Method for quickly preparing synthetic glass microlens having adjustable curvature through excimer laser rotary etching

The technology of excimer laser and excimer laser is applied in the field of rapidly manufacturing plexiglass microlenses with adjustable radius of curvature, which can solve the problems of difficult control of manufacturing process, difficult control of lens shape and curvature, and low efficiency of processing methods, and achieves low thermal effect. , The effect of good continuity and high machining accuracy

Inactive Publication Date: 2015-12-02

BEIJING UNIV OF TECH

View PDF6 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Traditional microlens processing methods mainly include compression molding, plastic molding, grinding, photolithography hot-melt molding, grayscale masking, LCVD, inkjet, etc. Most of the processing methods have low processing efficiency and low manufacturing efficiency. Process control is difficult, and lens shape and curvature are difficult to control. Therefore, how to use low-cost, high-efficiency, high-precision, and adjustable processing methods to manufacture microlenses has become an important development direction for microlens manufacturing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

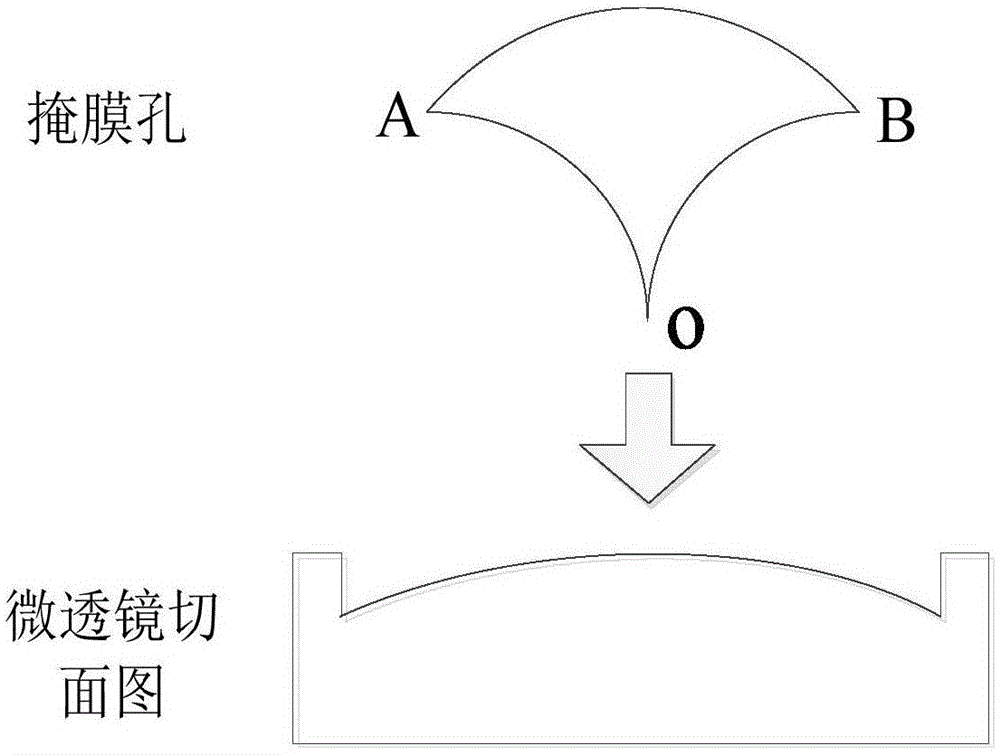

[0044] When the diameter side of the fan-like mask hole is a concave side concave inward (see image 3 ), the resulting microlens is a convex lens, and its cross-section is shown in image 3 .

Embodiment 2

[0046] When the diameter side of the fan-like mask hole is an outwardly convex convex side (see Figure 4 ), the obtained microlens is a concave lens, and its section view is shown in Figure 4 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

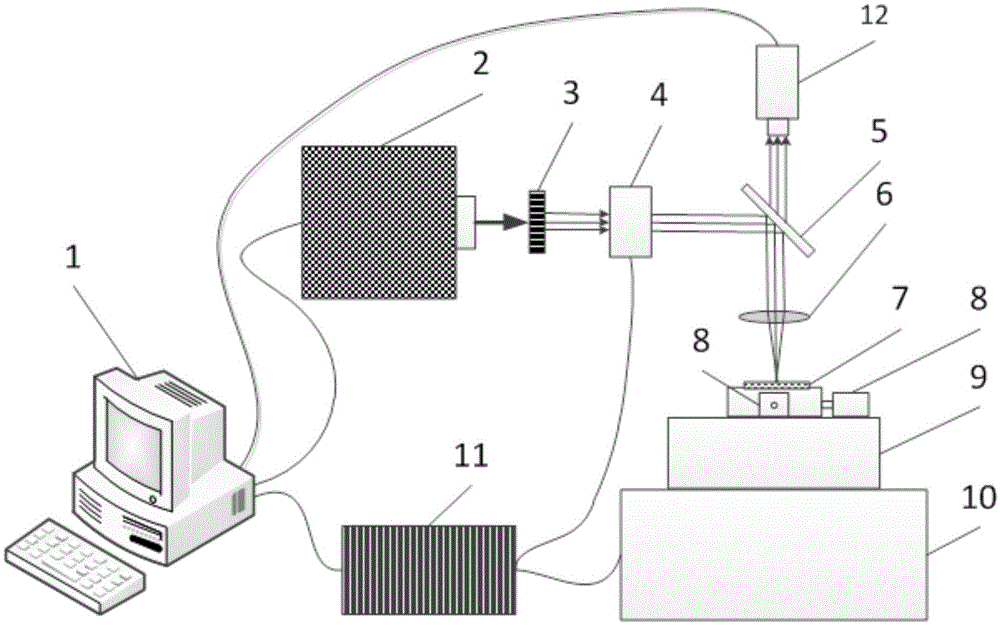

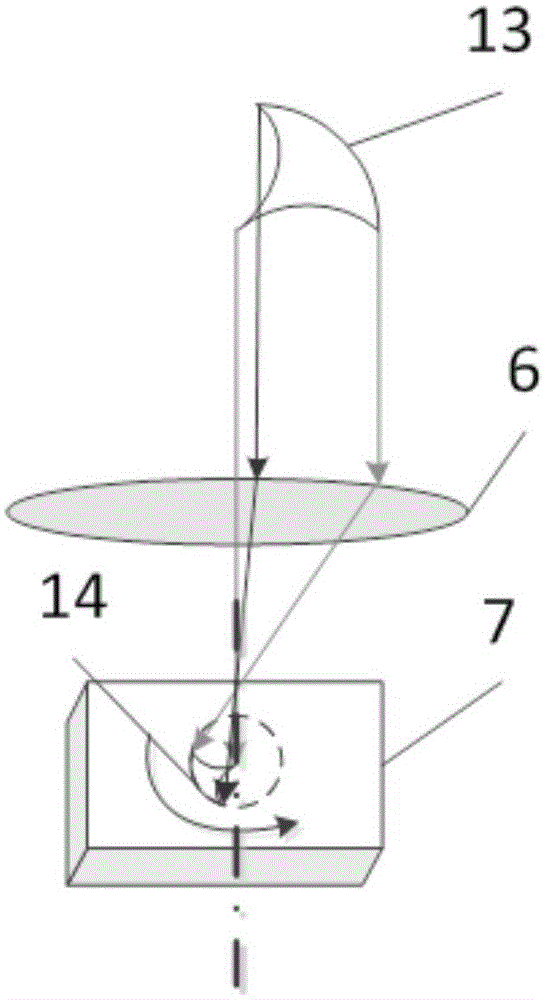

The invention relates to a method for quickly preparing a synthetic glass microlens having adjustable curvature through excimer laser rotary etching, and belongs to the field of micro-optical devices and laser advanced manufacturing technology. A machining system is mainly composed of a computer, a laser, a laser homogenizer, a mask layer, a mask layer, a mask layer exchanging platform, a focusing object lens, a coaxial observation system, a rotating platform and a micromotion workbench. A synthetic glass PMMA is machined through a mask layer projection rotary etching method to make a microlens having good circularity, after mask layer design, preparation of optical paths a machining system and calibration of an axle center of the rotating platform, the shape and the size of a hole in mask layer is determined according to parameters of a microlens to be machined. The method can be used for making a microlens or a microlens array, and the method is low in heat effect influence and cost, high in efficiency and precision, good in repeatability without contact and having adjustable curvature.

Description

technical field [0001] The invention relates to a method for rapidly manufacturing organic glass microlenses with adjustable curvature radius by using excimer laser and mask projection rotary etching, and belongs to the technical field of micro-optical devices and laser advanced manufacturing. Background technique [0002] In the field of modern micro-optical systems, micro-lenses have the characteristics of miniaturization compared with traditional optical lenses, making micro-lenses can replace traditional optical systems in many fields, especially in the field of opto-mechanical integration, optical fiber connectors and optical fibers in the field of optoelectronics. Collimator, optical switch, optical information storage and other devices, input and output ports and connectors of various sensors and detectors in the field of optical sensing, secondary micro-manufacturing in the field of micro-manufacturing, and micro-lenses have increasingly broad applications. Applicati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K26/362B23K26/402B23K26/035B23K26/08B23K26/066

CPCB23K26/0823

Inventor 陈涛杨桂栓郑崇闫晓光

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com