Electrojet 3D printing device and method based on combination of electric field and heat field

A 3D printing and electrojet technology, applied in the field of electrojet 3D printing devices, can solve the problems of limited application, difficult to achieve 3D structure printing and manufacturing, ink curing, etc., and achieve the effect of strong material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

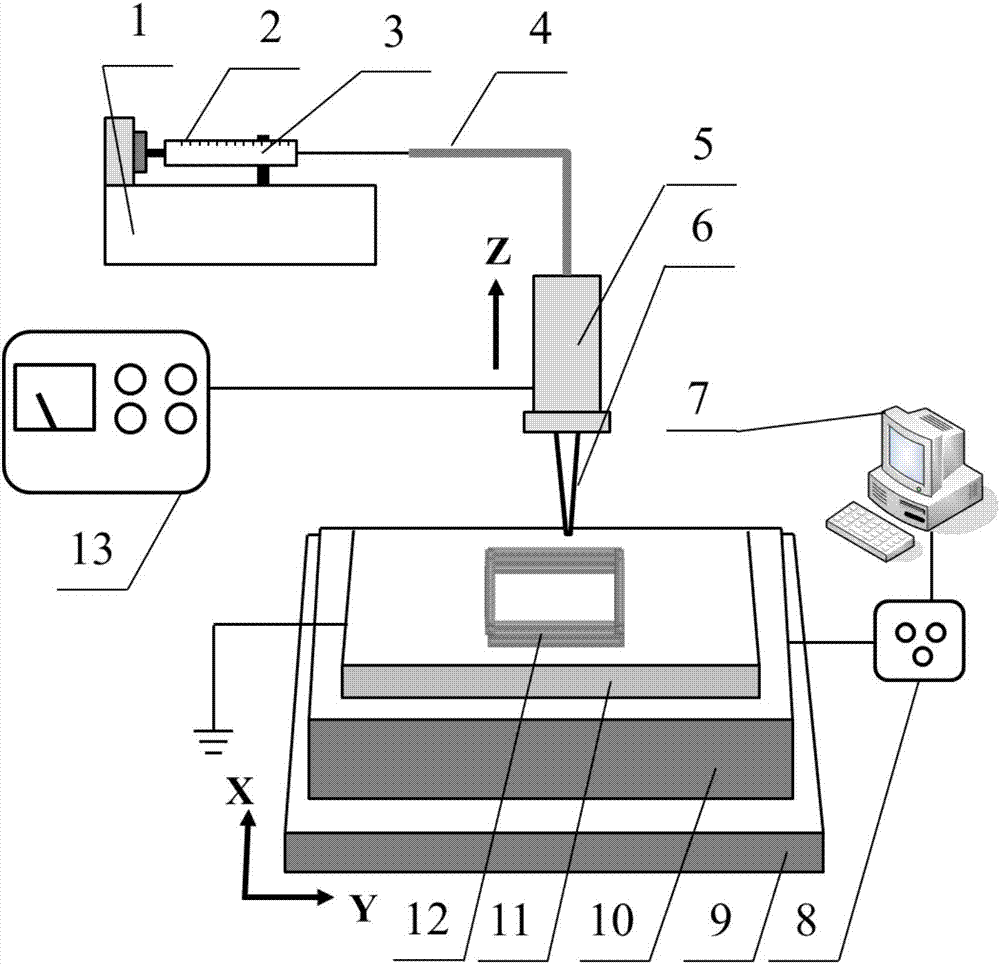

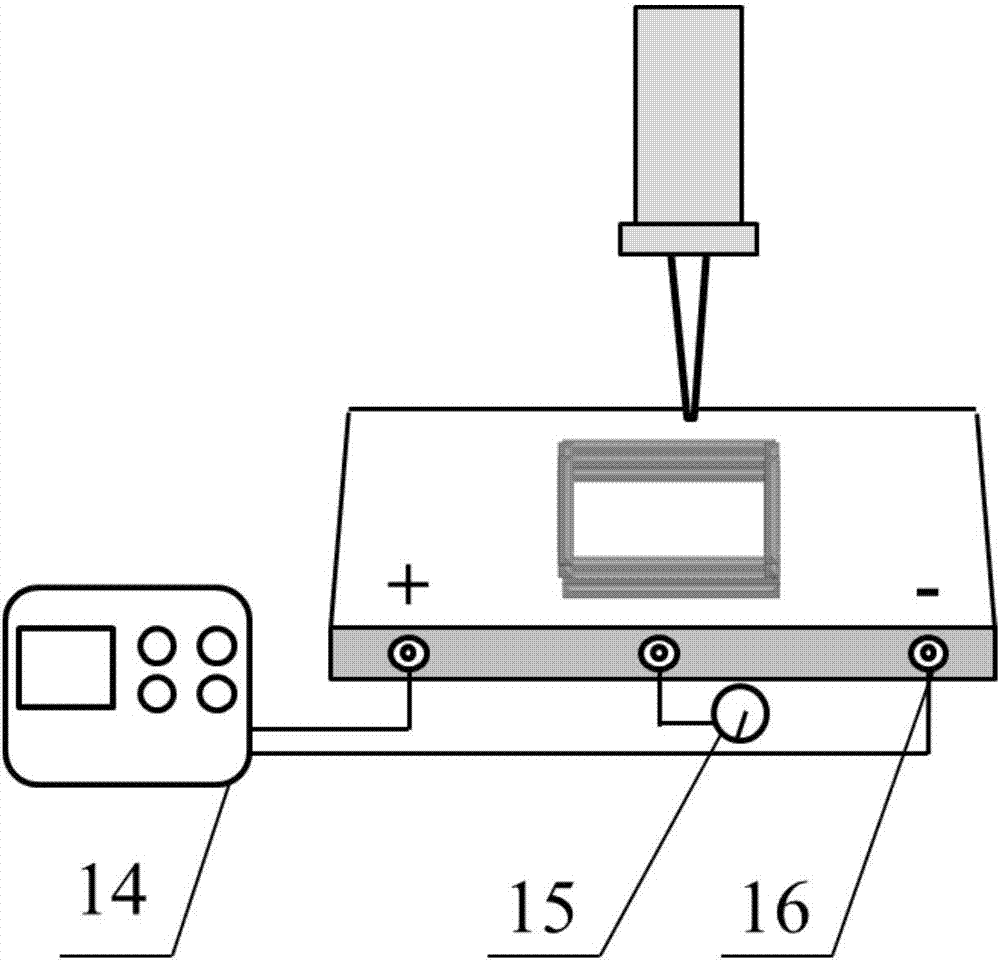

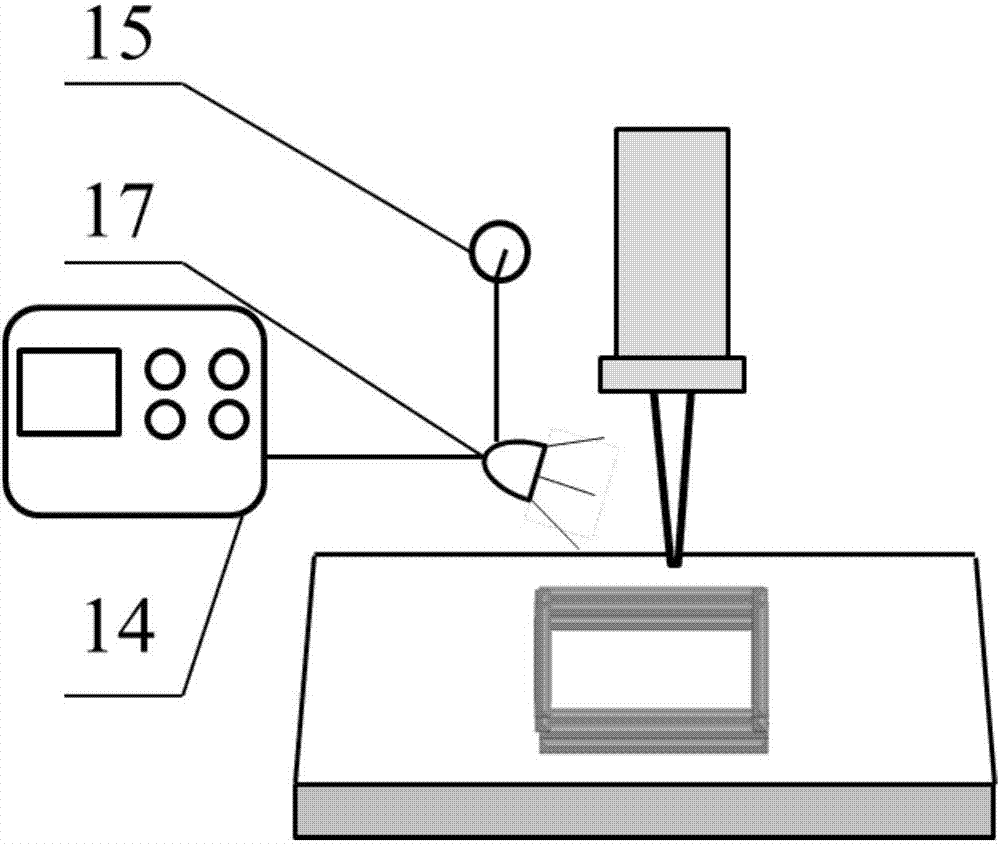

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. The electric field-thermal field composite electrospray 3D printing device of the embodiment mainly includes four parts: an electric power injection module, an XYZ moving module, a thermal field module, and a control module.

[0024] The syringe 2 is placed above the precision syringe pump 3, and the ink 3 is installed in the syringe 2. The ink 3 is a polyethylene glycol solution, wherein the solvent is a mixed solution of ethanol and deionized water, and the quality of polyethylene glycol is The fraction is 40%; the two ends of the connecting pipe 4 are respectively connected with the syringe 2 and the injection needle 6; the injection needle 6 is installed and fixed on the injection needle fixture 5, and the injection needle 6 contains an injection hole with an inner diameter of 80±5 μm; The injection nee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com