Crucible for vacuum induction melting and manufacturing method thereof

A vacuum induction melting and vacuum induction furnace technology, applied in crucible furnaces, furnaces, lighting and heating equipment, etc., can solve the problems of high comprehensive cost, increased cost and limitation of smelting special alloys, and achieves excellent performance and processing. The effect of good performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The specific implementation of the vacuum induction melting crucible and its manufacturing method will be described in detail below in conjunction with the examples and accompanying drawings, but the specific implementation of the vacuum induction melting crucible and its manufacturing method is not limited to the following examples.

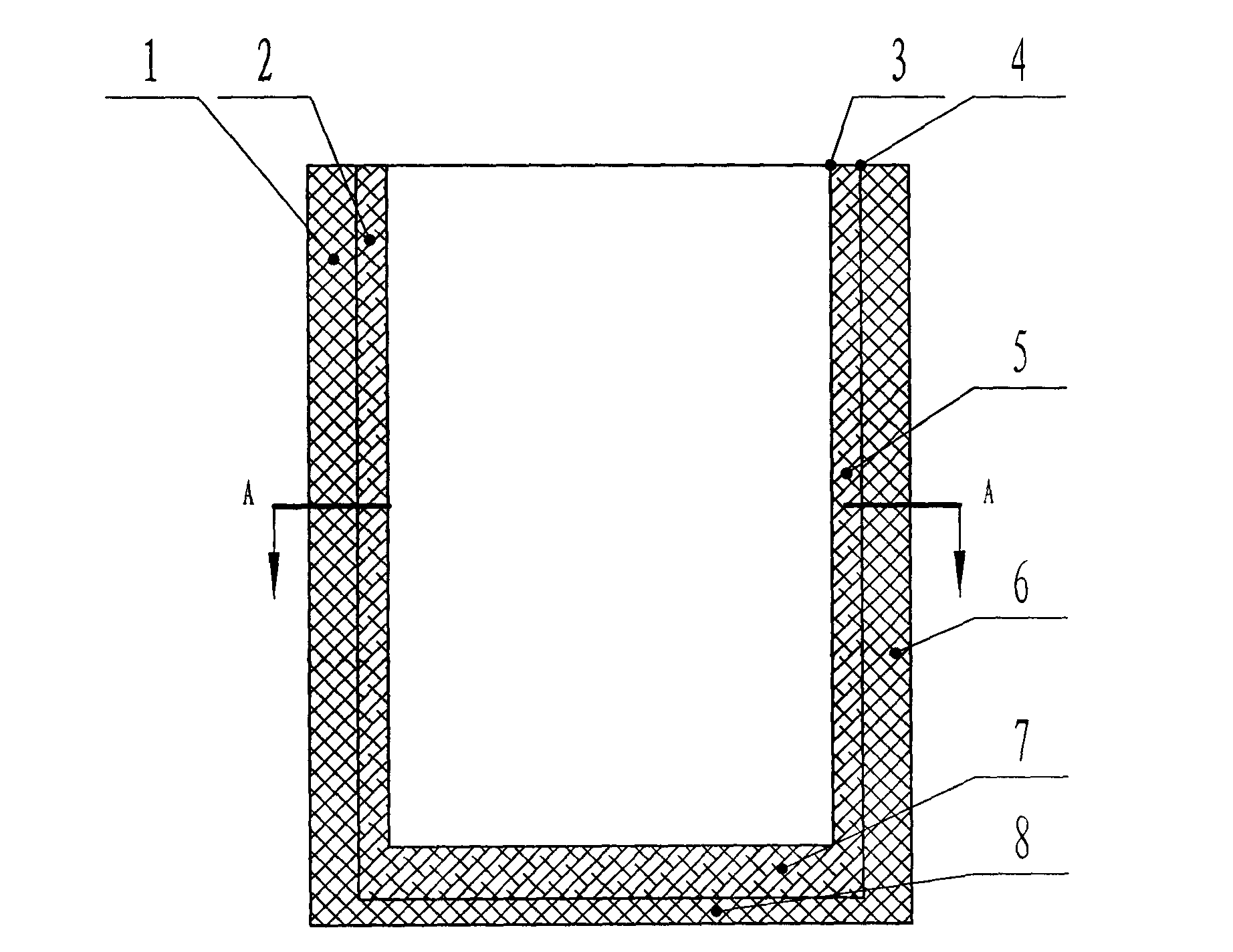

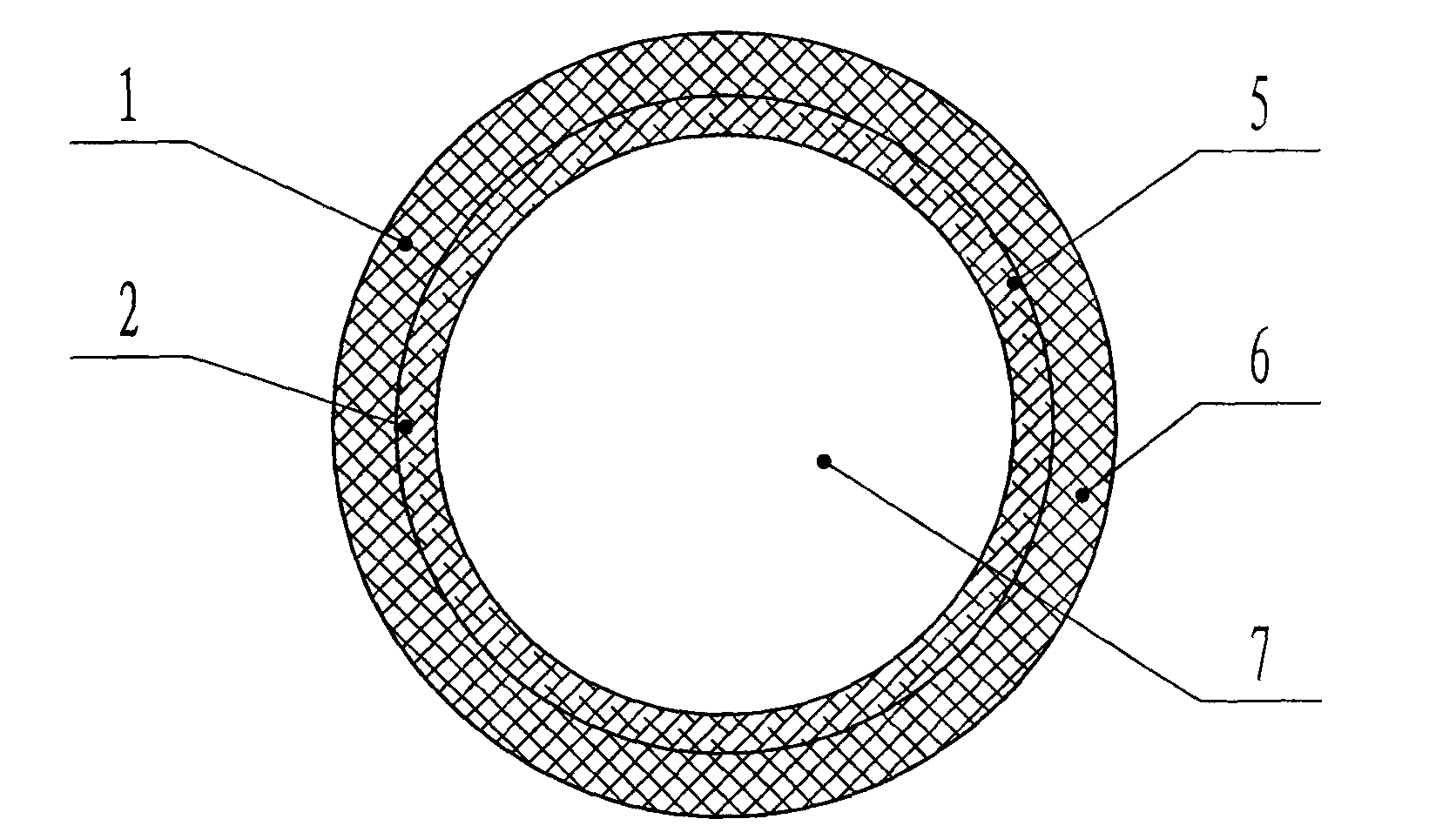

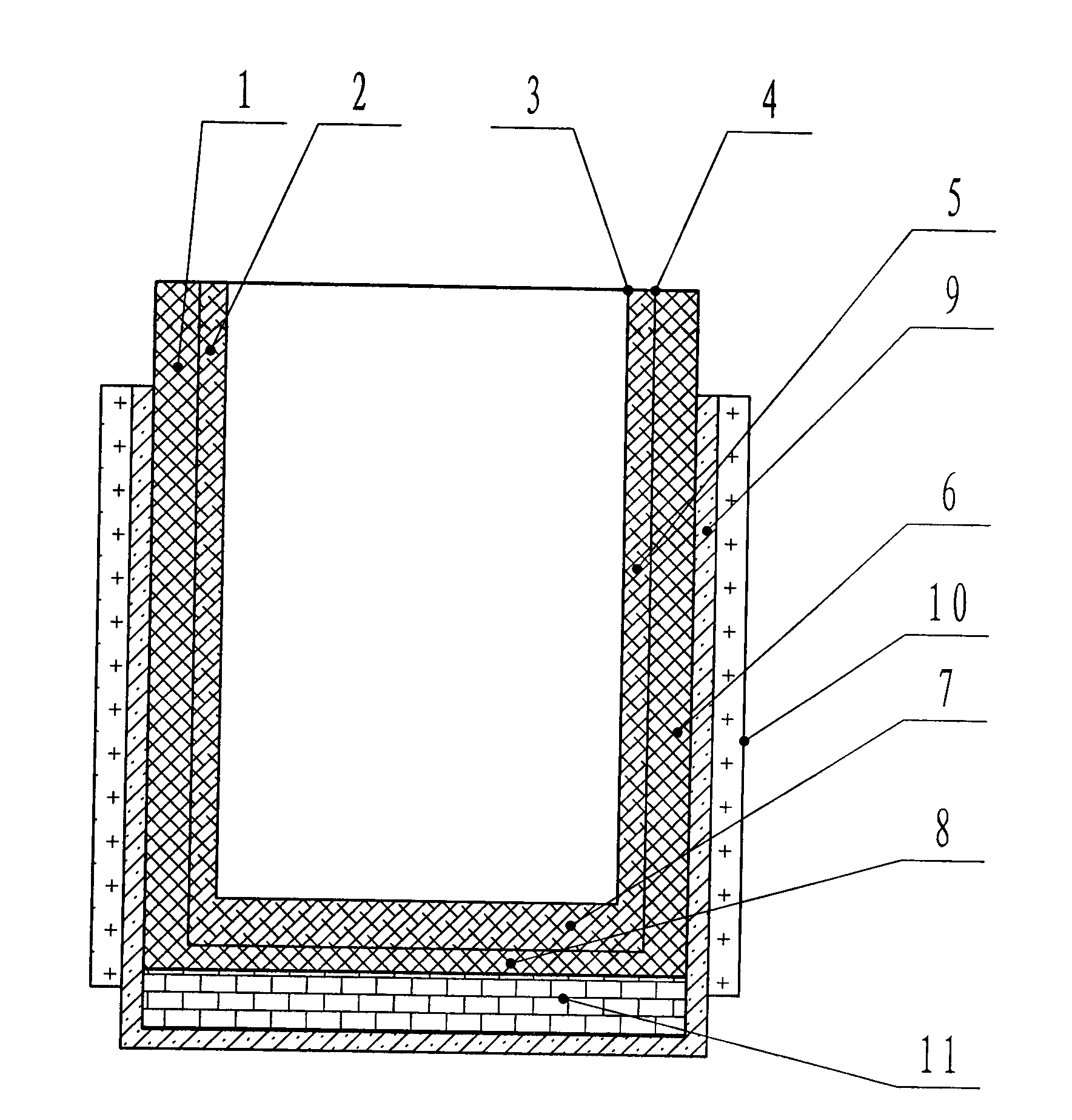

[0061] Crucible Example

[0062] figure 1 , figure 2 and image 3 The described crucible for vacuum induction melting is in the shape of a cylinder, which is knotted in the asbestos heat insulation layer 9 in the induction coil 10 of the vacuum induction furnace, and is located on the bottom brick 11, and is characterized in that it is a double-layer composite structure, The inner layer is the inner shell 2 of the calcia composition crucible material, the outer layer is the crucible material shell 1 of the magnesia composition, the inner shell 2 of the crucible material of the calcium oxide composition is knotted in the crucible materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com