured of an optical delay line interferometer of a waveguide interference type. The S / N ratio of a demodulated signal in the demodulator formed by the optical delay line interferometer can be also improved. Further, both the polarization dependence and the temperature dependence of the optical delay line interferometer can be reduced. The disposition of a polarization converter and groves filled with a temperature compensation material makes it possible to provide a circuit configuration suitable for eliminating the polarization dependence and the temperature dependence of the optical delay line interferometer.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Waveguide-type optical interferometer

ActiveUS8150219B2Reduced polarization dependenceEliminate dependenceSpeed measurement using gyroscopic effectsSagnac effect gyrometersOptical pathlengthPolarization coupling

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

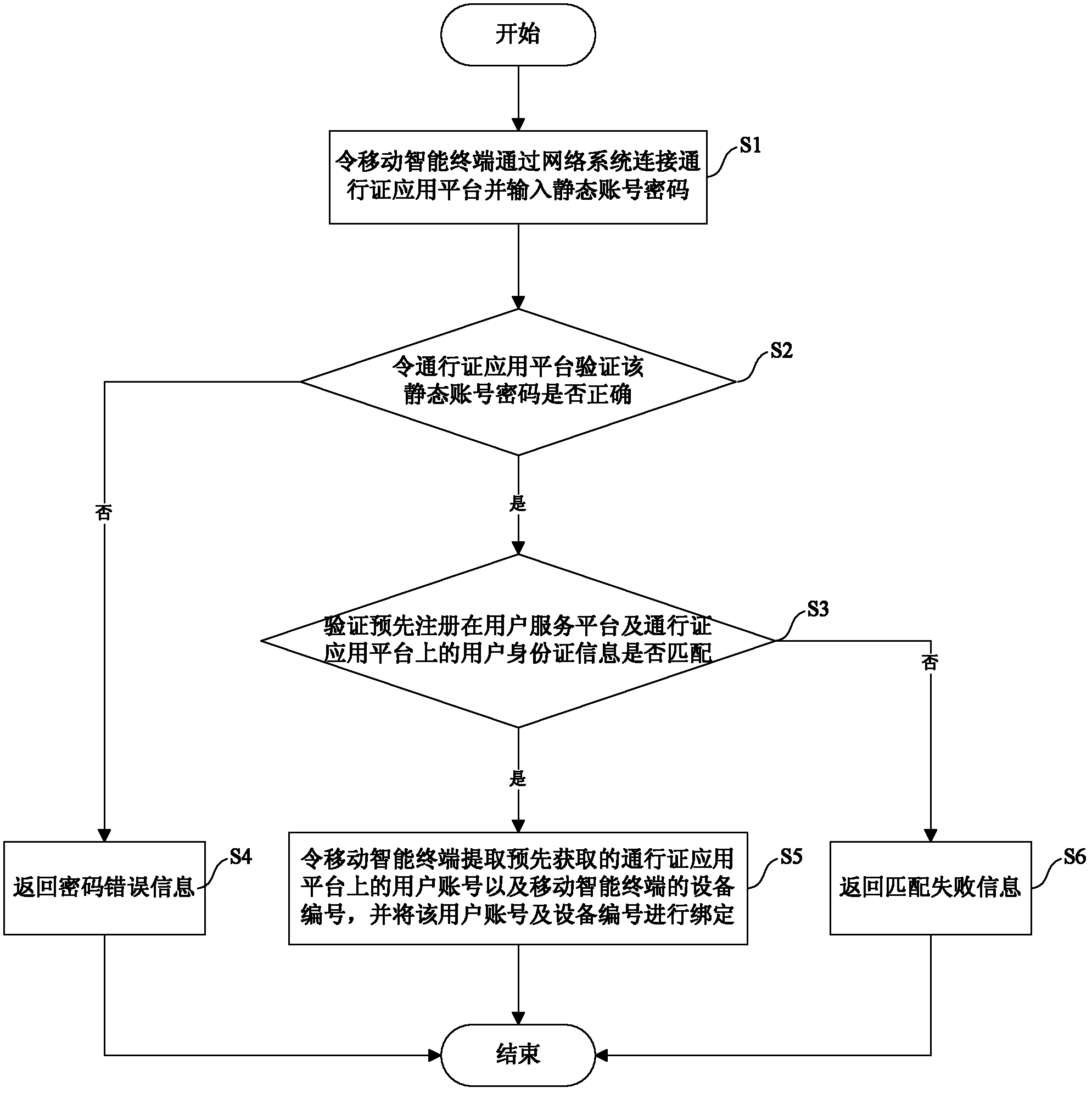

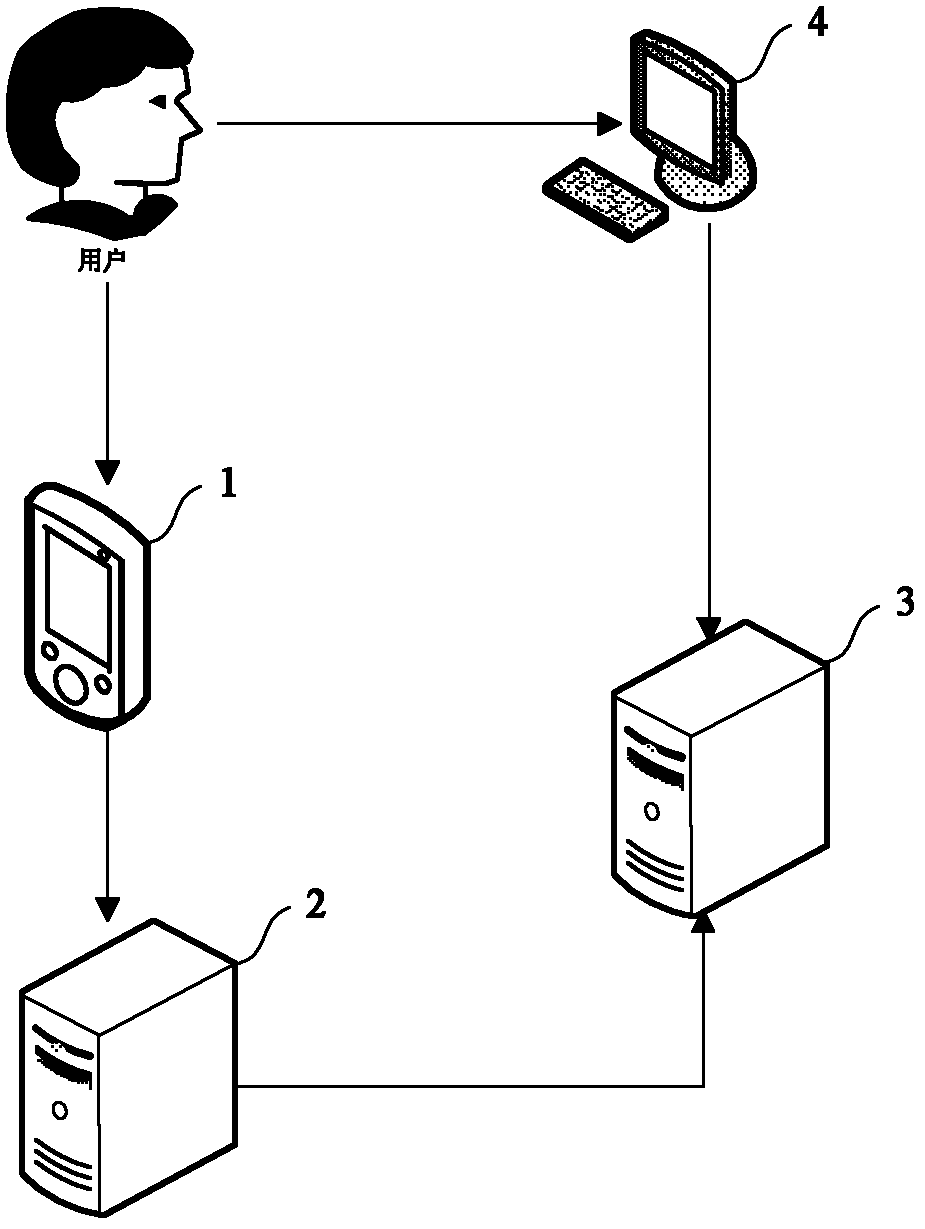

User account management method based on mobile intelligent terminal number

InactiveCN103188241APut an end to behaviorEliminate dependenceTransmissionSecurity arrangementPasswordTerminal equipment

The invention provides a user account management method based on a mobile intelligent terminal number. The user account management method is applied to a network system formed by a mobile intelligent terminal, a user service platform and an access permit application platform. The method comprises a first step of commanding the mobile intelligent terminal to be connected with the access permit application platform and inputting a static state password, and a second step of checking whether user identification information registered in advance on the user service platform is matched with user identification information registered on the access permit application platform or not after the mobile intelligent terminal is certificated through the static state password. If the user identification information registered in advance on the user service platform and on the access permit application platform is matched, the mobile intelligent terminal is commanded to acquire the pre-acquired user account of the access permit application platform and the mobile intelligent terminal number, and the user account and the terminal number are bound. According to the user account management method, an intelligent mobile device number serves as an evidence of the user identification, functions of blocking / deblocking the user account and directly resetting a password are utilized, behaviors of Trojans account-stolen people are eradicated fundamentally, and the defects that people depend on a client device and software encryption algorithm are overcome.

Owner:SHANGHAI NINTH CITY INFORMATION TECH CO LTD

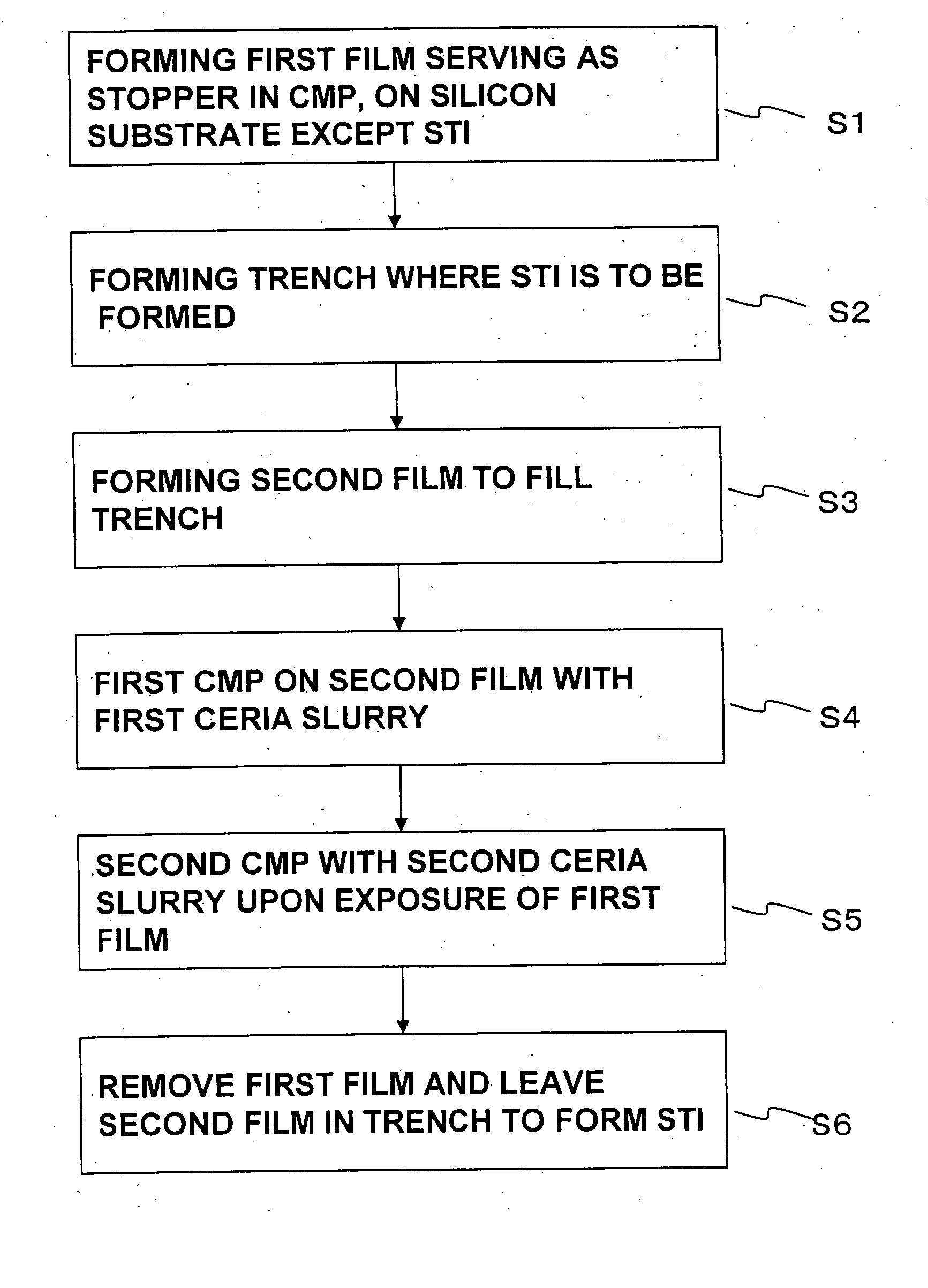

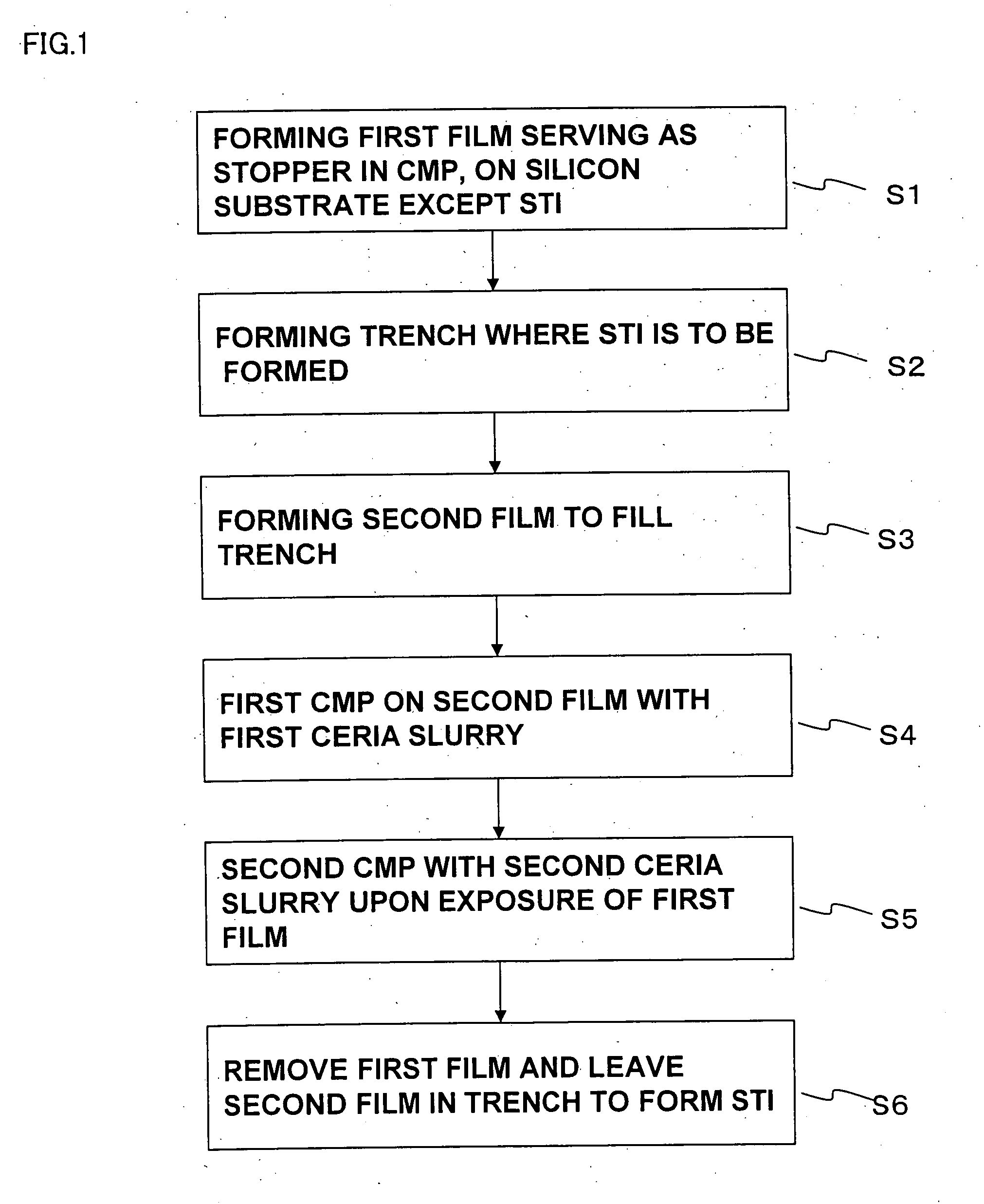

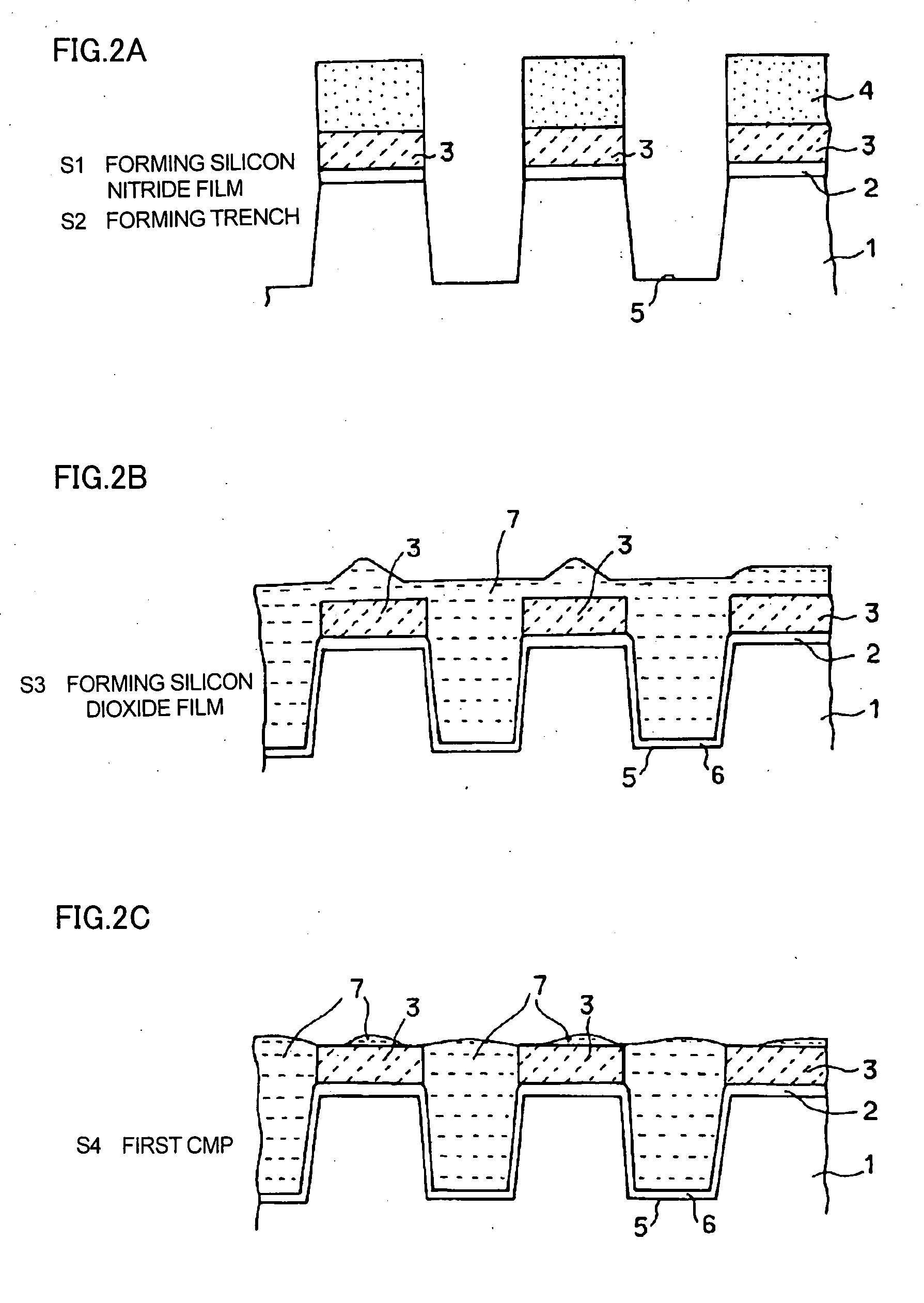

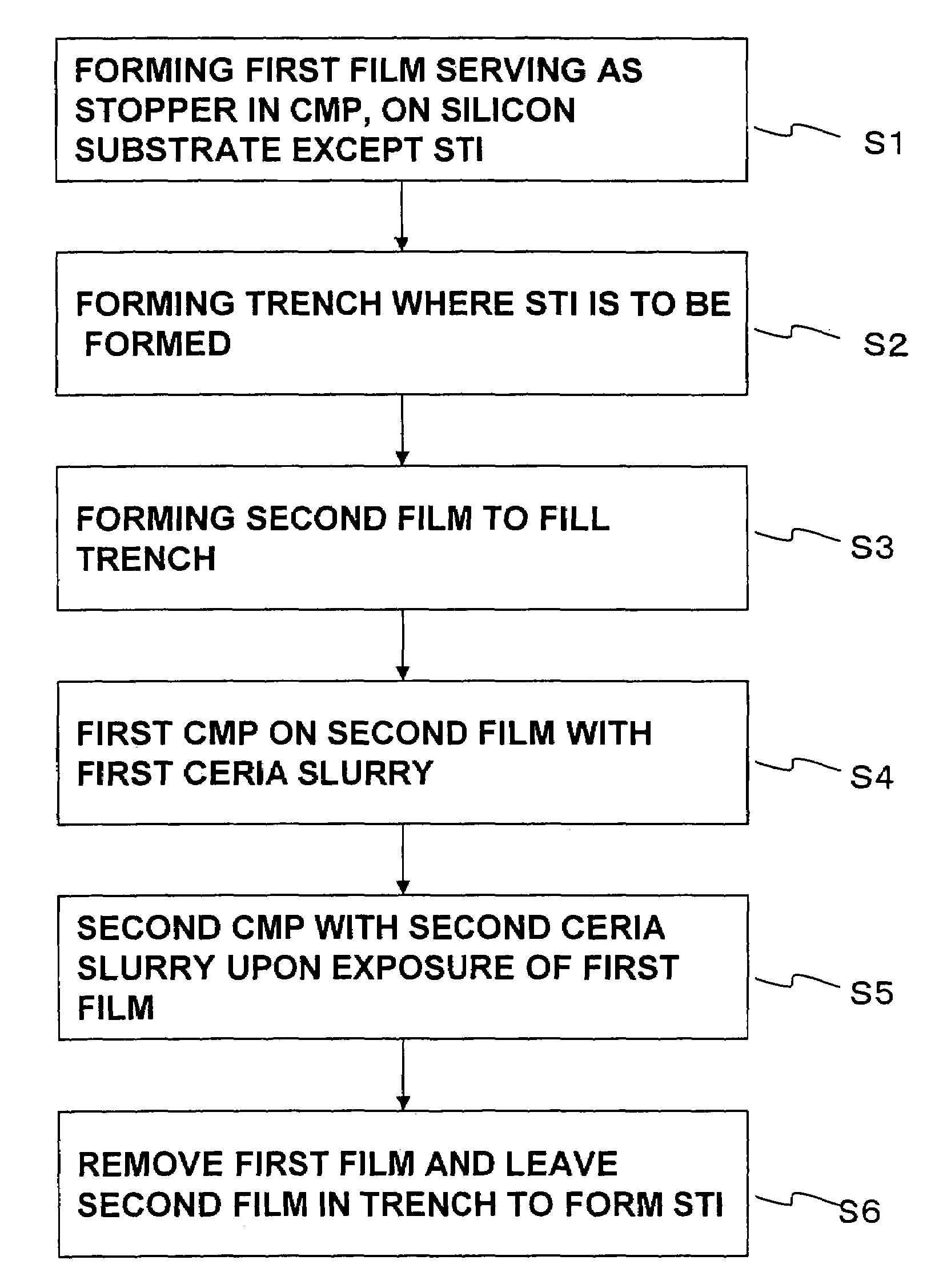

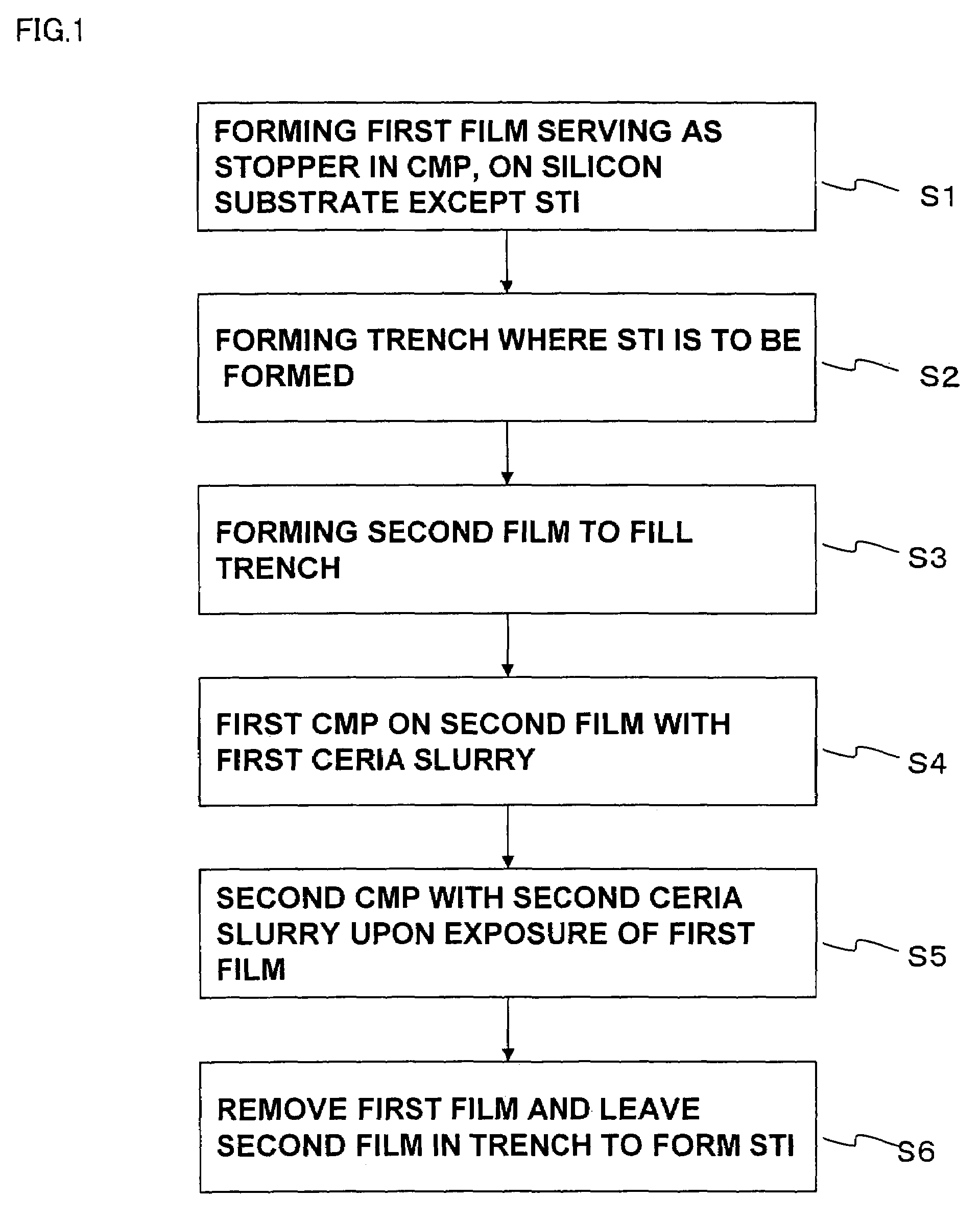

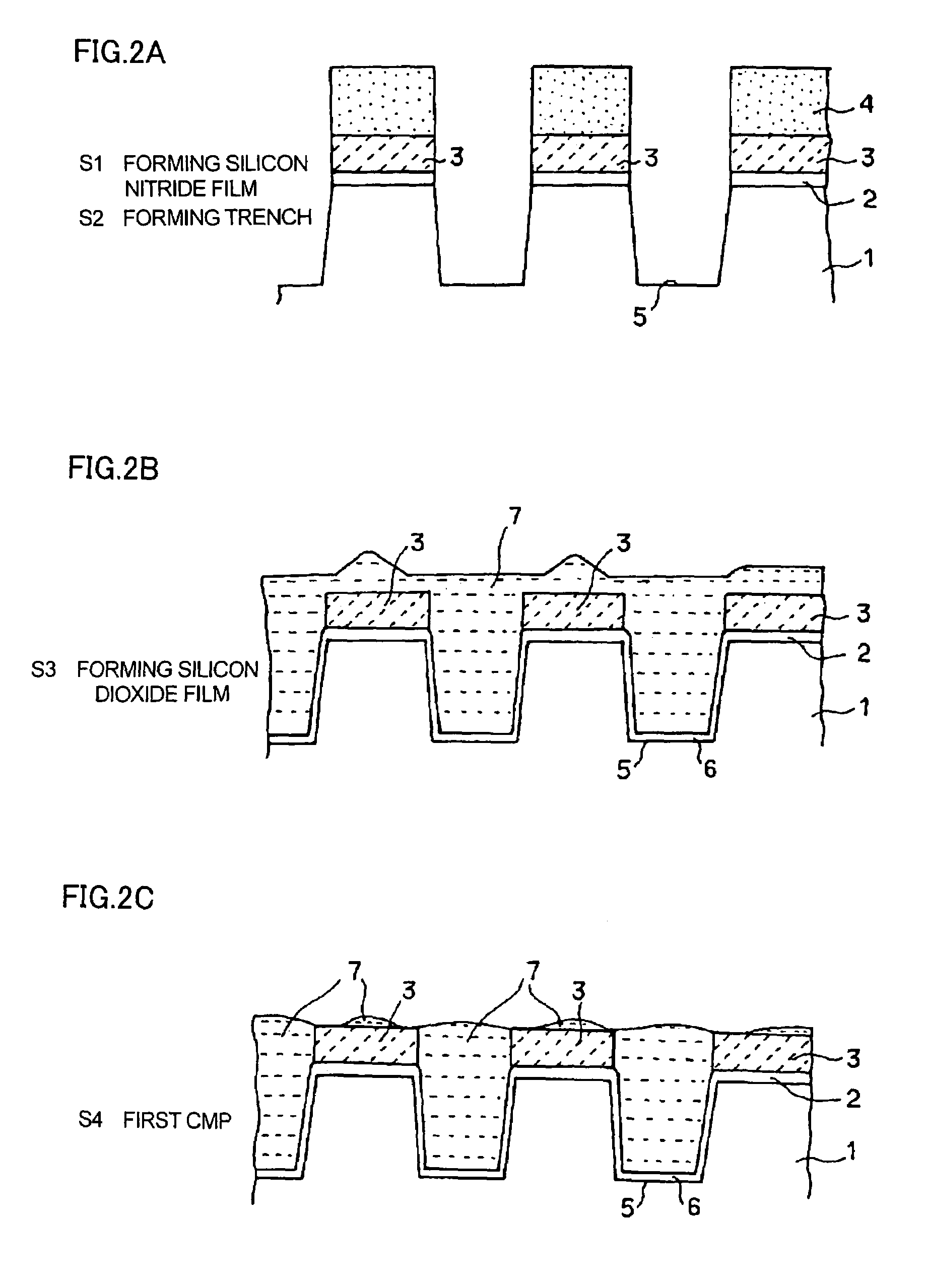

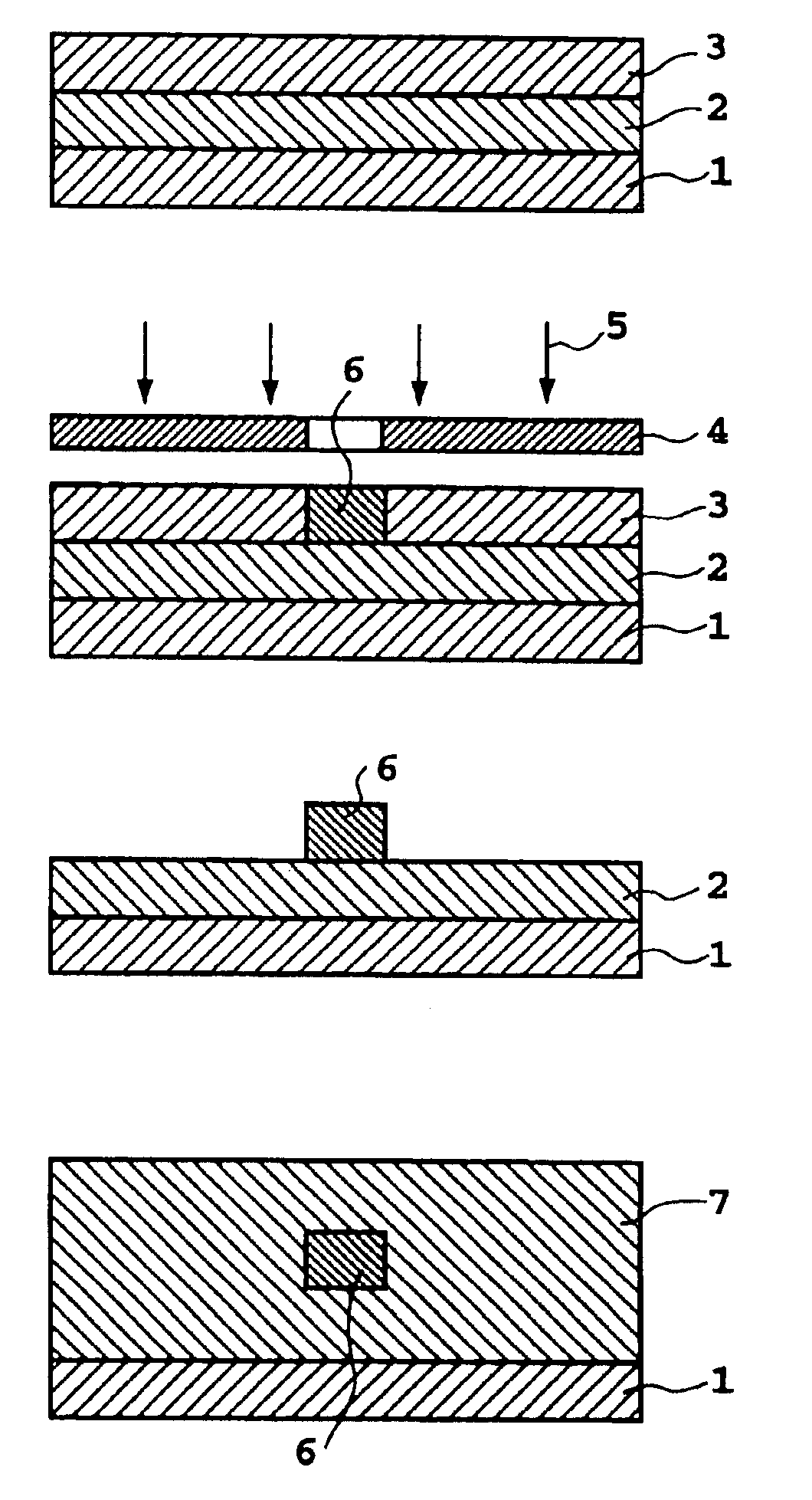

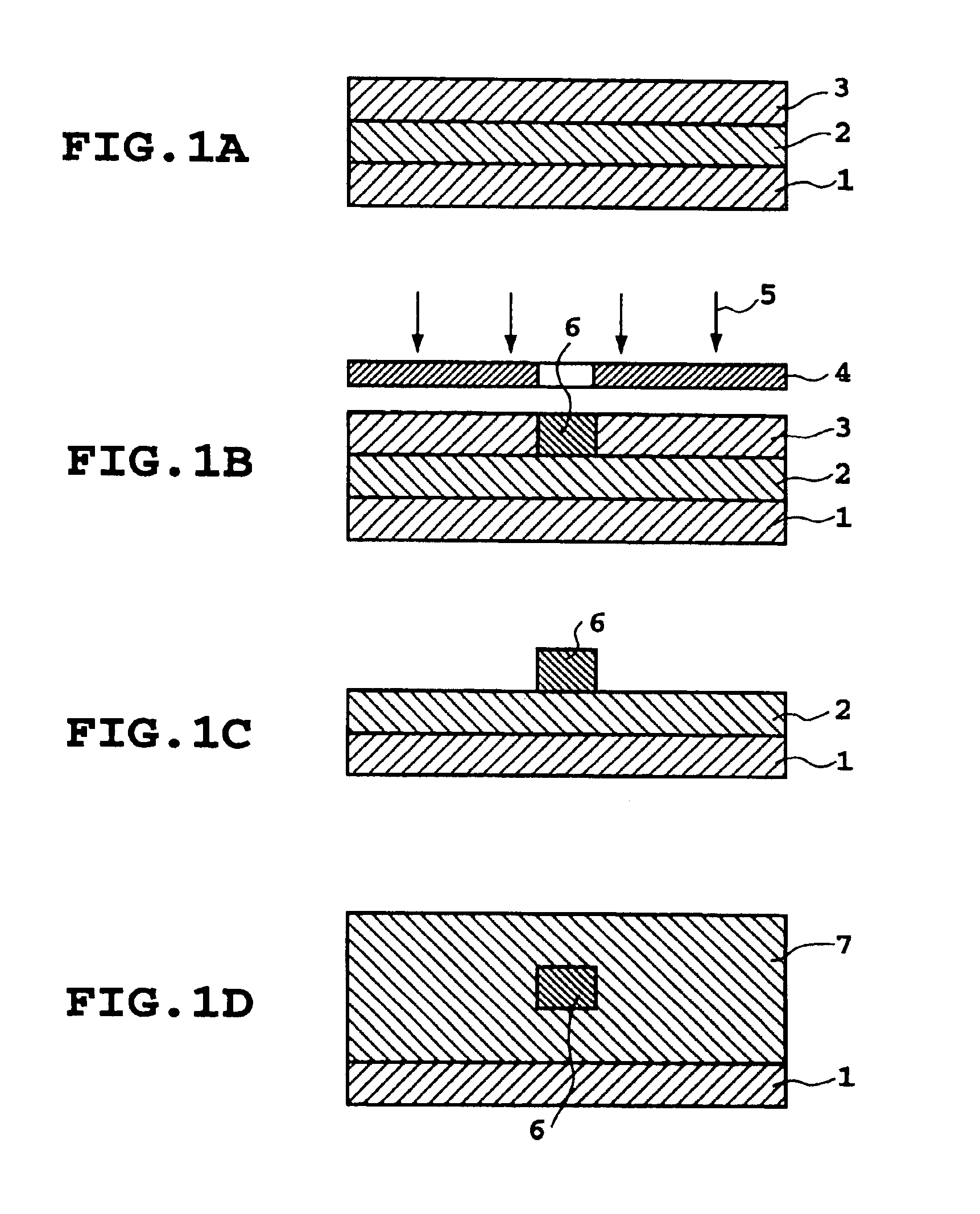

Method of manufacturing a semiconductor device

InactiveUS20050153560A1Eliminate pattern dependenceSecure desired planaritySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

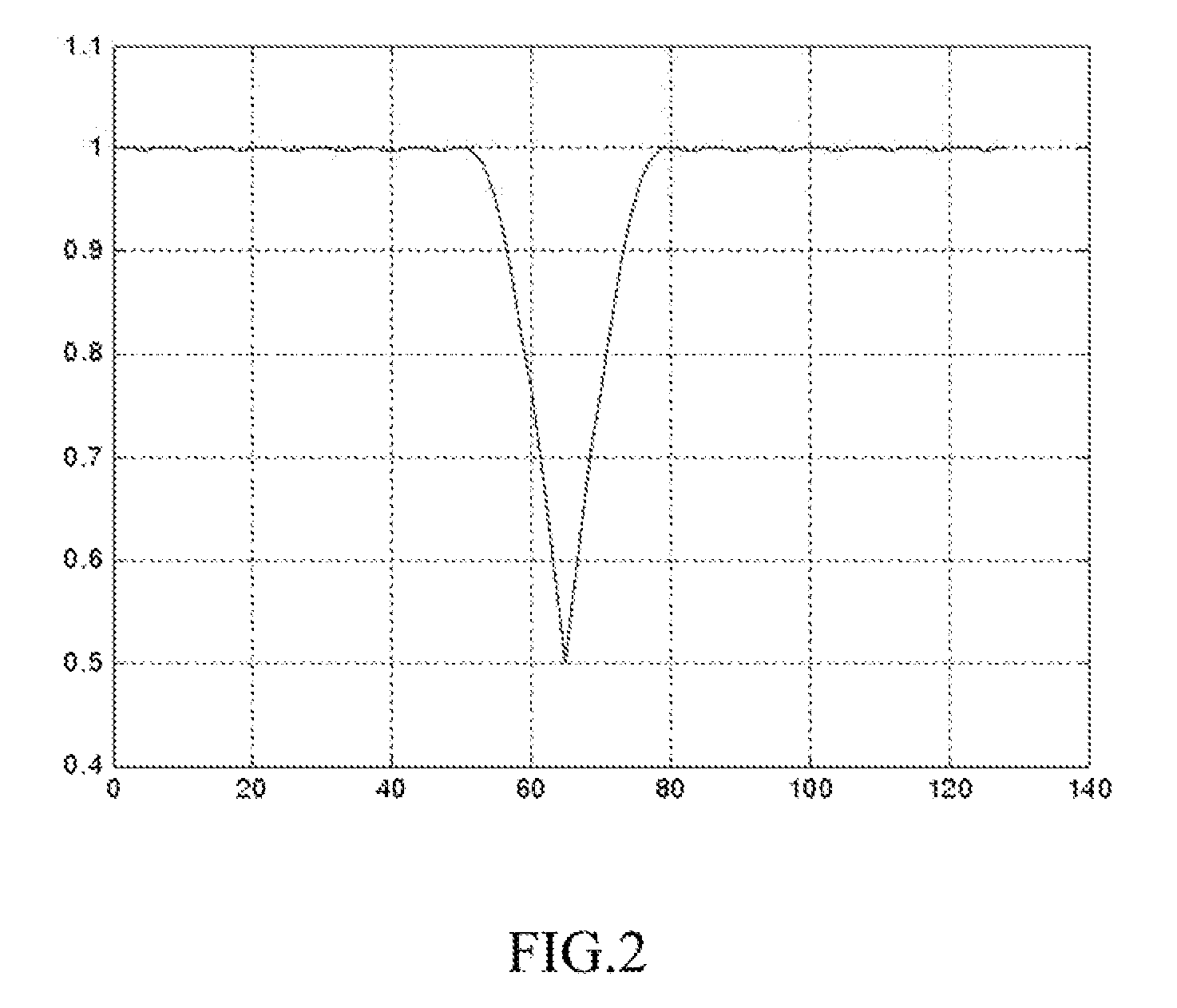

In a method of manufacturing a semiconductor device that prevents formation of scratches and occurrence of dishing in a CMP process utilizing a ceria slurry is to be provided. The method includes forming a first film on a part of a semiconductor substrate, forming a second film all over the semiconductor substrate, and a CMP process utilizing a ceria slurry to planarize the second film using the first film as a mask, and the CMP process includes performing a first CMP until a portion of the first film is exposed and performing a second CMP. A first ceria slurry of a predetermined abrasive grain concentration is employed in the first CMP, and a second ceria slurry of a lower abrasive grain concentration is employed in the the second CMP, in which the number of scratches is reduced by reducing the abrasive grain concentration of the ceria slurry, and also a dishing is prevented by reducing a polishing rate ratio between the first and the second films.

Owner:RENESAS ELECTRONICS CORP

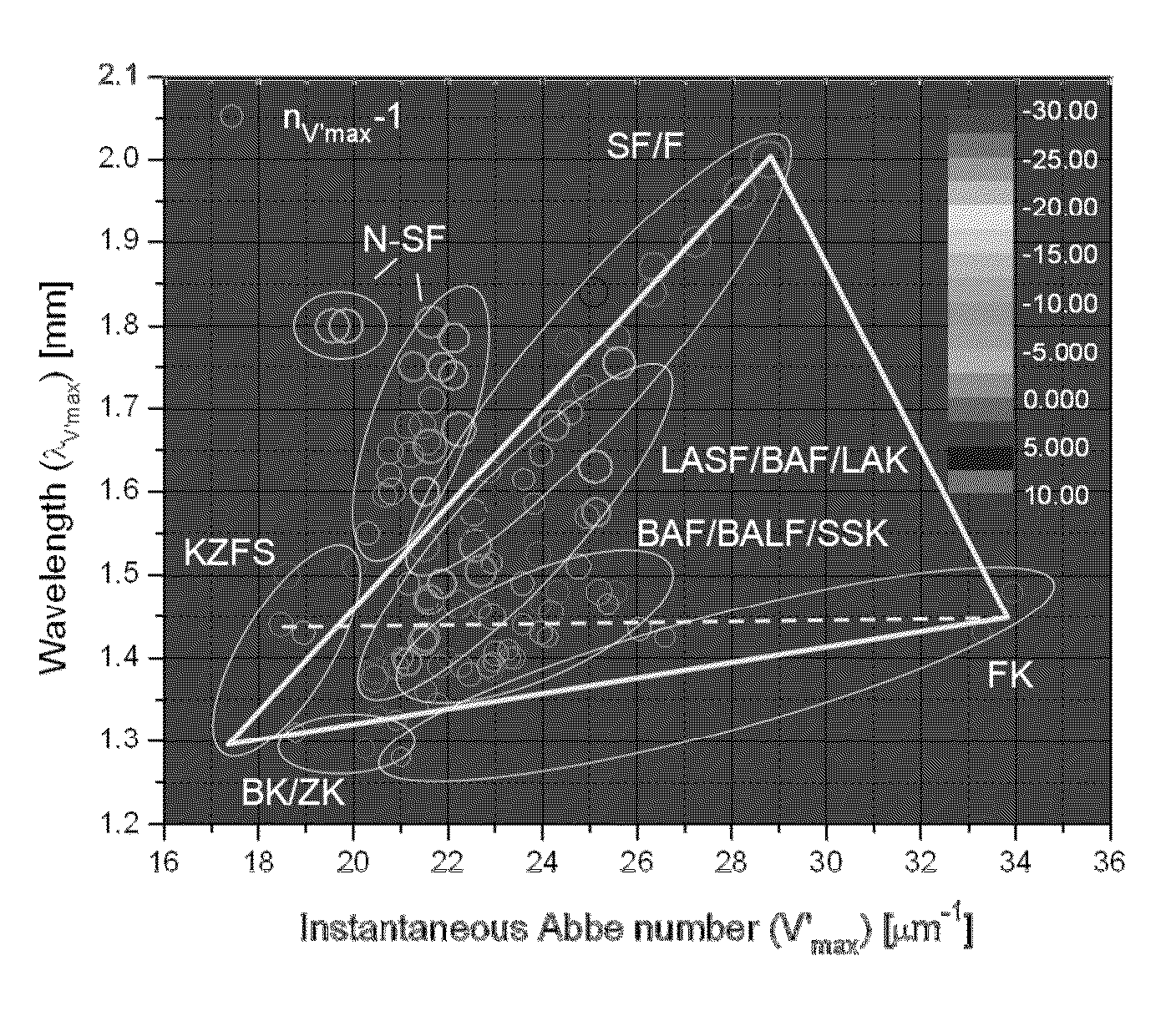

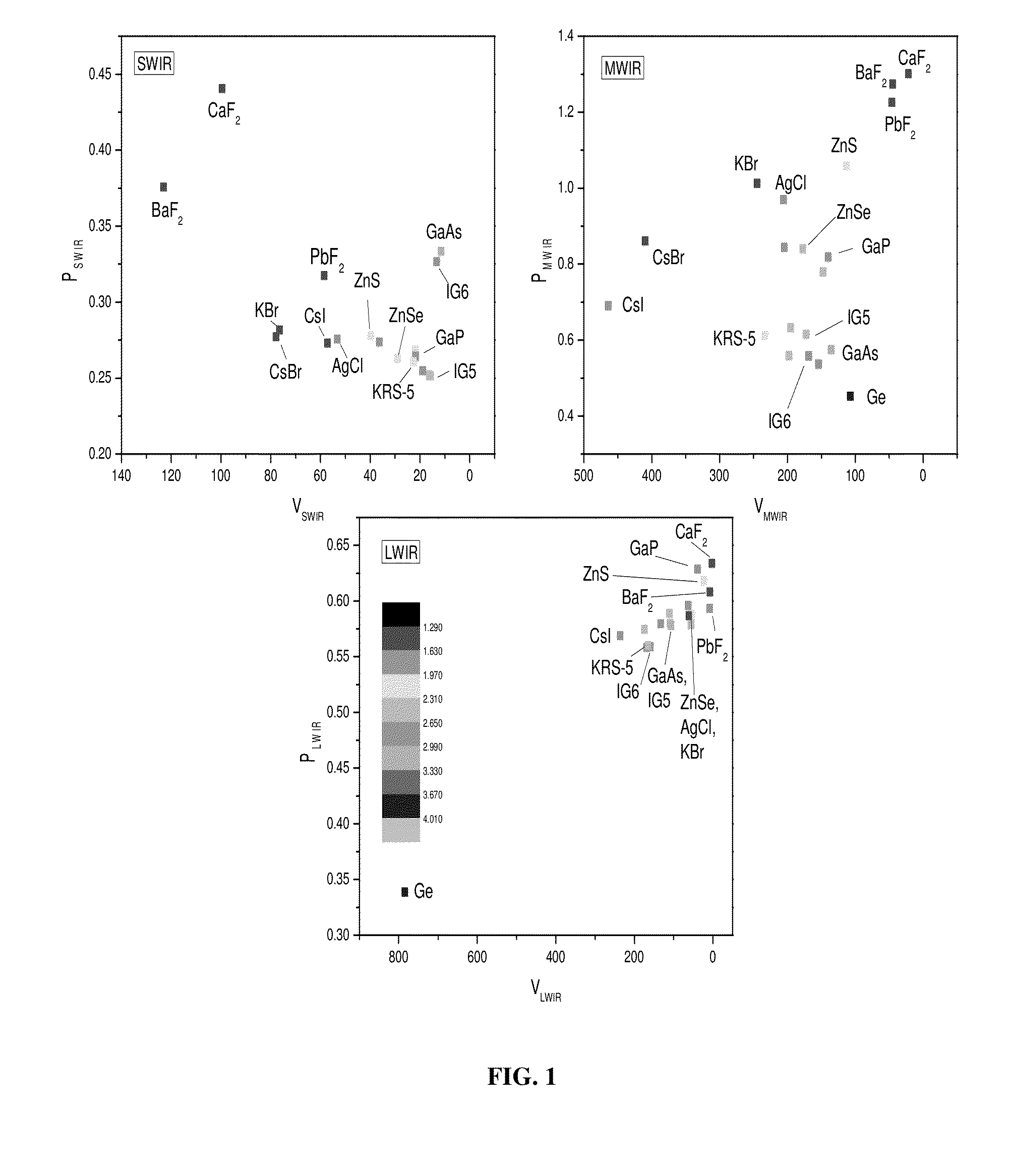

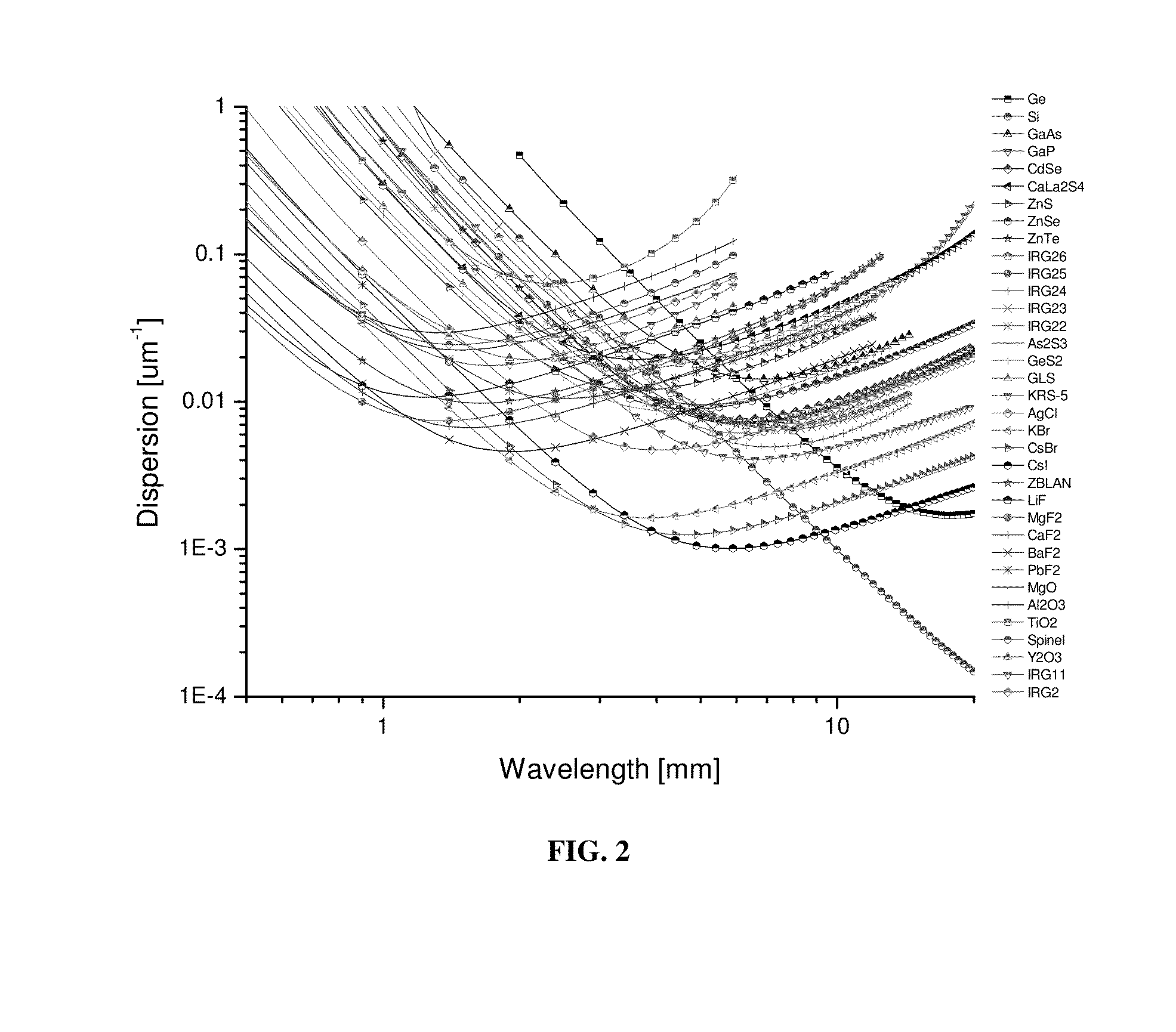

Glass selection for infrared lens design

InactiveUS20140268315A1Reduce overall chromatic aberrationEasy material selectionOptical elementsLength wave

The invention relates to process for manufacturing infrared optical lenses that will transmit in multiple infrared bands, for example, lenses with multiple optical elements such as doublet and triplet lenses (i.e., achromatic, apochromatic, and superachromatic optical elements). The lens materials are selected on the basis of dispersion ratios and / or minimum dispersions and minimum dispersion wavelengths as defined herein.

Owner:SCHOTT CORP

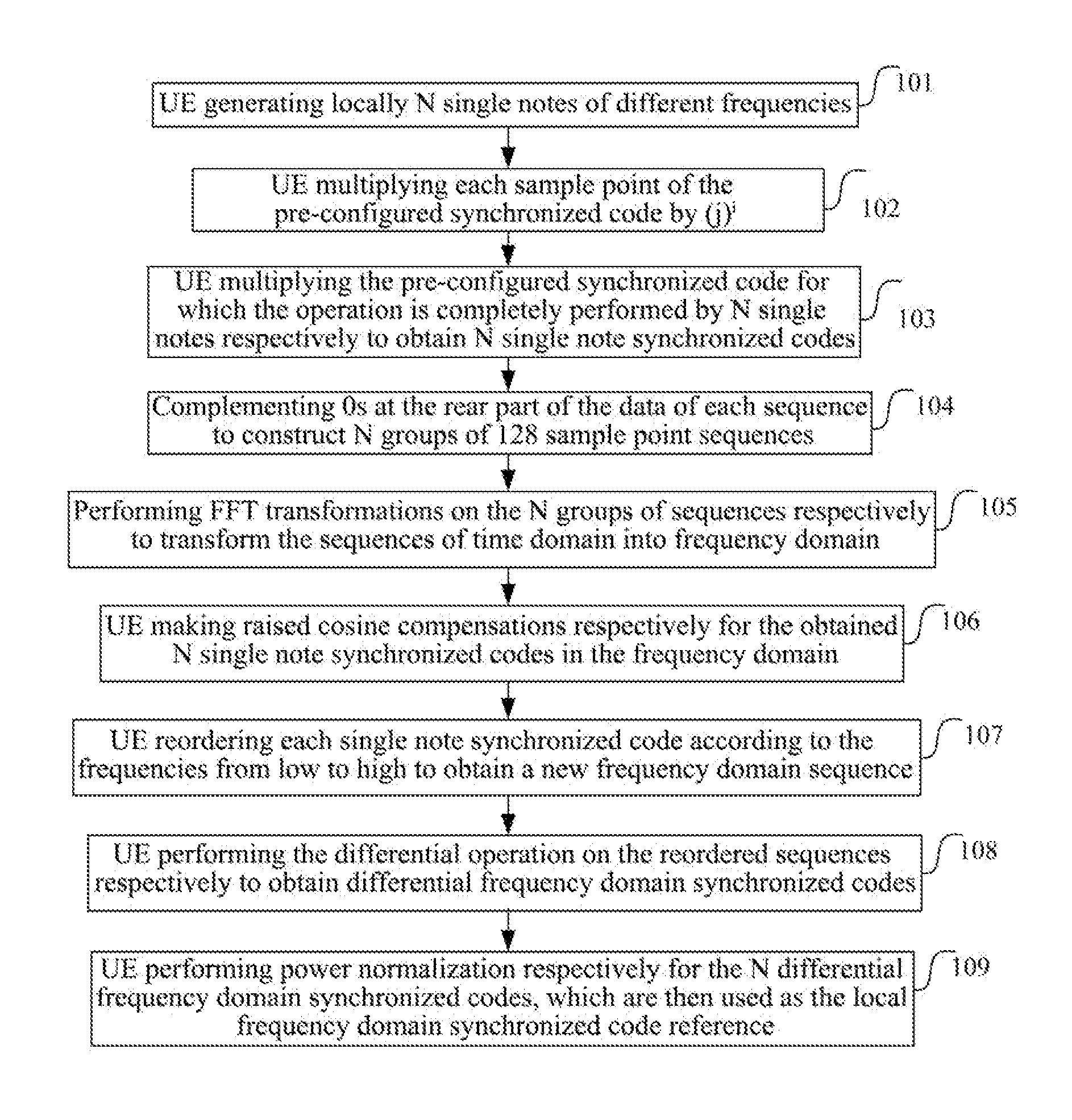

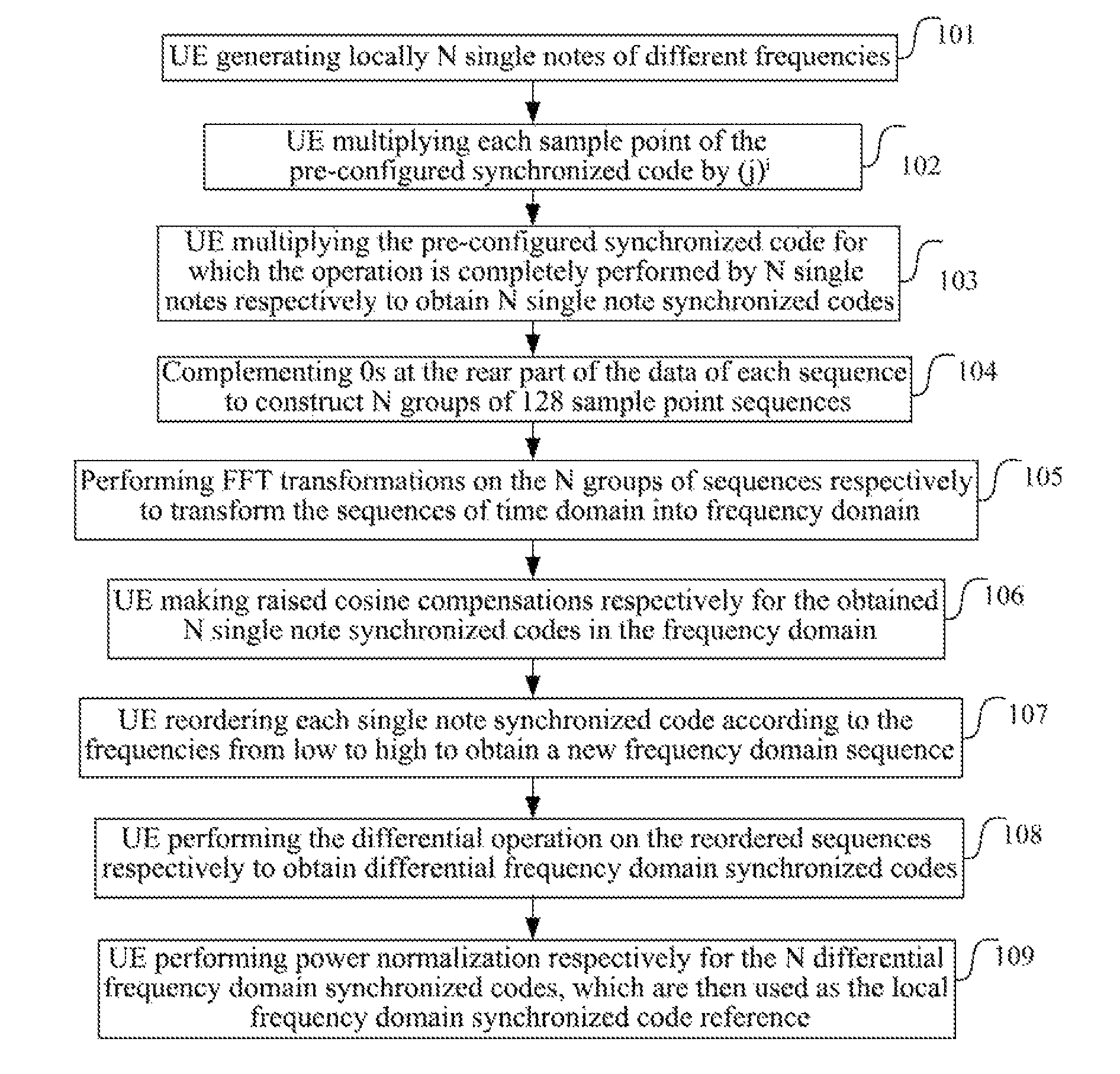

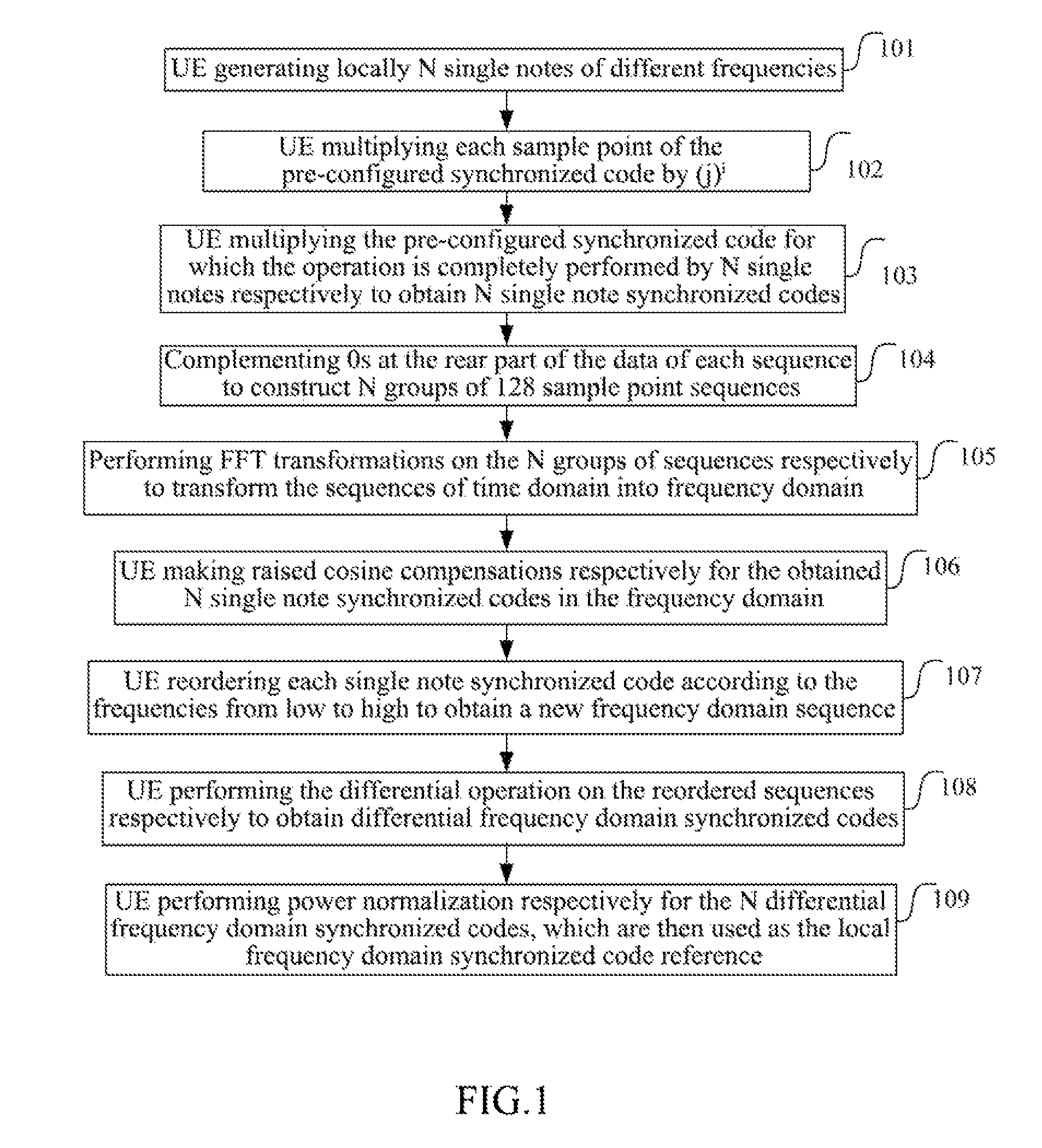

Method and Apparatus for Estimating Frequency Deviation

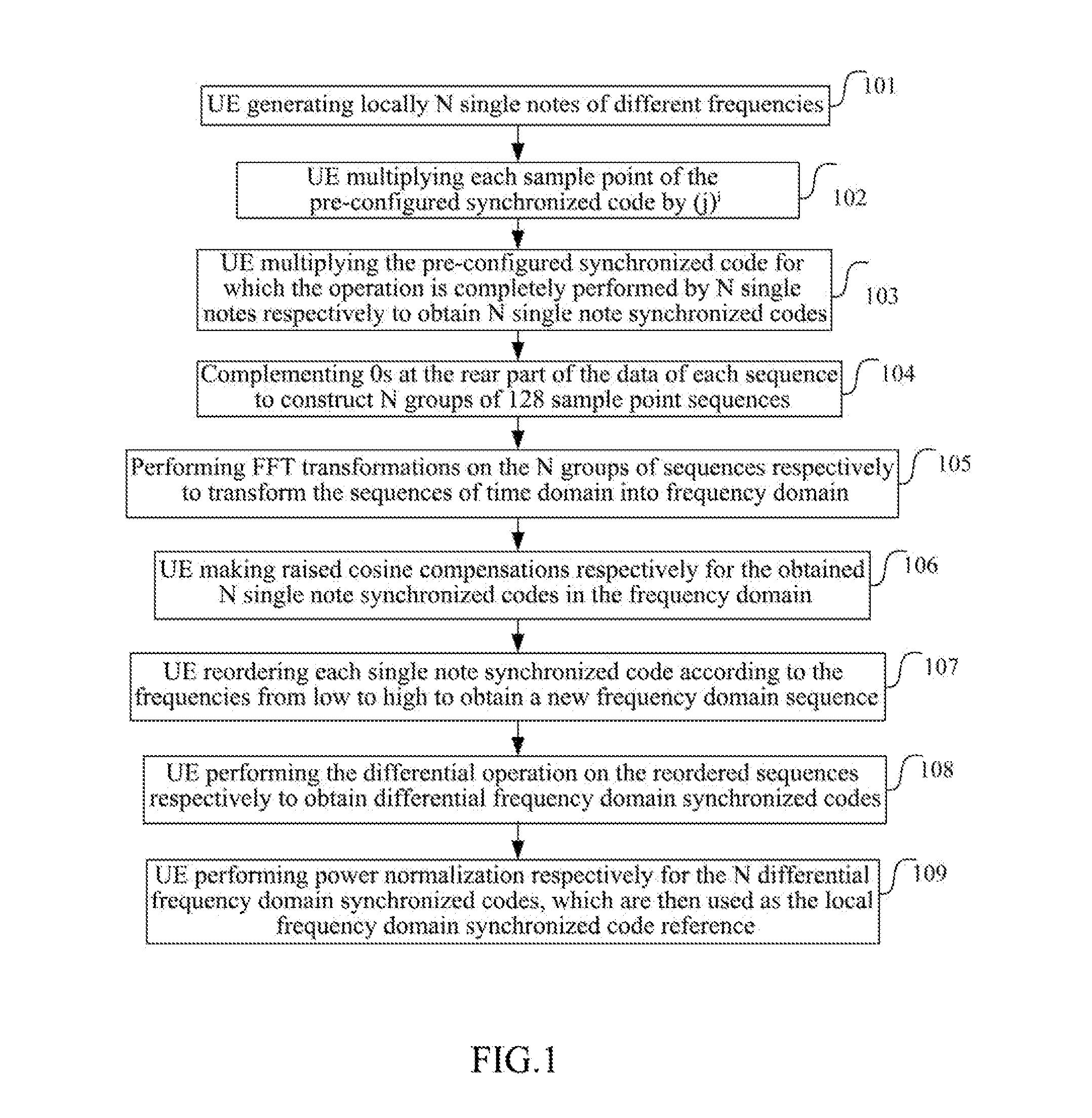

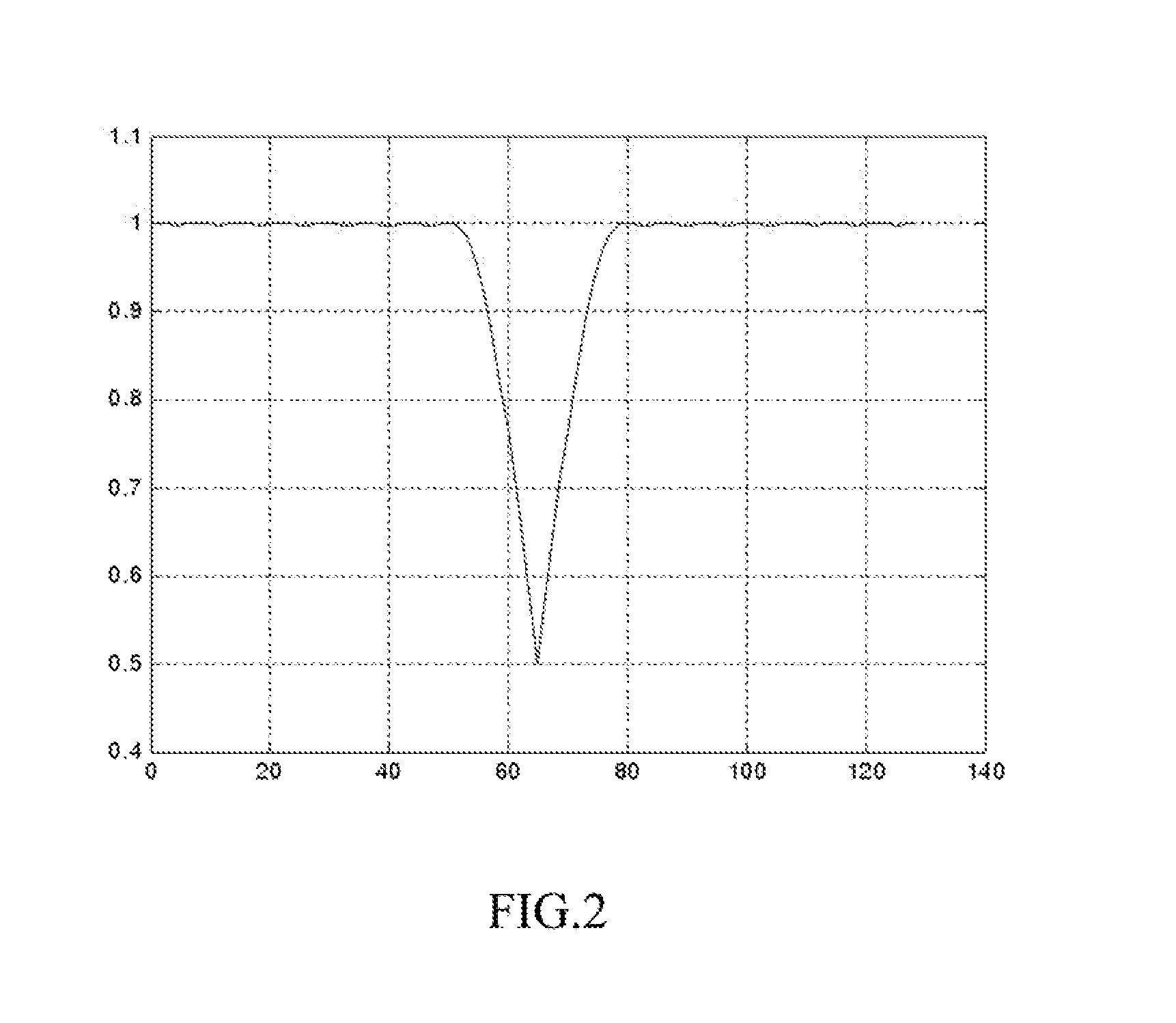

InactiveUS20130021966A1Lower performance requirementsReduced stabilitySynchronisation arrangementCode division multiplexComputer scienceMulti path

The invention provides a method and an apparatus for estimating frequency deviation, the method comprising: after receiving a sub-frame, transforming a downlink synchronized code of the sub-frame to a frequency domain, and performing a correlation operation between the transformed downlink synchronized code and a local frequency domain synchronized code to obtain a conjugate downlink synchronized code sequence; judging a location of a maximum value in the conjugate downlink synchronized code sequence, and calculating a frequency deviation value according to the location of the maximum value. The estimating method provided in the invention can realize a stable work with no need of a precise sampling value location, an accurate timing synchronization, or even obtaining the information for the multi-path distribution and locations.

Owner:SANECHIPS TECH CO LTD

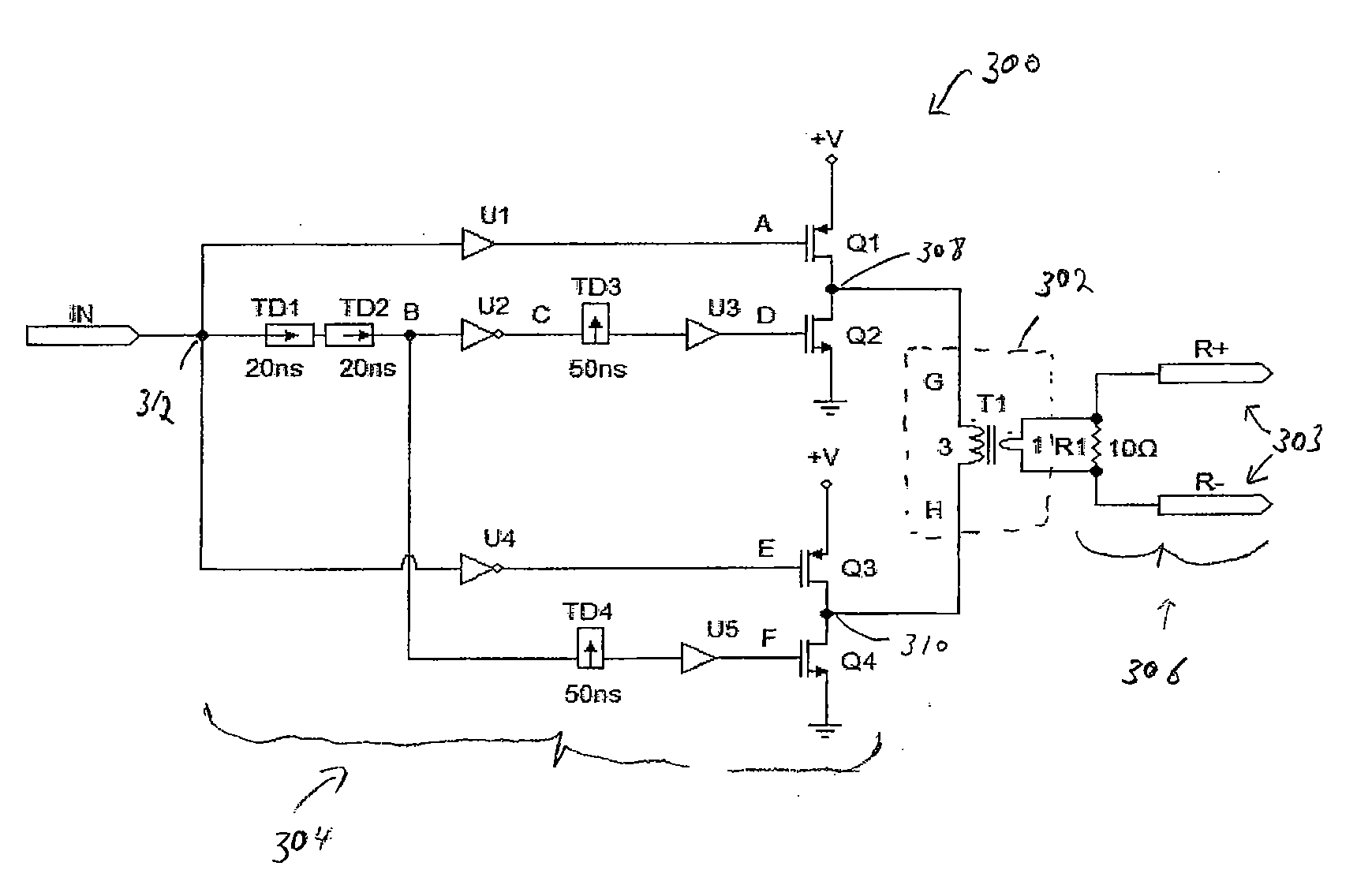

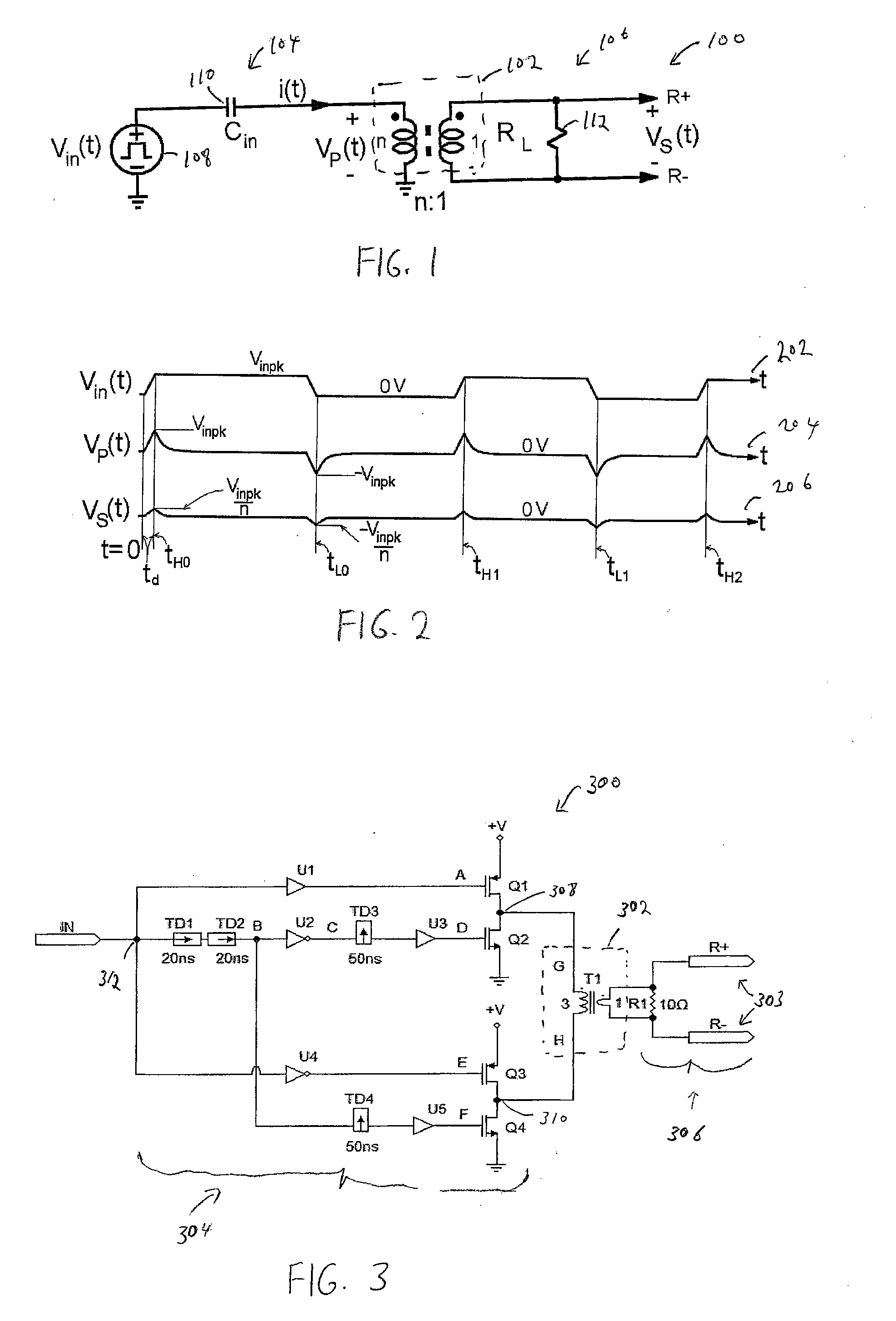

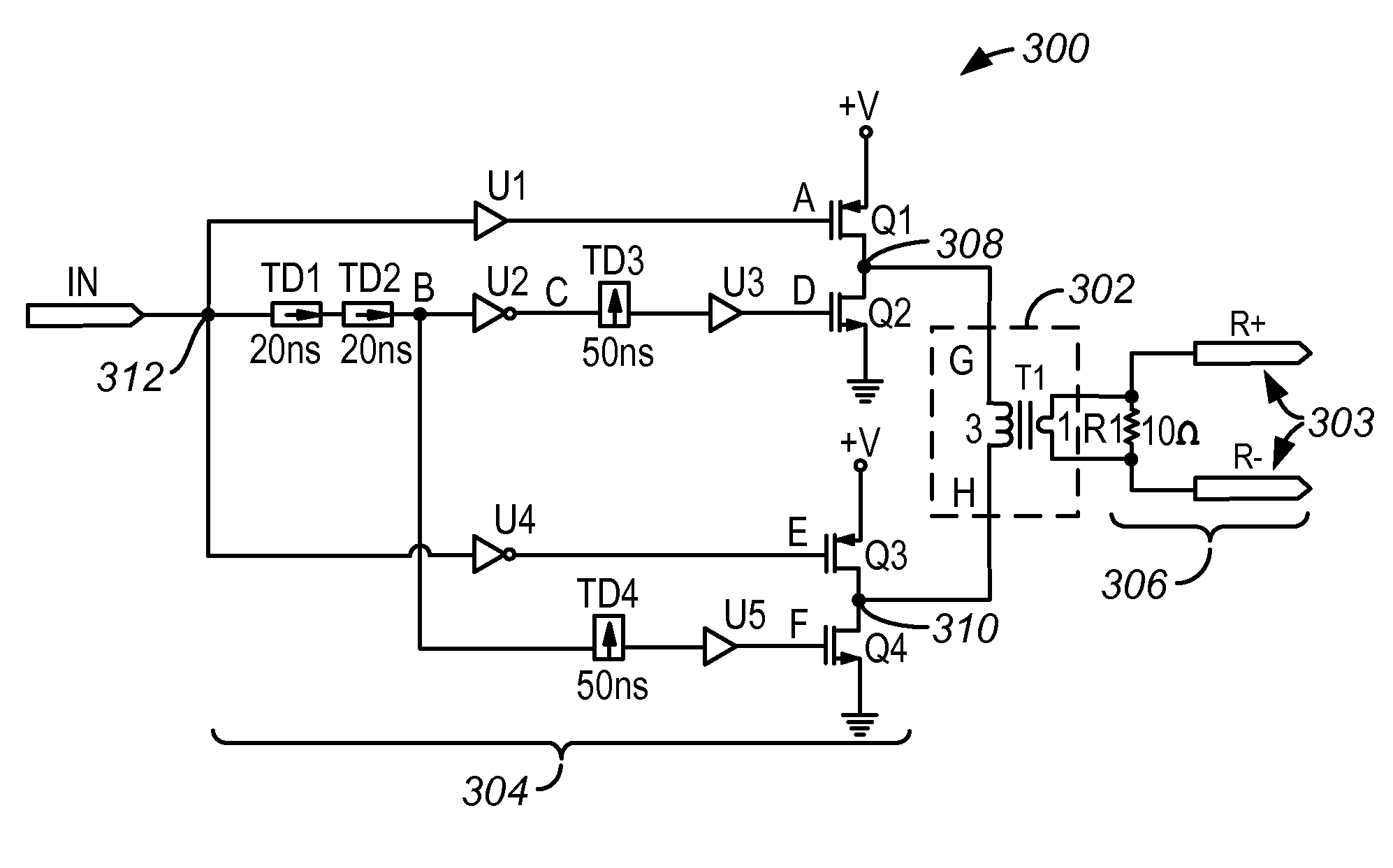

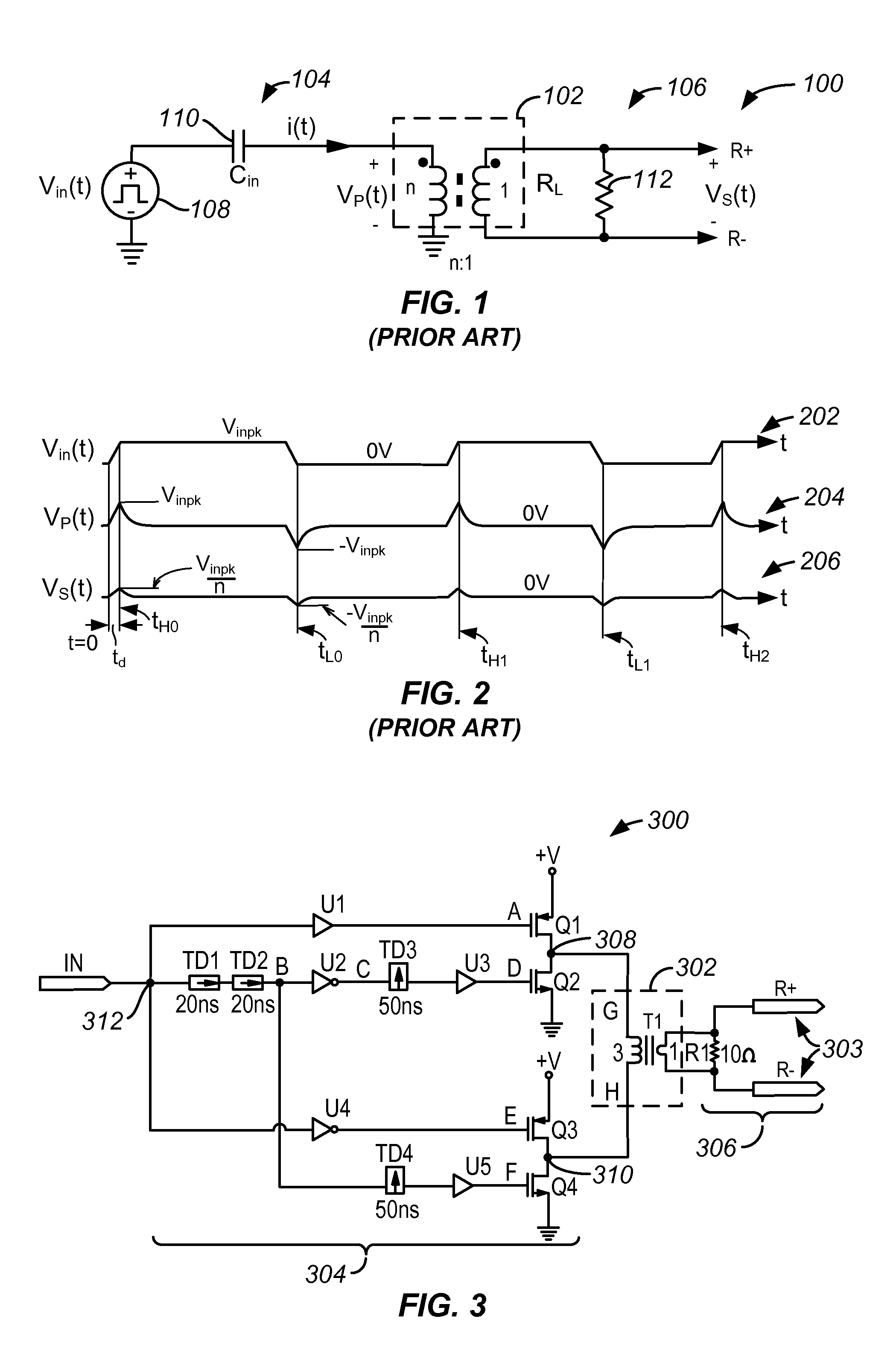

Signal differentiation with differential conversion circuit

ActiveUS20070194831A1Prevent transformer saturationEliminates frequency dependenceAc-dc conversionDc-dc conversionTransformerDifferential signaling

A circuit for transmitting signals includes a transformer having an input side and an output side, the input side having a first end and a second end. A first transistor is coupled to the first end of the transformer, the first transistor being configured to provide a first signal to the first end in response to an input signal transitioning to a first state. A second transistor is coupled to the second end of the transformer; the second transistor being configured to provide a second signal to the second end in response to the input signal transitioning to a second state. The output side is configured to output differential signals according to the first and second signals applied to the transformer.

Owner:LITTELFUSE INC

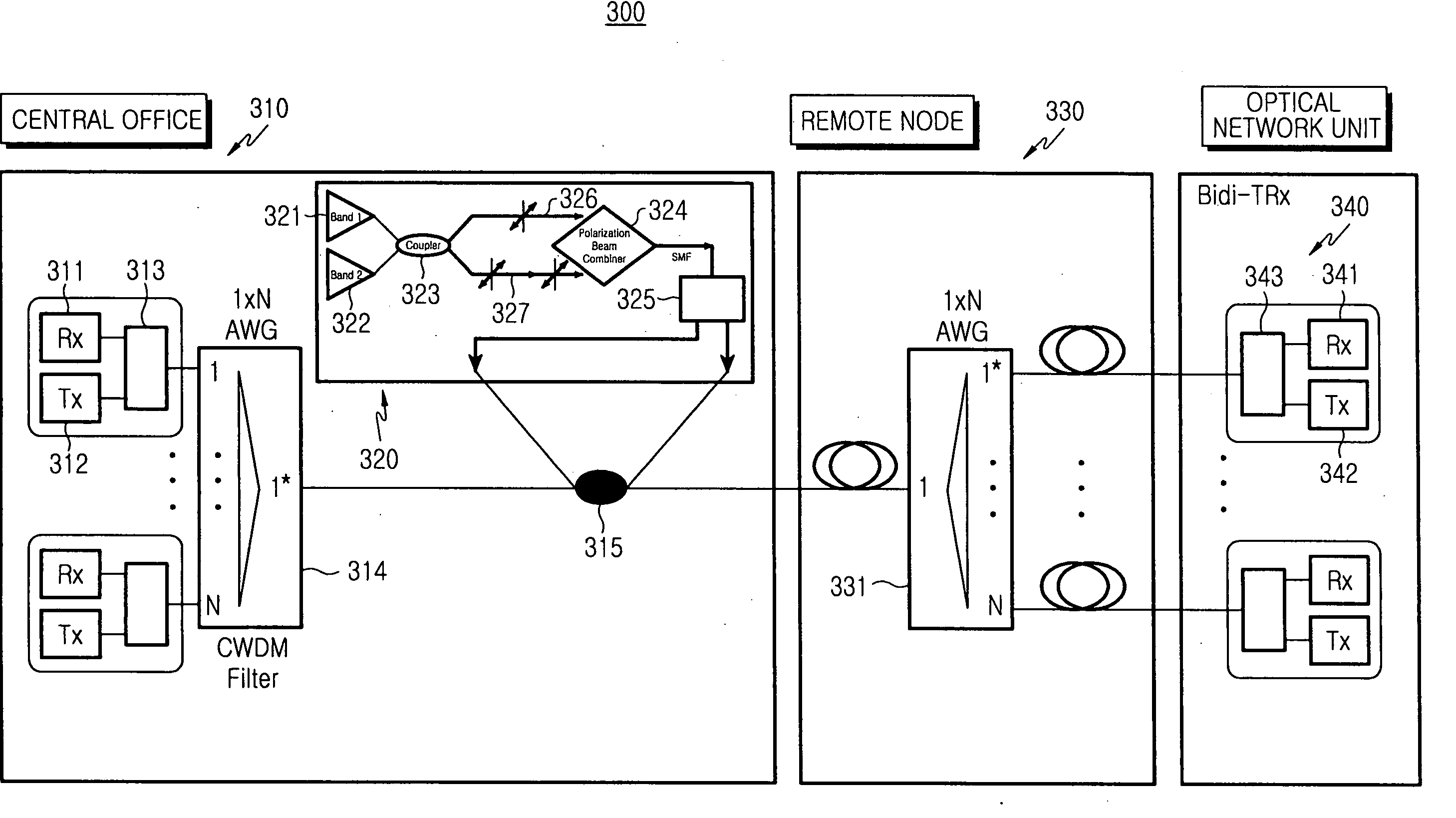

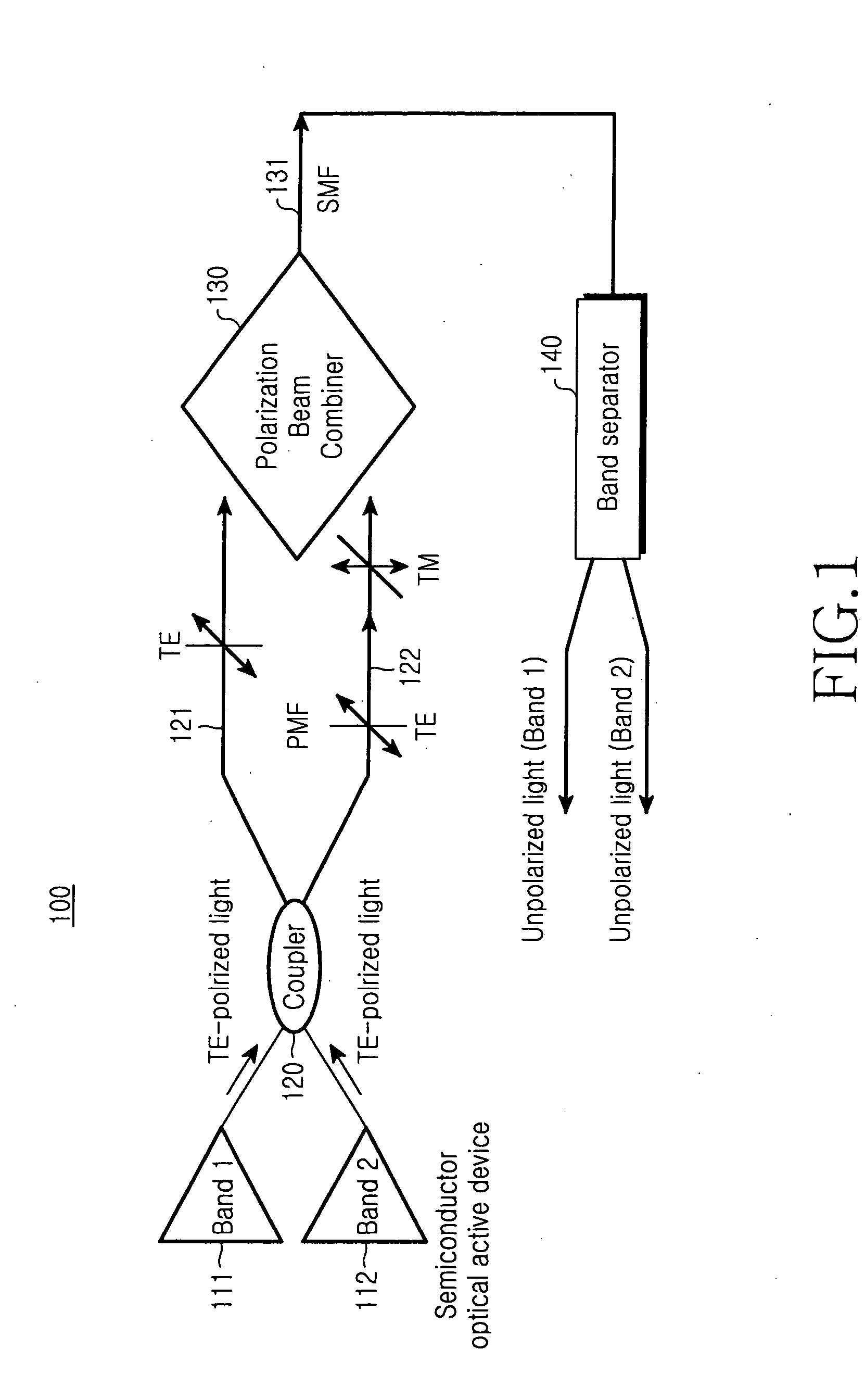

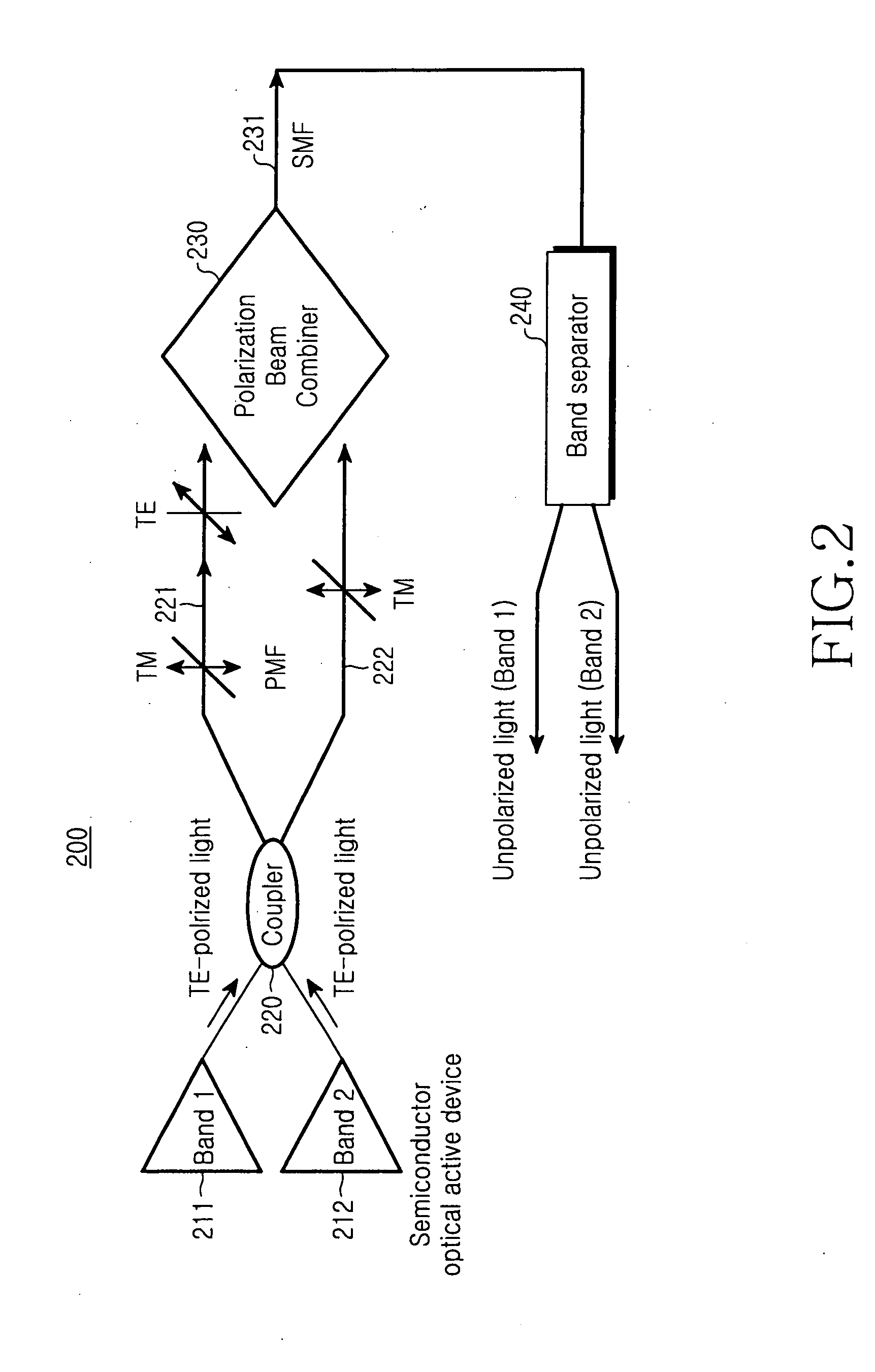

Wavelength-division-multiplexed passive optical network

InactiveUS20060147210A1Eliminating polarization dependenceEliminate dependencePolarisation multiplex systemsWavelength-division multiplex systemsBroadband light sourceLength wave

A broadband light source includes: at least two semiconductor optical active devices for generating TE polarized lights of different wavelength bands; an optical coupler for dividing each of the TE polarized lights input from each of the semiconductor optical active devices into two TE polarized lights, and outputting the two TE polarized lights, the two TE polarized lights including a first TE polarized light and a second TE polarized light; a first optical line for transmitting the first TE polarized light, while maintaining a polarization mode of the first TE polarized light; a second optical line for converting the second TE polarized light into a TM polarized light; a polarization beam combiner for combining the first TE polarized light and the TM polarized light to generate a polarization-independent light; and a band separator for separating and outputting the polarization-independent light according to wavelength bands.

Owner:SAMSUNG ELECTRONICS CO LTD

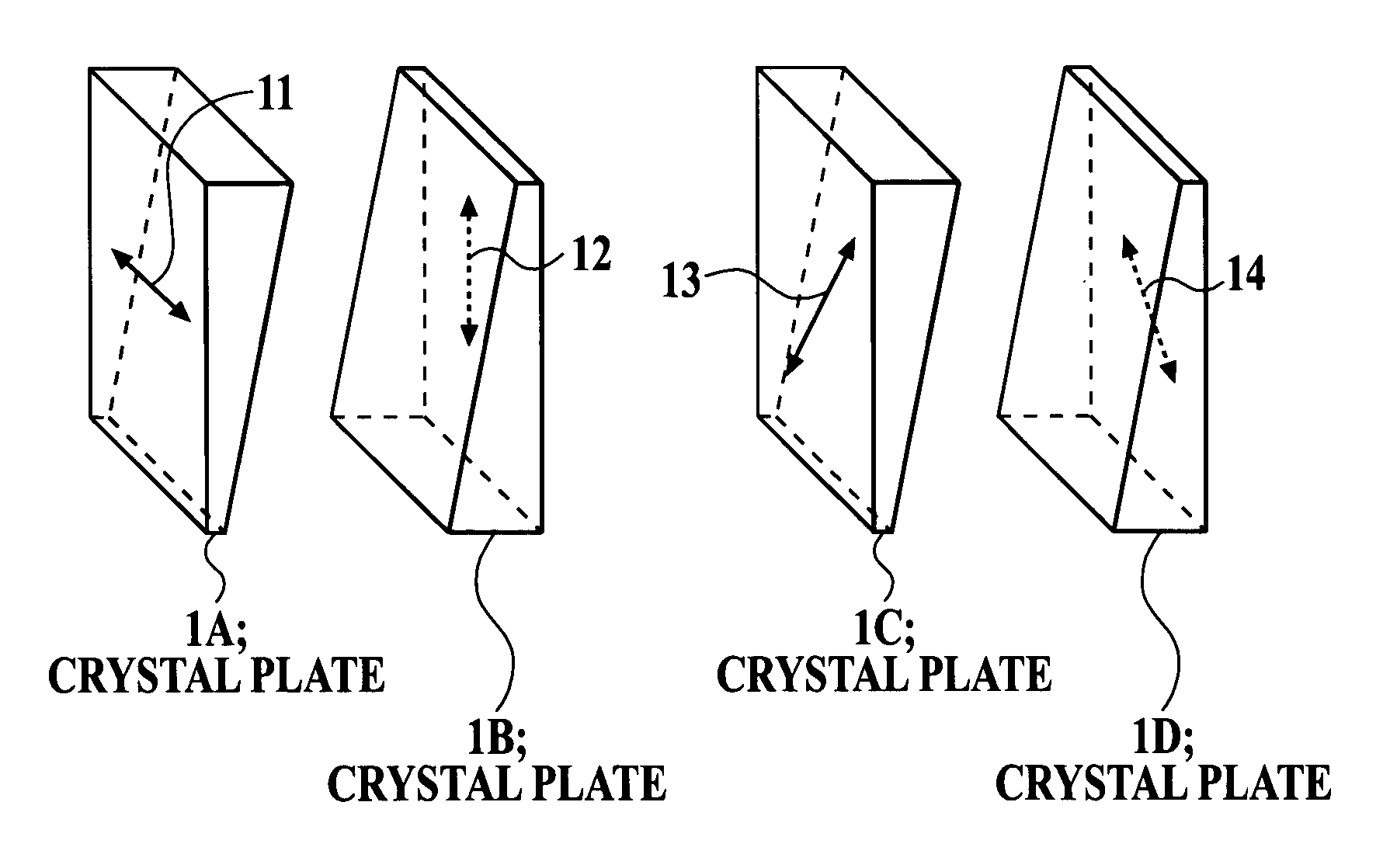

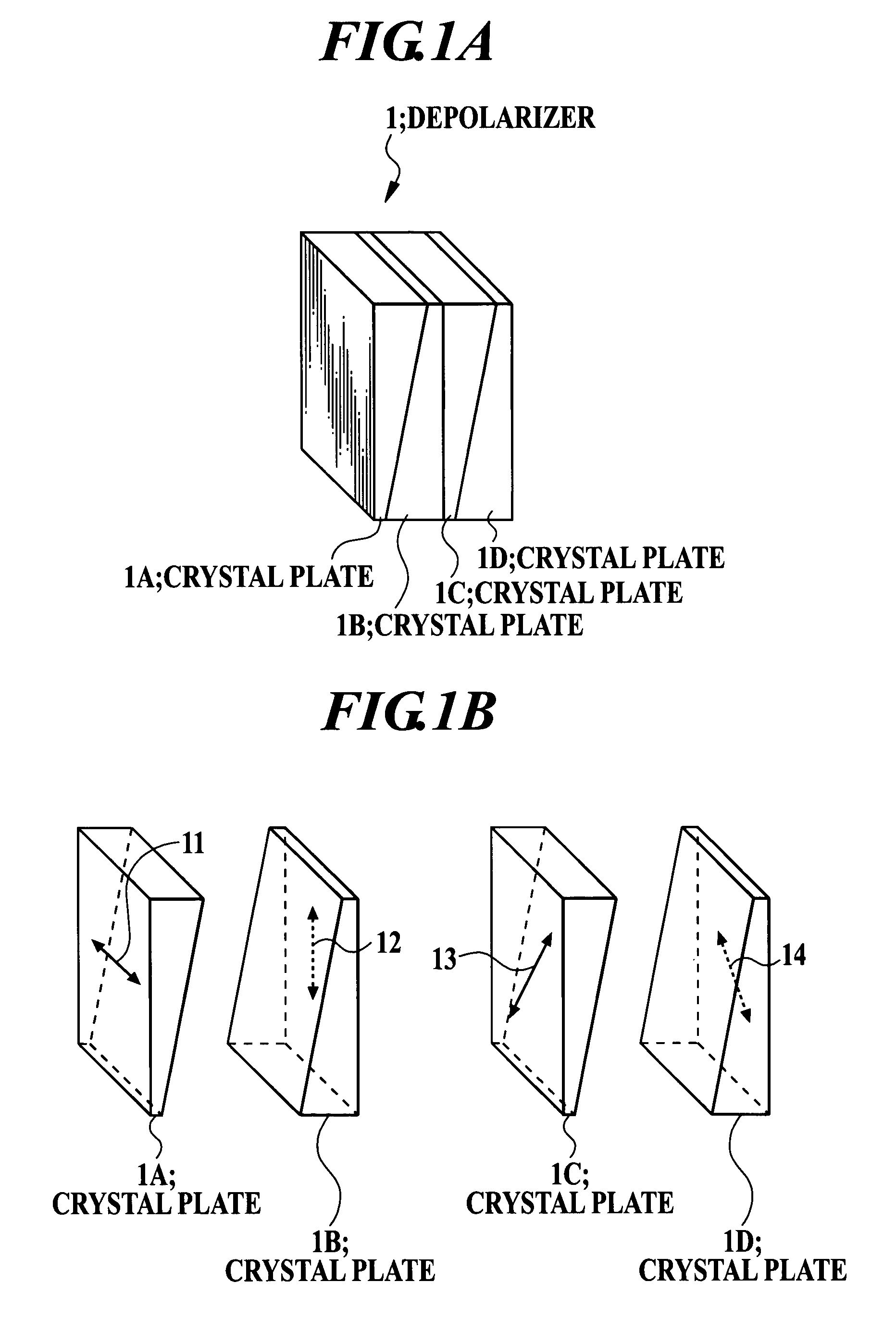

Depolarizer and spectroscope and polychromater

ActiveUS7075644B2Eliminate dependenceRadiation pyrometrySpectrum investigationOptical axisDepolarizer

Owner:YOKOGAWA ELECTRIC CORP

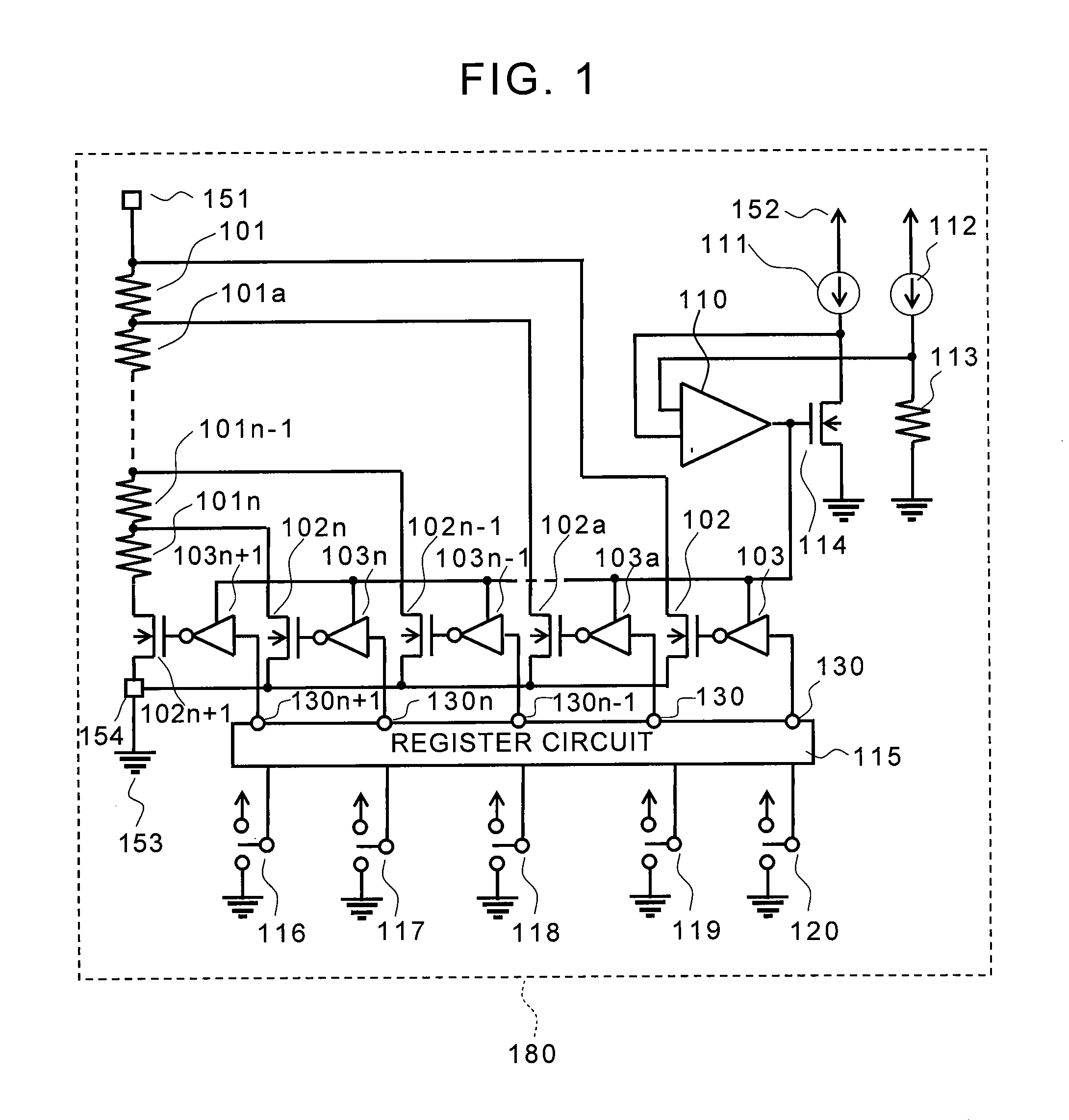

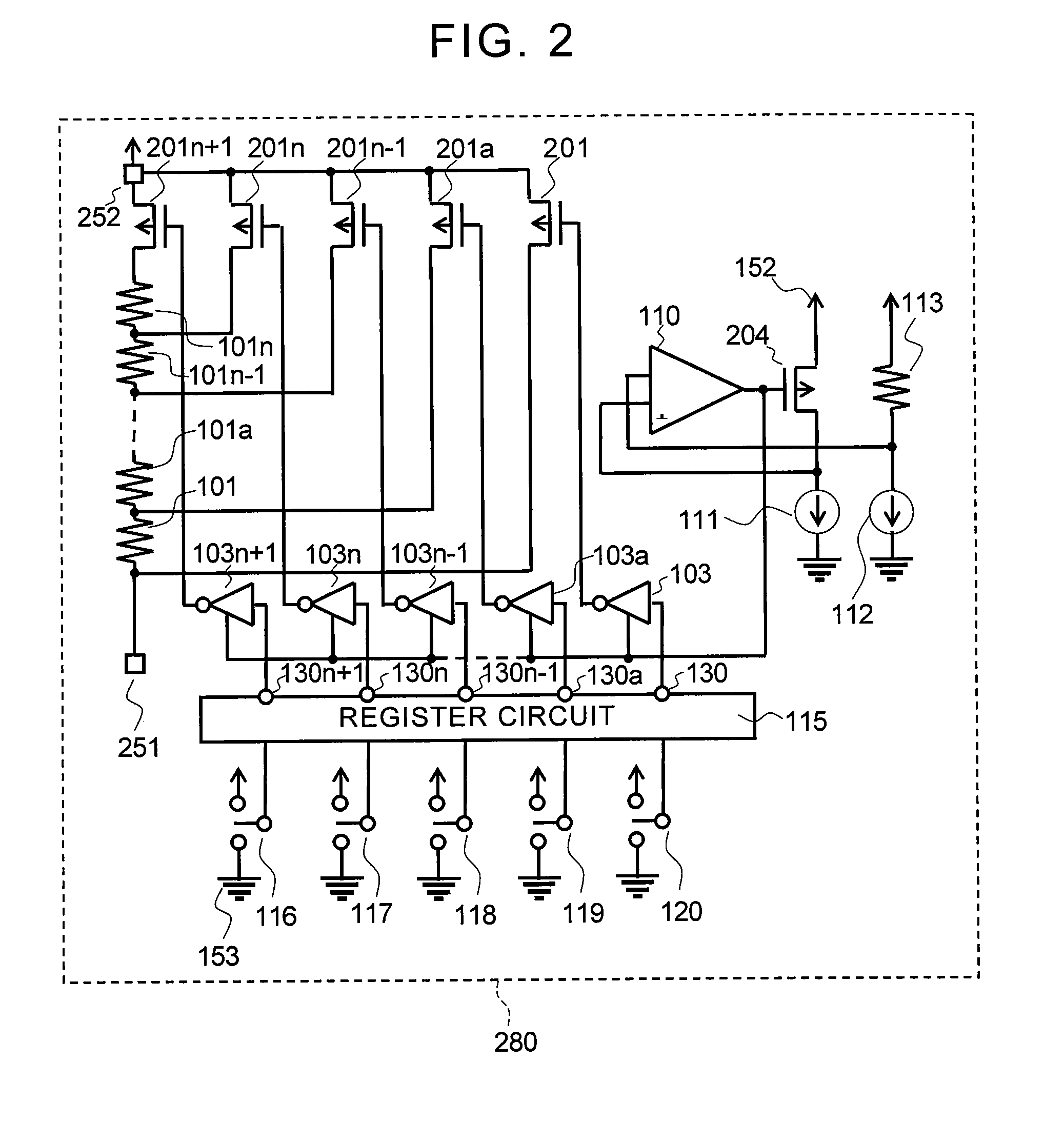

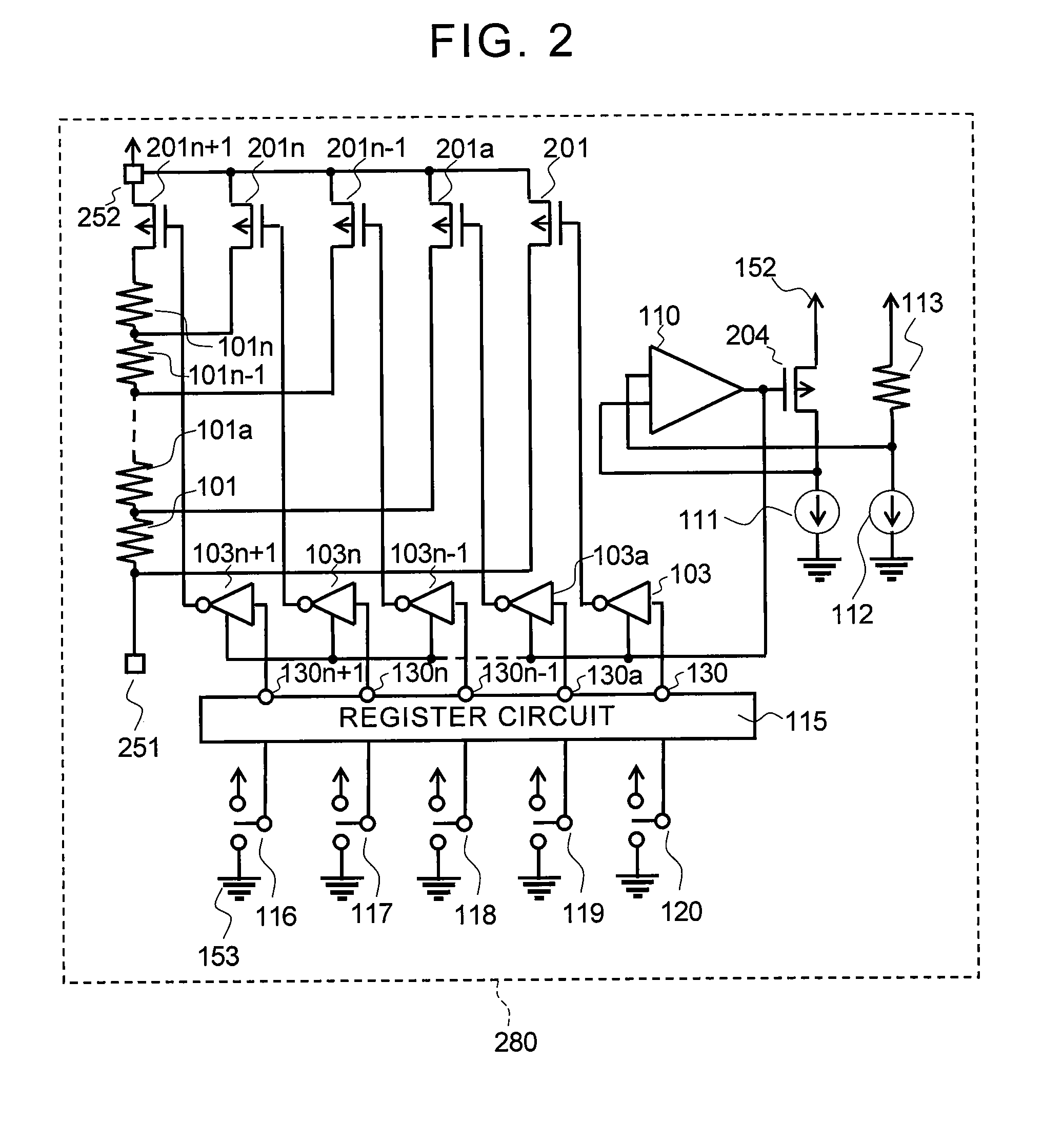

Semiconductor integrated circuit including variable resistor circuit

ActiveUS20110304376A1Amount of errorEliminating power supply voltage dependence dependenceOther resistor networksPulse automatic controlControl circuitSemiconductor

Provided is a semiconductor integrated circuit including a variable resistor circuit of the small layout area, which is free from an error in resistance caused by ON-state resistances of switch elements for trimming, and is also free from power supply voltage dependence and temperature dependence. The semiconductor integrated circuit including a variable resistor circuit includes: a resistor circuit including a plurality of series-connected resistors; a selection circuit including a plurality of switch elements for selecting a connected number of the plurality of series-connected resistors; and a control circuit for controlling ON-state resistances of the plurality of switch elements. The control circuit controls the ON-state resistances of the plurality of switch elements so as to obtain a predetermined ratio to a resistance of the plurality of series-connected resistors of the resistor circuit.

Owner:ABLIC INC

Method and apparatus for estimating frequency deviation

InactiveUS8867443B2Lower performance requirementsReduced stabilitySynchronisation arrangementAmplitude-modulated carrier systemsComputer scienceMulti path

The invention provides a method and an apparatus for estimating frequency deviation, the method comprising: after receiving a sub-frame, transforming a downlink synchronized code of the sub-frame to a frequency domain, and performing a correlation operation between the transformed downlink synchronized code and a local frequency domain synchronized code to obtain a conjugate downlink synchronized code sequence; judging a location of a maximum value in the conjugate downlink synchronized code sequence, and calculating a frequency deviation value according to the location of the maximum value. The estimating method provided in the invention can realize a stable work with no need of a precise sampling value location, an accurate timing synchronization, or even obtaining the information for the multi-path distribution and locations.

Owner:SANECHIPS TECH CO LTD

Method of manufacturing a semiconductor device

InactiveUS7300877B2Secure desired planarityInhibition formationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSlurry

A method of manufacturing a semiconductor device that prevents formation of scratches and occurrence of dishing in a CMP process. The method includes forming a first film on a part of a semiconductor substrate, forming a second film all over the semiconductor substrate, and a CMP process utilizing a ceria slurry to planarize the second film using the first film as a mask, the CMP process including performing a first CMP until a portion of the first film is exposed and performing a second CMP. A first ceria slurry of a predetermined abrasive grain concentration is employed in the first CMP, and a second ceria slurry of lower abrasive grain concentration is employed in the the second CMP. The number of scratches is reduced by reducing the abrasive grain concentration of the ceria slurry, and dishing is prevented by reducing a polishing rate ratio between the first and second films.

Owner:RENESAS ELECTRONICS CORP

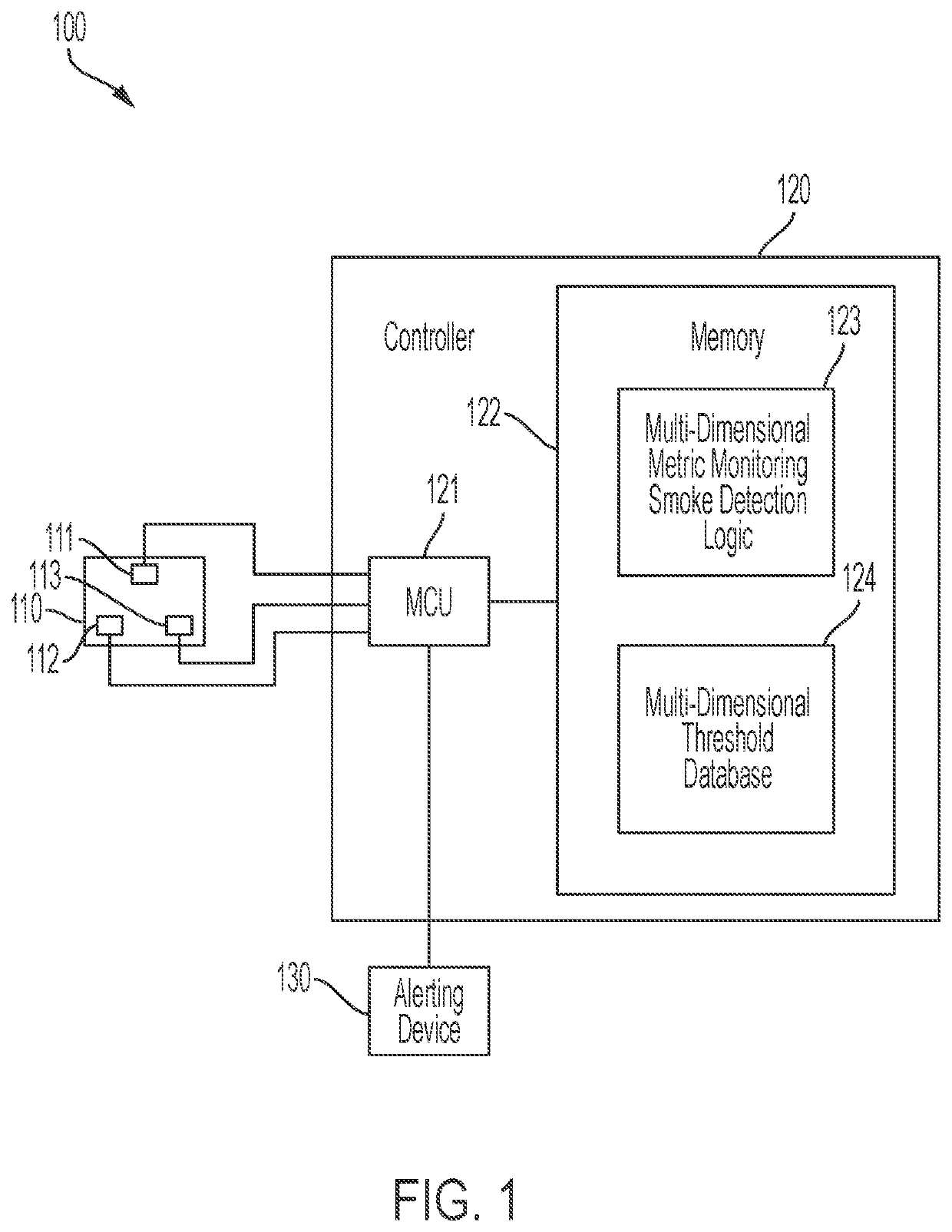

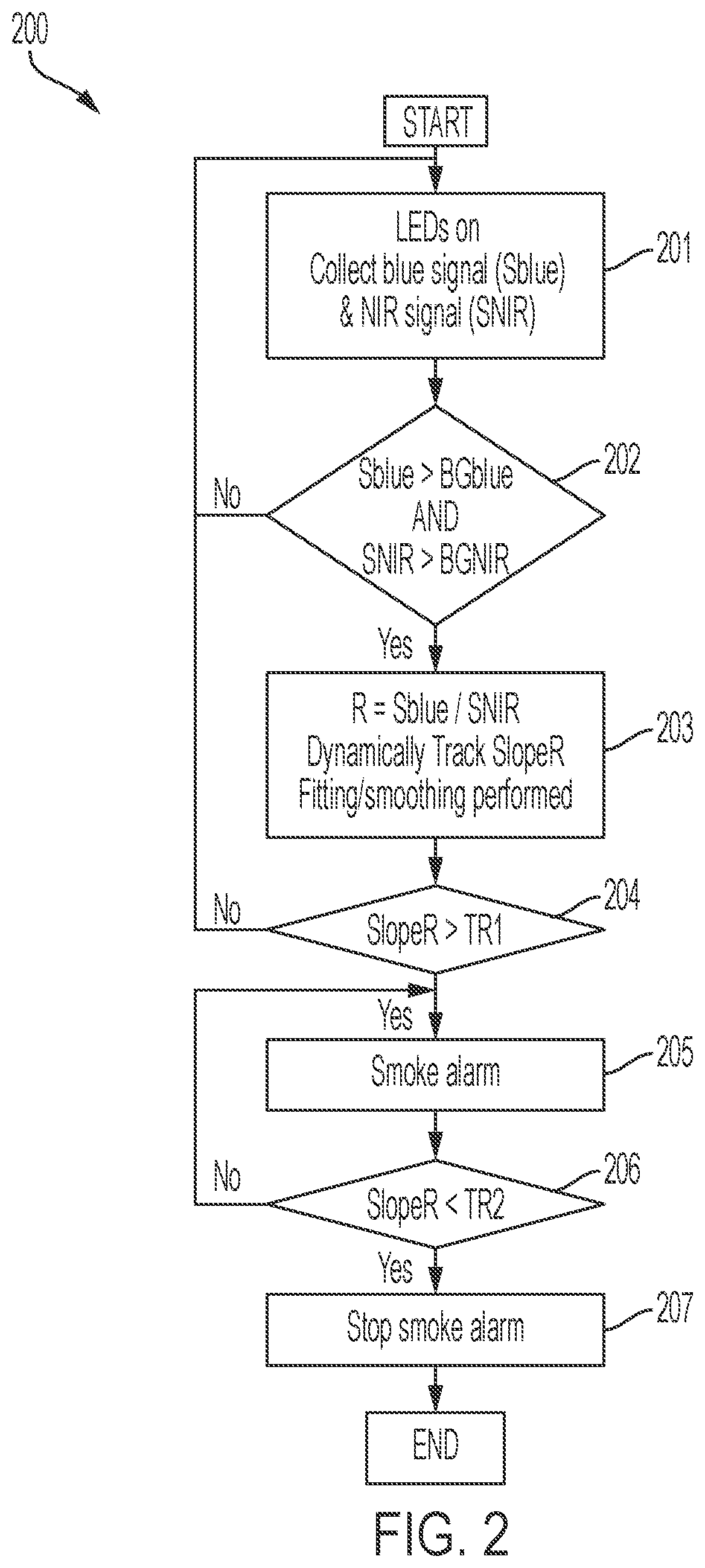

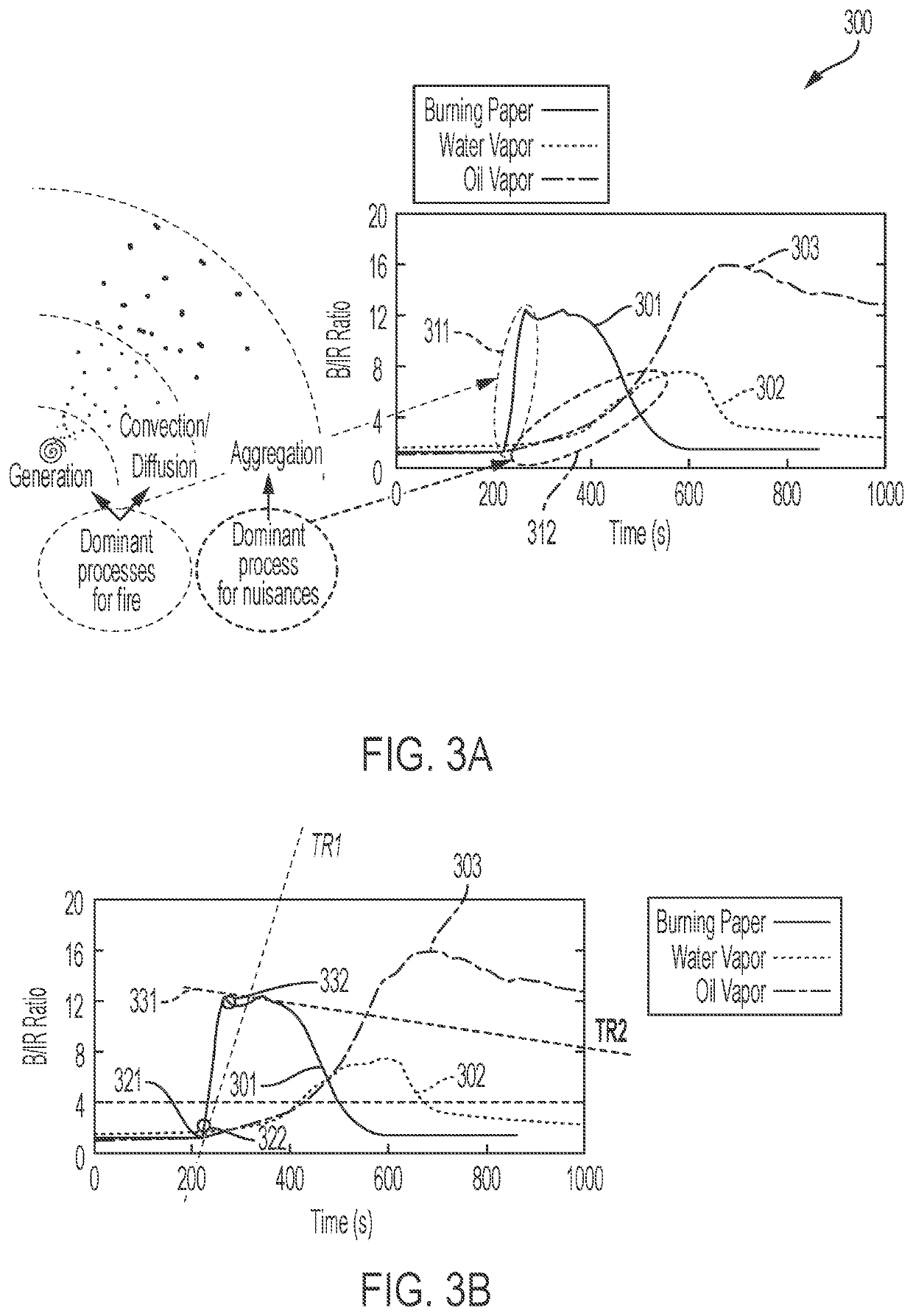

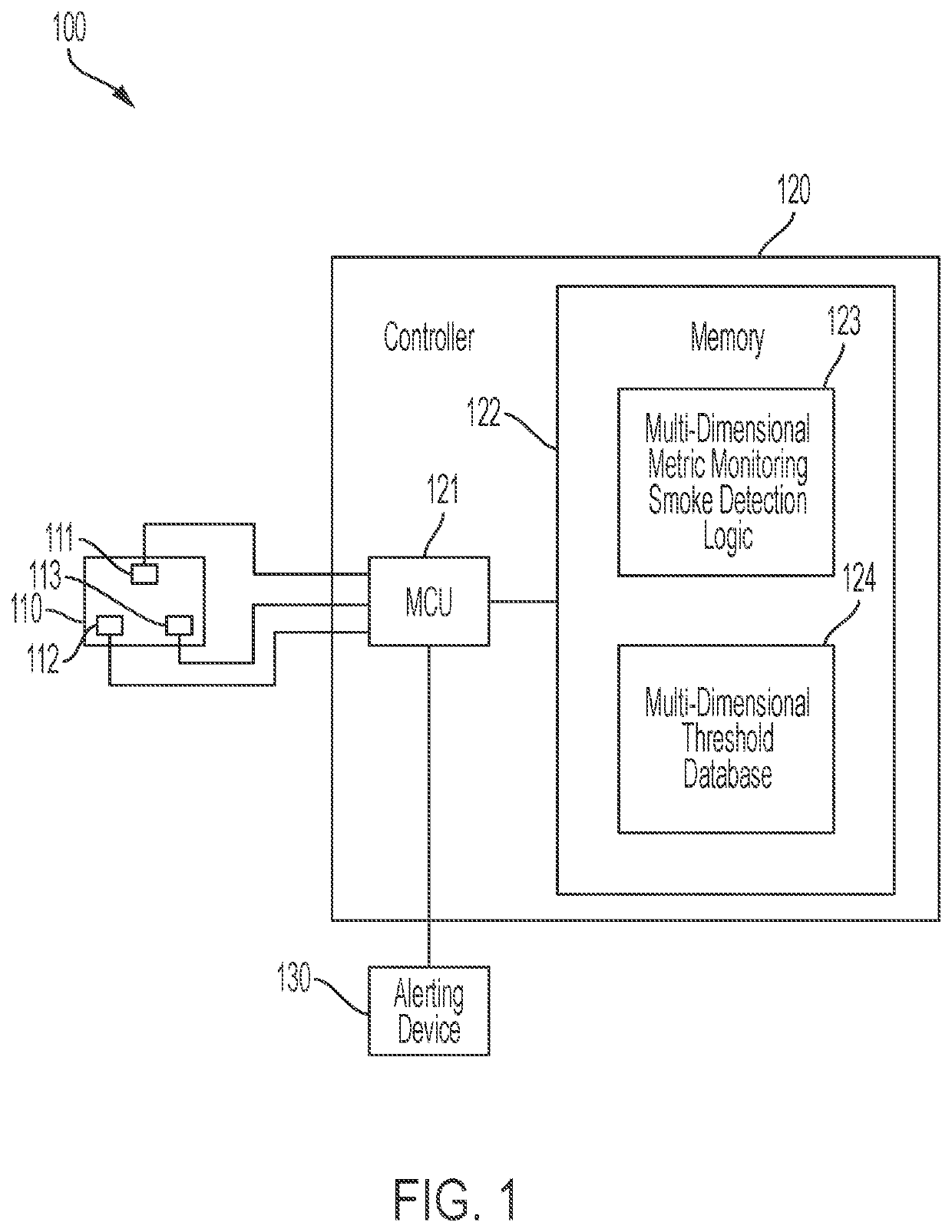

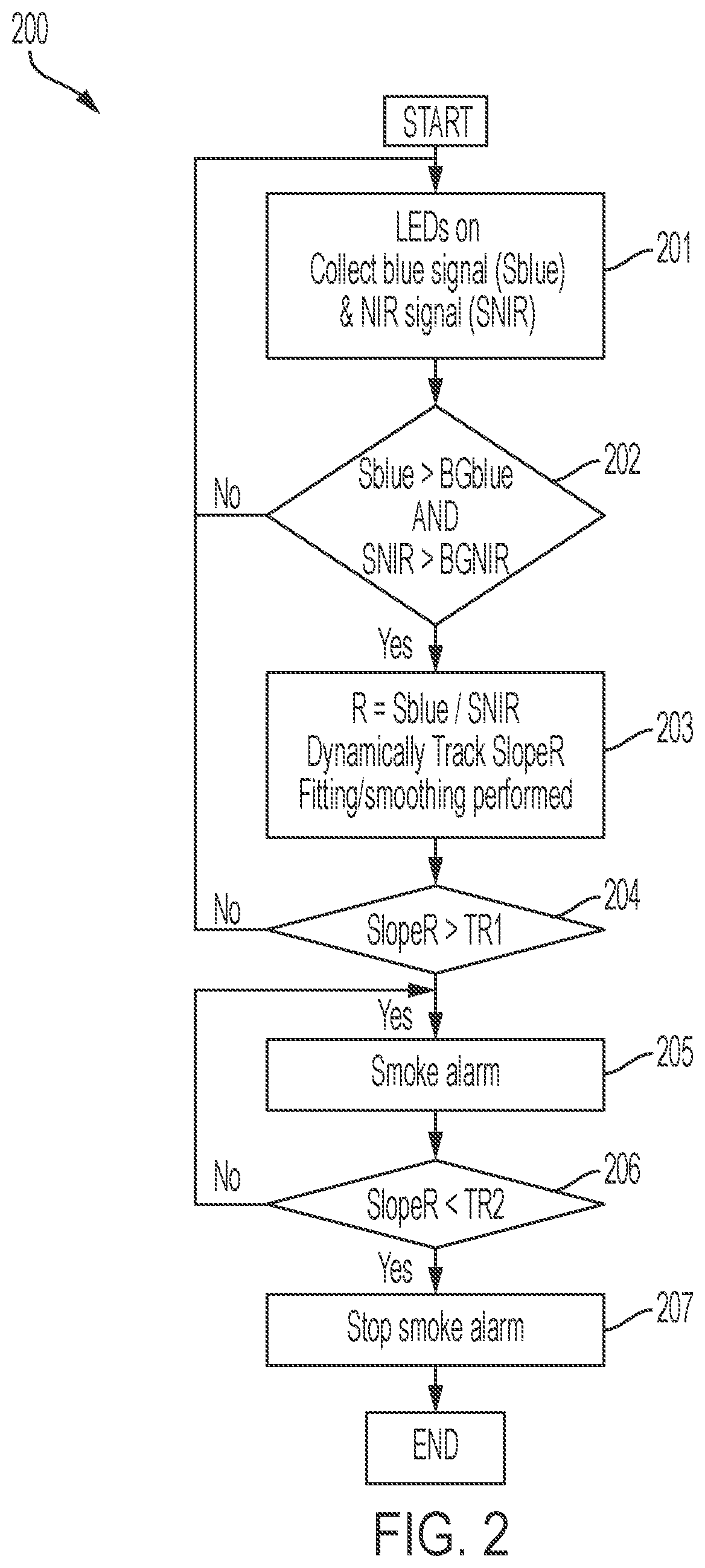

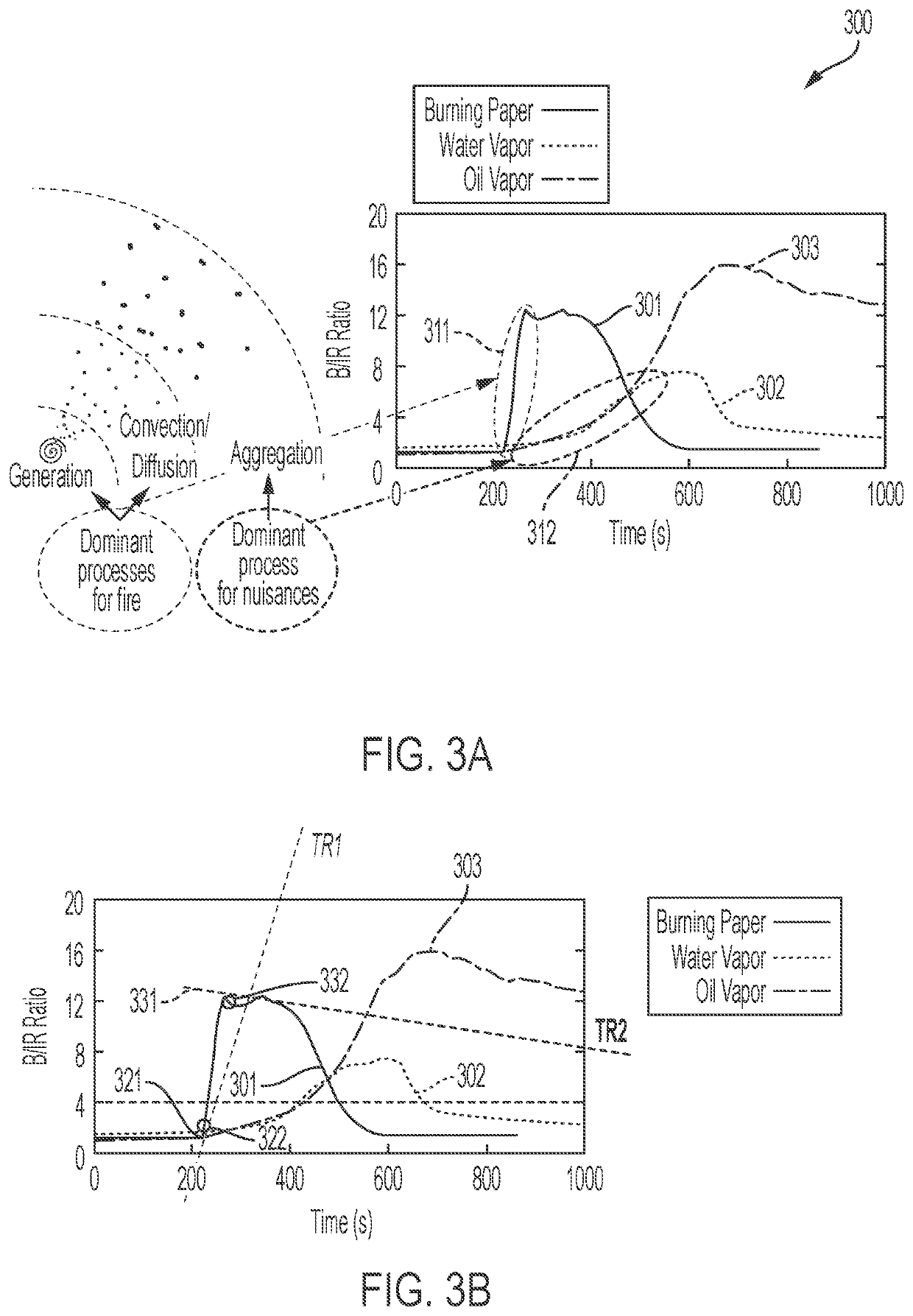

Systems and methods for multi-wavelength scattering based smoke detection using multi-dimensional metric monitoring

ActiveUS20220099572A1Facilitate reliable alarm initiationEliminate dependenceScattering properties measurementsFire alarmsMonitoring systemEngineering

Systems and methods in which multi-dimensional metric monitoring is used with respect to multi-wavelength scattering for smoke detection are described. A multi-dimensional metric may dynamically track a slope of a relationship between scattered light of multiple wavelengths of scattered light being monitored. A multi-dimensional metric monitoring smoke detection algorithm may utilize multi-dimensional thresholds with respect to monitoring of the multi-dimensional metric for initiating a fire alarm and resetting the fire alarm. An optical measuring chamber utilized for providing multi-wavelength scattering signals utilized in deriving a multi-dimensional metric for smoke detection may be configured for wide-scattering-angle signal collection, such as using a light trapping sub-chamber having a light-guide diaphragm assembly configured for wide-scattering-angle signal collection.

Owner:HONG KONG APPLIED SCI & TECH RES INST

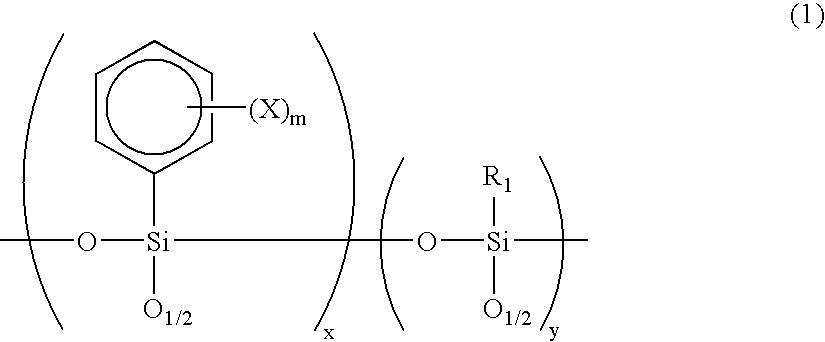

Photosensitive composition for manufacturing optical waveguide, production method thereof and polymer optical waveguide pattern formation method using the same

InactiveUS6933097B2Improve performanceImprove thermal stabilityPhotosensitive materialsRadiation applicationsPolymer optical waveguideWaveguide

A photosensitive composition for optical waveguides comprising of an organic oligomer, a polymerization initiator and a crosslinking agent, the organic oligomer being a silicone oligomer represented by the following formula (1), wherein X denotes hydrogen, deuterium, halogen, an alkyl group or an alkoxy group; m is an integer from 1 to 5; x and y represent the proportion of respective units, and neither x nor y is 0; and R1 denotes a methyl, ethyl, or isopropyl group; a production method thereof, and a polymer optical waveguide pattern formation method using the same.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Signal differentiation with differential conversion circuit

ActiveUS7719861B2Avoid saturationEliminate dependenceAc-dc conversionDc-dc conversionTransformerDifferential signaling

Owner:LITTELFUSE INC

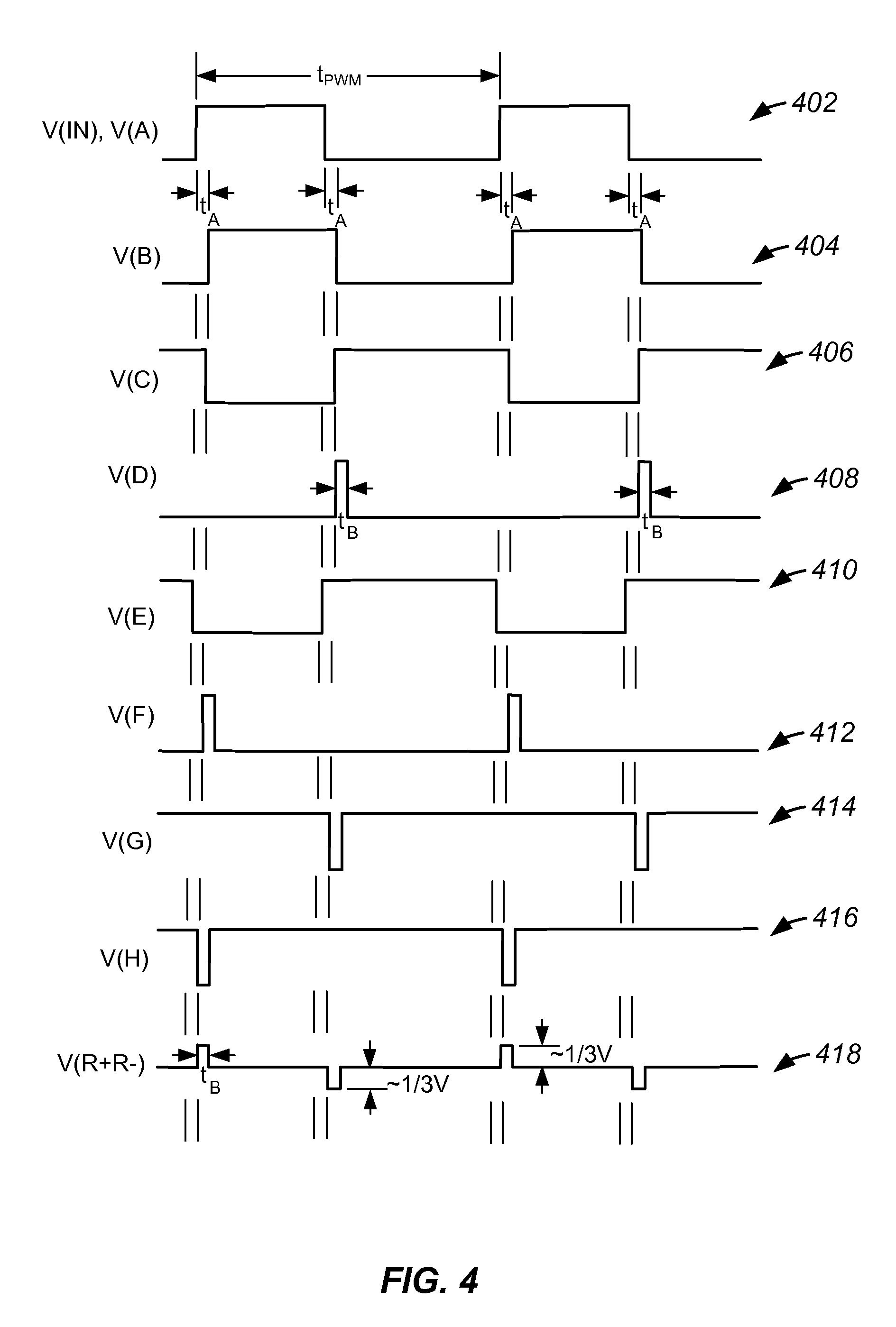

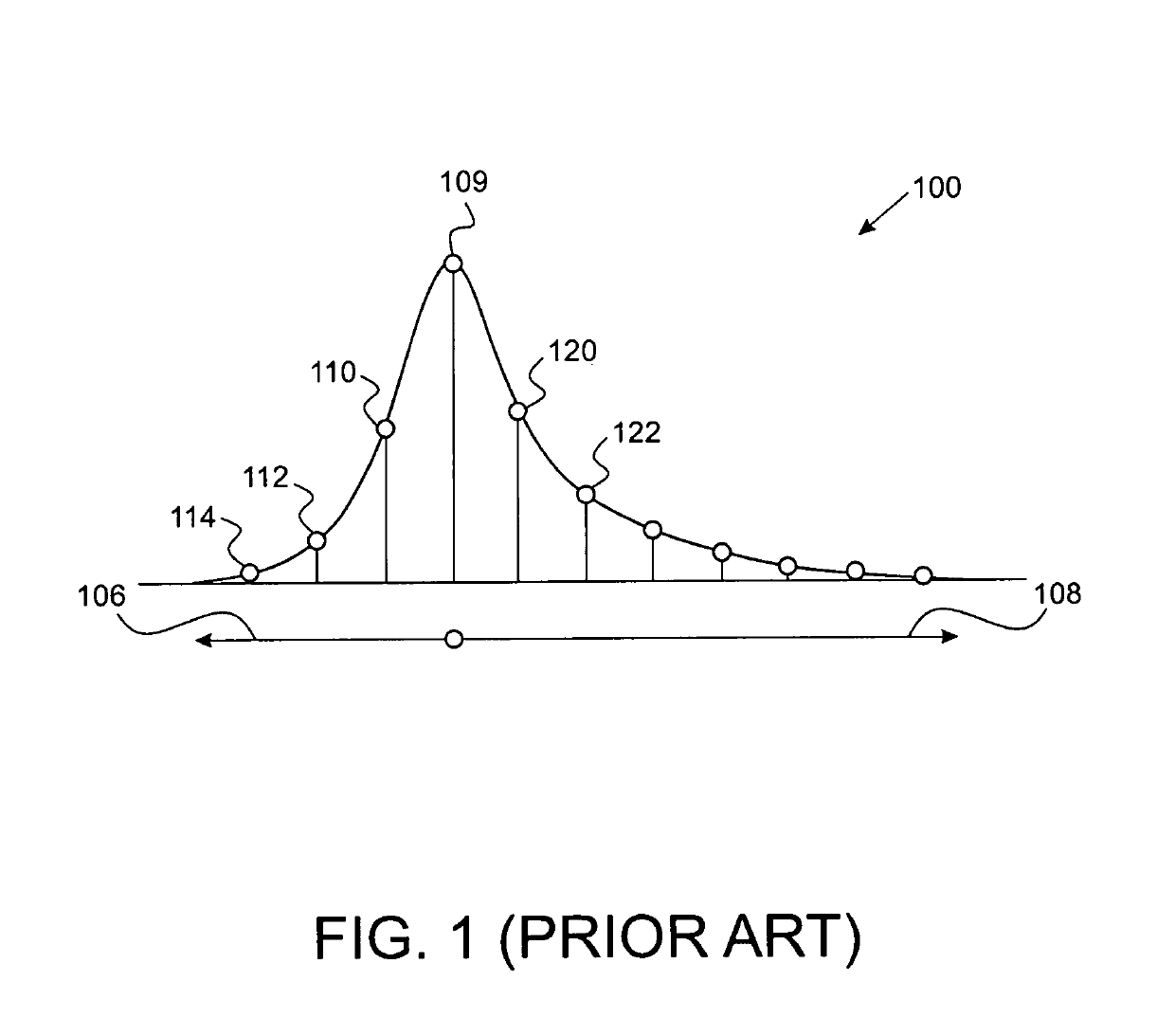

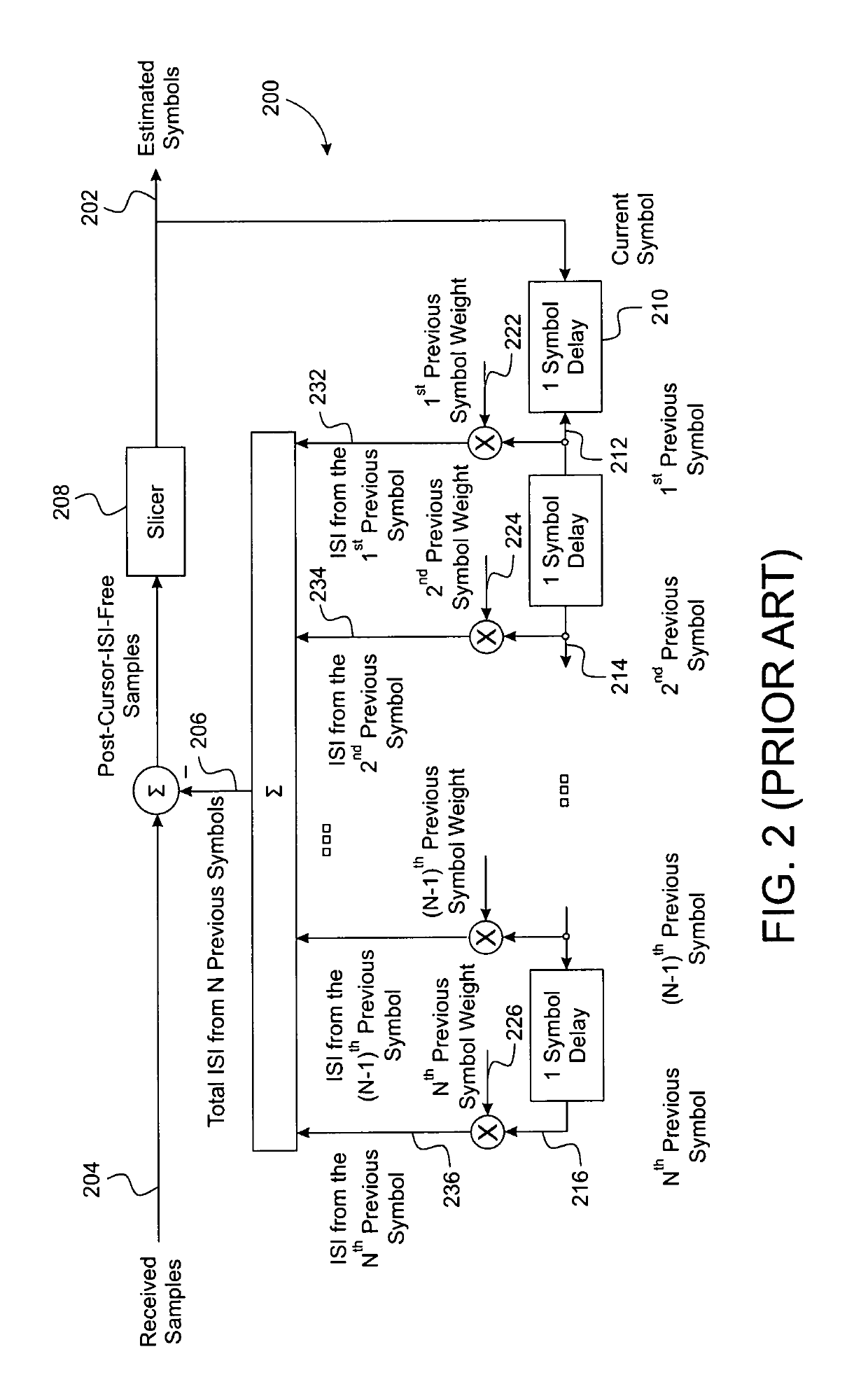

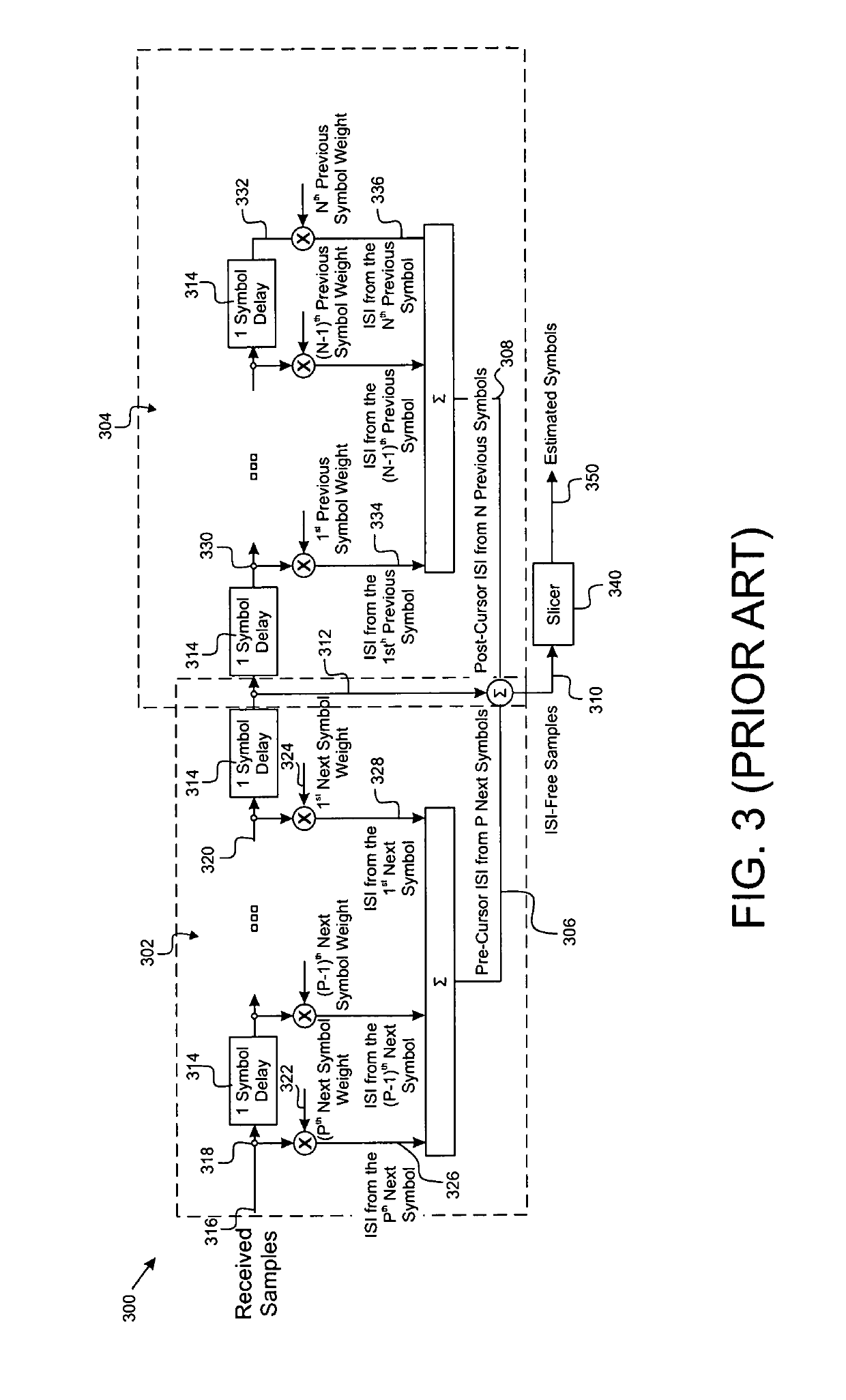

Decision feed-forward reduced-state sequence detection

ActiveUS10425257B1Eliminate dependenceEliminate dependenciesTransmitter/receiver shaping networksIntersymbol interferenceAlgorithm

Systems and methods are disclosed for detecting sequences of symbols in a received signal in the presence of inter-symbol interference. Maximum Likelihood Sequence Detection (MLSD) is a known method for optimum detection of such sequences. To reduce the complexity of the MLSD, a Reduced-State Sequence Detection (RSSD) technique has been considered based on partitioning the states of the MLSD. In this approach, a simplified sequence detector is placed within a global decision feedback loop. The disclosed architecture shortens the feedback loop by moving the sequence detector outside the loop and converting the interaction between the two to a feed-forward manner. This is achieved through slicing the signal and closing a nested loop around the sliced bins. A further variant simplifies the detector even more by reducing the number of bins.

Owner:HUAWEI TECH CO LTD

Resolver signal converter and resolver signal conversion method

ActiveUS8825440B2Eliminate dependenceReduce impactAnalogue/digital conversionElectric signal transmission systemsBand-pass filterExcitation signal

A resolver signal converter and a resolver signal conversion method amplify and perform analogue-digital conversion on a sine wave output from a resolver; thereafter, among frequency components of the sine wave output, pass and thereby extract a predetermined bandwidth of which the center frequency is the frequency of an excitation signal, by means of a band-pass filter; sample the sine wave output while synchronizing the sine wave output with a reference signal which is based on the excitation signal; and generate a detection angle signal sine value from the sampled signal. Similarly, a detection angle signal cosine value is generated from a cosine wave output from the resolver. A detection angle is calculated based on the detection angle signal sine value and the detection angle signal cosine value. Accordingly, an influence, on an input resolver signal, of disturbance noise such as noise caused due to a magnetic field generated by a motor and switching noise caused due to PWM driving, is eliminated, and frequency dependence of arithmetic processing is eliminated. As a result, detection angle errors are reduced.

Owner:KAWASAKI HEAVY IND LTD

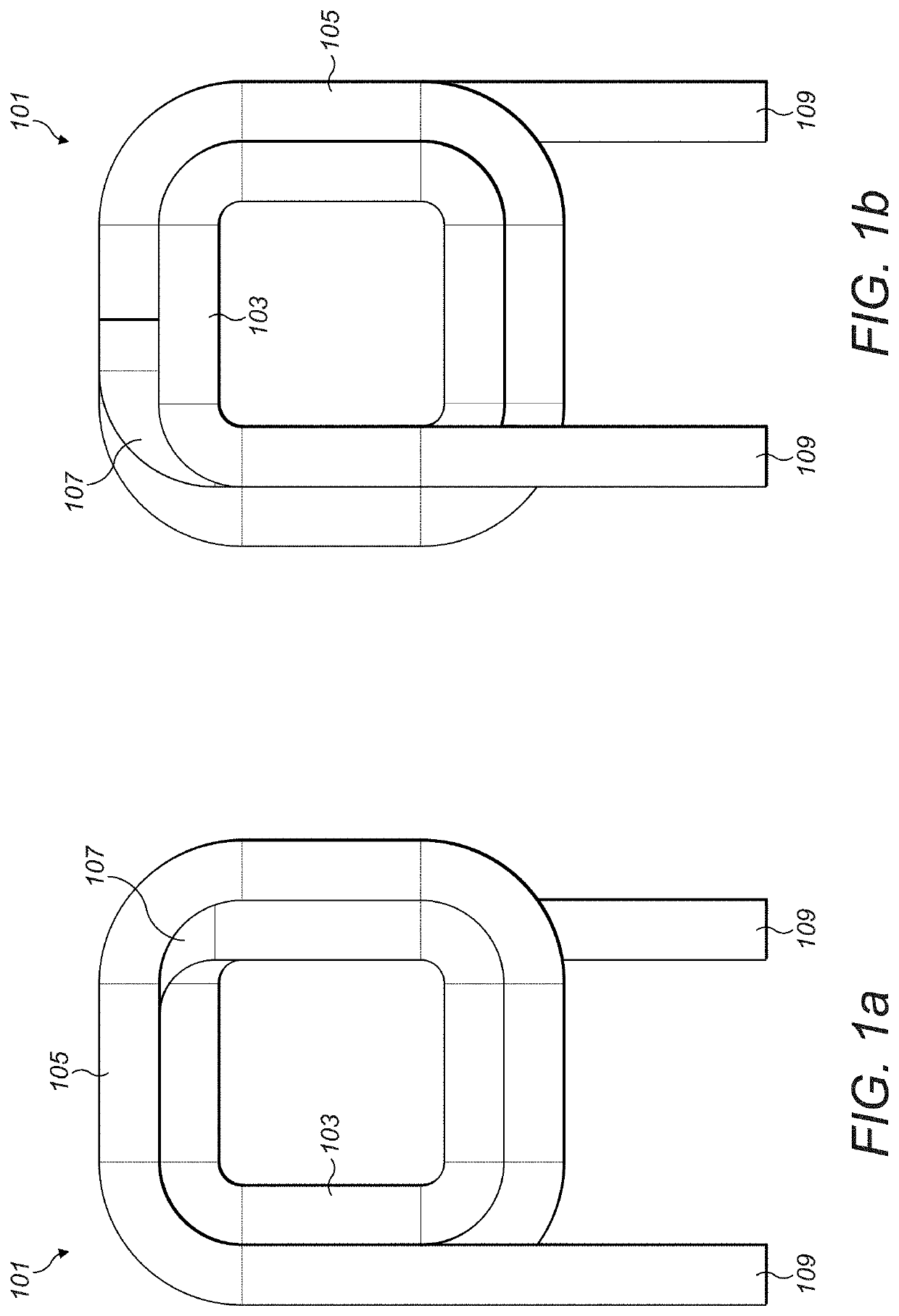

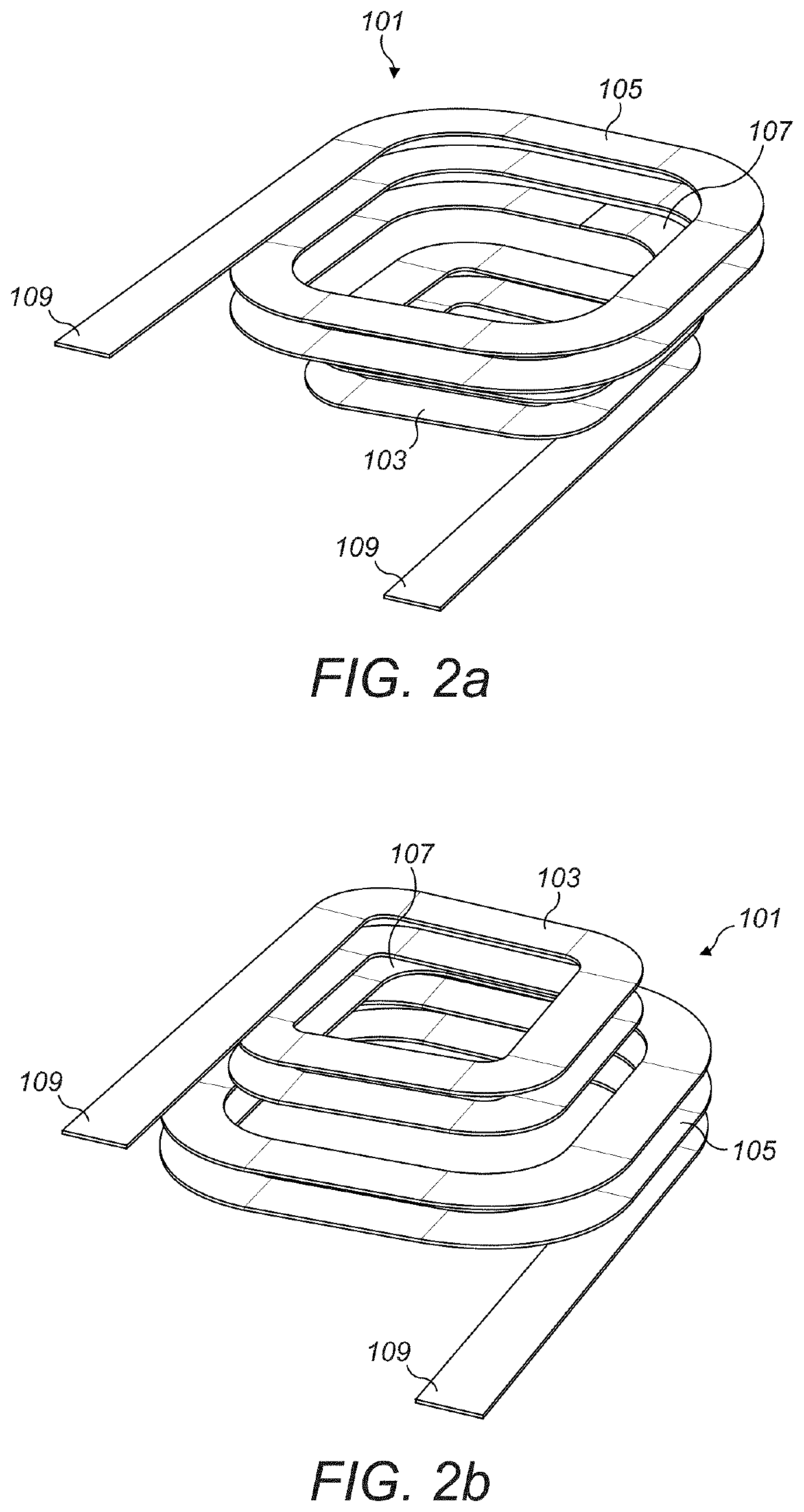

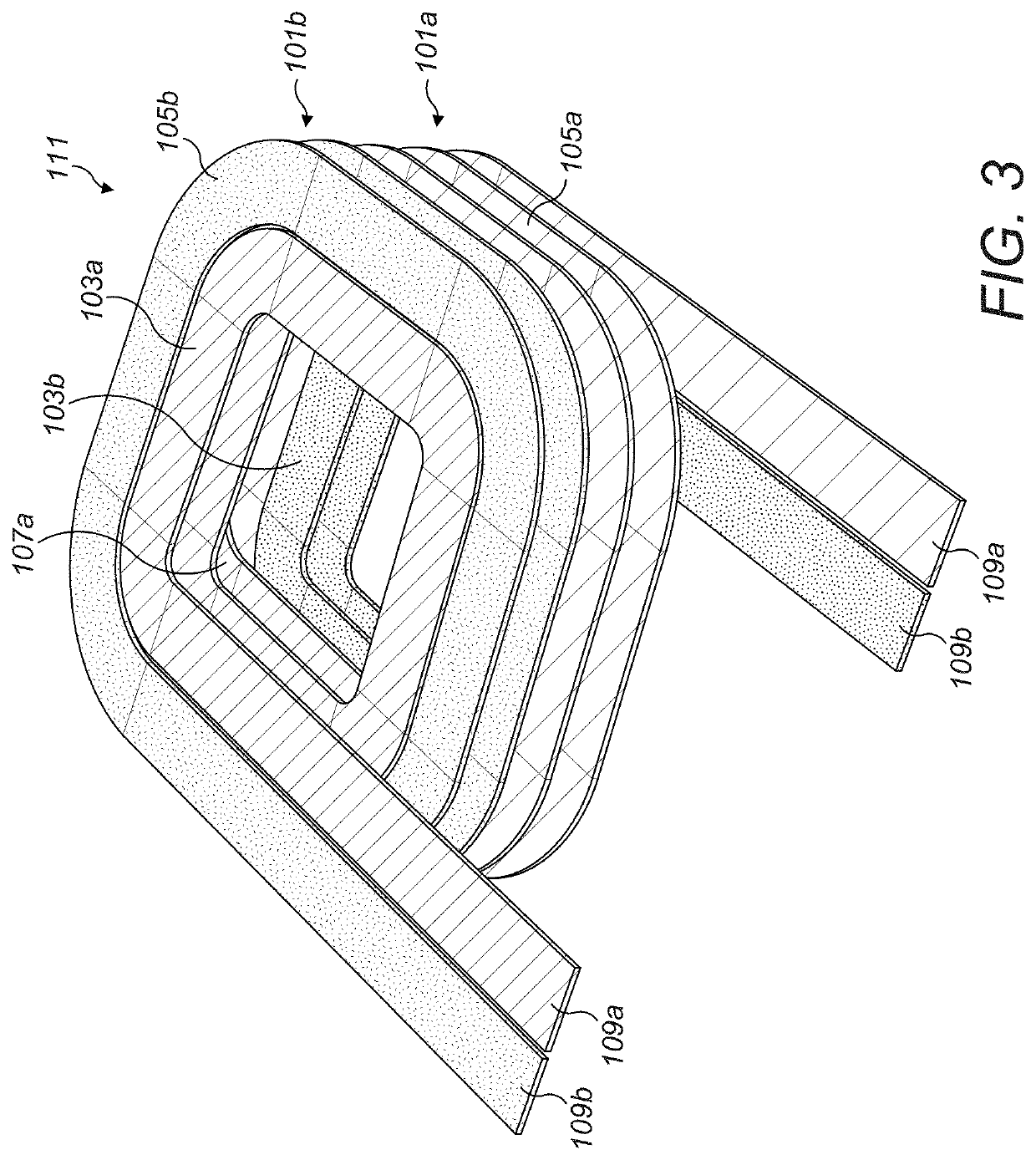

Winding arrangement for use in magnetic devices

PendingUS20210118607A1Reduce proximity effectManufacturing limitationTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresConductive materialsMechanical engineering

A coil of electrically conductive material includes first and second sections, the first section including a first plurality of turns and the second section including a second plurality of turns. Both the first plurality of turns and the second plurality of turns are arranged around a winding axis of the coil. The first plurality of turns are smaller than the second plurality of turns such that when viewed along the winding axis of the coil, the first plurality of turns fit within the second plurality of turns. When viewed perpendicular to the winding axis of the coil, the first and second sections are adjacent.

Owner:MURATA MFG CO LTD

Semiconductor integrated circuit including variable resistor circuit

ActiveUS8587358B2Reduce resistanceAmount of errorMultiple-port networksOther resistor networksControl circuitSemiconductor

Provided is a semiconductor integrated circuit including a variable resistor circuit of the small layout area, which is free from an error in resistance caused by ON-state resistances of switch elements for trimming, and is also free from power supply voltage dependence and temperature dependence. The semiconductor integrated circuit including a variable resistor circuit includes: a resistor circuit including a plurality of series-connected resistors; a selection circuit including a plurality of switch elements for selecting a connected number of the plurality of series-connected resistors; and a control circuit for controlling ON-state resistances of the plurality of switch elements. The control circuit controls the ON-state resistances of the plurality of switch elements so as to obtain a predetermined ratio to a resistance of the plurality of series-connected resistors of the resistor circuit.

Owner:ABLIC INC

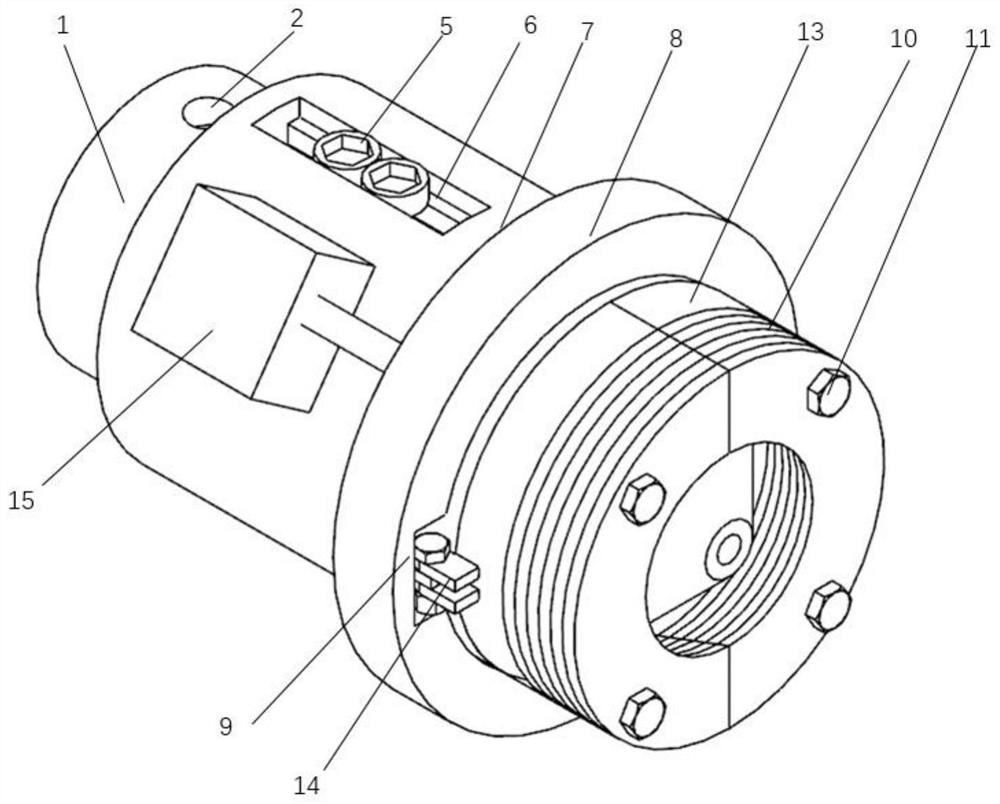

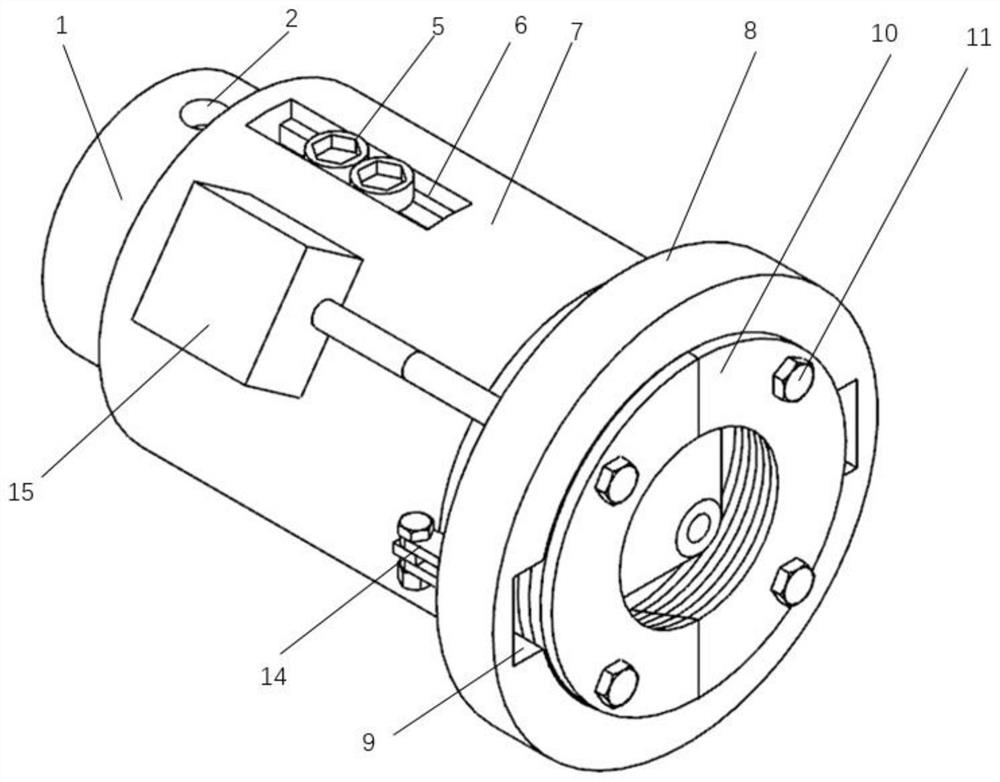

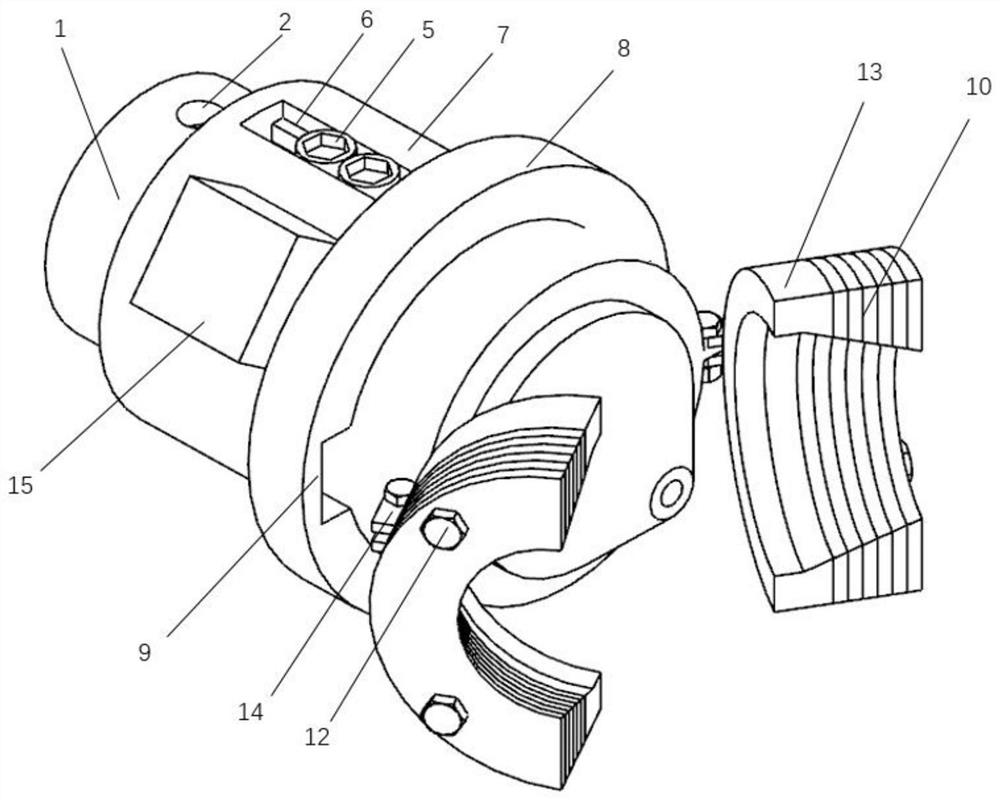

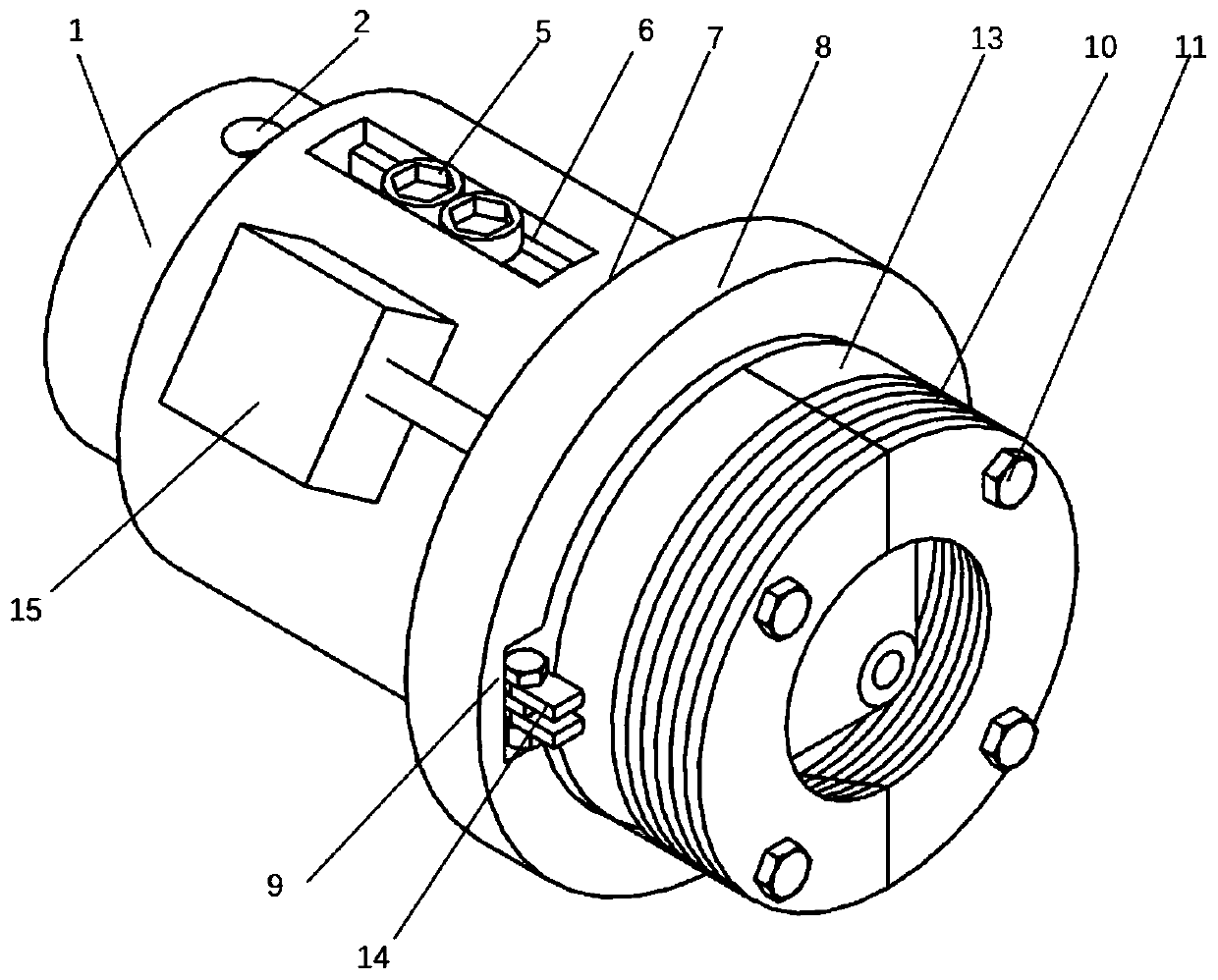

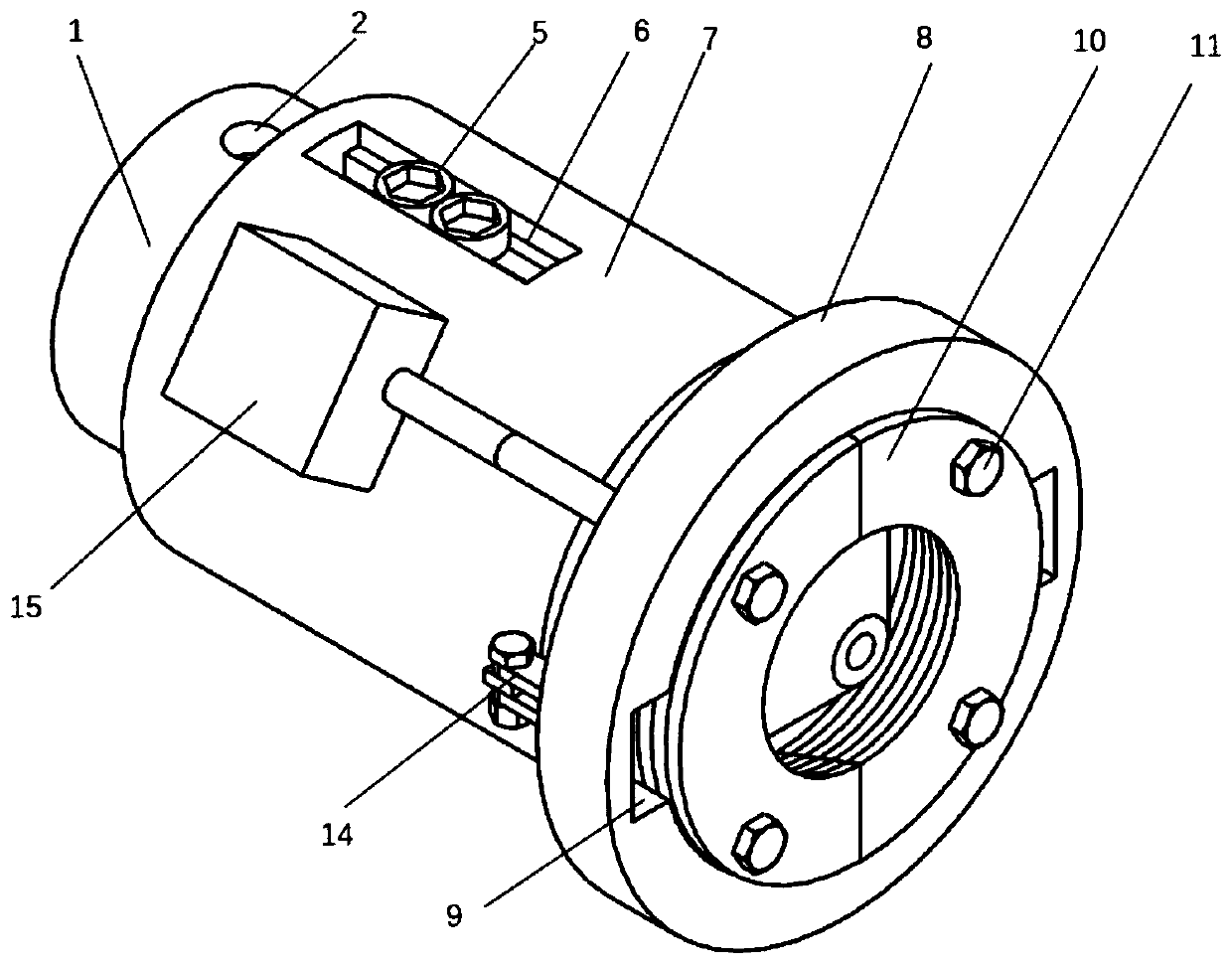

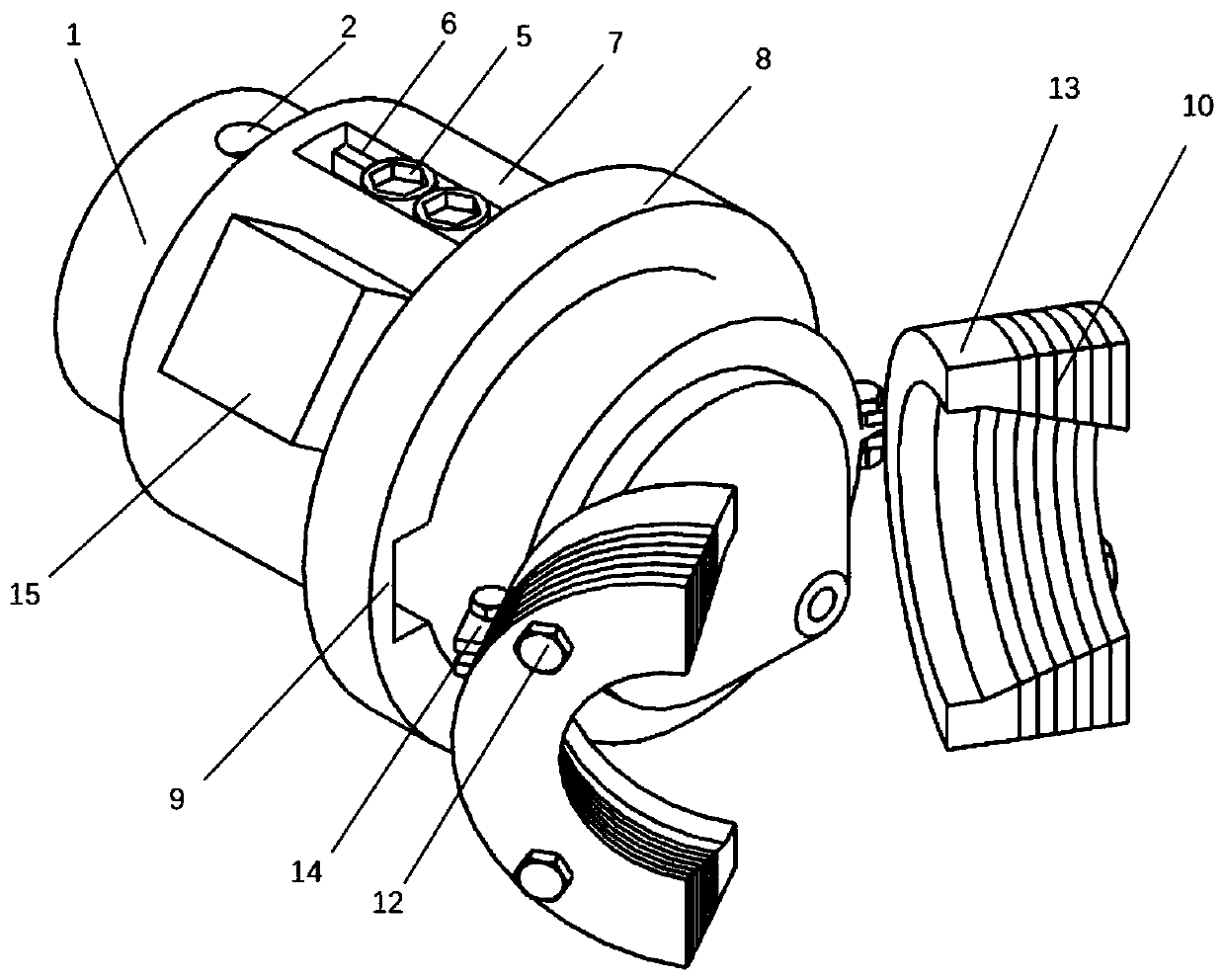

A flanging type pipe liquid filling forming sealing device and method

The invention discloses a sealing device and method for flanging-type pipe liquid-filled forming, which comprises two sealing punches respectively used for sealing the two ends of the tube blank. The sealing punches include an inner punch, an outer punch and a restraining ring; the inner punch The end surface of the head head is a conical surface, and the outer punch is set outside the inner punch; the outer punch includes an outer punch seat, an outer punch sealing head and a sealing insert, and the outer punch seat is set outside the inner punch; The head end of the inner cavity of the sealing head of the outer punch and the sealing insert is a tapered cavity; when sealing, the pipe end is inserted into the gap between the front ends of the inner punch and the outer punch, and the conical surface of the inner punch is pressed into the end face of the tube blank to realize rigid expansion. And with the increase of the insertion depth of the tube blank, the gap is continuously narrowed, and the tube end is closely attached to the sealing section of the inner and outer punches to realize the self-sealing of the tube end; effective sealing can be achieved in both the internal high-pressure forming and the hydraulic filling of the tube, And by adjusting the number of sealing inserts of the outer punch and the gap between the outer punch and the inner punch, the sealing of pipes with different diameters and different wall thicknesses can be realized.

Owner:哈尔滨工达海卓智能成形科技有限公司

Flanging type pipe hydroforming sealing device and method

The invention discloses a flanging type pipe hydroforming sealing device and method. The device comprises two sealing punches which are respectively used for sealing two ends of a pipe blank, whereineach sealing punch comprises an inner punch, an outer punch and a restraint ring, a head end face of the inner punch is a conical surface, the outer punch is arranged outside the inner punch in a sleeving mode, the outer punch comprises an outer punch base, an outer punch sealing head and a sealing insert, the outer punch base is arranged outside the inner punch in a sleeving mode, head ends of the inner cavities of the outer punch sealing head and the sealing insert are conical cavities, during sealing, a pipe end is inserted into a gap between front ends of the inner punch and the outer punch, a conical surface of the inner punch is pressed into an end surface of a pipe blank to realize rigid flaring, the gap is continuously reduced along with increase of the insertion depth of the pipeblank, the pipe end is tightly attached to sealing sections of the inner punch and the outer punch, and self-sealing of the pipe end is realized. The device is advantaged in that effective sealing canbe achieved in the inner high-pressure forming and pipe hydroforming pressing process, and sealing of pipes with different diameters and different wall thicknesses can be achieved by adjusting the number of the outer punch sealing inserts and the gap between the outer punch and the inner punch.

Owner:哈尔滨工达海卓智能成形科技有限公司

Fluid absorber with adjustable damping coefficient

ActiveCN100497993CChange the damping factorGuaranteed reliabilitySpringsShock absorbersDamping factorShape-memory alloy

The invention provides a fluid buffer with adjustable damping coefficient, it includes: cylinder tank which has a placing space, the placing space is filled with fluid; piston which is equipped with piston head moving in the placing space and the piston bar extending from the piston head to two ends of the tank body. The piston head is equipped with at least one fluid channel passing through the piston head and the piston head consists of at least one piston discs. The piston disc includes: the disc plate which is equipped with the via hole forming the fluid channel; the valve which is installed on the disc body and can be moved from the first position opening the via hole to the second position closing the via hole, and vice versa; the driver which controls the movements of valve through the deformation of from memory alloy, thereby opens or closes said fluid channel to adjust the number of damping force. Due to the valve in buffer of the invention is driven by form memory alloy, so the leaning on the outer force is eliminated, so the reliability of the buffer is maintained.

Owner:THE HONG KONG POLYTECHNIC UNIV

Systems and methods for multi-wavelength scattering based smoke detection using multi-dimensional metric monitoring

ActiveUS11402326B2Facilitate reliable alarm initiationEliminate dependenceScattering properties measurementsFire alarmsMonitoring systemEngineering

Owner:HONG KONG APPLIED SCI & TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com