Multi-element micro-alloyed high-strength high-conductivity copper alloy and preparation technique thereof

A technology of micro-alloying and preparation technology, which is applied in the direction of metal/alloy conductors, conductors, conductive materials, etc., can solve the problems of inability to meet production requirements, poor performance of copper alloy conductor resistivity, breaking force and tensile strength, etc. Achieve the effect of reasonable design, excellent resistivity, and meet production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

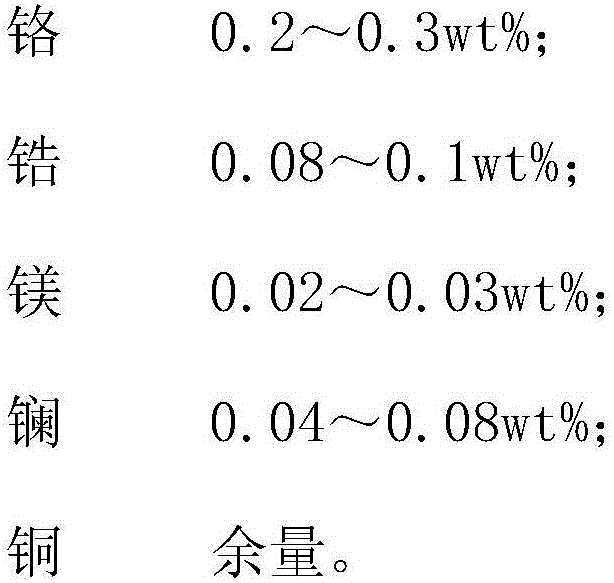

[0031] A multi-element microalloyed high-strength and high-conductivity copper alloy, which is characterized in that its composition is:

[0032]

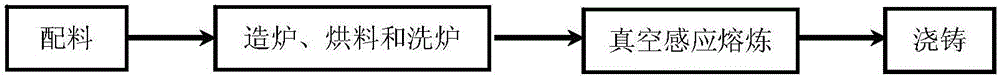

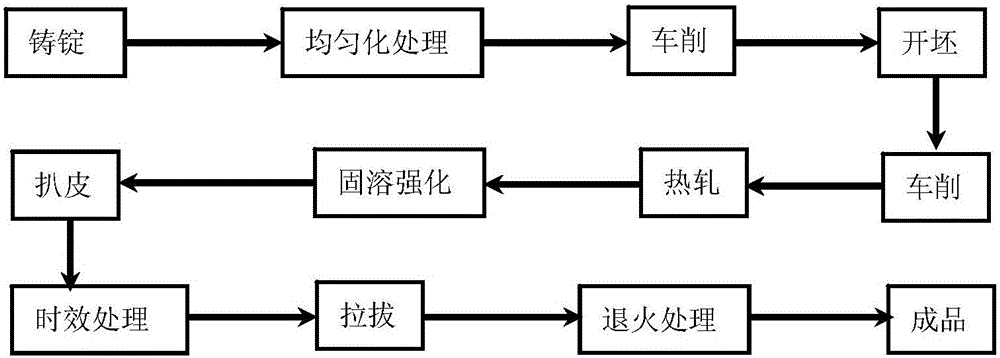

[0033] The preparation process of this multi-element microalloyed high-strength high-conductivity copper alloy has the following steps:

[0034] (1) Prepare ingredients and prepare copper-chromium alloy, copper-zirconium alloy, copper-magnesium alloy and copper-lanthanum alloy in the melting furnace;

[0035] (2) Furnace, graphite crucible is used as melting crucible, graphite crucible is fixed in the melting furnace, oven is carried out, and the furnace time is kept at more than 2 hours to remove the water vapor in the crucible;

[0036] (3) Baking and washing the furnace. Cut 100 kilograms of electrolytic copper with a purity of 99.9% into the required shape, put it in the heat treatment furnace, and keep the temperature below 600℃ to bake the material to remove internal water vapor. The baking time is 1 hour. The baking temperature of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com