Alloy for cutter ring of disk type hobbing cutter and preparation method thereof

A disc-shaped hob and cutter ring technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of shallow permeation layer and few research reports on alloy steel carburizing, achieve uniform alloy composition and meet performance requirements , Control the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The disc-shaped hob alloy and the disc-shaped hob cutter of the present invention are prepared according to the following steps.

[0022] (1) Ingredients:

[0023] The raw materials are 45# steel, high-purity graphite, pure chromium, ferromolybdenum (containing 61wt% Mo), ferro-vanadium (containing 51wt% V), ferro-niobium (containing 66wt% Nb), ferrosilicon (containing 73wt% Si) master alloy , The quality requirements of 45# steel are in accordance with national standards, and the impurity content in other raw materials: S≤0.03%, P≤0.03%.

[0024] The design alloy composition (mass percentage of elements) is: C0.45%, Si0.5%, Mn0.65%, Cr5.2%, Mo1.4%, V0.8%, Nb0.5%, Fe balance. S and P are impurities, and the others are added. The burning loss of each element is set to 16%C, 3%Si, 4%Mn, 2%Cr, 4%Mo, 8%V, and 13%Nb. The ingredients are distributed according to the design ingredients, and the total amount of ingredients is about 70kg.

[0025] (2) Vacuum induction furnace...

Embodiment 2

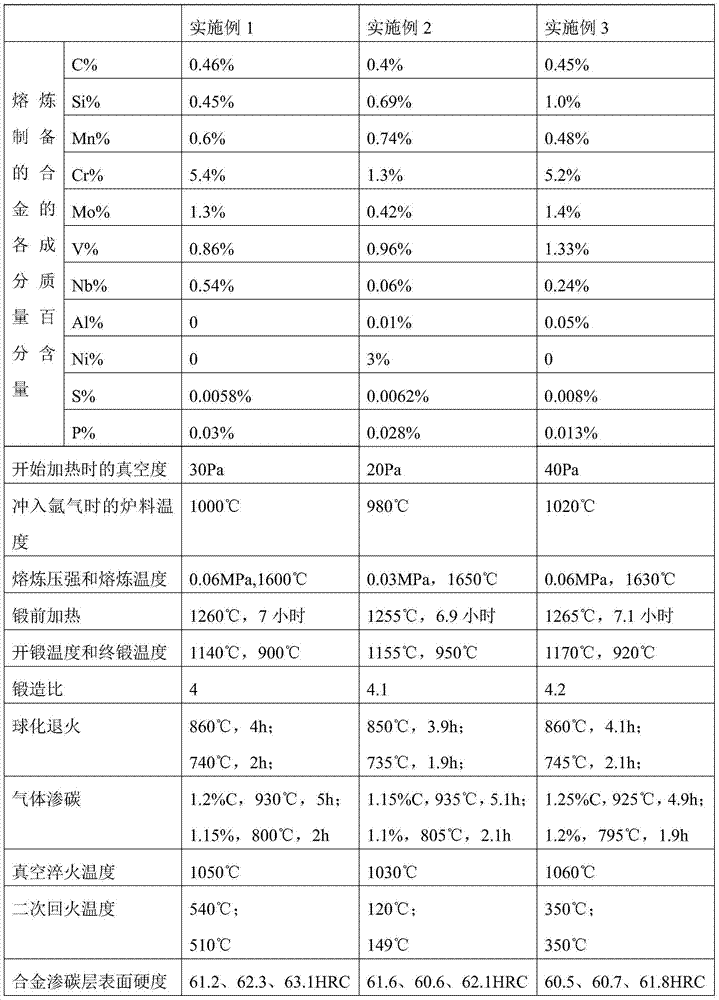

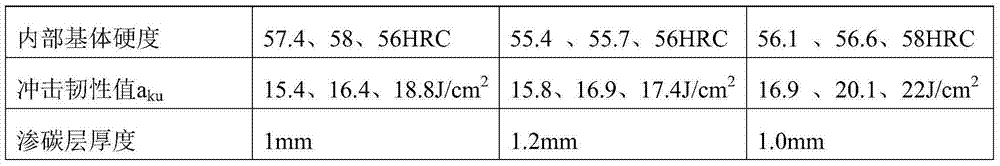

[0040] Prepare disc-shaped hob cutter ring alloy and disc-shaped hob cutter ring of the present invention by the method of embodiment 1, each process parameter and the parameter of the product that obtains are shown in Table 1, and difference is:

[0041] The raw materials are No. 45 steel, high-purity graphite, pure chromium, pure nickel, pure aluminum, ferromolybdenum (containing 61wt% Mo), ferro-vanadium (containing 51wt% V), ferro-niobium (containing 66wt% Nb), ferrosilicon (containing 73wt%Si) master alloy. The design alloy composition (mass percentage of elements) is: C0.43%, Si0.7%, Mn0.75%, Cr1.3%, Mo0.45%, V0.9%, Nb0.06%, Al0.05%, Ni3%, the burning loss of each element is set to 16%C, 3%Si, 4%Mn, 2%Cr, 2%Ni, 4%Mo, 8%V, 13%Al, 13%Nb.

[0042] The alloy was melted and smelted for 3 minutes, then the samples were taken and measured. The analysis results showed that the contents of Mn and Mo were unqualified, and the corresponding intermediate alloy was calculated and ad...

Embodiment 3

[0044] Prepare disc-shaped hob cutter ring alloy and disc-shaped hob cutter ring of the present invention by the method of embodiment 1, each process parameter and the parameter of the product that obtains are shown in Table 1, and difference is:

[0045] The raw materials are 45 steel, high-purity graphite, pure chromium, pure aluminum, ferromolybdenum (containing 61wt% Mo), ferro-vanadium (containing 51wt% V), ferro-niobium (containing 66wt% Nb), and ferrosilicon (containing 73wt% Si) master alloy. The design alloy composition (mass percentage of elements) is: C0.44%, Si1%, Mn0.5%, Cr5.3%, Mo1.5%, V1.4%, Nb0.25%, Al0.05%, each element The burning loss is set to 16%C, 3%Si, 4%Mn, 2%Cr, 4%Mo, 8%V, 13%Al, 13%Nb respectively.

[0046] After the alloy melting was continued to smelt for 3 minutes, samples were taken and measured. The analysis results showed that the content of C, V, and Al was unqualified, and the corresponding intermediate alloy was calculated and added. %, Mn0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com