Integration method of collaborating assembly design, process planning and simulation verification of complicated product

A technology for complex product and process planning, applied in computing, special data processing applications, instruments, etc., can solve problems such as difficult assembly quality assurance, assembly process planning, and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

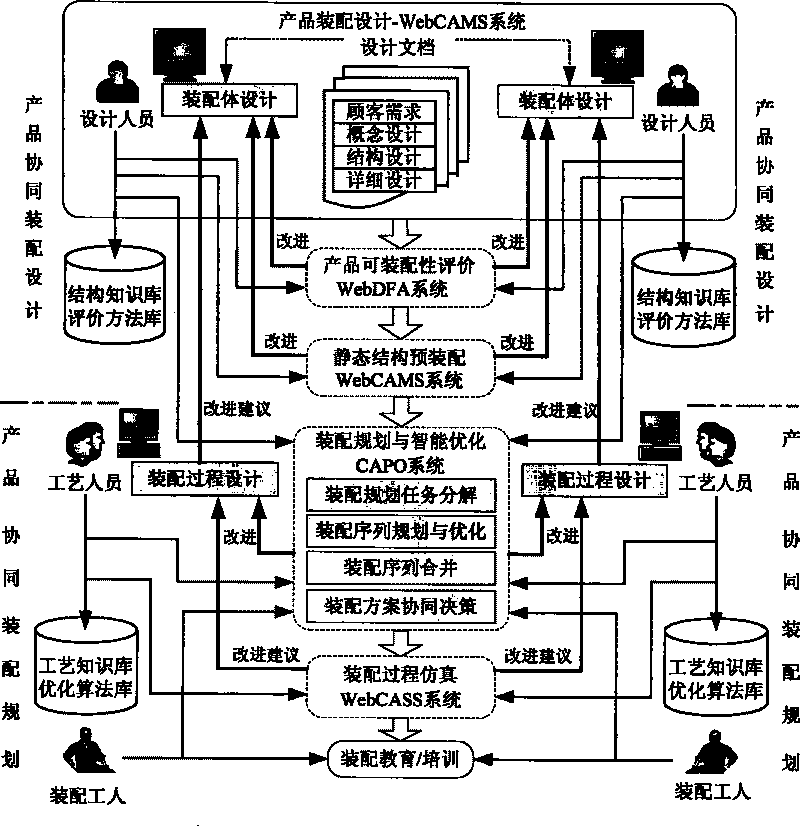

[0015] 1. The workflow of the integrated method of complex product collaborative assembly design, process planning and simulation verification

[0016] The workflow of the integrated method of complex product collaborative assembly design, process planning and simulation verification is as follows: figure 1 shown. It is mainly divided into four stages, namely, collaborative assembly design stage, assemblability evaluation stage, assembly planning and optimization stage and assembly process simulation stage.

[0017] (1) Collaborative assembly design stage:

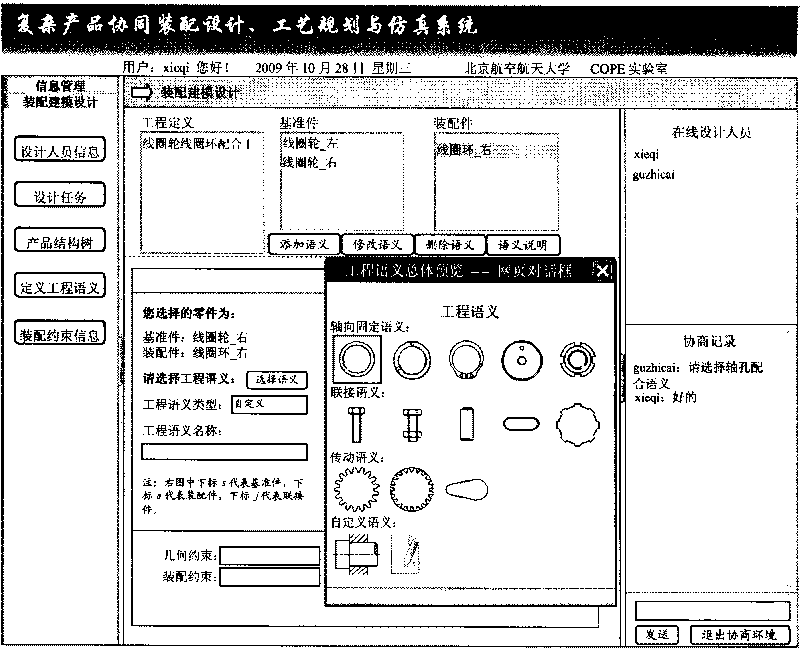

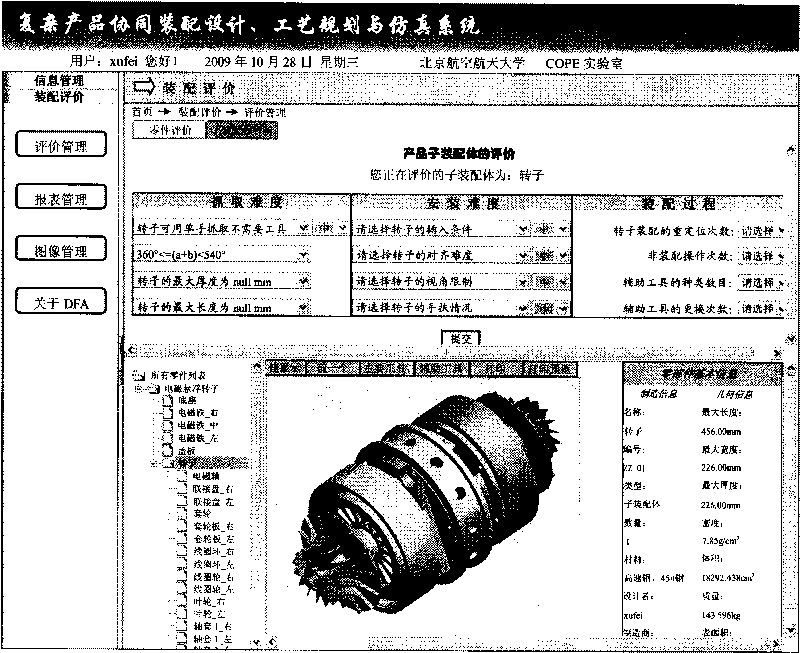

[0018] The network-based collaborative assembly design provides designers with a shared workspace. The project leader is responsible for establishing the product structure tree and assigning design tasks. Designers establish assembly constraint relationships, add engineering semantic information and product geometric information according to the design tasks, and then Upload the assembly model with compound information t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com