E-jet printing method for solar photovoltaic cell electrode

A technology of photovoltaic cells and solar energy, applied in photovoltaic power generation, printing, circuits, etc., can solve the problem of limiting the open circuit voltage of photovoltaic cells, short-circuit current plane utilization, photoelectric conversion efficiency, difficulty in controlling the line width accuracy of secondary printed electrodes, increasing photovoltaic Solve problems such as battery manufacturing costs, achieve the effect of improving photoelectric conversion efficiency, improving plane utilization, and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

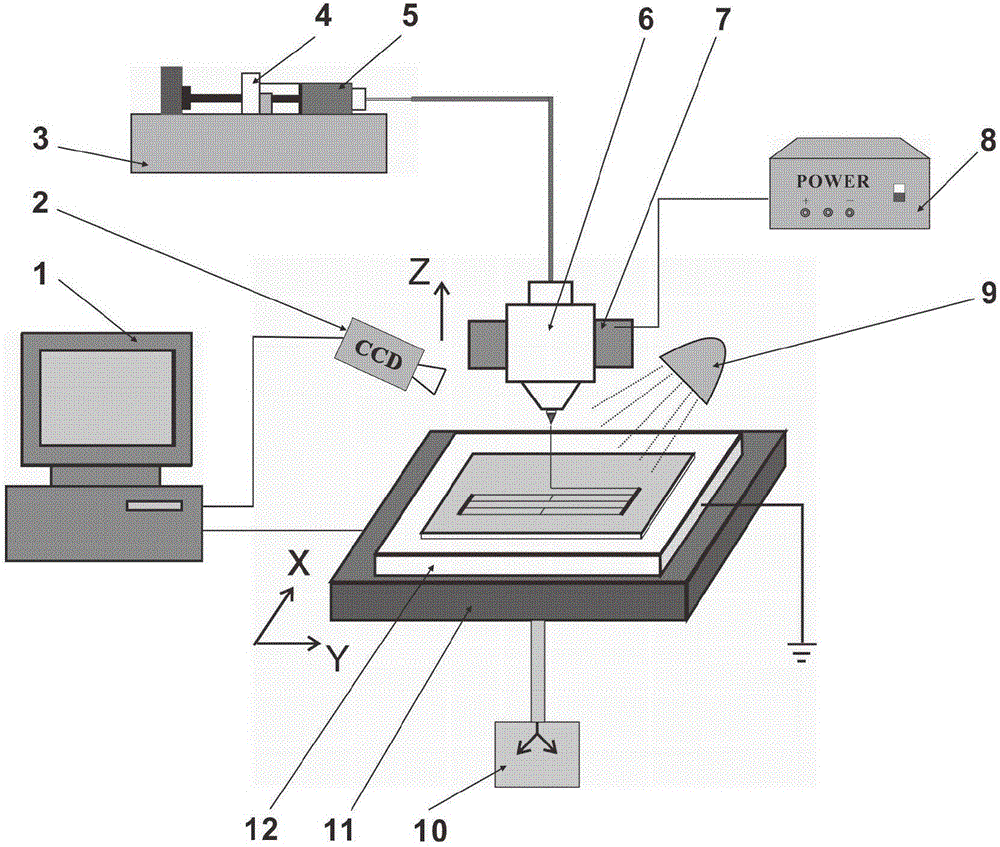

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. The jet printing device of the embodiment is mainly composed of four parts: a fluid jet printing module, a motion module, a micro vision module and a control module.

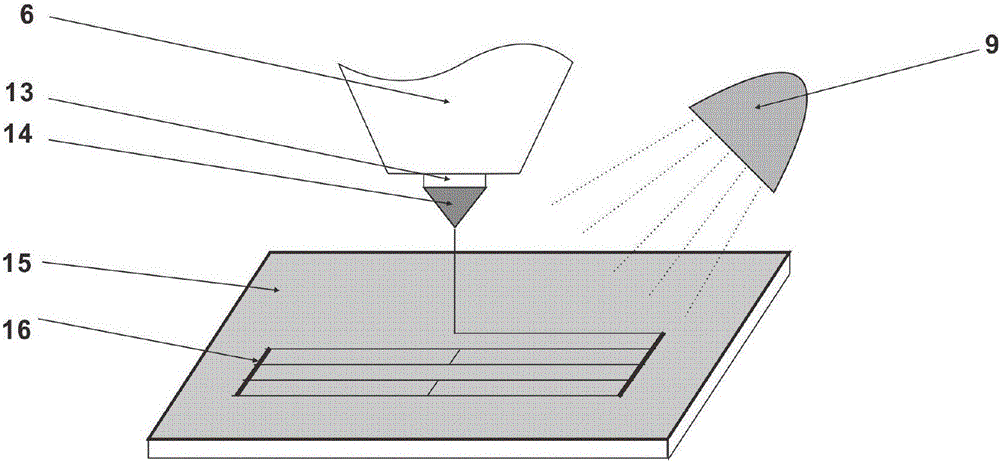

[0025] The syringe 4 is fixed on the top of the syringe pump 3, and the conductive ink 5 is housed in the syringe 4, and the syringe 4 is connected with the upper inlet of the nozzle 6 through a conduit. The nozzle 6 is made of conductive material, and the head is processed with a nozzle hole 13 with an inner diameter of 100 microns, and is positioned and clamped by the nozzle clamp 7 . The rear end of the nozzle clamp 7 is insulated and fixed on the Z displacement axis that can move longitudinally; the front end is conductive and clamps the nozzle 6 . The output end of the voltage controller 8 is connected to the right end of the shower hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com