Method of controlling molten steel pourability under condition of calcium-free treatment

A technology of calcium treatment and conditions is applied in the field of controlling the pourability of molten steel under the condition of calcium-free treatment, which can solve problems such as poor molten steel fluidity and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

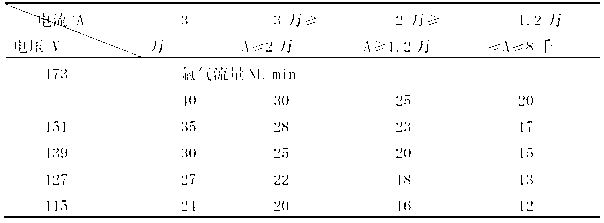

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with examples, which are only used as explanations of the present invention rather than limitation.

[0027] A method for controlling castability of molten steel under calcium-free treatment conditions for smelting GCr15 steel, comprising:

[0028] 1) The top-bottom combined blowing converter adopts high-drawing carbon technology, and the opening blowing and oxygen pressure are used as follows: opening blowing 1400-1500mm, foam slag rises in the early stage, oxygen lance position is pressed down 100mm-150mm, and carbon-oxygen reaction period is 4-5 minutes At the beginning, gradually raise the gun to 1600-1800mm, and after 8 minutes, raise the gun position to 1900-2000mm at one time, and then adopt dynamic gun position, that is, the gun position alternately changes up and down between 1700mm-1900mm, and start pressing the gun at 12 and a half minutes , Slowly press the gun to 1200~1300mm. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com