Method and system for high speed laser directly writing of diffraction light change image

A laser direct writing and diffracting light technology, which is applied in the direction of diffraction grating, optics, optical elements, etc., can solve the problems of short beam coherence length, inability to generate interference light field, and inability to write directly in micron-scale fringe lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

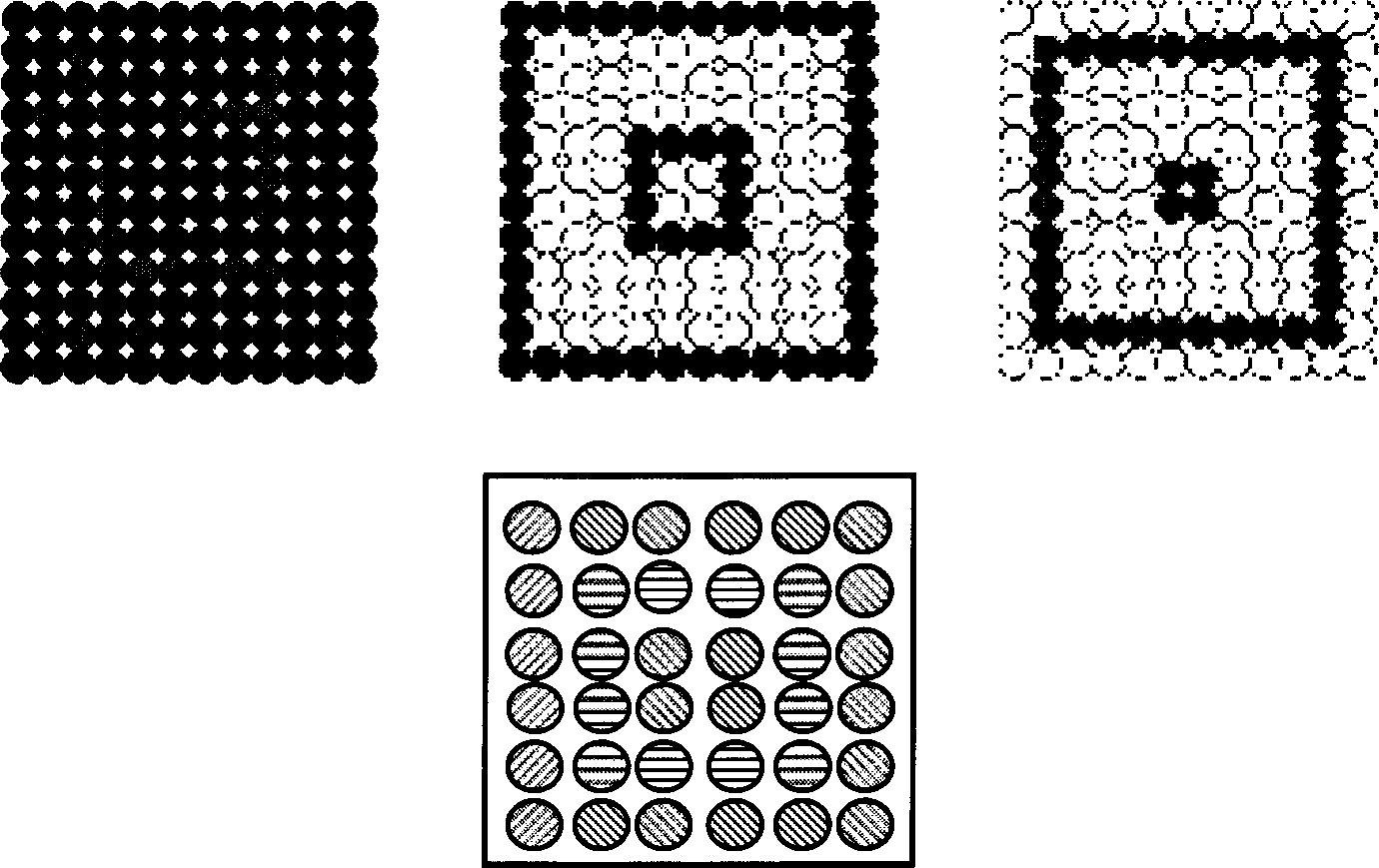

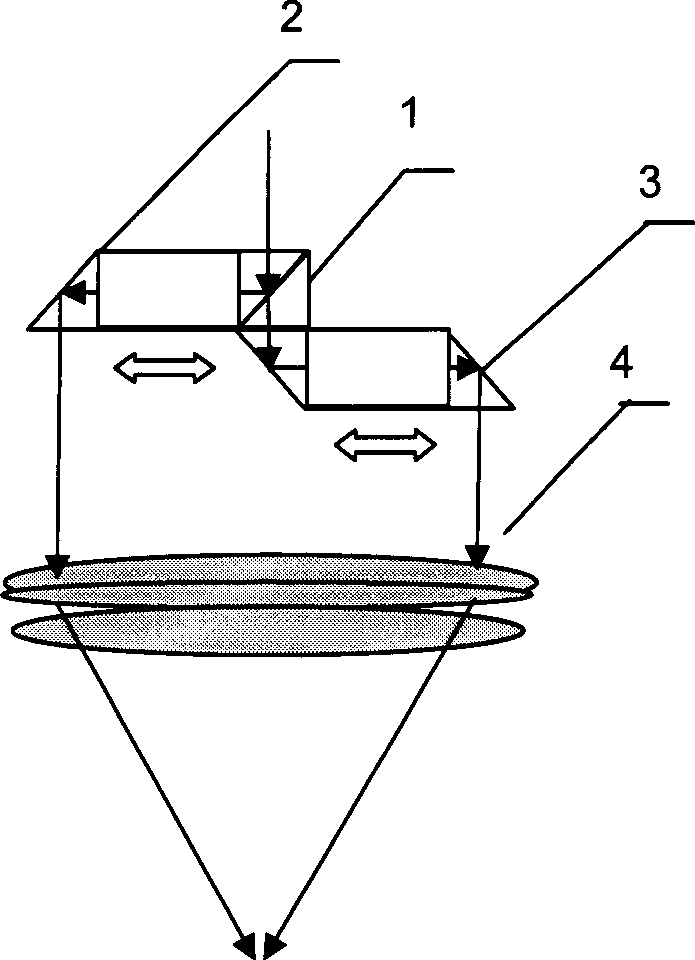

[0046] Embodiment one: see attached Figure 2-4 As shown, a method for making diffractive light-variable images converts the image distribution into a pulse control signal, adjusts the steering of the beam splitting elements (6, 7) according to the orientation of the unit grating and the space-frequency synchronization, and simultaneously performs interference between the optical head and Platform movement, high-speed rotation of beam-splitting elements and light pulse input, line by line detour, continuous pulse exposure on recording materials, platform, interference optical head, and beam-splitting elements do not need to pause during exposure until the entire image is produced. For how the system works, see Figure 4 .

[0047] The laser lithography direct writing system that realizes the above method includes a DPSSL laser light source 1 output by ultraviolet light with a TTL signal interface, a beam expander and a collimating mirror 2, an iris diaphragm 3, a lens 4, a mi...

Embodiment 2

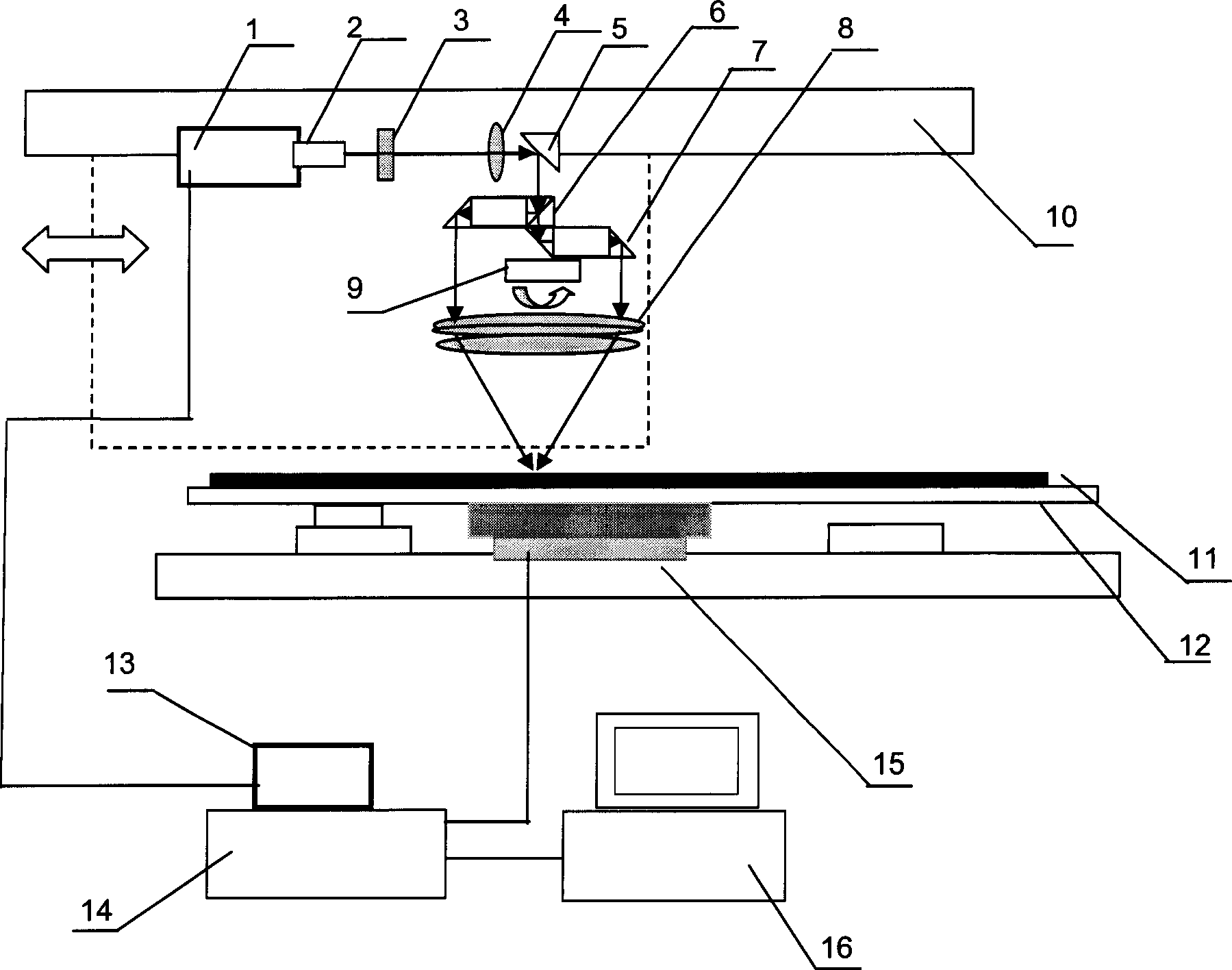

[0049] Embodiment two: see attached Figure 5 And attached Image 6 As shown, a lithographic direct writing system for making digital diffraction optically variable images, including a laser light source 1, a beam expander and a collimating mirror 2, a variable rectangular diaphragm 3, and an imaging system before beam splitting (lens f1 , f2 and the diaphragm form a 4F system with a miniature function), an optical path system composed of an imaging system after beam splitting (including a beam splitting element 18, an imaging lens group 8, and a high-speed turntable 9), the above-mentioned light source, an imaging system before beam splitting, The interferometric optical head composed of the post-beam imaging system is assembled on the X-direction horizontal movement system 10, the recording material 11 is placed on the Y-direction movement table 12, and the power supply 13 including TTL and power control, and the motion control system 14 , 15 and computer 16.

[0050] The ...

example 3

[0052] Example 3: A method for making a diffractive optically variable image. First, the image is decomposed into different sub-images according to the orientation of the interference fringes, and each sub-image is continuously exposed. During the exposure of the sub-images, the grating in the optical head does not need Rotation, the beam splitting grating needs to be rotated only when switching between sub-images. This production method avoids large-angle rotation during continuous operation, and improves the continuity of lithography operation and the production quality of diffractive light-variable images.

[0053] The overall structure of the laser direct writing system in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com